Denim feels timeless. It looks familiar, wears familiar, and often gets described in simple terms—“cotton denim,” “stretch denim,” “raw denim.” But behind that familiarity, modern denim manufacturing has quietly become far more technical than most people realize. Today’s denim is no longer defined by a single fiber or a single rule. It is engineered—sometimes subtly, sometimes aggressively—to meet expectations around comfort, durability, fit retention, and repeatability.

The question “What is denim fabric made of?” used to have a simple answer: cotton. Today, the real answer is layered. Cotton is still the foundation, but blends and performance fibers now play strategic roles, solving problems that pure cotton cannot—especially once garments are worn, washed, and produced at scale. Modern denim fabric is primarily made from cotton, but it increasingly incorporates blended and performance fibers such as elastane, polyester, and regenerated fibers to improve comfort, durability, stretch, and fit retention. While cotton defines denim’s look and breathability, fiber blends allow manufacturers to engineer how denim behaves during wear and washing. Understanding fiber composition is essential for selecting denim that performs consistently in real-world use.

A designer once joked, “Denim hasn’t changed—but expectations have.” Fiber choices are where those expectations are quietly met.

What is Denim Fabric Made of in Modern Manufacturing Today?

Denim fabric, once synonymous with rugged workwear and utilitarian style, has evolved significantly from its early origins. In modern manufacturing, denim remains fundamentally cotton-based, yet its composition has diversified in response to consumer demands for comfort, fit, durability, and sustainability. Today’s denim is not merely woven cotton—it is the result of strategic engineering that blends natural fibers with performance synthetics to deliver specific functional attributes.

This detailed overview examines the materials used in contemporary denim production, why certain blends are now commonplace, and how these choices influence garment behavior from manufacturing floor to consumer wardrobe.

The Anatomy of Modern Denim: More Than Just Cotton

Historically, denim began as a heavyweight cotton twill designed for durability. Over decades of innovation, textile engineers and brands have adapted denim to suit a multitude of styles—from vintage rigid jeans to high-stretch skinny silhouettes and performance-oriented denim.

Although cotton still dominates, very few commercial denims today are truly “just cotton” in performance terms. Manufacturers frequently incorporate additional fibers to achieve desired performance characteristics such as stretch recovery, strength, dimensional stability, and even moisture management.

Fiber Composition Breakdown

| Fiber Category | Typical Share in Modern Denim | Purpose in Fabric Performance |

|---|---|---|

| Cotton | 90–100% | Natural breathability, hand feel, traditional appearance |

| Elastane (Spandex) | 0.5–3% | Stretch and recovery—comfort and fit |

| Polyester | 0–30% | Strength, reduced shrinkage, dimensional stability |

| Other fibers (Modal, TENCEL™, Recycled Polyester) | 0–20% | Enhanced softness, sustainability, drape |

Although the percentages of supplementary fibers appear small, their influence is disproportionately large. Even a 1–2% inclusion of elastane can dramatically change how denim stretches and recovers during wear.

Why Pure Cotton Denim Behaves the Way It Does

Denim made from 100% cotton carries a distinctive set of characteristics that many denim purists appreciate:

- Natural Breathability: Cotton fibers allow air circulation, making 100% cotton denim comfortable in a wide range of temperatures.

- Authentic Aging and Fade Patterns: Because cotton fibers break down and interact with indigo dyes uniquely over time, pure cotton denim develops individualized wear patterns.

- Traditional Hand Feel: Rigid denim offers a firm, substantial texture that collectors and denim aficionados prize.

However, these benefits come with trade-offs:

- Shrinkage: Unblended cotton tends to shrink significantly during the first few wash cycles unless extensively pre-shrunk during manufacturing.

- Poor Stretch Recovery: Pure cotton cannot return to its original dimensions after stretching, which can lead to deformation—especially in fitted cuts.

- Extended Break-In Time: Rigid denim often requires weeks or months of wear before becoming comfortable.

For heritage-inspired styles and workwear aesthetics, these traits are desirable. For contemporary fashions emphasizing fit and comfort, they often prove limiting.

The Shift Toward Engineered Blends

The textile industry responded to the limitations of pure cotton denim by experimenting with performance fibers. This shift began in earnest in the late 20th century with the introduction of small percentages of elastane and polyester into denim yarns.

Elastane: Comfort Without Compromise

Elastane, commonly known by brand names such as Spandex and Lycra®, is typically added at 0.5–3% in stretch denim. While this number seems negligible, elastane dramatically enhances the fabric’s ability to stretch and recover, particularly:

- Enhanced Fit: Stretch denim conforms to body shape without sagging.

- Improved Comfort: Greater elasticity reduces pressure points and supports movement.

- Reduced Size Complaints: Garments made with elastane exhibit less distortion after repeated wear.

A common industry standard for “comfort stretch” denim is 98% cotton / 2% elastane—a balance that preserves natural appearance while offering noticeable flexibility.

Polyester: Stability and Durability

Polyester is often used in more technical denim constructions. Because polyester fibers have inherently higher tensile strength than cotton, incorporating them can:

- Reduce dimensional change after washing

- Increase abrasion resistance

- Support higher-speed manufacturing without compromising fabric integrity

Denim blends with polyester typically range from 5% to 30% polyester depending on target performance. Higher polyester content is more common in denim designed for industrial or utility applications.

Sustainable and Specialty Fibers

In recent years, brands and mills have introduced fibers such as Modal, TENCEL™, and recycled polyester into denim for specific purposes:

- Modal or TENCEL™ improves softness and drape, enhancing wear comfort.

- Recycled fibers align with sustainable sourcing goals without dramatically affecting performance.

These fibers are typically blended within the 5–20% range, striking a balance between enhanced properties and maintaining a predominantly cotton character.

How Fiber Choices Affect Denim Manufacturing Processes

Fiber selection is not merely a material decision—it dictates manufacturing parameters across spinning, dyeing, weaving, and finishing stages.

