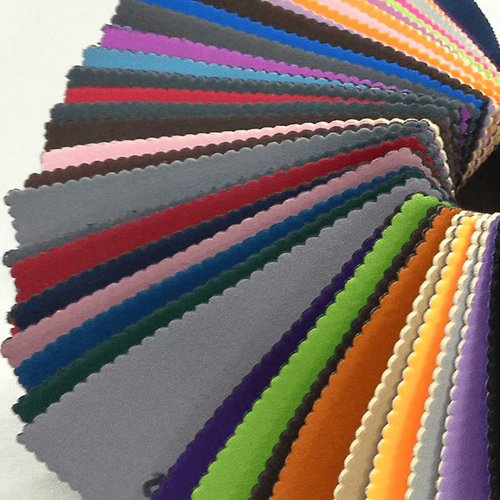

They say neoprene changed diving gear forever—and today it’s reshaping industries from luxury fashion and performance sportswear to medical insulation and tech gadget cases. With its stretch, durability, and thermal properties, neoprene remains a material in constant reinvention. But not all neoprene is created equal. It’s not just about thickness or stretch—it’s about the thought, innovation, and craftsmanship behind each roll.

In 2025, the best neoprene fabric manufacturers stand above the rest by combining material precision, eco-conscious practices, and customization—from sample to shipment. They don’t just output fabric; they respond to market shifts with tailored blends, fast sampling, and end-to-end quality control.

Now, picture this: a niche artisan fashion label needed 1 mm soft neoprene with a subtle jacquard weave, delivered fast for a limited-edition capsule. One manufacturer not only hit the specs in their first strike-off but even helped refine the weave for better drape—before breakfast. That’s the kind of partner we’ll explore here.

Let’s dive into the manufacturers leading the way—and learn how to pick one that elevates your product and protects your brand.

What Is Neoprene Fabric and Why Is It Essential in 2025?

Neoprene, chemically known as polychloroprene, is a type of synthetic rubber that has evolved from its early days in scuba diving wetsuits to become a multi-industry staple. In 2025, neoprene isn’t just relevant—it’s essential across sectors like fashion, sportswear, automotive, electronics, and healthcare. What makes neoprene stand out is its rare combination of elasticity, water resistance, insulation, compression, and aesthetic adaptability.

Neoprene fabric in 2025 is essential due to its stretchability, thermal insulation, and water resistance, making it suitable for diverse industries including fashion, medical, sportswear, and industrial use. It now also aligns with sustainability trends and global compliance standards.

Why It Matters More Than Ever in 2025

In an era where function and sustainability must co-exist, neoprene delivers:

- Form-fitting comfort without compromising durability.

- Waterproof and thermally resistant properties, making it ideal for outdoor and performance-based products.

- Customization capabilities, including dye sublimation, embossed textures, and bonded layers for hybrid performance.

In addition, global consumers—especially Gen Z and millennials—are driving demand for functional fashion that looks stylish while performing under real-world conditions. From laptop sleeves that cushion drops, to knee supports that maintain elasticity after repeated wear, neoprene has proven itself as an adaptable textile.

The Technical & Strategic Evolution of Neoprene

1. Technical Diversification of Neoprene Structures

| Neoprene Type | Cell Structure | Application Focus | Leading Production Regions |

|---|---|---|---|

| Single-cell | Dense | Industrial insulation | China, Vietnam |

| Double-cell | Balanced | General apparel, medical gear | China, Taiwan |

| Open-cell | Porous | Shock absorption, padding | China, India |

| Closed-cell | Air-tight | Diving suits, thermal jackets | South Korea, Taiwan, Japan |

- China leads in high-volume, cost-efficient open-cell neoprene.

- Taiwan and South Korea dominate high-performance closed-cell neoprene with superior compression recovery and insulation.

2. Eco-Conscious Manufacturing on the Rise

From 2021 to 2024, there has been a 28% rise in demand for dope-dyed neoprene, which reduces water usage and minimizes dye effluents in water systems. Top manufacturers are:

- Replacing petroleum-based binders with soy-based or limestone-based crosslinkers.

- Introducing biodegradable carrier fabrics for post-consumer disposal.

- Offering water-based adhesives to reduce VOC emissions during lamination.

