There is a reason why serious bag makers keep coming back to 18oz natural cotton duck canvas, even as lighter synthetics flood the market. When weight matters, when structure must hold without foam, and when a bag needs to age with character instead of wearing out, fabric choice stops being a design detail and becomes a structural decision.

Many buyers first ask about price per yard. Experienced developers ask a different question: “Will this fabric still behave the same after cutting, sewing, washing, loading, and years of use?” That is where heavy-duty cotton duck quietly separates itself from ordinary canvas. 18oz natural cotton duck canvas is a tightly woven, high-mass cotton fabric designed for structural strength, abrasion resistance, and long service life in bag manufacturing. Compared with lighter canvas, it offers higher tear resistance, better shape retention, and predictable sewing behavior, making it a preferred material for tool bags, travel bags, totes, and heritage-style carry goods.

A sourcing manager once told us: “If a bag collapses on the shelf, customers don’t pick it up. If it collapses after a year, customers don’t come back.” That sentence explains why fabric weight and construction matter far more than most spec sheets admit.

What Is 18oz Natural Cotton Duck Canvas, and How Does It Differ From Regular Canvas Fabric for Bags?

18oz natural cotton duck canvas is a heavy-weight, plain-weave cotton fabric produced from tightly twisted yarns and measured at approximately 18 ounces per square yard. Within bag manufacturing, this weight class sits firmly in the structural category rather than the decorative one. Compared with what is commonly marketed as “regular canvas” (usually 10–14oz), 18oz cotton duck delivers markedly higher tensile strength, abrasion resistance, and dimensional stability. These properties allow it to support bag structure without relying heavily on internal reinforcement layers.

In practical production terms, the difference is not subtle. A bag made from standard canvas often depends on interlinings, foam, or stiffeners to hold shape. A bag made from 18oz cotton duck frequently does not. The fabric itself becomes part of the engineering.

In practice, “regular canvas” is a broad marketing term. Cotton duck is not.

What Actually Defines Cotton Duck (Beyond the Label)

The word duck originates from the Dutch word doek, meaning cloth. In modern manufacturing, however, cotton duck has a far more specific meaning. It refers to a class of canvas fabrics characterized by high yarn twist, tight weave density, and controlled construction tolerances. Weight alone does not define cotton duck, but at 18oz, those structural attributes become dominant.

A) Fabric Anatomy: Why “Duck” Is Not Just Thicker Canvas

Cotton duck differs from generic canvas primarily in weave density and yarn quality, not merely thickness.

| Parameter | Regular Canvas (Typical) | 18oz Cotton Duck |

|---|---|---|

| Weave type | Plain weave | Plain weave (high density) |

| Yarn twist | Medium | High twist |

| Ends per inch (EPI) | 38–46 | 55–70 |

| Picks per inch (PPI) | 20–26 | 30–40 |

| Fabric hand | Soft / flexible | Firm / structured |

Higher EPI and PPI mean more yarn intersections per square inch, which directly reduces yarn slippage under load. In bag construction, this translates into stronger seams, cleaner stitch lines, and less distortion over time. Even when two fabrics share a similar weight, the one with higher density will almost always perform better in structural applications.

Another often-overlooked factor is yarn twist. High-twist yarns resist fuzzing, flattening, and premature wear. In heavy duck canvas, this contributes to the crisp, almost dry handfeel that many brands associate with durability and authenticity.

B) Structural Behavior During Bag Production

The real difference between 18oz duck and standard canvas becomes clear on the factory floor.

During cutting and sewing, fabric behavior matters as much as fabric specs. Regular canvas, especially in the 10–12oz range, exhibits noticeable bias stretch. Panels may drift slightly during cutting, and long seams can “grow” under stitch tension. This forces operators to compensate manually, increasing variability.

With 18oz cotton duck:

- Panels stay dimensionally stable during cutting

- Edges remain straight without curling

- Stitch tension stays consistent across long seams

- Box stitches and handle reinforcements sit flatter

Factories producing tool bags, heavy totes, heritage backpacks, and work gear consistently report lower rework rates when switching from 12–14oz canvas to 18oz duck. The fabric reduces the need for corrective handling, which improves repeatability across batches.

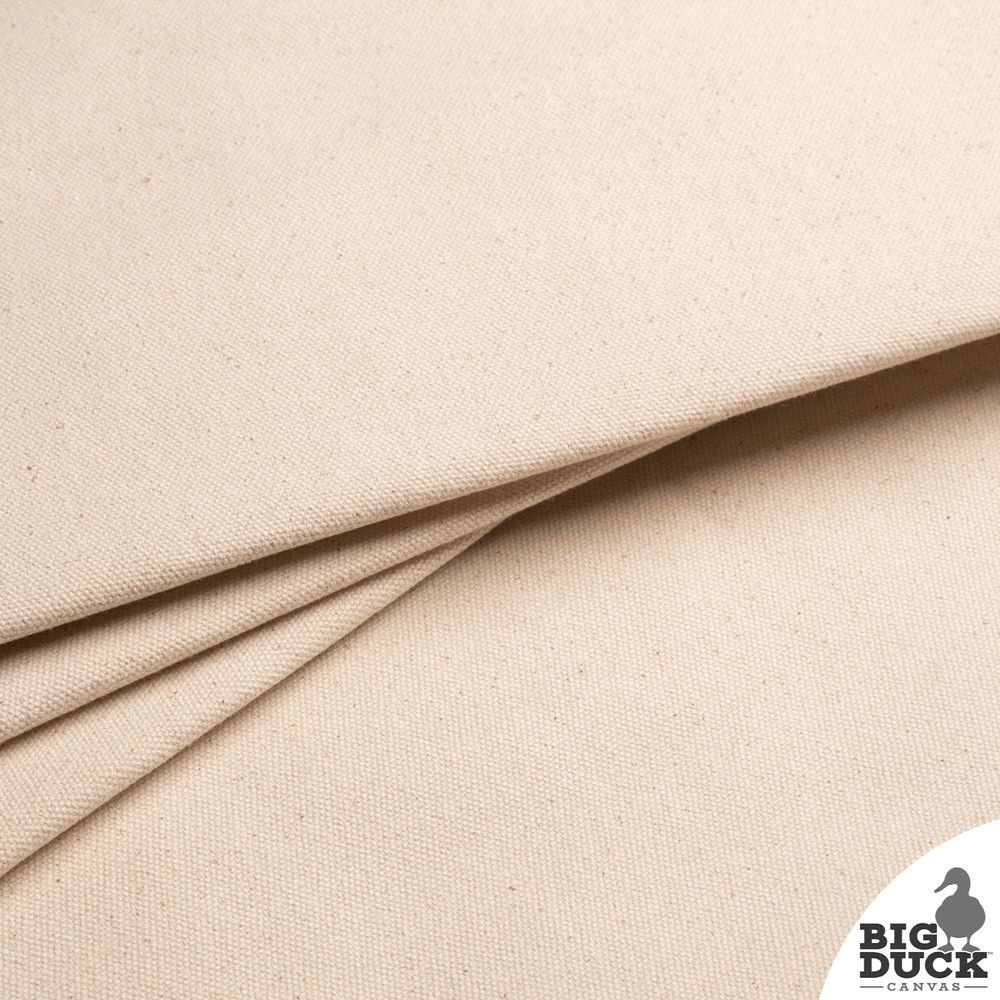

C) Natural Color Is Not a “Raw” Shortcut

Natural cotton duck is often misunderstood as unfinished or low-effort. In reality, it undergoes critical preparation steps before it ever reaches the cutting table.

Natural duck is typically:

- Scoured to remove waxes and impurities

- Desized for consistent absorbency

- Free from optical brighteners

This results in a neutral, stable base fabric. It is not visually processed, but it is technically prepared. That neutrality is precisely why many brands select natural duck as a platform fabric.

From this base, manufacturers can apply:

- Piece dyeing for controlled color depth

- Waxing for water resistance

- Pigment finishes for vintage aesthetics

- Coatings for outdoor or industrial use

The fabric does not dictate the final look; it supports it.

Why 18oz Matters Specifically for Bags

In bag design, fabric weight is not about prestige—it is about load paths. Handles, straps, and stress points transfer force directly into the fabric. If the fabric deforms, the entire structure fails gradually.

18oz cotton duck sits at a threshold where:

- The fabric itself can carry load

- Reinforcement layers become optional rather than mandatory

- Seam strength improves without changing thread or stitch count

This simplifies construction. Fewer layers mean easier sewing, fewer needle breaks, and more consistent stitch formation. Over thousands of units, those efficiencies add up.

Comparison With Typical Bag-Grade Canvas

Most mass-market canvas bags use fabrics between 10oz and 14oz. These fabrics are not inherently bad. They are simply designed for different priorities.

| Attribute | 10–14oz Canvas | 18oz Cotton Duck |

|---|---|---|

| Primary use | Light totes, promos | Load-bearing bags |

| Structure source | Interlining + fabric | Fabric itself |

| Seam distortion | Moderate | Low |

| Abrasion resistance | Medium | High |

| Longevity expectation | Short–medium | Long-term |

When brands attempt to push lighter canvas into heavy-duty roles, problems emerge slowly: sagging bottoms, stretched handles, distorted openings. These issues rarely show up in early samples but become obvious after months of use.

Performance Over Time: Aging vs Degrading

One of the defining characteristics of cotton duck is how it ages. Regular canvas tends to soften quickly and lose body. Heavy duck softens gradually while retaining structure.

Over time, 18oz cotton duck typically:

- Develops surface character without collapsing

- Shows wear at stress points rather than across entire panels

- Maintains bag geometry even after repeated loading

For heritage-inspired or utility-driven brands, this controlled aging is part of the product story. The bag does not simply wear out—it wears in.