Spinning and Yarn Formation

Adding elastane or polyester affects:

- Yarn strength: Synthetic fibers often increase overall yarn tenacity.

- Twist requirements: Optimal twist levels change based on fiber mix to control elasticity and fiber cohesion.

- Dye uptake: Natural cotton and synthetic fibers react differently to indigo and sulfur dyes, necessitating tailored dyeing recipes.

For example, cotton-rich yarns require more aggressive indigo saturation to achieve deep blue hues, while polyester-rich yarns may require specialized disperse dyes to achieve a cohesive color.

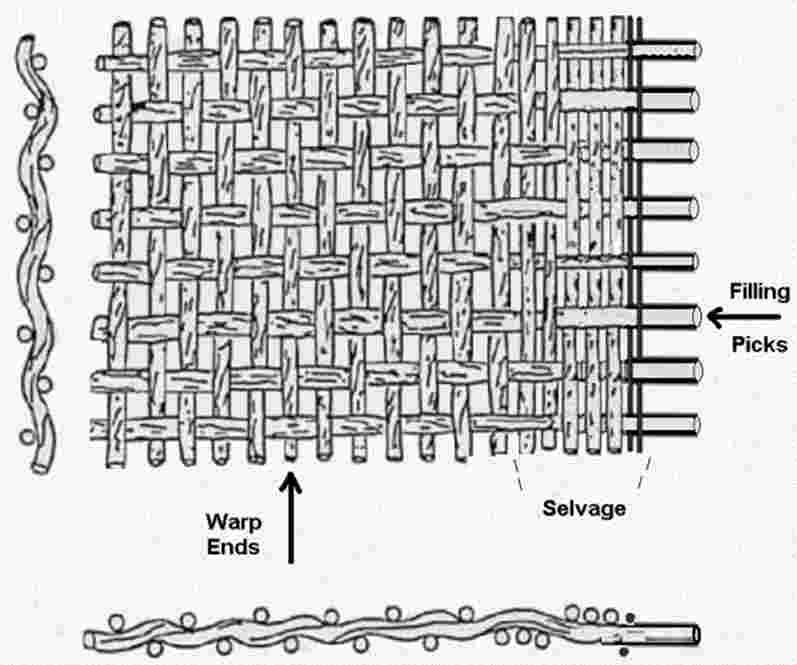

Weaving Dynamics

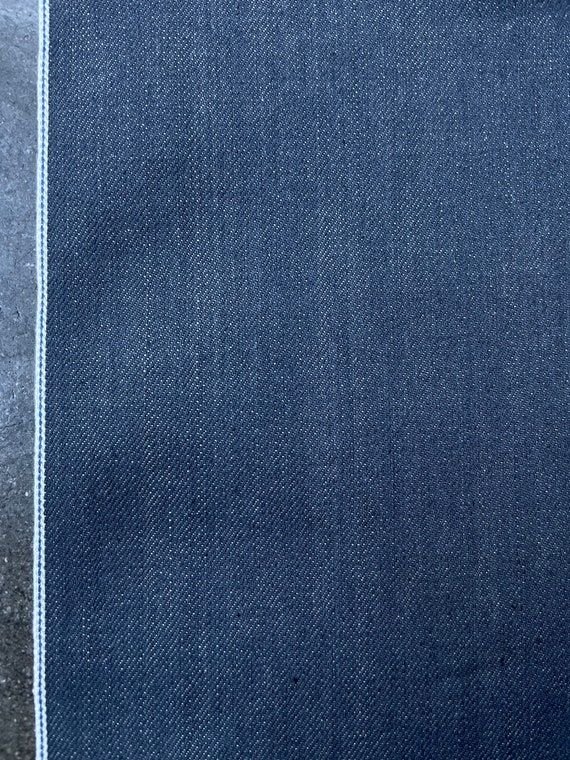

The structure of denim—traditionally 3/1 right-hand twill—is preserved regardless of fiber content. However:

- Stretch denim looms may incorporate elastomer core-spun yarns, which behave differently under tension.

- Warp stability adjustments are often necessary when polyester content increases to maintain consistent fabric width and reduce loom waste.

Finishing and Pre-Shrink Operations

Blended denim frequently undergoes finishing treatments to:

- Control shrinkage: Sanforization or other pre-shrink processes stabilize dimensional changes.

- Enhance hand feel: Enzyme washes or softeners improve fabric softness without weakening fiber structure.

- Lock in stretch performance: Heat-set treatments for elastane ensure long-term recovery.

These finishing choices are essential for delivering denim garments that meet performance expectations in competitive markets.

Real-World Insights: Manufacturing Perspectives

At SzoneierFabrics, many denim development projects begin with a cotton-first mindset that prioritizes natural hand feel and breathability. Engineers then assess where pure cotton might struggle—such as in stretch recovery or stability under repeated wear—and introduce performance fibers only when necessary.

This approach preserves the heritage aesthetic of denim while addressing practical wear issues that consumers increasingly expect.

For example:

- A pre-washed 98/2 cotton/elastane denim may show less relaxation around knees and hips after multiple wears, compared to 100% cotton denim with identical initial weight.

- Denim with 15–25% polyester often exhibits tighter dimensional control after repeated laundering, reducing returns related to fit change.

Such empirical observations inform fabric specifications and help brands balance tradition with consumer expectations.

Modern denim remains cotton-based, yet its performance characteristics are increasingly engineered, not assumed.

- Pure cotton denim holds cultural and stylistic value, particularly in heritage or rigid styles.

- Blended denim uses strategic fiber additions to enhance comfort, durability, and stability, aligning with contemporary wear demands.

- Performance improvements from even small percentages of elastane or polyester can significantly influence garment behavior.

In practice, yarn engineers and developers carefully calibrate fiber content to achieve desired outcomes, resulting in denim that behaves predictably in real wear while preserving its authentic aesthetic.

Through this engineered approach, denim continues to evolve—honoring its roots while meeting the functional expectations of today’s global consumers.