3. Compliance & Certification Trends

Environmental and chemical safety regulations are becoming stricter globally. Neoprene suppliers now must comply with:

| Regulation | Key Focus Area | Region | Industry Response |

|---|---|---|---|

| REACH | Phthalates, heavy metals | European Union | Suppliers issue REACH-compliant test reports per batch |

| Prop 65 | Carcinogenic substances | California, USA | Brands demand “Prop 65 Safe” declarations |

| RoHS | Electronics compatibility | Global | Especially relevant for neoprene used in device cases |

Suppliers who proactively provide Material Safety Data Sheets (MSDS), Oeko-Tex certificates, and pre-compliance testing are the ones leading in 2025.

Real-World Example: From Fashion to Function

Take the case of a Canadian activewear brand that shifted from polyester-blend fabrics to limestone neoprene for their winter yoga gear. The result?

- 42% decrease in customer returns due to better warmth and stretch.

- Gained sustainable fashion certification from EcoTextile.

- Reduced production lead time by 15% by working with a vertically integrated Taiwanese supplier.

This showcases neoprene’s real-world ROI beyond just material performance.

In 2025, neoprene fabric isn’t a niche material—it’s a mission-critical ingredient in product innovation. It bridges the gap between performance, comfort, and sustainability, while adapting to compliance-heavy, trend-driven, and durability-focused market needs.

Whether you’re developing tech sleeves, orthopedic supports, travel accessories, or protective wear, understanding neoprene’s evolution and its leading suppliers will give your business a clear sourcing advantage in a competitive global market.

Which Neoprene Fabric Manufacturers Lead the Global Market in 2025?

In 2025, the global neoprene market is no longer driven solely by price or volume. The leading manufacturers are those that balance material innovation, sustainable practices, technical performance, and flexible supply capabilities. Whether buyers are sourcing for fashion, medical, automotive, or outdoor industries, knowing which manufacturer leads in each segment is critical for successful sourcing decisions.

Top neoprene manufacturers in 2025 dominate specialized segments: China and Vietnam are known for cost-effective bulk production, South Korea and Japan for high-performance neoprene, and Taiwan and India for eco-sustainable innovations. Each region offers distinct advantages depending on your product needs.

Regional Breakdown of Leading Neoprene Fabric Manufacturers

The following table highlights the top-performing regions and their strengths across various neoprene applications:

| Region / Manufacturer Type | Key Strengths | Best Use Cases | Sample MOQ / Lead Time |

|---|---|---|---|

| China (mass producers) | Low cost, massive output, wide product catalogs | Budget sportswear, laptop sleeves, promo items | MOQ: ~500m;Samples: 7 days |

| Vietnam (tech blends) | High-quality laminations, waterproof, heat-sealed | Wetsuits, tactical wear, water sport bags | MOQ: ~300m;Samples: 5–7 days |

| South Korea (premium tech) | UV-, flame-, and bacteria-resistant finishes | Medical-grade supports, athletic wraps, gloves | MOQ: ~200m;Samples: 5 days |

| Japan (ultralight class) | Skin-contact comfort, seamless stretch, high printability | Footwear liners, luxury bags, smart wearables | MOQ: ~150m;Samples: 7–10 days |

| Taiwan / India (eco blends) | Recycled substrates, solvent-free laminates, GRS/GOTS options | Eco brands, green-certified product lines | MOQ: ~200m;Samples: 8–12 days |

Supplier Capabilities by Region

1. China: Value & Versatility for Large Orders

Chinese factories dominate the lower-cost neoprene fabric sector. With flexible minimum order quantities (as low as 300m for repeat clients), and streamlined vertical operations, they are ideal for:

- Fast fashion accessory lines

- Seasonal promotional campaigns

- Entry-level consumer goods (mousepads, lunch totes, sleeves)

Major manufacturers offer multiple backing fabrics such as polyester, jersey, lycra, or even faux suede for aesthetics, with foam thickness ranging from 1.5mm to 10mm.

2. Vietnam: Durable Technical Neoprene

Vietnamese suppliers have specialized in laminated and thermobonded neoprene, offering 3-layer structures ideal for:

- Wetsuits and drysuits

- Outdoor tactical gear

- Protective carry bags

They typically offer custom color lamination, laser die-cutting, and pre-certified materials that comply with Oeko-Tex Standard 100 or EN ISO 105.