Weight vs Perceived Quality in the Market

Consumers often associate heavier fabrics with durability, even if they cannot articulate why. When a customer lifts an 18oz duck bag, the weight communicates seriousness. The fabric resists casual folding, and seams feel anchored.

However, this perception only holds when weight is paired with correct construction. Heavy fabric sewn poorly still fails. The advantage of cotton duck is that it supports good construction practices rather than masking poor ones.

Manufacturing Trade-Offs to Consider

18oz cotton duck is not universally better. It introduces its own constraints.

Designers and developers must account for:

- Increased sewing resistance

- Slower stitch speeds

- Heavier finished product weight

For minimalist designs or fashion-driven silhouettes, this may be undesirable. But for bags intended to carry tools, groceries, equipment, or daily loads, these trade-offs are usually acceptable.

Cost Considerations Beyond Fabric Price

On paper, 18oz cotton duck costs more per yard than regular canvas. In practice, total product cost can narrow—or even reverse—when factoring in construction.

Potential offsets include:

- Reduced need for interlining

- Fewer reinforcement patches

- Lower defect and rework rates

When evaluated at the finished-bag level rather than the fabric-only level, heavy duck often proves more cost-efficient for structural designs.

Why Brands Choose Duck for “No-Excuses” Products

Products that promise durability must withstand scrutiny. Customers test them harder. Returns are less forgiving.

Brands producing:

- Work totes

- Tool rolls

- Heritage backpacks

- Utility organizers

often choose 18oz cotton duck precisely because it leaves less room for failure. The fabric supports the promise rather than challenging it.

When Regular Canvas Still Makes Sense

This comparison does not imply that regular canvas is obsolete. Lighter canvas remains appropriate for:

- Promotional bags

- Foldable totes

- Fashion accessories

- Lightweight travel items

The mistake occurs when designers expect regular canvas to perform like duck without changing construction logic.

A Practical Selection Perspective

Instead of asking “Is 18oz better?”, experienced developers ask:

- What load will this bag carry repeatedly?

- Where will stress concentrate?

- Should structure come from fabric or construction layers?

If the answer points toward fabric-led structure, 18oz cotton duck becomes a rational choice rather than an aesthetic one.

18oz natural cotton duck canvas is not simply thicker canvas. It is a structural textile defined by high yarn density, tight weave, and controlled behavior under load. Compared with standard canvas fabrics used in bags, it offers superior seam strength, shape retention, and long-term durability—often reducing the need for internal reinforcement.

Understanding this distinction allows designers and product developers to choose materials intentionally. When the fabric is expected to do real work, cotton duck earns its place not as a trend, but as engineering.

Which Bag Applications Need Heavy-Duty 18oz Canvas Rolls, and What Performance Can Buyers Expect?

18oz cotton duck canvas is not a fabric chosen for aesthetics first. It is chosen when bags are expected to work, not just look good. In bag development, the critical question is rarely “Is this luxury or casual?” but rather how much stress the bag will experience and for how long. Load, abrasion, repeated handling, and long-term shape retention define whether 18oz canvas is appropriate—or excessive.

When buyers select 18oz cotton duck canvas rolls, they are typically designing products intended to survive years of use, not a single fashion cycle. This fabric shifts structural responsibility away from internal reinforcements and onto the textile itself, simplifying construction while improving durability.

The key is not “luxury vs casual,” but load and lifecycle.

Matching Fabric Weight to Real-World Bag Stress

Every bag experiences stress differently. Handles, corners, base panels, and openings each concentrate force in distinct ways. Heavy-duty canvas earns its value when these stresses are frequent, cumulative, and unavoidable.

Lighter canvas can handle occasional load. Heavy duck is chosen when load is predictable and repetitive.

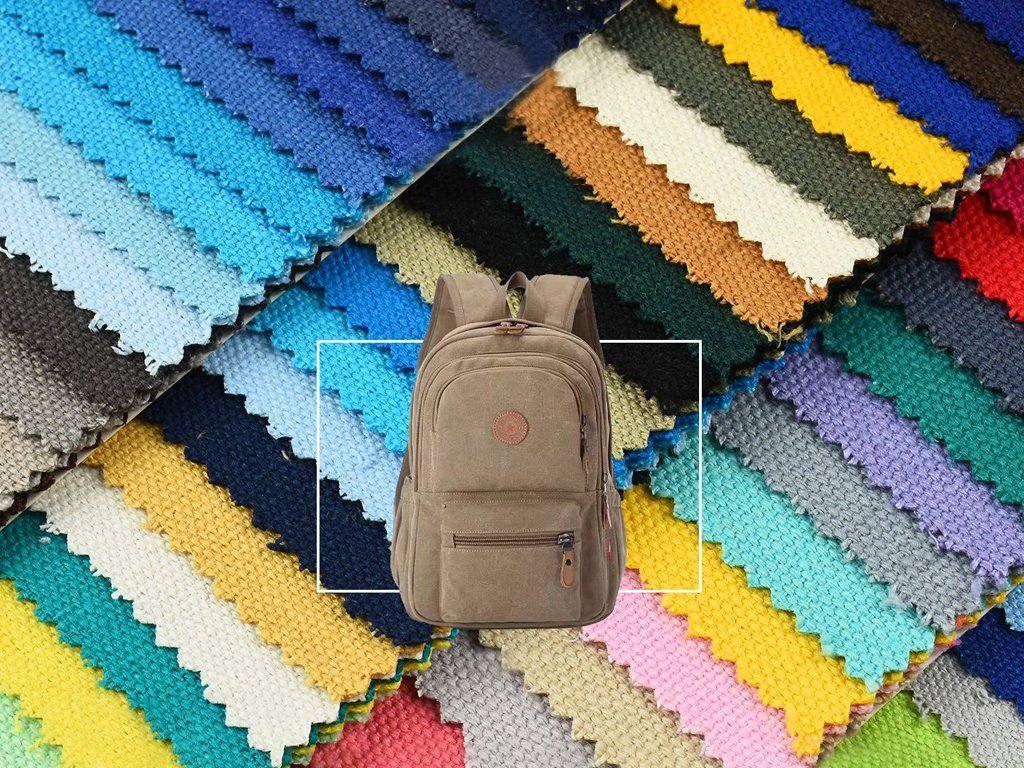

A) Bag Categories Where 18oz Canvas Performs Best

18oz cotton duck canvas consistently outperforms lighter canvas fabrics in applications where structure and durability are non-negotiable.

| Bag Type | Why 18oz Works |

|---|---|

| Tool & hardware bags | Handles concentrated weight without tearing |

| Heavy grocery totes | Maintains upright structure under load |

| Travel duffels | Resists abrasion during transit |

| Heritage backpacks | Supports leather trims and hardware |

| Event & promo bags | Designed for long-term reuse |

These categories share a common trait: failure is gradual, not immediate. Handles stretch, seams creep, and panels distort over time. 18oz duck slows these processes dramatically.

Tool and Hardware Bags: Concentrated Load, Small Failure Margin

Tool bags are among the most punishing environments for textile products. Load is dense, uneven, and often localized at handles and base corners.

18oz cotton duck excels here because:

- High yarn density resists seam slippage

- Firm hand prevents base collapse

- Abrasion resistance protects against metal edges

In practice, many tool bags made from lighter canvas fail not because seams break, but because the fabric surrounding them deforms. Duck canvas distributes stress across more yarn intersections, delaying deformation.

Heavy Grocery Totes: Repeated Load Cycles

Reusable grocery bags experience frequent loading and unloading, often beyond their nominal design capacity. The stress pattern is repetitive and cumulative.

With 18oz duck:

- Handles remain aligned over time

- Bag mouths stay open instead of collapsing

- Bottom panels resist sagging

For brands promoting sustainability through reuse, durability becomes part of the message. A bag that fails early undermines that narrative.

Travel Duffels: Abrasion and Handling Abuse

Travel duffels are dragged, stacked, and compressed. Abrasion resistance matters as much as tensile strength.

18oz cotton duck offers:

- Thick yarn surfaces that wear slowly

- Resistance to fuzzing and surface breakdown

- Stable panels that protect seams from twisting

Compared with lighter dyed canvas, heavy duck often shows cosmetic wear before structural damage, which is preferable in travel products.

Heritage Backpacks: Supporting Mixed Materials

Heritage-style backpacks frequently combine canvas with leather trims, metal buckles, and heavy webbing. These components place localized stress on the fabric.

18oz duck supports this hybrid construction by:

- Holding rivets and bartacks securely

- Preventing leather trim from pulling or puckering

- Maintaining silhouette even as leather softens

In these designs, fabric and trim must age together. If the canvas collapses faster than the leather, the bag looks prematurely worn.

Event and Promotional Bags: Designed for Reuse

High-end promotional bags are often intended to outlive the event itself. Brands want visibility over years, not weeks.

Using 18oz duck for promo bags:

- Extends usable life dramatically

- Reduces replacement frequency

- Aligns with sustainability claims

While material cost is higher, the cost per year of use is often lower.

B) Performance Metrics Buyers Should Realistically Expect

Beyond subjective durability, 18oz cotton duck delivers quantifiable performance advantages. Based on internal production testing and third-party lab data, buyers can expect the following ranges.

| Performance Metric | Typical Result (18oz Duck) |

|---|---|

| Tensile strength (warp) | 1200–1500 N |

| Tear strength | 60–80 N |

| Abrasion resistance | 30,000+ cycles |

| Seam slippage | Minimal |

| Shape retention | High |

These figures matter because they correlate directly with returns, complaints, and warranty claims. Tensile and tear strength protect against catastrophic failure. Abrasion resistance determines how long the bag looks acceptable. Shape retention defines perceived quality over time.

Why Tensile Strength Alone Is Not Enough

Buyers often fixate on tensile strength numbers. In bag applications, this is only part of the picture.