Why is Cotton Still the Primary Fiber Used in Denim Fabric Production?

Denim occupies a unique place in the global apparel landscape: it is both everyday wardrobe staple and a material with deep cultural resonance. At the heart of this fabric’s enduring appeal lies a simple truth—cotton continues to be its most essential component. Even as textile science introduces new fibers and performance blends into denim, cotton’s role remains dominant because it delivers a combination of attributes that are hard to replicate or surpass.

This article explores why cotton still “wins” in denim production, how its natural characteristics contribute to the fabric’s sensory and performance qualities, and why, in most applications, it remains irreplaceable despite the advances in synthetic fibers.

The Primacy of Cotton in Denim

To understand why cotton remains the principal fiber in denim, we must look beyond mere tradition. Cotton’s properties are inherently aligned with what wearers expect from denim: comfort, breathability, aesthetic depth, and a distinctive aging profile. These are not just technical criteria; they form the denim experience itself.

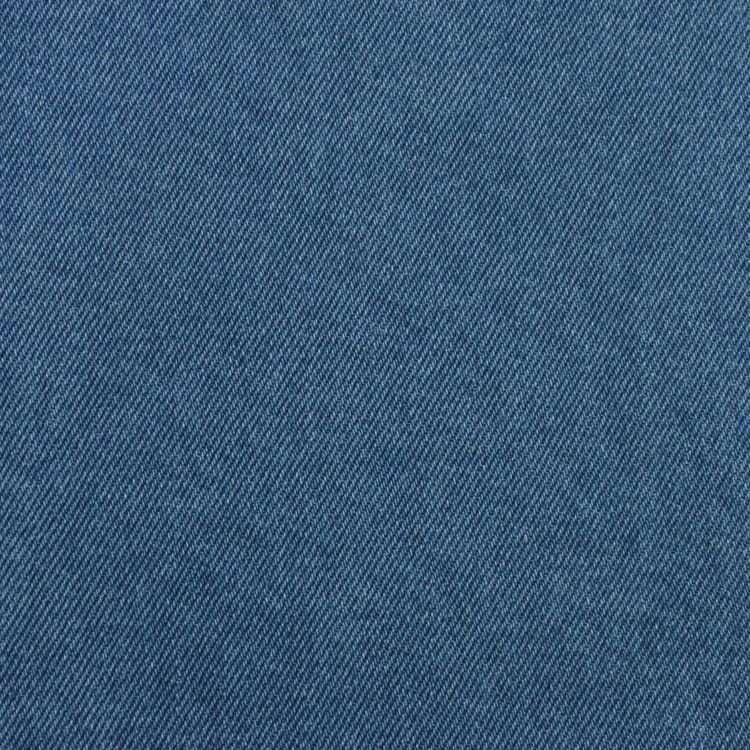

Denim fundamentally is a cotton twill weave—a structure that presents cotton’s natural strengths in the most pronounced way. This structure interacts with the fiber’s intrinsic qualities, resulting in a fabric that performs well across diverse climates, end-uses, and fashion expressions.

Cotton’s Natural Advantages in Denim Fabric

The table below summarizes several core properties of cotton and explains why they matter specifically for denim:

| Cotton Property | Why It Matters in Denim |

|---|---|

| Breathability | Ensures comfort in varied temperatures; air flows through cotton fiber structures more readily than synthetics. |

| Indigo dye affinity | Supports deep surface coloration and distinct fading characteristics; cotton’s cellulose readily interacts with indigo molecules. |

| Moisture absorption | Reduces clamminess and sweat build-up; cotton can absorb up to ~8% of its weight in moisture without feeling wet. |

| Natural fading behavior | Produces desirable, high-contrast wear patterns over time—an aesthetic central to denim culture. |

These traits explain why even highly technical denim blends still rely on cotton as the majority fiber. In most blended denim constructions, cotton typically ranges from 90% to near 100% of the fiber content, with remaining percentages allocated to performance fibers like elastane or polyester.

Breathability and Comfort: A Non-Negligible Advantage

Breathability is more than a comfort metric; it influences how denim feels against the skin and throughout the day. Cotton’s fiber morphology—composed of natural cellulose with a hollow core and surface twists—permits ambient air exchange and moisture wicking in a way most synthetic fibers cannot match.

In practical terms:

- During warm weather, cotton helps dissipate body heat more effectively than polyester-rich fabrics.

- In cooler conditions, cotton layers can retain a degree of warmth while still allowing moisture transport.

Synthetic fibers tend to trap heat or feel slick because they lack the complex microstructure of cotton. For denim—a fabric worn close to the skin in jeans, jackets, and shirts—this comfort factor is critical to consumer satisfaction.

Indigo Dye Affinity: The Soul of Denim Aesthetics

One of the most defining visual features of denim is how it fades and ages. That visual narrative—the way a pair of jeans tells a story through wear marks, honeycombs, and knee fades—is largely a result of how indigo dye interacts with cotton fibers.

Indigo dyes do not fully penetrate cotton fibers; they cling to the outer layers, creating a surface color that gradually wears away with abrasion. This surface dye behavior is essential for:

- High-contrast fades that evolve with use.

- Customized aging patterns shaped by wearer movements and activities.

- Fabric depth and dimensional coloration that enhances visual interest.

In contrast, synthetic fibers do not bind with indigo in the same way, often resulting in flatter color and less dynamic fading. This difference is why even stretch denim—which includes elastane to improve comfort—still uses cotton as the dye-carrying backbone.

Why Synthetics Can’t Fully Replace Cotton

It is true that some synthetic fibers outperform cotton in isolated metrics:

- Polyester has higher tensile strength and dries more quickly.

- Elastane provides significantly greater stretch and recovery.

Yet, when it comes to the combined sensory and aesthetic experience of denim, synthetics fall short:

- Handfeel: No synthetic fiber yet replicates the tactile warmth, softness, and evolving texture of cotton denim.