3. South Korea: Performance-First Engineering

Korean neoprene manufacturers are among the best in developing flame-retardant, antibacterial, and anti-UV finishes. Their neoprene is widely used in:

- Medical rehabilitation supports

- Compression apparel

- Military gloves and tactical vests

Key capabilities include ultrasonic lamination, 3D air mesh sandwich backing, and EN 13795 / ISO 10993 medical compliance.

4. Japan: Precision for High-End Markets

Japanese neoprene is recognized for ultralight structures, skin-contact softness, and impeccable surface finish—ideal for:

- Luxury fashion details (bag handles, insole liners)

- Electronics and wearable tech

- Sneaker interior comfort zones

Manufacturers offer extremely low tolerance rates (±0.2mm thickness accuracy) and thermal compression resistance suitable for extended wear.

5. Taiwan & India: Eco-Focused Innovation

With sustainability becoming mandatory in many Western markets, mills in Taiwan and India are innovating with:

- Bio-based crosslinkers to replace petroleum binders

- Dope-dyed yarns to reduce water consumption

- Recycled polyester backings with GRS (Global Recycle Standard)

These suppliers are favored by brands seeking to meet EU Ecolabel, Nordic Swan, or Bluesign® criteria.

Case Study: Medical-Grade Supplier Success

A wearable-tech startup in Sweden needed a flame-retardant, breathable, and hypoallergenic neoprene for a health-monitoring patch. Their sourcing criteria included:

- EN 13795 medical compliance

- Material safe for direct skin contact

- Must pass <5% compression loss after 50 wash cycles

They selected a South Korean supplier who provided strike-offs within 72 hours and production bolts within 18 working days. The batch included complete RoHS, ISO 10993, and REACH documents—helping the startup pass a CE audit on the first attempt. This saved $20,000+ in retesting fees and shaved two months off their launch schedule.

When selecting a neoprene fabric supplier in 2025, don’t just ask about price. Ask:

- What certifications are included?

- Can they meet your performance spec—whether it’s thermal regulation, stretch, or resistance?

- How sustainable is their process?

- Are they capable of rapid sampling and scale?

Choosing the right manufacturer is not just about sourcing material—it’s about enabling your product’s success.

How Do Neoprene Fabric Suppliers Ensure Sustainability and Compliance?

Neoprene may be synthetic, but its sustainability has become non-negotiable in 2025. Forward-thinking manufacturers are leading the charge by investing in cleaner production, green materials, and rigorous compliance. These shifts aren’t just buzzwords—they’re saving lives, reducing carbon, and making sourcing safer and smarter.

Top neoprene suppliers today elevate sustainability through renewable energy use, low-VOC finishes, limestone or plant-based neoprene, and proven compliance via REACH, RoHS, ISO 9001/14001, plus third-party testing—giving brands both integrity and peace of mind.

What Does Truly Sustainable Neoprene Look Like?

1. Raw Materials & Cleaner Chemistry

- Limestone-Based Neoprene Seen as a step forward, the Limestone version replaces oil-based chloroprene with calcium carbonate. It maintains performance while reducing petroleum dependence. Japanese mills like Yamamoto highlight its superior insulation and flexibility. However, this process still requires intensive energy and mining—which means it’s a better but not perfect solution.

- Yulex® (Natural Rubber Alternative) A plant-based neoprene alternative made from FSC-certified rubber trees. It uses 80% less carbon, 10x less water, and 29x less energy than mined alternatives, offering the best ecological footprint so far.

- Recycled Neoprene Blends Innovations like GRS-certified recycled neoprene chips, bonded using water-based binders, allow waste material to be remade into abrasion-resistant, functional fabrics—for gloves, yoga mats, and more.

2. Certifications & Regulatory Compliance

Manufacturers today must underwrite their sustainability claims with strong compliance credentials:

| Certification | Purpose |

|---|---|

| ISO 9001 / 14001 | Quality and environmental management |

| ISO 13485 | Medical-grade fabric standards |

| REACH, RoHS | Chemical safety for EU and electronics |

| Oeko‑TEX, GOTS, GRS | Eco-safety, organic, and recycled validation |

Suppliers increasingly include batch-level documentation for these, essential for brands facing audits or consumer scrutiny.