High tensile strength without density can still allow:

- Seam creep

- Panel distortion

- Handle misalignment

18oz duck combines strength with density, reducing deformation before failure occurs.

Abrasion Resistance and Visual Longevity

Abrasion resistance affects not just durability, but brand perception. Bags that pill, fuzz, or thin quickly appear cheap, even if they technically remain functional.

The coarse, tightly packed yarns in cotton duck wear gradually, developing surface character rather than bald spots. This controlled aging is especially valued in heritage and utility segments.

Shape Retention as a Hidden Performance Metric

Shape retention is rarely listed on spec sheets, but it strongly influences user satisfaction. A bag that slumps loses usability.

18oz duck maintains:

- Upright walls

- Defined corners

- Stable openings

This reduces the need for internal stiffeners, which can crack or delaminate over time.

C) A Real Sourcing Scenario

A European outdoor brand initially used a 14oz dyed canvas for a roll-top gear bag. Early feedback was positive, but after one season, issues emerged: handle distortion, base sagging, and cosmetic abrasion.

The brand switched to 18oz natural cotton duck. Material cost increased approximately 12%.

After one selling season:

- Return rate dropped by 38%

- Handle tear complaints were nearly eliminated

- Visual aging improved brand perception

The higher fabric cost was offset quickly by reduced returns and stronger customer reviews. The fabric paid for itself well before the second production run.

Why Natural Duck Often Outperforms Dyed Canvas

Natural cotton duck retains more fiber integrity than heavily dyed or processed canvas. Dyeing and finishing can weaken yarns slightly, especially at higher intensities.

Using natural duck as a base allows brands to:

- Apply controlled finishing later

- Preserve maximum strength

- Customize aesthetics without structural compromise

For heavy-duty applications, this sequencing matters.

When 18oz Canvas Is Excessive

Not every bag benefits from heavy duck. In some applications, it introduces unnecessary weight and stiffness.

18oz may be excessive for:

- Foldable totes

- Fashion-driven handbags

- Ultralight travel gear

In these cases, lighter canvas paired with smart construction delivers better user experience.

Cost Evaluation Beyond Fabric Price

Buyers evaluating 18oz canvas should look beyond price per yard.

Total cost considerations include:

- Reduced reinforcement materials

- Faster, cleaner sewing due to stability

- Lower defect and rework rates

- Fewer returns and replacements

When evaluated per finished bag rather than per meter, heavy duck often competes well with lighter alternatives.

Manufacturing Considerations Buyers Should Anticipate

18oz canvas is more demanding in production.

Buyers should expect:

- Slower sewing speeds

- Stronger needles and thread

- Slightly heavier finished products

Experienced factories factor these requirements into process planning. Problems arise when heavy fabric is treated like light canvas.

Lifecycle Thinking: Designing for Years, Not Seasons

The strongest argument for 18oz cotton duck is lifecycle performance. Bags made from this fabric tend to stay in use longer, which:

- Strengthens brand trust

- Supports sustainability messaging

- Reduces total environmental impact through longevity

In functional categories, durability is not just a feature—it is part of the value proposition.

How Buyers Should Frame the Decision

Instead of asking “Is 18oz too heavy?”, experienced buyers ask:

- How often will this bag be loaded?

- Where will stress concentrate?

- How long should this bag remain functional and presentable?

When answers point toward repeated stress and long service life, 18oz cotton duck becomes a logical, defensible choice.

18oz cotton duck canvas is best suited for bags that must carry weight, hold shape, and endure abrasion over long service cycles. Tool bags, heavy totes, travel duffels, heritage backpacks, and long-life promotional bags benefit most from its density and strength.

Buyers should expect high tensile and tear strength, excellent abrasion resistance, minimal seam slippage, and superior shape retention. While material cost is higher, total product cost often decreases through reduced failure, lower returns, and stronger brand perception.

In bag development, heavy-duty canvas is not about overbuilding. It is about aligning fabric capability with real-world demands—and letting the material carry its share of the work.

How Do Width, Roll Length, GSM/oz, and Shrinkage Specs Affect Wholesale Bag Production Yield and Costing?

In wholesale bag manufacturing, fabric specifications do far more than define material quality—they quietly decide whether a production run is profitable or painful. Width, roll length consistency, finished GSM/oz, and shrinkage are not abstract technical details. They directly influence cutting efficiency, labor stability, usable yield per roll, and final unit cost.

Many sourcing decisions focus on price per yard, yet most margin erosion happens later, at the cutting table, when fabric behavior collides with real production constraints.

Many sourcing mistakes happen not at the quote stage—but at the cutting table.

The Hidden Cost Mechanics Behind Fabric Specifications

In bag production, costs accumulate through thousands of small, repeatable actions: laying fabric, placing markers, cutting panels, sewing seams, and managing leftovers. Fabric specs either support these actions—or quietly work against them. Even small deviations, when multiplied across hundreds or thousands of bags, can outweigh any initial savings on fabric price.

A) Fabric Width: The Silent Cost Multiplier

Fabric width is one of the most underestimated cost drivers in bag manufacturing. Most suppliers quote nominal width, often expressed as “58/60 inches,” but factories work with usable width—the space that can actually be cut after accounting for selvedges, edge variation, and finishing distortion.

| Item | Nominal Spec | Real Impact |

|---|---|---|

| Quoted width | 60″ | Marketing number |

| Usable width | 57–58″ | Selvedge + edge variation |

| Layout loss | 3–6% | Affects marker efficiency |

For structured bags—such as tool bags, heavy totes, or duffels—panel sizes are large and rectangular. Marker layouts are width-sensitive. Losing just 2 inches of usable width can force pattern rotation, split panels, or inefficient nesting.

In practical terms, this often means:

- One fewer full bag cut per roll

- Higher fabric waste along edges

- Longer cutting time due to re-layout

For a wholesale order, that lost efficiency compounds quickly.

At SzoneierFabrics, width tolerance is controlled within ±0.5 inch, allowing factories to reuse cutting markers across batches instead of redesigning layouts for each roll. This stability directly reduces cutting labor and fabric waste.

Why Width Matters More for Bags Than Apparel

Unlike garments, bags cannot rely on stretch, drape, or shaping to compensate for width loss. Panels must be square, aligned, and repeatable. Any deviation forces compromise in either design or yield.

B) Roll Length Consistency: Planning vs Reality

Roll length is rarely discussed in detail during sourcing, yet it has a major impact on production planning. Wholesale bag factories depend on predictable roll lengths to plan cutting sequences, labor allocation, and inventory flow.

| Roll Length Type | Common Issue |

|---|---|

| Mixed roll lengths | Inconsistent cut plans |

| Short-end rolls | Excess leftovers |

| Length variance >3% | Production delays |

When roll lengths vary widely, factories face several problems:

- Cutting plans must be recalculated mid-run

- Operators stop and restart layouts more often

- Leftover fabric accumulates in unusable quantities

Short-end rolls are particularly costly. A roll that is 10–15 yards shorter than expected may not complete a full cutting batch, leaving partial panels or unusable remnants. These remnants often end up as dead inventory.

For wholesale orders, consistent roll length simplifies everything. Factories prefer rolls in the 80–100 yard range, with verified length reports, because they align well with standard batch sizes and reduce leftover waste.

The Labor Cost of Inconsistent Rolls

Every time a roll ends unexpectedly, cutting must stop. Operators wait. Supervisors adjust plans. These interruptions may seem minor, but across multiple days and shifts, they erode efficiency and increase labor cost per unit.

C) GSM vs oz: Why Finished Weight Matters More Than Loom Weight

Fabric weight is often specified as GSM or ounces per square yard, but many buyers overlook which stage that weight refers to. Some suppliers quote loom-state weight, which does not reflect how the fabric behaves after finishing.

| Stage | Weight Difference |

|---|---|

| Loom-state | Higher |

| Scoured | -3% to -5% |

| Dyed / washed | ±2% variance |

| Finished & conditioned | True usable weight |

For heavy-duty fabrics like 18oz cotton duck, this distinction is critical. If “18oz” refers to loom-state weight, the finished fabric may behave more like a 16.5–17oz material—affecting structure, seam strength, and perceived quality.

From a costing perspective, inconsistent finished weight creates hidden problems:

- Bags from different batches feel different

- Sewing tension and needle choice must be adjusted

- Structural expectations are no longer predictable

At SzoneierFabrics, 18oz cotton duck is specified and controlled as finished weight, locked within ±3% tolerance. This ensures that every roll supports the same construction logic, reducing adjustments during sewing and inspection.

Why Finished Weight Affects Yield Indirectly

Weight variation can subtly change fabric thickness and compressibility. Thicker-than-expected fabric may reduce cutting accuracy or slow sewing speed. Thinner fabric may require reinforcement, increasing material and labor cost. Both scenarios affect unit cost without appearing on the original fabric quote.

D) Shrinkage: The Spec That Destroys Margins if Ignored

Shrinkage is often treated as an apparel issue, but in bag manufacturing, uncontrolled shrinkage can be even more damaging. Bags rely on dimensional accuracy for panel alignment, print placement, and hardware positioning.

Uncontrolled shrinkage affects:

- Panel symmetry

- Print or embroidery registration

- Final bag dimensions and fit

| Shrinkage Level | Production Risk |

|---|---|

| <2% | Safe |

| 2–4% | Manageable with allowance |

| >5% | High rejection risk |

When shrinkage exceeds expectations, factories face rejections that are expensive to fix. A bag panel that shrinks unevenly cannot be “let out” or reshaped easily.

Pre-shrunk or sanforized 18oz cotton duck stabilizes fabric dimensions before cutting. This allows pattern allowances to be calculated once and reused reliably.