- Visual Character: Synthetic fibers tend to produce surface visual monotony; they age uniformly rather than develop rich, characterful patterns.

- Wear Narrative: Denim’s appeal is partly cultural—rooted in how wearers imprint personal history into the fabric. Synthetics don’t facilitate this narrative.

Thus, “all-synthetic denim” remains niche and usually caters to specialized technical applications rather than mainstream fashion.

The Importance of Cotton Quality

Not all cotton is created equal. When textile engineers discuss denim fiber quality, they focus on several key attributes:

| Cotton Attribute | Impact on Denim Fabric |

|---|---|

| Fiber length (staple) | Longer fibers produce stronger, smoother yarns with fewer weak points. |

| Fiber maturity | More mature fibers absorb dye more evenly, enhancing color depth and consistency. |

| Cleanliness (trash content) | Fewer impurities mean fewer yarn defects, reduced slubs, and cleaner surface appearance. |

Long-staple cotton—such as Extra-Long Staple (ELS) varieties like Pima or Egyptian cotton—tends to yield denim that is stronger, more consistent, and better at showcasing indigo dye depth. However, higher cotton quality also raises raw material costs, affecting pricing and positioning in the marketplace.

Manufacturing and Performance: Why Cotton Fits Best

In practical garment manufacturing, cotton’s behavior influences multiple downstream processes:

- Yarn Spinning: Cotton fibers twist into yarns with a balance of strength and softness that suits the heavy twill structure of denim.

- Weaving: Cotton yarns maintain consistent tension and shrinkage during weaving, simplifying quality control.

- Finishing: Cotton can endure sanforization (pre-shrinking) and various wash treatments without overly compromising fabric integrity.

These predictable, manageable properties help mills and brands achieve consistent production outcomes — a crucial business consideration.

A Real-World Example

Consider a mid-sized denim brand that experimented with replacing 15% of cotton content with polyester to improve durability and reduce shrinkage. Although the garments achieved modest gains in tensile strength, customer feedback focused overwhelmingly on one issue: the fabric’s feel.

Consumers described the denim as “plasticky” and “lifeless” compared to traditional cotton blends. The visual aging patterns were also reported as “flat” and less attractive after wash cycles. In response, the brand adjusted its formula to reduce polyester content to 5%, re-emphasizing cotton’s role while maintaining modest performance benefits.

This example highlights a central point in denim production: technical performance gains are valuable, but not at the expense of sensory expectations tied to cotton.

Cotton in Technical and Performance Denim

Blended denim—such as cotton with elastane or cotton-polyester mixes—is common in contemporary fashion. These blends seek to maintain cotton’s sensory and aesthetic virtues while adding targeted enhancements:

- Elastane (typically 1–3%) delivers controlled stretch and recovery for improved comfort and fit.

- Polyester (typically up to 30%) can enhance dimensional stability and reduce shrinkage.

Even here, cotton remains the majority component because it anchors the fabric’s look and natural behavior.

Cultural and Psychological Dimensions

Denim’s story is intertwined with identity: workwear, rebellion, artistry, and self-expression. Cotton plays a role in this psychological dimension because it offers a natural counterpart to synthetic uniformity. Wearers often associate cotton with authenticity—a connection that extends beyond measurable performance.

This cultural value cannot be overstated; it affects how consumers perceive quality and justify premium pricing for denim that “feels right” even before it is worn.

Cotton remains the primary fiber in denim fabric production not out of inertia or tradition alone, but because it continues to deliver a unique combination of:

- Breathability and comfort

- Indigo affinity and visual depth

- Moisture management and evolving wear character

- Predictable manufacturing behavior and consumer satisfaction

While synthetic fibers play valuable roles in enhancing specific performance aspects, none has supplanted cotton’s central role in defining what denim feels and looks like in real wear. This enduring relevance of cotton is the reason manufacturers, brands, and wearers alike continue to prioritize it—and why denim remains one of the most iconic and enduring textiles in the world.

Which Cotton Types and Yarn Qualities Matter Most in Denim Manufacturing?

In denim manufacturing, conversations about cotton often focus on origin names—Egyptian, American, Indian, organic, or long-staple varieties. While origin can influence quality, it is not the decisive factor in how denim actually performs. What matters far more are fiber characteristics and yarn engineering: how long and mature the fibers are, how clean they arrive at the mill, and how those fibers are spun into yarn.

In real production environments, mills quickly learn that not all cotton makes good denim—and not all “good cotton” translates into reliable denim yarn. High-performing denim depends on measurable, controllable properties rather than marketing labels.

What Actually Separates High-Performing Denim Cotton

From a manufacturing standpoint, cotton suitability for denim is judged less by geography and more by behavior under tension, dyeing, weaving, and washing. Denim is a demanding fabric: warp yarns endure repeated indigo dyeing cycles, high loom tension, and abrasive finishing processes. Cotton that cannot tolerate these stresses will reveal weaknesses long before garments reach consumers.

Four factors consistently prove decisive:

- Fiber length

- Fiber maturity

- Cleanliness and contamination control

- Yarn construction and spinning method

Each influences denim performance in different but interconnected ways.

Cotton Fiber Length and Its Impact on Denim Strength

Fiber length—often referred to as staple length—has a direct relationship with yarn strength, smoothness, and durability. Longer fibers overlap more during spinning, creating stronger inter-fiber cohesion and fewer weak points along the yarn.

| Fiber Length Category | Typical Result in Denim |

|---|---|

| Short-staple cotton | Increased fuzz, higher breakage risk, weaker yarn |

| Medium-staple cotton | Balanced strength and cost efficiency |

| Long-staple cotton | Stronger yarn, smoother surface, better abrasion resistance |

In heavier denim constructions—typically above 12 oz—the benefits of long-staple cotton become more pronounced. Stronger yarns withstand higher loom tension and repeated dyeing without excessive fiber loss. This results in denim that resists premature wear, especially at stress points such as knees, seams, and pocket edges.