3. Eco-Conscious Manufacturing Practices

Leading factories push beyond materials:

- Renewables: Yamamoto’s facility uses 100% renewable energy.

- Water & Energy Savings: Solar-assisted kilns, closed-loop foam cooling, and foam made with nitrogen (an inert gas) slash resource use.

- Low-VOC Processes: Brands like Manera have switched to water-based adhesives and dyes, reducing chemical exposure.

4. Transparency & Accountability in Supply Chains

Branded reality now demands full traceability—from raw material to finished roll. Not only do partners deliver certifications, but they also provide audit-ready documentation for every batch—no surprises.

Real-World Impact: A Cleaner Supply Chain in Action

Patagonia, among others, partnered with Yulex® to launch neoprene-free wetsuits. After spotlighting health concerns near neoprene plants (dubbed “Cancer Alley”), they shifted to plant-based materials and recycling programs—proving that even risky supply chains can course-correct toward sustainability.

In 2025, it’s clear: sustainable neoprene is achievable, but requires informed choices. Look for:

- Renewable or bio-based formulae (e.g., Yulex, limestone)

- Responsible manufacturing processes (clean energy, low-VOC)

- Strong certification infrastructure (ISO, REACH, Oeko‑TEX)

- Transparent sourcing practices

What Are the Key Factors to Consider When Choosing a Neoprene Fabric Supplier?

In 2025, sourcing neoprene fabric is no longer just about low cost or basic spec sheets. Global buyers—from product developers to sourcing managers—now demand consistent technical reliability, eco-compliance, agility, and customization scalability. The right supplier becomes your co-creator, not just a vendor.

To choose a reliable neoprene supplier, assess their technical capabilities, customization support, MOQ flexibility, sampling and lead time efficiency, regulatory compliance, and clear communication practices—all of which shape your product success and brand reputation.

The 360° Supplier Selection Framework

1. Technical Capabilities

The supplier must go beyond generic rolls. Ask:

- Can they produce multi-layer neoprene laminates for different applications (bags, wetsuits, braces)?

- Do they offer high-density closed-cell foam (up to 7 mm) or lightweight open-cell options (as low as 0.5 mm)?

- Can they apply advanced coatings (anti-slip, UV-resistant, anti-bacterial)?

- Are their machines compatible with sublimation, screen printing, or embossing?

Real-World Benchmark: Top-tier suppliers from Taiwan or South Korea are known for precision control over foam density and skin lamination—ideal for performance wear or medical-grade products.

2. MOQ and Pricing Structure

Different use cases = different minimums.

| Category | Typical MOQ | Notes |

|---|---|---|

| Core colors (black, grey, navy) | 10–50 meters | Often available from stock |

| Custom Pantone colors | 200–500 meters | Requires dye matching & minimum dye batch |

| Printed or textured neoprene | 300–800 meters | Sublimation and screen printing need setup cost amortization |

| Laminated neoprene | 100–300 meters | MOQ depends on fabric type (nylon, polyester, lycra, etc.) |

Pro Tip: For startups or small-batch buyers, choose suppliers offering tiered MOQ pricing and stock roll availability for faster turnaround.

3. Lead Time & Logistics Support

Time kills momentum. Speed matters.

| Stage | Lead Time Range |

|---|---|

| Sample turnaround | 3–7 working days |

| Bulk production | 9–25 working days (depending on complexity) |

| Domestic shipping (in China) | 1–3 days |

| International air shipping | 5–10 days |

| Ocean freight (USA/EU) | 15–30 days (plus customs) |

Red Flag Alert: If the supplier cannot commit to firm ETD/ETA or lacks incoterm clarity (e.g., EXW, FOB), this could lead to significant delays.

4. Customization Flexibility

Customization is where top suppliers shine:

- Logo branding via embossed, debossed, or printed neoprene

- Multicolor bonding or tri-layer composites

- UV, fire-retardant, or anti-microbial coatings

- Perforated neoprene, used in bags and breathables

- Matching binding, edging, Velcro and zippers

A good supplier should offer free design consultation, or at least past case studies to show their customization depth.