Shrinkage and Print Accuracy

For branded bags, shrinkage also affects graphics. Screen prints, heat transfers, and embroidery rely on stable panel dimensions. Fabric that shrinks after printing causes distortion that is immediately visible and often unacceptable.

How These Specs Interact in Real Production

Width, roll length, weight, and shrinkage do not act independently. They compound.

For example:

- Reduced usable width lowers marker efficiency

- Inconsistent roll length interrupts cutting rhythm

- Variable finished weight slows sewing

- Unexpected shrinkage causes rejections

Each issue alone may seem manageable. Together, they can push unit cost well beyond original estimates.

A Realistic Yield Scenario

Consider a wholesale order of 5,000 heavy canvas tote bags:

- Losing 1 bag per roll due to width inefficiency

- Accumulating short-end leftovers from roll length variance

- Slowing sewing by 5–8% due to thickness inconsistency

- Rejecting 2–3% of bags due to shrinkage-related misalignment

The combined cost impact can exceed 10–15% of total production cost, far more than the difference between a cheaper and a better-controlled fabric.

Why Fabric Price Alone Is Misleading

A lower fabric price per yard often looks attractive at the sourcing stage. But if that fabric introduces yield loss, labor inefficiency, or rejection risk, the true cost per finished bag increases.

Experienced buyers evaluate fabric based on:

- Usable yield per roll

- Cutting and sewing stability

- Predictability across batches

These factors determine real profitability.

What Buyers Should Specify Clearly in Wholesale Orders

To protect yield and costing, buyers should specify:

- Usable width after finishing, not nominal width

- Roll length range and variance limits

- Finished GSM/oz, not loom weight

- Maximum allowable shrinkage, tested after finishing

Clear specs shift responsibility from assumptions to measurable standards.

Why Factories Prefer Tighter Tolerances

Factories value predictability. When fabric specs are tight and reliable, they can:

- Standardize cutting markers

- Train operators consistently

- Reduce QC intervention

This lowers production risk and often results in better pricing over time, even if the fabric itself costs more.

SzoneierFabrics’ Production-Oriented Approach

In wholesale bag programs, SzoneierFabrics focuses on production-friendly fabric control:

- Width tolerance within ±0.5 inch

- Verified roll length reports

- Finished weight locked within ±3%

- Pre-shrunk or sanforized heavy duck options

These controls are designed not for marketing, but for cutting rooms and sewing lines—where real costs are determined.

The Long-Term Cost Perspective

Fabric specs that protect yield do more than reduce immediate cost. They:

- Improve delivery reliability

- Reduce factory friction

- Enable repeat orders with minimal re-testing

Over multiple production runs, this consistency becomes a competitive advantage.

A Mindset Shift for Buyers

Instead of asking “Is this fabric cheaper?”, experienced wholesale buyers ask:

- How many bags can I reliably cut from each roll?

- How stable will production be across batches?

- What risks does this fabric introduce downstream?

These questions move the decision from price-focused to process-focused.

Fabric width, roll length consistency, finished GSM/oz, and shrinkage specs are not minor technical details—they are primary cost drivers in wholesale bag manufacturing. Small deviations in these parameters often cost more than the initial fabric price difference.

Buyers who evaluate fabric through the lens of yield, stability, and repeatability protect margins and simplify production. In heavy-duty bag programs, controlling these specs is not an optimization—it is a requirement.

In wholesale bag manufacturing, the fabric that looks cheaper on paper is often the most expensive once production begins.

What Weaving, Yarn Count, and Construction Details Define “Heavy-Duty” Cotton Duck for Bag Factories?

In bag manufacturing, the term “heavy-duty cotton duck” is often simplified to weight alone—14oz, 16oz, 18oz. But experienced bag factories know that weight is only the visible outcome of deeper structural decisions. Two fabrics can both measure 18oz and still perform very differently once they are cut, sewn, loaded, dragged, and stressed over time.

What truly defines heavy-duty cotton duck is how the fabric is engineered: yarn count strategy, yarn twist, weave density, warp-to-weft balance, and edge stability. These construction details determine whether a bag survives years of real use or fails quietly at seams, corners, and handles.

Weight tells part of the story. Construction tells the rest.

Engineering Cotton Duck for Real Load Conditions

Bag fabrics do not experience uniform stress. Loads concentrate at handles, bases, corners, and stitched junctions. Unlike apparel, bags cannot rely on drape or body movement to dissipate force. The fabric must absorb, distribute, and recover from stress repeatedly.

Heavy-duty cotton duck is engineered to perform under cyclic load, not just static strength tests. This requires a construction philosophy that prioritizes stability and balance over bulk.

A) Yarn Count: Finer Yarn, Tighter Structure

A common misconception is that heavier fabric automatically means thicker yarns. In reality, many unstable “heavy” canvases are produced by using coarse yarns woven at low density. The result is bulk without control.

Heavy-duty cotton duck takes the opposite approach.

| Yarn Strategy | Result |

|---|---|

| Thick yarn, low density | Bulky, unstable |

| Finer yarn, high density | Strong, stable |

| Balanced twist | Reduced fuzzing |

Most true 18oz cotton duck fabrics use 10s–12s cotton yarn, which are relatively fine compared to the yarns used in loosely woven canvas. Strength comes from packing more yarns into each inch, not from oversized yarn diameter.

This strategy delivers several advantages in bag production:

- Reduced yarn slippage at seams

- Cleaner stitch definition

- Better load distribution across panels

Finer yarns also allow more precise control of weave geometry, which becomes critical when bags are cut repeatedly from large rolls.

Why Yarn Count Matters More Than Marketing Claims

Two fabrics can both be labeled “18oz canvas,” yet one may rely on thick yarns at low density, while the other uses finer yarns at high density. The former often feels bulky but deforms under load. The latter feels firm and controlled.

Bag factories quickly learn which one survives real use.

Yarn Twist: Controlling Surface and Longevity

Yarn twist is another defining factor. Heavy-duty duck typically uses high-twist yarns.

Higher twist:

- Increases tensile strength

- Reduces surface fuzzing

- Improves abrasion resistance

Low-twist yarns may feel softer initially, but they flatten, pill, and weaken faster. In bags that rub against floors, vehicles, and tools, low twist becomes a liability.

Balanced twist does not make the fabric harsh—it makes it predictable.

B) Warp vs Weft Balance: Preventing Directional Failure

Many bag failures are not caused by overall weakness, but by directional imbalance. Fabric may be strong along the warp but weak along the weft, or vice versa.

| Direction | Poor Fabric | Heavy-Duty Duck |

|---|---|---|

| Warp | Strong | Strong |

| Weft | Weak | Reinforced |

| Bias | Unstable | Controlled |

In poorly balanced fabrics, common failure modes include:

- Handle tearing along the weft

- Bottom seams splitting diagonally

- Panels distorting after repeated lifting

Heavy-duty cotton duck is engineered with balanced warp-to-weft strength, meaning both directions contribute meaningfully to load bearing.

This balance matters because bag stress rarely aligns perfectly with fabric directions. Loads shift, twist, and pull diagonally during use. A balanced fabric absorbs those forces instead of concentrating them along a single yarn path.

Bias Stability: The Silent Requirement

Bias distortion is often overlooked until it causes visible problems. When bags are lifted by one handle or carried unevenly, stress travels along the bias. Loose constructions stretch here first.

Dense duck construction restricts bias movement, keeping bag geometry intact even under asymmetrical load.

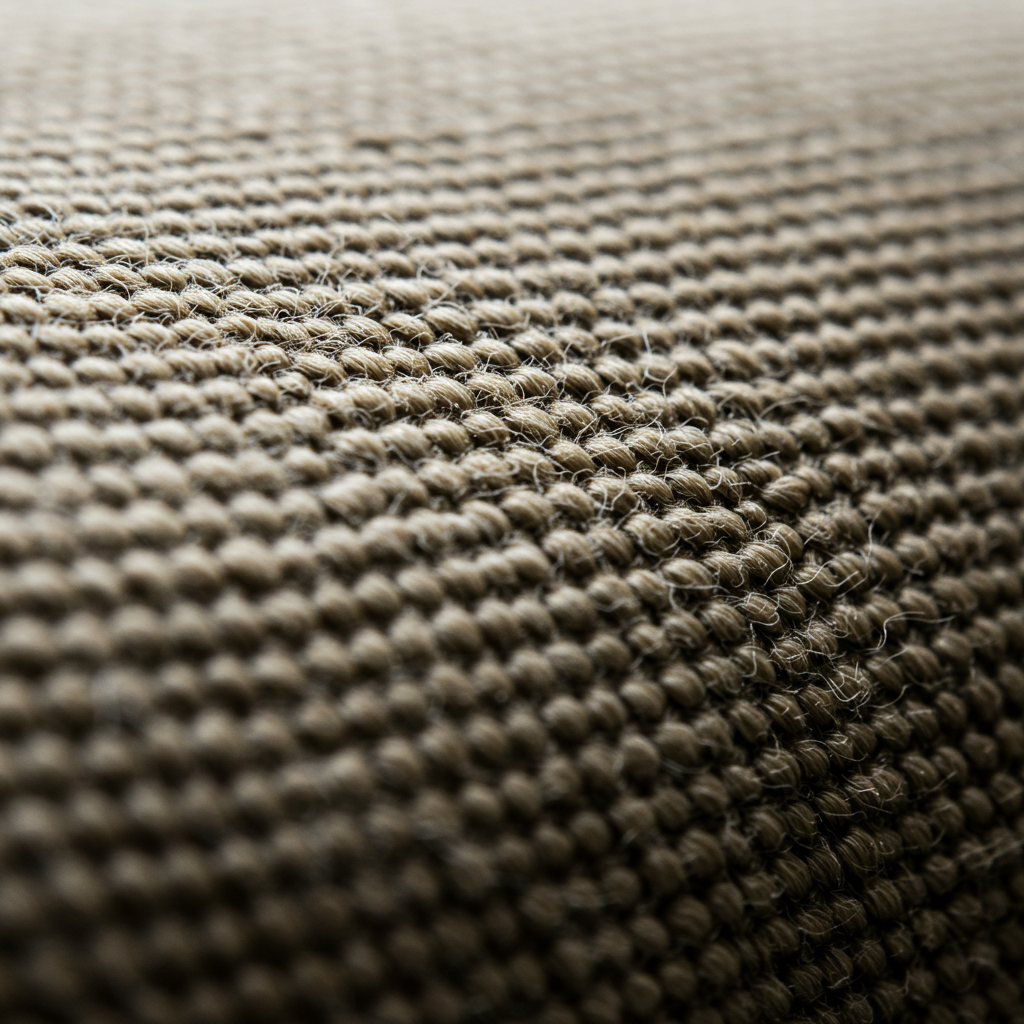

C) Weave Tightness and Pick Density

Cotton duck uses a plain weave, but not all plain weaves are equal. Density is what separates utility duck from decorative canvas.

| Construction Element | Typical Range (18oz Duck) |

|---|---|

| Ends per inch (EPI) | 60–70 |

| Picks per inch (PPI) | 32–40 |

| Weave type | Plain |

| Yarn twist | High |

Higher EPI increases strength along the warp. Higher PPI increases resistance to abrasion and tearing along the weft. Together, they create a compact, interlocked structure.