However, longer fibers also raise raw material costs. For this reason, many mills opt for optimized medium-to-long staple blends, rather than extreme long-staple cotton, to balance durability and price.

Fiber Maturity and Indigo Dye Consistency

Fiber maturity is one of the most overlooked yet influential factors in denim quality. Mature cotton fibers have fully developed cellulose walls, while immature fibers remain thin and flat. This structural difference directly affects how fibers absorb indigo dye.

When immature fibers are present in significant quantities, manufacturers often encounter:

- Patchy or cloudy coloration after dyeing

- Uneven indigo penetration along the yarn

- Weak spots that break more easily during weaving

- Increased pilling after washing

Mature fibers, by contrast, absorb dye more uniformly and retain it more predictably during abrasion. This leads to cleaner indigo surfaces and controlled, intentional fading patterns rather than random discoloration.

In practice, mills assess maturity through fiber testing rather than relying on supplier descriptions. Denim programs with tight color consistency requirements—especially for premium or repeat-order styles—place heavy emphasis on this parameter.

Cleanliness and Contamination Control

Raw cotton arrives at mills with varying levels of natural contamination, including leaf fragments, seed particles, and dust. While some texture variation is acceptable in certain rustic denim styles, uncontrolled contamination introduces risk.

| Cleanliness Level | Impact on Denim Production |

|---|---|

| High cleanliness | Smooth yarn surface, stable weaving, consistent fabric appearance |

| Medium cleanliness | Minor texture variation, manageable with process control |

| Low cleanliness | Yarn defects, weak spots, loom stoppages, visible fabric flaws |

Contamination increases the likelihood of yarn imperfections that later become visible defects or points of mechanical failure. In modern denim mills, additional opening and cleaning steps are often introduced when raw cotton quality varies. These steps improve consistency but also increase processing costs.

As a result, mills frequently prioritize reliable cleanliness over nominal cotton grade, especially for large-volume or high-speed production lines.

Yarn Spinning Method: Where Cotton Quality Becomes Performance

Even high-quality cotton can underperform if yarn construction is poorly matched to the denim’s intended use. Spinning method determines yarn structure, surface texture, and mechanical behavior.

| Spinning Method | Typical Denim Outcome |

|---|---|

| Ring-spun | Soft handfeel, natural slub, strong visual character |

| Open-end (rotor) | Uniform appearance, high strength, cost efficiency |

| Compact spinning | Very smooth yarn, high strength, reduced hairiness |

Ring-spun yarns are widely favored for premium and heritage denim because they preserve fiber irregularities that contribute to natural texture and fading. The trade-off is slightly lower production speed and higher cost.

Open-end yarns dominate cost-efficient and mass-market denim due to their strength and uniformity. They perform well in industrial settings but produce flatter visual results.

Compact spinning, though less common, delivers exceptionally smooth and strong yarns by controlling fiber alignment more tightly. This method is often used when denim must meet stringent performance or aesthetic specifications.

Yarn Evenness and Long-Term Denim Behavior

Beyond spinning method, yarn evenness and twist control significantly influence denim performance after washing and wear. Uneven yarns may look appealing at first but can lead to unpredictable shrinkage, seam distortion, or premature thinning.

Well-controlled yarns offer:

- More predictable shrinkage behavior

- Reduced stress concentration during wear

- Improved consistency across production batches

In large denim programs, these benefits translate directly into fewer size complaints, lower return rates, and greater confidence in repeat production.

Practical Manufacturing Insight

At SzoneierFabrics, many denim programs achieve noticeable performance improvements not by increasing fabric weight, but by upgrading yarn quality. Stronger, more uniform yarns often reduce breakage during weaving, minimize stress during finishing, and maintain structural integrity through repeated wash cycles.

In several cases, mills observed that improving yarn maturity and cleanliness reduced long-term wear issues more effectively than simply adding weight or increasing polyester content. This approach preserves the cotton-dominant character of denim while addressing durability concerns at the fiber level.

Cost Versus Performance: A Realistic Balance

Higher-quality cotton and advanced spinning methods inevitably raise costs. However, the relationship between cost and performance is not linear. Small improvements in fiber maturity or yarn control can produce disproportionate gains in fabric stability and consumer satisfaction.

For many brands, the optimal strategy is not chasing the “best” cotton available, but selecting the most consistent cotton-yarn system that meets design, durability, and price targets.

In denim manufacturing, “better cotton” is not defined by labels or origin stories. It is defined by:

- Fiber length that supports yarn strength

- Fiber maturity that enables even dyeing

- Cleanliness that ensures process stability

- Yarn construction that matches intended wear and aesthetics

When these factors align, denim behaves predictably under tension, dyeing, and washing—delivering both performance and character. Ultimately, it is yarn control, not cotton mythology, that determines whether denim succeeds in real-world use.

How Do Cotton-Blend Denims Differ from 100% Cotton Denim in Performance?

At a glance, 100% cotton denim and cotton-blend denim may look nearly identical. Both rely on the same twill structure, often use similar indigo dyeing methods, and can be finished to comparable surface appearances. Yet once these fabrics are worn, washed, and lived in, their differences become clear. Cotton-blend denims are engineered for control, while pure cotton denim is defined by organic variability.

This distinction explains why blends have become dominant in modern apparel—and why 100% cotton denim continues to hold a powerful position in heritage and premium niches. The difference is not about quality versus compromise, but about performance priorities.

Blends do not replace cotton. They discipline it.

Performance Trade-Offs Between Pure Cotton and Blended Denim

Pure cotton denim behaves according to the natural limits of cellulose fibers. Cotton-blend denim introduces additional fibers—often elastane, polyester, or regenerated fibers—to modify those limits. The result is a shift in how the fabric stretches, recovers, shrinks, and ages.