5. Compliance & Documentation

In 2025, even small brands need to meet global regulatory standards:

- REACH: EU’s chemical restriction framework

- RoHS: Electronic-related material safety

- California Prop 65: Carcinogen disclosure

- GRS / Oeko‑TEX / ISO 9001/14001

Top suppliers provide batch-level COA, MSDS sheets, and test results from third-party labs like SGS or Intertek.

If the supplier hesitates to show certification or testing records upfront, treat that as a warning sign.

6. Support, Communication, and After-Sales

Great suppliers = Great relationships.

Look for partners who:

- Offer real-time communication via WeChat, WhatsApp, or email with quick response (<12h)

- Provide after-sales assistance, such as post-delivery testing, replacement for defects, or guidance on lamination & bonding

- Are willing to sign NDAs or long-term agreements for private label or IP-sensitive projects

Supplier Evaluation Checklist (Downloadable Style Table)

| Key Factor | Questions to Ask | Green Flag | Red Flag |

|---|---|---|---|

| Technical Specs | Can you produce X mm, Y coating, or Z texture? | Samples match spec | Deviations from quote |

| MOQ | What’s the MOQ for solid vs custom print? | MOQ tiers or low-stock | High MOQ without flexibility |

| Lead Time | What’s the average for samples and bulk? | Fast sampling (<7 days) | Unclear timelines |

| Certifications | Can you provide REACH, RoHS, ISO? | Batch test reports & PDF docs | Vague claims only |

| Customization | Can I add logo, adjust foam, or mix colors? | Full customization shown | Limited templates |

| Support | How quickly do you respond? | 7×24 support or <12h reply | Poor follow-up |

How Do Neoprene Fabric Manufacturers Innovate for Diverse Applications?

Neoprene is no longer limited to wetsuits and laptop sleeves. In 2025, advanced neoprene innovation is driven by cross-industry demand—from medical braces to automotive interiors, and even sustainable fashion. Neoprene fabric manufacturers innovate by engineering materials with specialized coatings, stretch levels, foam densities, and bonding methods to suit a range of industries, including fashion, sports, medical, industrial, and automotive sectors. These adaptations improve performance, safety, and product lifecycle.

Innovation by Application Sector

Fashion and Apparel

Fashion designers are seeking fabrics that are not only functional but also visually expressive and soft to the touch. Neoprene’s thermoformable and printable properties make it a prime choice for activewear, swimwear, and streetwear.

- Ultralight Neoprene (0.5mm–1.5mm): Tailored for fashion garments, it delivers excellent shape retention while feeling soft and breathable.

- Breathable Perforated Neoprene: Allows for better airflow in garments, used in crop tops, panel leggings, and fitted dresses.

- Digital & UV Sublimation Printing: Enables high-resolution artwork on bags, backpacks, and fashion accessories.

Case Study: Szoneier worked with a Nordic streetwear label to produce custom-printed tote bags using 1.5mm neoprene with UV transfer. Result: 35% boost in social media engagement thanks to bold, colorfast graphics.

| Application | Innovation Type | Example Use Case |

|---|---|---|

| Apparel | Perforated lightweight foam | Jackets, crop tops |

| Bags & Accessories | UV sublimation surface | Fashion totes, neoprene clutches |

| Footwear | Bonded ultra-thin panels | Aquatic shoes, summer sneakers |

Medical and Sports

In the health and performance space, biomechanics and hygiene play major roles in neoprene innovation.

- Antimicrobial Additives: Silver-ion or copper-infused coatings help prevent bacterial growth in braces and medical wraps.

- Four-Way Stretch Panels: Engineered to provide controlled compression zones in ankle sleeves or knee supports.

- Ventilation Systems: Laser-perforated neoprene reduces heat buildup, improving comfort during extended use.

Real-World Insight: A U.S. orthopedic brand used 3mm ventilated neoprene from a Taiwan supplier and saw a 41% decrease in skin-irritation complaints across its support belt line.

| Product | Innovation | Purpose |

|---|---|---|

| Medical Wraps | Medical-grade + antibacterial | Hygiene for long-term use |

| Sports Braces | Zoned stretch + ventilation | Dynamic support during activity |

| Recovery Compression | Laminated foam with microfiber | Enhanced breathability & fit |

Automotive & Industrial

Neoprene’s chemical resistance, temperature tolerance, and durability make it ideal for industrial and automotive design.