For bags that are dragged, stacked, or placed on rough surfaces, pick density is especially critical. Low PPI fabrics abrade quickly at the base. High PPI fabrics wear gradually instead of breaking down suddenly.

Density vs Weight: Why Numbers Matter

Two fabrics may weigh the same per square yard but differ in density distribution. One may be thick and loosely woven; the other thin and tightly woven.

In bag applications:

- Density improves seam strength

- Density improves abrasion life

- Density improves cutting accuracy

Weight without density is unreliable.

D) Selvedge Quality and Edge Stability

Edge integrity is rarely discussed outside factories, but it matters greatly in production. Poor selvedge quality introduces problems long before the bag reaches the customer.

Poor selvedge often causes:

- Curling during spreading

- Inaccurate stacking

- Edge fraying during cutting

These issues slow cutting lines and increase waste.

High-quality heavy-duty duck features consistent, reinforced selvedges that remain flat and stable during spreading. This supports both manual and CNC cutting workflows.

At SzoneierFabrics, selvedge consistency is controlled specifically to accommodate high-stack cutting, where even minor edge instability multiplies across layers.

Edge Stability and Yield

When edges curl or fray, factories must trim more aggressively, reducing usable width. Over thousands of bags, this translates directly into lost yield.

Stable edges protect margins.

Construction Consistency Across Rolls

Heavy-duty duck must not only be strong—it must be repeatable. Bag factories depend on consistent behavior from roll to roll.

Key construction controls include:

- Tight tolerance on EPI/PPI

- Uniform yarn twist across batches

- Stable loom tension

Inconsistent construction leads to inconsistent sewing behavior. Operators adjust tension, needles, and stitch length mid-run, which increases defect risk.

Consistency reduces learning curves on the sewing line.

How Construction Affects Sewing Performance

Dense duck interacts with sewing equipment differently than loose canvas.

Properly engineered duck:

- Accepts stitches cleanly

- Holds thread without cutting

- Resists seam slippage

Poorly engineered heavy canvas may feel strong but causes:

- Needle heating

- Thread abrasion

- Uneven stitch formation

These problems show up as skipped stitches or premature seam failure.

Construction vs Reinforcement: A Strategic Choice

One reason factories value true heavy-duty duck is that it reduces reliance on reinforcement layers.

Instead of compensating for weak fabric with:

- Extra interlinings

- Additional bartacks

- Multiple reinforcement patches

Factories can simplify construction, relying on the fabric itself to carry load. This reduces labor, material complexity, and long-term failure points.

Long-Term Durability: Wearing In, Not Wearing Out

Well-constructed cotton duck does not fail suddenly. It ages progressively.

Over time, heavy-duty duck typically:

- Softens without losing shape

- Shows wear at high-stress points only

- Maintains overall panel integrity

This controlled aging is valued in utility, heritage, and professional bag categories.

Loose canvas, by contrast, often degrades globally—panels lose structure everywhere, not just where stress is concentrated.

Testing That Confirms Heavy-Duty Construction

Factories often validate heavy-duty duck through practical tests rather than marketing claims:

- Repeated handle load testing

- Abrasion testing on base panels

- Seam slippage under cyclic load

Fabrics that pass these tests consistently share the construction traits described above.

Why Weight Alone Misleads Buyers

Buyers who specify only “18oz canvas” without construction parameters leave room for interpretation. Mills can meet weight targets in multiple ways—some durable, some not.

Experienced buyers specify:

- Yarn count range

- EPI/PPI targets

- Warp-weft balance expectations

This removes ambiguity and protects performance.

SzoneierFabrics’ Heavy-Duty Duck Standard

For bag factories, SzoneierFabrics defines heavy-duty cotton duck through construction discipline, not just weight:

- 10s–12s high-twist cotton yarn

- EPI 60–70, PPI 32–40

- Balanced warp and weft strength

- Reinforced, stable selvedges

These parameters are designed around cutting rooms and sewing lines, not showroom samples.

When Heavy-Duty Construction Is Overkill

Not every bag needs this level of engineering. Lightweight fashion totes and foldable bags may prioritize softness and drape instead.

The mistake is using decorative canvas where structural duck is required.

How Factories Should Frame the Question

Instead of asking “Is this fabric heavy enough?”, bag factories and buyers should ask:

- How is strength distributed across directions?

- How stable is the weave under load?

- Will seams remain intact after years of use?

When these questions guide sourcing, heavy-duty duck becomes a precise tool, not a vague category.

“Heavy-duty” cotton duck is not defined by ounces alone. It is defined by fine yarns packed densely, balanced warp-weft strength, high twist, tight plain-weave construction, and stable edges. These details determine whether a bag fabric truly supports load, resists abrasion, and maintains integrity over time.

For bag factories, understanding construction—not just weight—separates fabrics that merely look strong from those that perform reliably in the real world.

Which Finishing Options Improve Bag Performance—Water Resistance, Waxed, Flame Retardant, Anti-Mildew, or Coating—and How Are They Selected?

An 18oz cotton duck canvas roll is a structural foundation, not a finished solution. On its own, it delivers strength, abrasion resistance, and shape retention. But in real-world bag use—rain, humidity, friction, heat, storage, and transport—finishing choices determine whether that strength translates into reliability or risk.

Finishing is where cotton duck stops being generic heavy canvas and becomes task-specific material engineering. The right finish protects the bag against predictable threats without undermining sewability, yield, or long-term appearance. The wrong finish, by contrast, often introduces new problems: stiffness, cracking, odor claims, or regulatory non-compliance.

Finishing is not decoration. It is risk management.

Choosing Finishes Based on Real Use, Not Trends

Many bag programs fail not because the base fabric is wrong, but because finishing decisions are driven by trends or marketing language rather than use environment. A canvas bag used for daily commuting faces different risks than one shipped by sea and stored for months. A heritage backpack ages differently from a promotional tote designed for uniformity.

Effective finish selection starts by answering three questions:

- Where will the bag be used?

- How will it be stored and transported?

- How should it age over time?

Only then does finishing become a tool rather than a gamble.

A) Water-Resistant Finishes: Repellency vs Breathability

Water exposure is the most common real-world challenge for canvas bags. However, most bags do not need to be fully waterproof. Over-engineering water protection often harms comfort, appearance, and longevity.

| Finish Type | Water Behavior | Best For | Trade-Offs |

|---|---|---|---|

| C0 / C6 DWR | Repels light rain | Everyday totes | Loses effect over time |

| PU back-coating | Water barrier | Tool & travel bags | Reduced breathability |

| Acrylic coating | Splash resistance | Promo bags | Stiffer hand feel |

DWR (Durable Water Repellent)

DWR finishes create a hydrophobic surface that causes water to bead and roll off. On 18oz duck, DWR maintains fabric handfeel and breathability, making it suitable for daily-use bags exposed to occasional rain.

However, DWR is a surface treatment. Abrasion, washing, and friction gradually reduce effectiveness. From a lifecycle perspective, DWR is best when:

- Water exposure is intermittent

- Breathability matters

- Uniform appearance is preferred

For most consumer canvas bags, water resistance—not waterproofing—delivers better long-term satisfaction.

PU Back-Coating

PU (polyurethane) back-coating creates a continuous barrier on the reverse side of the fabric. This significantly improves water protection, making it appropriate for tool bags, travel duffels, and utility gear.

Trade-offs include:

- Reduced breathability

- Increased stiffness

- Slightly more complex sewing

PU-coated duck excels when water ingress would damage contents or create liability, not when comfort or aging aesthetics are priorities.

Acrylic Coatings

Acrylic coatings offer light splash resistance at lower cost. They are often used for promotional bags where price sensitivity outweighs long-term durability.

The downside is a noticeably stiffer hand and limited abrasion life. Acrylic coatings are functional, not refined.

B) Waxed Canvas: Controlled Aging, Not Uniform Performance

Waxed 18oz cotton duck occupies a unique position between engineering and storytelling. Wax penetrates the fabric, increasing water resistance and abrasion durability while creating a distinctive surface.

Waxed duck offers:

- Moderate water repellency

- Increased abrasion resistance

- Visual patina that evolves with use

However, waxed canvas is not a neutral choice.

| Consideration | Impact |

|---|---|

| Temperature | Wax softens in heat |

| Color variation | Natural and uneven |

| Re-waxing | Periodic maintenance |

Wax migrates under heat and pressure, which means appearance changes with handling and climate. This behavior is desirable in heritage and lifestyle products, but problematic in programs that demand strict visual uniformity.