The table below summarizes the most practical performance differences observed in manufacturing and wear:

| Performance Aspect | 100% Cotton Denim | Cotton-Blend Denim |

|---|---|---|

| Stretch | Minimal, mechanical only | Controlled, elastic |

| Recovery | Low; deformation over time | Medium–High |

| Shrinkage | Higher, less predictable | Lower, more stable |

| Aging behavior | Organic, high-contrast fades | More uniform, restrained |

| Comfort timeline | Requires break-in | Comfortable immediately |

These differences explain why blends are widely used in fitted garments, while pure cotton remains preferred for rigid, character-driven denim.

Stretch and Recovery: The Most Visible Difference

One of the most obvious distinctions between pure cotton denim and blends is stretch behavior. Cotton fibers themselves do not stretch significantly; any flexibility in 100% cotton denim comes from fabric construction rather than fiber elasticity. Over time, this mechanical stretch leads to permanent deformation.

Cotton-blend denims—especially those containing 1–3% elastane—introduce true elasticity. This allows the fabric to:

- Stretch during movement

- Recover its original shape after wear

- Maintain fit at stress points such as knees, hips, and seat

From a manufacturing perspective, this directly reduces size complaints and fit-related returns. In slim-fit or high-mobility garments, the difference is substantial. Where pure cotton denim may bag out after a few hours of wear, a cotton-elastane blend maintains shape throughout the day.

Shrinkage and Dimensional Stability

Shrinkage is a persistent challenge in pure cotton denim. Even with sanforization or pre-shrinking, 100% cotton fabrics often exhibit residual shrinkage after repeated washing. This is due to fiber swelling and relaxation under heat and moisture.

Blended denim mitigates this behavior in several ways:

- Polyester fibers resist swelling and help anchor fabric dimensions

- Elastane contributes elastic recovery that counters fiber relaxation

- Regenerated fibers like modal or TENCEL™ can stabilize drape and reduce stiffness

As a result, cotton-blend denim typically shows lower and more predictable shrinkage. For brands selling through e-commerce—where customers cannot try garments before purchase—this stability is a critical advantage.

Common Cotton-Blend Configurations and Their Intent

Not all blends are created for the same purpose. Each fiber combination targets a specific performance goal.

| Blend Type | Typical Purpose in Denim |

|---|---|

| Cotton + Elastane | Stretch, comfort, shape retention |

| Cotton + Polyester | Strength, durability, dimensional stability |

| Cotton + Modal / TENCEL™ | Softness, fluid drape, reduced stiffness |

Cotton-elastane blends dominate fashion-forward and body-conscious silhouettes. Cotton-polyester blends are common in workwear, uniforms, and high-wear applications. Cotton-modal and cotton-TENCEL™ blends are often used where softness and comfort are prioritized over rugged aging.

Each blend solves a problem—and introduces its own compromises.

Comfort: Immediate Versus Earned

Comfort is where blended denim often wins early, while pure cotton catches up over time.

Blended denim typically:

- Feels softer from first wear

- Requires little to no break-in

- Adapts easily to body movement

Pure cotton denim, by contrast, often feels rigid initially. Over weeks or months of wear, the fabric softens, molds to the wearer, and develops a personalized fit. For some consumers, this journey is part of denim’s appeal. For others, it represents unnecessary discomfort.

From a commercial standpoint, immediate comfort reduces friction at the point of purchase—especially for first-time buyers.

Washing Behavior and Care Sensitivity

Blended denim generally responds more predictably to washing. It tends to:

- Shrink less overall

- Retain original size and shape

- Soften more quickly with fewer wash cycles

However, blends introduce new sensitivities. Elastane, in particular, is vulnerable to:

- Excessive heat

- Harsh mechanical agitation

- Strong chemical treatments

If washing processes are not well controlled, differential shrinkage between cotton and synthetic fibers can occur, leading to puckering or surface distortion. For this reason, blended denim requires more disciplined finishing and care guidelines than pure cotton denim.

Visual Aging: Character Versus Control

Perhaps the most debated difference between pure cotton denim and blends lies in how they age.

100% cotton denim is prized for:

- High-contrast fading

- Sharp whiskers and creases

- Visible wear patterns tied to individual movement

Cotton-blend denim, by comparison, often fades:

- More evenly

- With lower contrast

- With softer, less defined wear lines

This is not inherently negative. For clean, modern aesthetics or uniform color retention, controlled fading is desirable. For raw denim enthusiasts and heritage brands, however, it can feel like a loss of personality.

The choice depends entirely on design intent.

A Real-World Brand Scenario

A contemporary denim brand specializing in slim-fit jeans experienced high return rates due to discomfort and fit distortion. By switching from 100% cotton to a 98/2 cotton-elastane blend, the brand saw immediate improvements:

- Fewer size-related complaints

- Better wearer comfort

- More consistent fit after washing

Encouraged by these results, the brand later launched a heritage capsule collection aimed at denim purists. For this line, it returned to 100% cotton denim to preserve authentic fade behavior and tactile rigidity.

Same brand. Same production capabilities. Different fiber logic—aligned with different product goals.

Durability: Strength Versus Longevity Perception

Blends can improve certain aspects of durability, particularly tensile strength and resistance to tearing. Polyester fibers, for example, significantly increase yarn strength and abrasion resistance.

Yet durability is not perceived purely through laboratory metrics. Many consumers associate durability with how denim looks after wear, not just how long it lasts structurally. A pair of pure cotton jeans that fades beautifully may be perceived as “aging well,” even if it thins at stress points faster than a blended alternative.

This perception gap plays a major role in product positioning.

Manufacturing Control and Consistency

From a mill and factory perspective, blended denim offers greater control:

- More consistent batch-to-batch performance

- Reduced variability in shrinkage and fit

- Easier scaling for large production runs

Pure cotton denim introduces more variability, requiring tighter raw material control and more conservative production planning. This does not make it inferior—it simply demands greater expertise and tolerance for variation.

Blends are often criticized for “not being real denim.” In practice, this criticism reflects aesthetic preference, not technical failure. Cotton-blend denims are purpose-built materials designed to meet modern expectations of comfort, fit, and predictability.