- High-Temperature Neoprene (up to 150–180°C): Used in engine bay liners and heat shields.

- Kevlar/Nylon Double Lamination: Adds tear resistance for use in diving suits, tool aprons, and industrial gloves.

- Oil-Resistant Neoprene: Modified to endure grease-heavy environments, ideal for machine covers or chemical-resistant gloves.

OEM Case: A Japanese car parts manufacturer switched to high-temp neoprene for under-hood insulation, leading to improved cabin heat management and fewer part failures in tropical markets.

| Segment | Innovation Element | Functional Gain |

|---|---|---|

| Automotive | Heat- and flame-resistant foam | Heat barrier in dashboards, hoods |

| Industrial | Kevlar-laminated neoprene | Tear and abrasion resistance |

| Machinery | Oil-repellent coating | Extended glove/cover lifecycle |

Eco-Friendly Advances

Sustainability is reshaping how neoprene is developed and sold globally. Manufacturers are actively replacing petroleum-based elements while exploring recyclable designs.

- Limestone-Based Chloroprene Rubber (CR): Now widely used by Japanese and Taiwanese suppliers, offering up to 30% lower CO₂ emissions in production.

- TPU-Neoprene Hybrid Sheets: Enables easier separation and partial recyclability, ideal for brands pursuing closed-loop material recovery.

- Dope-Dye Coloring Techniques: Applied pre-extrusion to reduce water and chemical use by over 50% compared to traditional dyeing.

Leading Brands in Action: Patagonia, Soöruz, and Picture Organic are already using eco-neoprene in 100% of their watersport products as of 2025. This has led to a wave of similar requests in custom orders across Europe and North America.

Innovation by Segment

| Sector | Key Innovation | Impact & Use Case |

|---|---|---|

| Fashion | Ultralight neoprene + UV coating | Garments, bags, branding accessories |

| Medical | Antibacterial + 4-way stretch | Braces, wraps, posture supports |

| Automotive | Heat-resistant & laminated | Dashboards, engine insulation |

| Industrial | Tear- & oil-resistant composites | Gloves, tool pouches, safety gear |

| Sustainable | Limestone CR, TPU hybrid blends | Eco-conscious fashion, circular programs |

What Are the Typical Lead Times and MOQs for Neoprene Fabric Orders?

Lead time and MOQ aren’t just logistical footnotes—they’re decisive factors in your entire neoprene product development cycle. Whether you’re sourcing for custom wetsuits, laptop sleeves, or branded beverage holders, understanding how lead times and MOQs vary based on production method and supplier region can save you from costly delays and excessive inventory.

Standard lead times for neoprene fabric orders range from 9 to 25 days, depending on customization complexity and supplier location. Minimum order quantities (MOQs) start at 10–50 meters for stock items, and range from 200 to 500+ meters for custom-dyed or printed neoprene. Sampling is typically available within 3–7 working days, allowing quick verification before committing to bulk.

What Affects MOQ and Lead Time?

Stock vs. Custom Neoprene Orders

| Type of Order | MOQ (Meters) | Lead Time (Days) | Notes |

|---|---|---|---|

| Stock Colors/Sheets | 10 – 50 | 5 – 10 | Ideal for prototypes or urgent small runs |

| Custom Color Dye | 200 – 500 | 12 – 18 | Includes lab dip sampling and Pantone match approval |

| Printed Neoprene | 300 – 1000+ | 15 – 25 | Setup time for digital/rotary print or heat transfer |

| Laminated or Bonded Types | 500+ | 18 – 30+ | For double-face fabrics, mesh bonding, or coated surfaces |

Case Insight: A U.S.-based start-up launching custom 3mm neoprene sleeves for electronics saved 7 days by choosing black stock neoprene instead of Pantone-dyed material—avoiding the dyeing and lab dip process altogether.