Waxed canvas works best when:

- Aging is part of the brand narrative

- Customers accept variation

- Maintenance is understood

It is not well suited to large promotional campaigns or tightly standardized retail lines.

Waxed vs Coated: A Strategic Choice

Wax sits within the fabric. Coatings sit on the fabric. This difference affects how bags age. Waxed duck wears in gradually. Coated duck tends to fail when the coating cracks or delaminates.

For brands selling longevity, wax is often the more honest solution.

C) Anti-Mildew Treatment: Often Overlooked, Often Critical

Cotton duck is organic. Moisture plus time equals mildew risk. Many bag claims—odor, spotting, discoloration—originate not in use, but in storage and transit.

| Storage Condition | Mildew Risk |

|---|---|

| Dry retail | Low |

| Ocean freight | Medium |

| Warehouse (humid) | High |

Anti-mildew treatments inhibit fungal growth without altering handfeel or strength. They are especially important for:

- Long ocean freight routes

- Seasonal inventory storage

- Warehouses in humid regions

Without anti-mildew finishing, even premium canvas bags can arrive compromised before reaching the customer.

Why Mildew Issues Are Expensive

Mildew problems are rarely repairable. They often result in:

- Full batch rejection

- Odor complaints

- Brand reputation damage

The cost of anti-mildew finishing is small compared to the cost of a single rejected shipment. For export-focused bag programs, it is often a baseline requirement, not an upgrade.

D) Flame-Retardant (FR) Treatments: Niche but Regulated

Flame-retardant finishes are not common in consumer bags, but they are essential in regulated environments.

FR-treated canvas is required for:

- Industrial tool bags

- Event and staging equipment bags

- Certain military or utility applications

| FR Standard | Typical Market |

|---|---|

| CPAI-84 | Events and tents |

| EN13501 | EU industrial |

| NFPA | Specialized use |

FR finishes alter fabric behavior. They increase stiffness and can slightly reduce tear strength. Cost is higher, and certification documentation is mandatory.

FR finishing should be applied only when required by regulation or contract. Using it without necessity adds cost and compromises handling without functional benefit.

Understanding FR Trade-Offs

FR-treated canvas is engineered to self特 but not to be soft or visually refined. For buyers unfamiliar with FR markets, the key risk is over-specifying and underperforming aesthetically.

FR is compliance-driven, not lifestyle-driven.

E) Coatings for Abrasion and Surface Control

Beyond water and fire, coatings can be used to enhance surface durability. High-friction environments—such as tool bags dragged across concrete—benefit from controlled surface protection.

Common outcomes include:

- Reduced surface fuzzing

- Slower base wear

- Easier cleaning

However, coatings must be selected carefully. Excessive coating thickness can:

- Crack under folding

- Increase needle resistance

- Reduce fabric flexibility

For 18oz duck, thin, flexible coatings preserve structural benefits while extending surface life.

Sewability: The Constraint That Governs All Finishes

A finish that looks good but sews poorly creates hidden cost. Heavy-duty bag production depends on predictable sewing behavior.

Finishes must preserve:

- Needle penetration consistency

- Thread seating

- Seam flexibility

Poorly selected coatings or excessive wax content can cause skipped stitches, thread breakage, or seam puckering. These problems slow production and increase defect rates.

How Finishing Affects Yield and Cost

Finishing choices influence not just performance, but manufacturing economics.

Potential impacts include:

- Reduced usable width after coating

- Increased cutting resistance

- Slower sewing speeds

For wholesale programs, these effects must be considered alongside performance gains. A finish that improves durability but increases unit cost beyond tolerance may not be viable.

Selecting the Right Finish: A Practical Framework

Experienced buyers and developers follow a simple decision logic:

- Identify dominant risk (water, abrasion, mildew, fire)

- Select the least intrusive finish that mitigates that risk

- Validate sewability and aging behavior

- Avoid stacking unnecessary finishes

Stacking multiple finishes often compounds stiffness and unpredictability without proportional benefit.

Why “More Protection” Is Not Always Better

Over-finished canvas can feel artificial, age poorly, and alienate users. The goal is appropriate protection, not maximum treatment.

Bags that feel natural, age gracefully, and survive expected conditions outperform over-engineered products in real markets.

SzoneierFabrics’ Finishing Philosophy

For 18oz cotton duck bag programs, SzoneierFabrics approaches finishing as application-specific engineering:

- DWR for daily-use and lifestyle bags

- PU back-coating for utility and travel gear

- Waxed finishes for heritage narratives

- Anti-mildew as standard for export-heavy programs

- FR treatments only for regulated markets

Each finish is tested for sewability, width stability, and long-term behavior before approval.

When Finishing Decisions Go Wrong

Most finishing-related failures stem from mismatched expectations:

- Expecting uniformity from waxed canvas

- Expecting breathability from coated fabric

- Ignoring mildew risk in humid logistics

These failures are preventable with upfront alignment.

The Lifecycle Perspective

Finishing should be evaluated across the entire lifecycle of the bag:

- Production

- Transport

- Storage

- Use

- Aging

A finish that performs well in one phase but fails in another is incomplete.

Finishing transforms 18oz cotton duck from a strong textile into a purpose-built bag material. Water resistance, waxed finishes, flame retardancy, anti-mildew treatment, and coatings each address specific risks—but each carries trade-offs.

The right finish is selected by understanding use environment, logistics conditions, regulatory needs, and aging expectations, not by chasing trends or marketing terms.

When finishing is treated as risk management rather than decoration, canvas bags become more reliable, more durable, and more aligned with real-world demands.

How Is 18oz Cotton Duck Canvas Dyed, Printed, or Laminated for Branding—and What Colorfastness Standards Matter?

For bag brands, branding does not end with a logo placement or a color decision. On 18oz cotton duck canvas, how color is introduced and fixed determines whether a bag looks premium after two years of use—or starts bleeding, fading, or cracking after the first season.

Heavy-duty duck is structurally forgiving, but visually unforgiving. Its dense plain weave, high yarn twist, and natural cotton fibers expose weaknesses in dyeing, printing, and lamination processes more quickly than lighter fabrics. What looks bold on day one can become uneven, dull, or unstable if the branding method is mismatched to the fabric and use case.

Good branding lasts longer than the first photo shoot.

Branding Methods That Survive Real Use

Branding on 18oz cotton duck must survive abrasion, friction, moisture, UV exposure, and repeated handling. The correct process is not chosen for speed or cost alone, but for how well it integrates with dense cotton structure.

A) Dyeing Methods: Depth vs Surface Color

Dyeing determines the base color of the canvas before printing or construction. On heavy duck, penetration depth matters more than shade accuracy alone.

| Method | Color Depth | Durability | Notes |

|---|---|---|---|

| Reactive dye | High | Excellent | Penetrates fiber |

| Vat dye | Very high | Premium | Higher cost |

| Pigment dye | Surface | Moderate | Vintage look |

Reactive Dyeing: The Workhorse for Branded Bags

Reactive dyeing forms a chemical bond with cellulose fibers, allowing color to penetrate deep into the yarn. For 18oz cotton duck, this is critical. Dense yarn packing means surface-only color often fails under abrasion.

Reactive-dyed duck offers:

- Strong wash fastness

- Stable rubbing resistance

- Consistent appearance across folds and seams

For most branded bags—totes, backpacks, tool bags—reactive dyeing provides the best balance between visual depth, durability, and cost control.

It also supports downstream processes like printing and lamination more reliably, because the color base remains stable during heat and pressure exposure.

Vat Dyeing: Premium Stability for Demanding Use

Vat dyes penetrate deeply and deliver exceptional lightfastness. They are commonly associated with workwear and heritage products where long-term fading control matters.

However, vat dyeing:

- Increases processing cost

- Limits color range flexibility

- Requires more complex effluent handling

Brands choose vat-dyed duck when long outdoor exposure or professional use demands maximum color permanence.

Pigment Dyeing: Surface Character Over Longevity

Pigment dyeing deposits color on the fabric surface rather than bonding within the fiber. On heavy duck, this creates a distinctive, slightly chalky appearance that ages quickly.

Pigment-dyed duck is chosen intentionally when:

- A vintage or distressed look is desired

- Color variation is acceptable

- Abrasion-driven aging is part of the brand story

It is not ideal for bags that must retain uniform color across years of use.

B) Printing Techniques on Heavy Canvas

Printing introduces logos, text, and graphics. On 18oz duck, printing success depends on ink penetration, registration control, and abrasion resistance.

| Printing Type | Best Use | Limitation |

|---|---|---|

| Screen printing | Logos | Limited detail |

| Digital printing | Graphics | Ink penetration |

| Discharge printing | Soft hand | Color limits |

Screen Printing: Industrial Reliability

Screen printing remains the most reliable method for heavy canvas branding. Thick inks sit securely on the surface while maintaining edge definition on dense fabric.

Advantages include:

- High opacity

- Strong abrasion resistance

- Excellent consistency at scale

Limitations appear with very fine detail or multi-color gradients. Screen printing excels at logos, icons, and bold marks, which is why it dominates utility and promotional bag categories.

Digital Printing: Visual Freedom with Constraints

Digital printing allows complex artwork and photographic detail, but heavy duck presents challenges. Dense weave limits ink penetration, increasing the risk of surface cracking under flex.

To compensate, experienced mills:

- Pre-treat the canvas surface

- Adjust ink viscosity

- Control drying temperature

Digital printing is best reserved for decorative panels or low-abrasion zones, not high-contact areas like bag bases or handles.

Discharge Printing: Softness First

Discharge printing removes existing dye to create a design rather than adding ink. The result is a soft handfeel with no ink buildup.