Pure cotton denim excels when character, aging, and tactile authenticity matter most. Blended denim excels when control, comfort, and consistency are the priority.

The real distinction is not authenticity versus compromise, but intentional design versus nostalgia. In denim manufacturing, performance is contextual—and the best fiber choice is the one that aligns with the product’s purpose.

What Performance Fibers Are Commonly Added to Modern Denim Fabrics, and Why?

Modern denim no longer relies on cotton alone to meet real-world wear expectations. While cotton remains the structural and aesthetic foundation, today’s denim fabrics frequently incorporate performance fibers to address specific shortcomings that emerge during use, washing, and long-term wear. These fibers are not added arbitrarily. Each one targets a clear performance gap—stretch recovery, dimensional stability, softness, durability, or sustainability—that cotton cannot always deliver on its own.

The key point is intent. Performance fibers are introduced to solve defined problems, not to replace cotton’s role in defining what denim looks and feels like. Understanding what each fiber does—and what it compromises—is essential for both manufacturers and brands making informed material decisions.

The Role Each Performance Fiber Actually Plays

In practice, modern denim blends rarely exceed a few percentage points of performance fibers, yet those small additions can fundamentally change fabric behavior. The most commonly used fibers include elastane, polyester (virgin and recycled), modal, lyocell, and TENCEL™. Each operates differently at the fiber and fabric level.

Elastane (Spandex, Lycra®): Stretch and Recovery Control

Elastane is by far the most widely used performance fiber in denim. Even at very low percentages, it introduces true elasticity—something cotton fibers cannot provide.

| Elastane Content | Functional Impact in Denim |

|---|---|

| 0.5–1% | Light comfort improvement, subtle shape support |

| 1.5–2% | Balanced stretch and recovery for daily wear |

| 2.5–3% | High adaptability, body-hugging silhouettes |

In most denim constructions, elastane is inserted in the weft direction only. This allows horizontal stretch—critical for sitting, bending, and walking—while preserving vertical stability so garments do not lengthen excessively.

Why elastane is used:

- Improves fit tolerance across body types

- Reduces size-related complaints

- Enhances comfort during prolonged wear

From a commercial perspective, elastane significantly lowers return rates in slim-fit and fitted denim styles.

Risks if misused:

- Knee bagging if recovery is insufficient

- Loss of structure over time, especially with excessive heat exposure

- Reduced fabric lifespan if elastane quality or placement is poorly controlled

In manufacturing, elastane requires disciplined yarn engineering and finishing. Poorly balanced elastane denim may feel comfortable initially but deteriorate faster than intended.

Polyester: Strength, Stability, and Durability

Polyester is commonly blended with cotton to improve mechanical strength and dimensional stability. Unlike elastane, polyester does not stretch significantly, but it reinforces the fabric’s resistance to deformation.

| Polyester Share | Typical Purpose in Denim |

|---|---|

| 5–10% | Reduced shrinkage, improved size stability |

| 10–20% | Enhanced abrasion resistance and durability |

| 20%+ | Utility-focused or workwear denim |

Why polyester is used:

- Reduces post-wash shrinkage

- Improves tear and tensile strength

- Enhances color retention over repeated laundering

In applications such as workwear, uniforms, or high-wear garments, polyester helps denim withstand frequent washing and mechanical stress.

Trade-offs:

- Reduced breathability compared to pure cotton

- Flatter, less dynamic fading over time

- Slightly synthetic handfeel at higher percentages

Polyester-rich denim often performs well in laboratory tests but may feel less “alive” during wear. For this reason, it is typically kept below 20% in lifestyle-focused products.

Modal, Lyocell, and TENCEL™: Softness and Drape Enhancement

Regenerated cellulose fibers such as modal, lyocell, and TENCEL™ have gained popularity in comfort-driven denim programs. These fibers are chemically processed but derived from natural cellulose, placing them somewhere between cotton and synthetics in behavior.

| Fiber Type | Primary Benefit in Denim |

|---|---|

| Modal | Exceptionally smooth handfeel |

| Lyocell | Moisture management and cooling effect |

| TENCEL™ | Softness combined with sustainability positioning |

Why they’re used:

- Improve next-to-skin comfort

- Enhance drape, especially in lightweight denim

- Create a softer, more fluid fabric hand

These fibers are particularly effective in denim designed for warm climates, women’s wear, or casual silhouettes where stiffness is undesirable.

Trade-offs:

- Lower abrasion resistance than cotton or polyester

- Potential surface fuzzing if overused

- Greater sensitivity to aggressive washing or finishing

In practice, these fibers are often limited to moderate percentages to avoid compromising durability.

Recycled Fibers: Sustainability with Technical Constraints

Sustainability initiatives have driven increased use of recycled polyester and recycled cotton in denim. These fibers allow brands to reduce environmental impact and support circular economy narratives.

Advantages:

- Lower resource consumption compared to virgin fibers

- Alignment with sustainability certifications and marketing claims

- Reduced waste entering landfills

Challenges:

- Inconsistent fiber length, especially in recycled cotton

- Greater variability in yarn strength

- Increased need for blending and quality control

Recycled fibers often require more conservative fabric engineering to maintain acceptable performance levels. Mills frequently compensate by improving yarn construction or blending recycled fibers with higher-quality virgin materials.

How Performance Fibers Change Washing and Wear Behavior

One of the most practical effects of performance fibers appears after repeated washing. Compared to pure cotton denim, blended fabrics typically:

- Shrink less overall

- Retain size and shape more consistently

- Soften more quickly

However, blends also introduce new sensitivities. Elastane, for example, degrades under high heat, while regenerated fibers can weaken if exposed to harsh mechanical action. As a result, blended denim demands more precise finishing and clearer care instructions.

When these controls are absent, differential shrinkage between fibers can occur, leading to surface distortion or seam irregularities.

Visual Aging: Control Versus Character

Performance fibers influence not only how denim performs, but how it ages visually.