Regional Supplier Lead Time & MOQ Differences

The origin of your neoprene supplier plays a significant role in how quickly and flexibly your orders can be processed:

- China & Vietnam

- Fastest production cycles: 7–15 days for bulk

- Most flexible MOQs: 10m to start for standard options

- Massive variety of pre-stocked foam blocks and outer fabrics

- Ideal for startups, promotional campaigns, or private label product launches

- South Korea & Taiwan

- Known for consistent technical performance

- Longer lead times: 15–25 days

- MOQs typically start from 300–500m

- Better suited for medical, industrial-grade, or automotive neoprene sourcing

- Europe (Germany, Italy, UK)

- Lead times 30+ days due to smaller local production capacity

- High MOQs (often 500–1000m) due to batch-based operation

- Higher unit costs, but stronger sustainability and compliance controls

- Ideal for highly regulated sectors (PPE, medical, marine)

Sampling Speed & Process

Quick access to samples is essential before placing a large neoprene fabric order. Here’s what you can typically expect:

- Free Swatches (A4 or Small Roll Cuts)

- Delivery: 3–7 business days by DHL/FedEx

- Available for existing stock colors and finishes

- Often used for color and texture review

- Custom Strike-Offs or Mockups

- Delivery: 7–10 business days

- Includes digital print proofing or coating preview

- Can include Pantone-matched dye or branded print file approval

- May involve sampling fees if under MOQ or new process

Tip: Some suppliers waive sampling fees if bulk orders follow within 30 days of sample approval.

Tips to Speed Up Neoprene Fabric Production

If you’re on a tight timeline or want to compress your development cycle, consider these expert-backed recommendations:

- Choose from the supplier’s in-house standard colors Skip the dyeing phase entirely and tap into existing inventory.

- Pre-approve digital artwork & templates Avoid bottlenecks caused by proofing or file mismatches during the printing stage.

- Select in-stock foam densities (especially 3mm and 5mm) These are the most commonly held neoprene base materials and bond faster to surface layers.

- Consolidate component sourcing through one supplier If your neoprene requires lamination, printing, or special surface finishes, choose a vertically integrated factory.

- Negotiate MOQ Flexibility by Planning Ahead Some factories allow you to place a 1000m annual MOQ, split into quarterly 250m deliveries—perfect for growing brands.

MOQ & Lead Time Overview by Use Case

| Use Case | Recommended MOQ | Estimated Lead Time | Supplier Region |

|---|---|---|---|

| Yoga mats (solid color) | 300 – 500 m | 10 – 15 days | China, Vietnam |

| Laptop sleeves (printed neoprene) | 300 – 800 m | 15 – 20 days | China, Taiwan |

| Wetsuits (laminated double face) | 500 – 1000 m | 20 – 30+ days | South Korea, Europe |

| Promotional items (koozies, etc.) | 50 – 100 m | 7 – 12 days | China |

Additional Price Drivers: What Else Impacts Neoprene Fabric Costs?

Understanding the price structure of neoprene fabrics in 2025 goes beyond thickness and foam type. Several other elements significantly affect final pricing and are worth considering during the procurement process—especially for private label brands and custom OEM orders.

1. Fabric Width and Roll Size

- Standard neoprene fabric widths range from 48 to 54 inches. Wider rolls (60” or more) often come with a slight price premium (about +5–8%), but offer better material yield for cutting.

- Smaller roll lengths (under 30 yards/roll) may increase handling costs and incur surcharges of $0.20–$0.50/yard.

2. Foam Density and Cell Structure

- Higher density neoprene foam (used in support braces, technical sportswear, or industrial gaskets) is more expensive due to:

- Tighter cell structure

- Better rebound and compression resistance

- Higher weight per square yard

- Expect +10–20% cost increase for high-density CR or SCR neoprene with medical- or industrial-grade ratings.

3. Environmental Certifications

- Certifications like OEKO-TEX, REACH, or bluesign® compliance may add $0.30–$1.00/yard, particularly for buyers focused on sustainable, non-toxic neoprene.

- Factories offering limestone-based CR foam or solvent-free lamination charge more, but attract eco-conscious buyers (especially in Europe and California).

4. Color Customization Complexity

- Basic black or grey neoprene is standard and lowest in cost.