However, discharge printing:

- Requires compatible base dyes

- Limits achievable colors

- Reduces contrast on dark shades

It works well on reactively dyed duck when softness is prioritized over high-contrast branding.

C) Lamination and Bonding for Branded Performance

Lamination adds a functional layer to cotton duck, often combining branding with protection. The challenge is preserving sewability and flexibility.

| Lamination Type | Added Benefit |

|---|---|

| TPU film | Waterproof |

| PE film | Cost-effective |

| Fabric-to-fabric | Strength layering |

TPU Lamination: Performance-Focused Branding

TPU-laminated duck creates a waterproof barrier while maintaining moderate flexibility. It is commonly used in:

- Travel bags

- Tool and gear bags

- Outdoor utility products

TPU lamination supports branding by:

- Locking in base color

- Protecting prints from moisture

- Enhancing wipe-clean surfaces

However, TPU increases stiffness and requires careful sewing calibration to avoid needle heating or seam cracking.

PE Lamination: Economy Protection

PE films provide basic moisture resistance at lower cost. They are suitable for promotional or short-lifecycle bags but offer limited durability.

PE-laminated duck is rarely chosen for premium branding due to reduced abrasion life and visual refinement.

Fabric-to-Fabric Bonding

In some cases, duck is bonded to another textile layer to combine aesthetics with performance. This method improves tear resistance and dimensional stability but adds weight and complexity.

Bonded constructions must maintain needle penetration integrity. Overly rigid bonding leads to broken needles and seam failure.

D) Colorfastness Benchmarks Buyers Should Request

Initial color appearance means little without measurable durability. For branded bags, colorfastness failures translate directly into returns and complaints.

| Test | Recommended Level |

|---|---|

| Wash fastness | Grade 4 |

| Crocking (dry) | Grade 4–5 |

| Crocking (wet) | Grade 3–4 |

| Light fastness | Grade 4 |

These benchmarks reflect real-use conditions rather than laboratory perfection. Heavy canvas bags are handled, rubbed, and exposed to light repeatedly.

Crocking: The Silent Brand Killer

Crocking—color transfer through rubbing—is one of the most common complaints with dyed canvas bags. Handles, clothing contact, and stacking exacerbate the issue.

Dense duck can increase crocking risk if dye fixation is poor. Reactive and vat dyes dramatically reduce this risk when properly processed.

Lightfastness: Outdoor Reality

Bags used outdoors or near windows face UV exposure. Low lightfastness leads to uneven fading and patchy appearance.

A minimum Grade 4 lightfastness ensures that fading occurs gradually and evenly rather than abruptly.

Why Standards Matter More Than Shade Matching

Many buyers focus on matching Pantone shades precisely, but overlook fastness testing. A perfectly matched color that fades or bleeds quickly damages brand perception far more than a slight shade variation that remains stable.

Durability defines quality.

Interaction Between Branding and Construction

Branding methods do not exist in isolation. They interact with:

- Yarn twist

- Weave density

- Finishing sequence

For example, printing before lamination produces different results than printing after lamination. Dyeing before sanforization affects shrinkage behavior differently than dyeing after.

Experienced suppliers define process order, not just process type.

A Practical Branding Scenario

A promotional bag program initially used pigment-dyed duck with screen printing to reduce cost. After one summer season, color transfer complaints emerged. Switching to reactively dyed duck increased fabric cost slightly, but eliminated complaints and improved repeat orders.

The branding became an asset instead of a liability.

Why Heavy Canvas Exposes Weak Branding

Light fabrics can hide poor fixation through drape and softness. Heavy duck does not. Its firmness and abrasion resistance place constant stress on color and print layers.

If branding survives on 18oz duck, it will survive almost anywhere.

SzoneierFabrics’ Branding Control Approach

For branded 18oz cotton duck programs, SzoneierFabrics aligns branding methods with performance expectations:

- Reactive dyeing as the default base

- Screen printing for high-contact branding

- Controlled digital printing for decorative zones

- Lamination only when functional gain outweighs stiffness

All branded fabrics are evaluated against wash, crocking, and lightfastness benchmarks before bulk approval, not after.

The Cost of Getting Branding Wrong

Failures in dyeing or printing often appear late—after production, shipping, or retail exposure. At that stage, correction is impossible.

Common consequences include:

- Discounting inventory

- Replacing customer orders

- Long-term brand erosion

Upfront investment in correct branding methods is consistently cheaper than downstream recovery.

How Buyers Should Frame the Decision

Instead of asking “Which branding method is cheapest?”, buyers should ask:

- How will this bag be handled daily?

- Where will friction occur?

- How long must the branding remain stable?

When these questions guide decisions, branding methods become strategic rather than cosmetic.

18oz cotton duck canvas supports a wide range of dyeing, printing, and lamination techniques—but not all branding methods perform equally under real use. Reactive and vat dyeing deliver depth and stability. Screen printing offers industrial reliability. Lamination adds protection when selected carefully. Colorfastness benchmarks protect brand reputation long after launch.

On heavy canvas, branding that lasts is not about visual impact alone. It is about engineering color to endure.

What Quality Tests Should Wholesale Buyers Require for Bag Canvas—Tear Strength, Abrasion, Seam Slippage, and Fabric Inspection Points?

For wholesale bag buyers, fabric quality is not defined by how clean a roll looks when it arrives, nor by how impressive a lab certificate appears in isolation. True quality is revealed only when canvas is cut, sewn, loaded, dragged, stored, and used repeatedly. This is why experienced buyers require performance-based testing that mirrors real bag use, not just textile theory.

Canvas failures are expensive because they surface late—often after bags are already in transit or in customers’ hands. At that stage, there are no easy fixes. Testing is not an administrative step; it is a cost-control and risk-management tool.

Testing prevents expensive learning curves.

Quality Control From Loom to Finished Bag

A reliable quality system for bag canvas spans three stages:

- Fabric intrinsic strength (what the material can handle on its own)

- Fabric behavior once sewn (how it performs as part of a bag)

- Fabric consistency before cutting (how defects and variation are controlled)

Skipping any one of these stages leaves blind spots that often turn into returns, complaints, or rework.

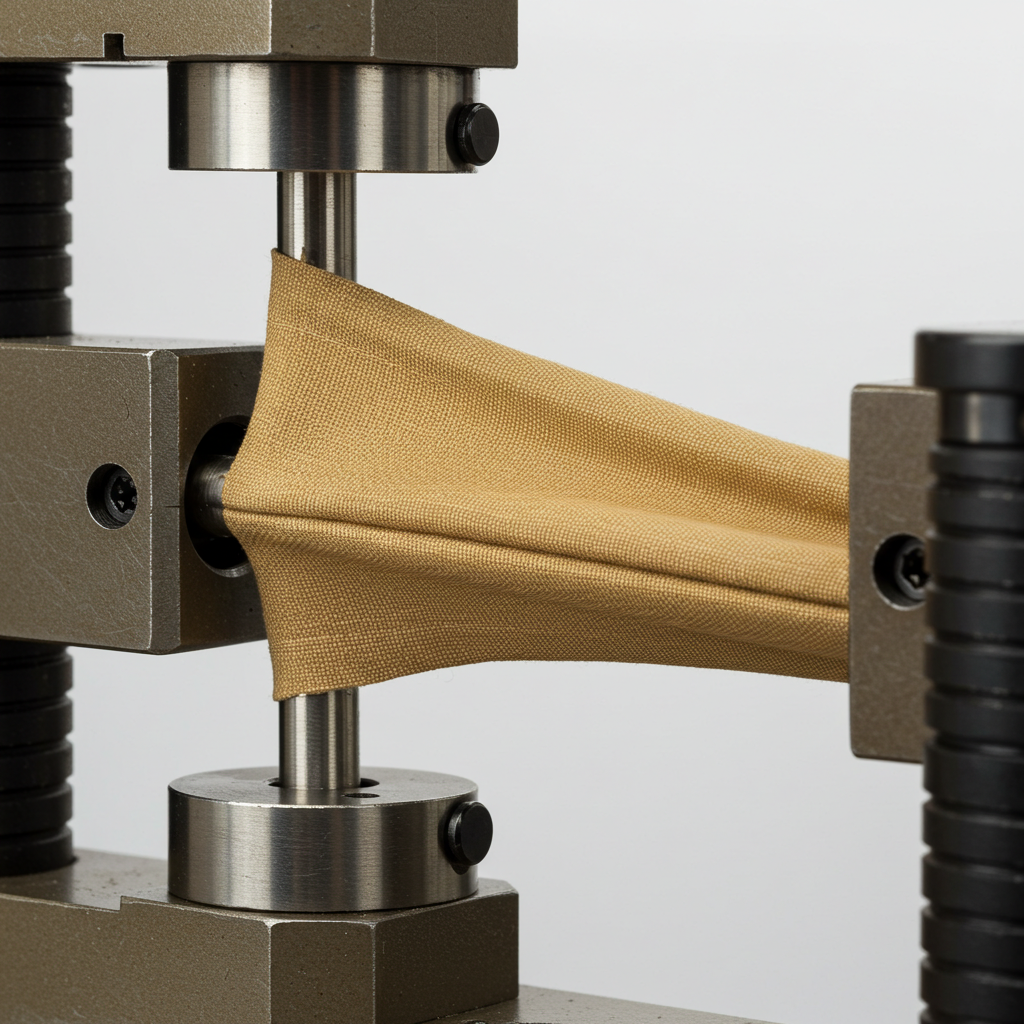

A) Tensile and Tear Strength: Load Reality, Not Lab Theory

Tensile and tear tests are often the first numbers buyers see, but they are frequently misunderstood. High peak strength alone does not guarantee bag durability.

| Test Type | Why It Matters in Bags |

|---|---|

| Tensile (warp/weft) | Handles static load |

| Tear strength | Resists sudden stress |

| Elmendorf tear | Simulates real ripping |

Tensile Strength: Balanced, Not Extreme

Tensile tests measure how much force fabric can withstand before breaking when pulled steadily. For bags, tensile strength matters most at:

- Handles

- Strap attachment zones

- Load-bearing panels

However, buyers should not chase the highest possible tensile numbers. A fabric that is extremely strong in warp but weak in weft often fails unpredictably once sewn.