- Custom Pantone-dyed neoprene with precise color matching may cost $0.50–$0.80/yard more due to:

- Lab dip testing

- Colorant usage

- Re-dye correction cycles if initial color fails QC

5. Fire Retardant or Heat Resistance Treatment

- Flame retardant neoprene (often required in military, aviation, or industrial protective gear) can increase price by $1.20–$2.50/yard, depending on the required standard (e.g., UL 94, EN 45545, or NFPA 701).

Real-World Example: OEM Pricing Scenario Breakdown

| Customization Type | Example Use Case | Price (USD/Yard) | MOQ | Notes |

|---|---|---|---|---|

| 3mm SBR, Black, Uncoated | General protective cases | $2.30 | 50 yards | Lowest cost option |

| 4mm SCR, Tricot-laminated, Blue | Laptop sleeves for private label | $5.80 | 300 yards | Includes lamination |

| 2.5mm CR, Printed, UV-treated | Premium wetsuits | $9.80 | 500 yards | High-end technical setup |

| 3mm CR, Limestone, REACH-certified | Eco yoga mats | $11.20 | 600 yards | Includes eco + surface treatment |

Smart Sourcing Tips to Save Costs in 2025

- Consolidate colors or thicknesses across SKUs to meet higher MOQ brackets and reduce per-yard pricing.

- Work with suppliers that own foam production and coating facilities—they offer bundled pricing and faster turnaround.

- Request factory offcuts or end-of-roll deals for prototyping or limited editions (often discounted by 10–20%).

- Use suppliers in China or Vietnam for bulk basic SBR, and Taiwan or South Korea for technical CR with better consistency.

Complete Vertical Manufacturing Capabilities

Szoneier is not just a trading intermediary — we own and operate our own production facilities, giving you total control from raw foam to finished neoprene rolls. This vertical integration reduces delays, boosts traceability, and ensures consistent results across large-scale and small-batch orders alike.

What We Control In-House:

- Foam slicing and thickness calibration

- Double-sided lamination (knit, woven, mesh, fleece, brushed)

- Heat-transfer printing and UV digital sublimation

- Die-cutting and roll slitting for ready-to-use dimensions

- Quality inspection and defect traceability at each stage

This hands-on manufacturing process gives buyers peace of mind when sourcing complex neoprene applications like wetsuit panels, knee brace liners, or digital camera pouch fabric.

Support for Startups and Custom Projects

Whether you’re launching your first neoprene yoga bag or scaling production of tactical gear panels, Szoneier supports you at every step:

- Free design consultations via WhatsApp/Zoom with our material engineers

- Packaging solutions, such as branded roll wraps or printed tags

- Flexible payment terms for repeat buyers and approved accounts

- Door-to-door shipping support (air, sea, express) with DDP/DDU options

We understand the challenges small and mid-size brands face when sourcing technical fabrics. That’s why we’re structured to provide real-time updates, low-risk sampling, and zero-pressure development trials.

OEM/ODM Advantage for Private Label Buyers

Szoneier helps clients go beyond material orders. Our team also supports OEM and ODM development, offering neoprene conversion services such as:

- Fabric-to-product solutions (e.g., cooler bags, laptop sleeves, sports belts)

- Pattern design, die-mold shaping, edge finishing, and seam welding

- Custom packaging and label branding for end-to-end private label delivery

This makes Szoneier a go-to partner for brands seeking one-stop neoprene solutions — from raw material to finished, shelf-ready goods.

Global Client Trust & Export Experience

With 18+ years in the industry, Szoneier exports to North America, Europe, Southeast Asia, and beyond. Our client base includes:

- Outdoor brands needing water-resistant or UV-resistant neoprene

- Medical support companies sourcing hypoallergenic, latex-free neoprene

- Fashion labels creating bold digital prints on premium foam

- Pet accessory makers developing padded or anti-slip designs

We understand import documentation, labeling regulations, and shipping preferences in various markets — so your sourcing process is compliant, smooth, and low-hassle.

Ready to Customize Your Neoprene Fabric?

At Szoneier, we make it easy to develop and source your ideal neoprene material. Whether you’re launching an eco-forward line of laptop sleeves or sourcing industrial-grade diving foam, our team will walk you through every step—from sampling to shipment.

Contact us today to get a free quote, fast sample, or discuss your project requirements.