For 18oz cotton duck, balanced warp and weft tensile values are far more important than a single impressive figure. Balance ensures that stress is distributed evenly across panels rather than concentrating along one direction.

Tear Strength: The Real Failure Scenario

Most bags do not fail under slow, even tension. They fail when:

- A bag catches on a sharp edge

- A handle jerks under sudden load

- A corner is pulled diagonally

Tear strength tests—especially Elmendorf tear—simulate these conditions more accurately than tensile tests alone.

A canvas with moderate tensile strength but high tear resistance often outperforms a stiffer, brittle fabric in real use.

B) Abrasion Resistance: Where Bags Actually Fail

Abrasion is one of the most common and least glamorous failure modes in bags. It happens quietly, over time, at predictable locations:

- Bag bottoms dragged on floors

- Corners rubbing against walls or vehicles

- Strap contact zones against clothing or hardware

| Abrasion Cycles | Expected Use Outcome |

|---|---|

| <15,000 | Short-term |

| 15,000–30,000 | Normal retail |

| 30,000+ | Heavy-duty |

Abrasion testing does not predict an exact lifespan, but it provides a comparative baseline. A bag canvas that survives 30,000 cycles under controlled testing will almost always outperform one that fails at 12,000 cycles, regardless of marketing claims.

Interpreting Abrasion Results Correctly

Buyers should evaluate abrasion results in context:

- Retail totes may perform well at 15,000–20,000 cycles

- Tool bags and travel gear should exceed 30,000 cycles

- Promotional bags may accept lower thresholds

At SzoneierFabrics, abrasion benchmarks are validated against end-use categories, not applied as one-size-fits-all numbers. This avoids over-specifying low-risk products and under-specifying high-risk ones.

C) Seam Slippage: The Most Overlooked Failure Mode

A canvas can be strong, thick, and abrasion-resistant—and still fail at the seam. Seam slippage occurs when yarns shift under stitch tension, causing visible gaps or distortion around seams.

| Risk Factor | Result |

|---|---|

| Loose weave | Stitch widening |

| Low yarn friction | Panel distortion |

| Poor balance | Handle failure |

Seam slippage is especially critical for:

- Handle box stitches

- Shoulder strap attachments

- Base reinforcement seams

Why Seam Slippage Matters More Than Fabric Strength

In bags, fabric rarely tears first. Seams fail first. A canvas that tests well in tensile strength but performs poorly in seam slippage creates a false sense of security.

Seam slippage testing evaluates:

- Yarn mobility under stitch load

- Interaction between fabric and thread

- Stability after repeated stress

Buyers who skip seam slippage testing often face complaints such as “handles pulling out” or “seams opening” even though the fabric itself looks intact.

D) Shrinkage and Dimensional Stability: Hidden Fit Risk

Although not always grouped with strength tests, shrinkage stability is critical for bag canvas—especially for structured designs.

Uncontrolled shrinkage leads to:

- Misaligned panels

- Twisted shapes

- Inconsistent finished dimensions

For wholesale production, buyers should require:

- Warp and weft shrinkage data

- Post-wash dimensional stability reports

Even 2–3% uncontrolled shrinkage can disrupt cutting plans and cause size variance across production batches.

E) Fabric Inspection: Quality Starts Before Cutting

No amount of lab testing can compensate for defective fabric entering the cutting room. This is why systematic roll inspection is essential.

The 4-point inspection system is widely used because it balances thoroughness with efficiency.

| Defect Type | Typical Impact |

|---|---|

| Broken ends | Weak zones |

| Oil spots | Dye rejection |

| Weave bars | Visual defects |

| Shade variation | Panel mismatch |

Why Inspection Matters for Bags More Than Apparel

Bag panels are large and highly visible. A defect that might be hidden in apparel seam allowances becomes obvious on a tote front or backpack body.

Early inspection allows factories to:

- Mark and avoid defect zones

- Allocate rolls strategically

- Prevent visible defects from reaching finished goods

For wholesale buyers, inspection reports provide confidence that quality control is proactive, not reactive.

Linking Fabric Tests to Bag Failure Modes

Each test corresponds to a real-world failure scenario:

- Tensile imbalance → handle tear

- Low tear strength → corner ripping

- Poor abrasion resistance → worn-through bases

- Seam slippage → distorted handles

- Uninspected defects → visible rejects

When buyers understand these links, test results become decision tools rather than abstract numbers.

How Buyers Should Specify Test Requirements

Instead of asking for generic “fabric test reports,” wholesale buyers should specify:

- Test methods (ASTM / ISO)

- Warp and weft values separately

- Acceptable ranges, not single targets

- End-use context for abrasion benchmarks

Clear test expectations reduce misalignment between buyer, mill, and factory.

Testing Frequency: One-Time vs Ongoing

A common mistake is treating testing as a one-time approval step. In reality, buyers should require:

- Initial qualification testing

- Periodic re-testing by lot

- Re-validation after any process change

Even small changes in yarn source, finishing sequence, or loom settings can alter performance.

Cost Perspective: Testing vs Failure

Testing adds cost—but failure costs far more. Typical downstream costs include:

- Rejected production

- Freight losses

- Chargebacks

- Brand reputation damage

Compared to these risks, systematic testing is inexpensive insurance.

A Practical Buyer Scenario

A wholesale buyer approved a visually clean 18oz canvas based on weight and color alone. After six months, bags showed handle seam distortion. Post-analysis revealed poor seam slippage performance that had never been tested. The next production run added seam slippage criteria, eliminating the issue entirely.

The lesson was not about changing fabric—it was about changing evaluation discipline.

SzoneierFabrics’ Testing Philosophy

For bag canvas programs, SzoneierFabrics aligns testing with how bags fail in reality, not just textbook metrics. Core requirements typically include:

- Balanced warp/weft tensile and tear data

- Abrasion benchmarks matched to end use

- Seam slippage validation on representative stitches

- Shrinkage and dimensional stability checks

- 4-point inspection reports before cutting

This approach reduces surprises and stabilizes long-term supply.

The Buyer’s Mindset Shift

The most effective buyers do not ask, “Is this fabric strong?” They ask, “How will this fabric fail—and when?”

Testing answers that question early, when adjustments are still affordable.

Wholesale bag buyers should require performance-based testing that mirrors real use, not just surface-level fabric approval. Tensile and tear strength establish load capacity, abrasion resistance predicts wear life, seam slippage reveals sewing behavior, and systematic inspection prevents defects from entering production.

When testing is treated as prevention rather than paperwork, bag canvas becomes predictable, production becomes stable, and quality becomes repeatable rather than accidental.

How Does SzoneierFabrics Support OEM/ODM Canvas Sourcing—MOQ, Sampling, Lead Time, Packaging, and Export Documentation?

For brands developing canvas bags, sourcing success is rarely determined by fabric specifications alone. Strength, weight, and finishing matter—but how those materials are developed, validated, packed, and delivered often determines whether a project scales smoothly or stalls under friction.

OEM/ODM sourcing is a process, not a transaction. At scale, small failures compound: a sample that doesn’t match bulk, a missed tolerance that disrupts cutting, a missing document that delays customs clearance. SzoneierFabrics approaches canvas sourcing as a system, designed to support brands from first concept through repeat production.

Support matters as much as specs.

What Reliable Canvas Sourcing Actually Looks Like

For wholesale and brand clients, reliability is built on five pillars:

- Development-friendly MOQ structure

- Sampling that truly reflects bulk production

- Transparent, stable lead times

- Controlled packaging and roll handling

- Complete, accurate export documentation

Each pillar removes a specific risk that commonly disrupts OEM/ODM projects.

A) MOQ Structure Designed for Development

One of the biggest barriers for emerging and mid-sized brands is minimum order quantity. High MOQs force decisions before markets are tested, increasing financial and inventory risk.

SzoneierFabrics structures MOQs around development stages, not just production efficiency.

| Stage | Typical MOQ |

|---|---|

| Sampling | Small yardage |

| Pilot run | Low MOQ |

| Bulk production | Scalable |

This staged approach allows brands to:

- Validate fabric behavior in real prototypes

- Test small production runs with customers

- Scale volume only after performance and demand are confirmed

Rather than forcing early commitment, the MOQ structure supports learning before locking.

Why Low-MOQ Development Matters

Many sourcing failures originate when brands skip proper validation to meet MOQ thresholds. By allowing small-yardage sampling and pilot runs, SzoneierFabrics reduces the pressure to approve fabric prematurely.

This approach shortens the overall development cycle by preventing costly redesigns later.

B) Sampling That Mirrors Bulk Reality

Sampling is where trust is built—or lost. A common industry problem is the “sample vs bulk gap,” where samples are produced under ideal conditions that are not repeated at scale.

At SzoneierFabrics, sampling is engineered to mirror bulk production conditions as closely as possible.

Samples are produced using:

- The same yarn source

- The same weaving and finishing lines

- The same quality tolerances as bulk

This ensures that what designers approve during development is what factories receive during production.

Eliminating the Sample Illusion

When samples are softer, cleaner, or more stable than bulk fabric, downstream issues emerge at cutting and sewing stages. By aligning sampling and bulk processes, SzoneierFabrics minimizes interpretation gaps and disputes.

Sampling is treated as early production, not a separate exercise.

C) Lead Time Transparency and Planning