- Elastane tends to soften crease definition over time

- Polyester reduces high-contrast fading

- Regenerated fibers promote even, subdued wear patterns

For modern, clean aesthetics, this controlled aging is often desirable. For raw denim enthusiasts or heritage brands, it can feel like a loss of authenticity. Neither outcome is inherently superior—the difference lies in design intent.

Manufacturing Perspective: Intentional Fiber Use

At SzoneierFabrics, performance fibers are typically introduced only after a specific limitation in cotton denim has been identified. Stretch is added when fit complaints are expected. Polyester is added when dimensional stability is critical. Regenerated fibers are added when softness or drape is a priority.

What is deliberately avoided is the default inclusion of performance fibers without a clear objective. Every added fiber complicates spinning, dyeing, weaving, and finishing. Without purpose, complexity becomes risk rather than advantage.

Cost, Complexity, and Diminishing Returns

Each performance fiber increases material cost and process complexity. Beyond certain thresholds, additional fibers yield diminishing returns—or even degrade overall fabric balance. The most successful denim programs typically rely on minimal, targeted additions, rather than heavy blending.

Small percentages, precisely engineered, often outperform more aggressive blends in both wear satisfaction and long-term reliability.

Performance fibers are sometimes viewed as compromises, especially by denim purists. In reality, they represent intentional engineering choices. When used thoughtfully, they allow denim to meet modern expectations of comfort, fit, durability, and sustainability—without abandoning cotton’s defining role.

Modern denim is not about choosing between tradition and technology. It is about understanding where cotton excels, where it struggles, and how carefully selected fibers can support it. In that balance lies the future of denim manufacturing.

How Do Fiber Compositions Affect Denim Comfort, Durability, and Fit Retention?

Fiber composition is the hidden architecture behind how denim behaves once it leaves the sample room and enters real life. Two fabrics with the same weight, weave, and finish can perform very differently depending on what fibers are inside them. Comfort, durability, and fit retention are not accidental outcomes—they are the direct result of fiber choices made early in fabric development.

In practical terms, cotton defines how denim feels and ages, while blended fibers define how predictable and controllable that experience becomes over time. Comfort is often felt immediately, durability reveals itself slowly, and fit retention sits in the middle—noticed only when it fails.

Understanding how fiber composition influences each of these dimensions helps explain why modern denim looks the way it does, and why certain blends dominate specific product categories.

Mapping Fiber Composition to Real-World Performance

Denim performance cannot be reduced to a single metric. A fabric that feels exceptional on first wear may lose shape quickly. Another that lasts for years may feel stiff or unforgiving. Fiber composition determines where a fabric lands along these trade-off curves.

From a manufacturing and product-development perspective, three questions matter most:

- How does the denim feel in motion?

- How does it resist wear and fatigue?

- How well does it hold its intended shape over time?

Each is influenced by different fiber behaviors.

Comfort: How Denim Feels in Motion

Comfort is the most immediate and subjective performance factor. It is shaped by breathability, flexibility, surface smoothness, and how the fabric responds to movement.

| Fiber Composition | Typical Comfort Profile |

|---|---|

| 100% Cotton | Breathable, initially firm, improves with wear |

| Cotton + Elastane | Immediate comfort, flexible in motion |

| Cotton + Lyocell / TENCEL™ | Soft, fluid, cool to the touch |

| Cotton + Polyester | Firmer, structured, less adaptive |

Pure cotton denim often feels stiff at first, especially in heavier weights. Over time, as fibers relax and abrade, comfort improves significantly. Many wearers value this gradual break-in as part of denim’s appeal.

Blended denim, particularly cotton-elastane constructions, offers comfort immediately. Stretch allows the fabric to move with the body, reducing pressure points when sitting, bending, or walking. Regenerated fibers such as lyocell and TENCEL™ further enhance comfort by smoothing the surface and improving moisture handling.

Polyester, while beneficial for stability, tends to reduce perceived softness. In higher percentages, it can make denim feel rigid or less breathable, which is why it is often reserved for workwear or structured applications.

Durability: How Denim Survives Wear

Durability in denim is not just about how long a garment lasts before tearing. It includes abrasion resistance, seam integrity, fiber fatigue, and how the fabric responds to repeated stress.

| Fiber Composition | Typical Durability Outcome |

|---|---|

| 100% Cotton | Natural wear, visible fading, gradual thinning |

| Cotton + Polyester | High abrasion resistance, long service life |

| Cotton + Elastane | Moderate; dependent on construction and care |

Pure cotton denim wears in a visible, narrative way. It thins at stress points, fades through abrasion, and eventually softens dramatically. This wear pattern is often perceived positively, even when structural strength declines.

Polyester significantly increases resistance to abrasion and tearing. Cotton-polyester blends often maintain structural integrity far longer than pure cotton fabrics, particularly in high-friction areas such as inner thighs or seat panels. This makes them suitable for uniforms, workwear, and high-rotation garments.

Elastane introduces a more complex durability profile. While it improves comfort and fit retention, elastane fibers are sensitive to heat, chemicals, and mechanical stress. If not properly protected through yarn construction and finishing, elastane can degrade faster than cotton, reducing long-term durability.

This is why excessive elastane content does not automatically improve performance. Without disciplined engineering, it can shorten a garment’s usable life.

Fit Retention: The Hidden Differentiator

Fit retention is often the deciding factor between customer satisfaction and disappointment. It refers to a garment’s ability to maintain its intended shape after repeated wear and washing.

| Fiber Composition | Fit Retention Performance |

|---|---|

| 100% Cotton | Low; prone to stretching and relaxation |

| Cotton + Elastane | High; elastic recovery supports shape |

| Cotton + Polyester | Medium; stability without elasticity |

| Multi-fiber blends | Tunable; adjustable through ratios |

Pure cotton denim stretches mechanically under stress and rarely returns fully to its original shape. Over time, this leads to issues such as knee bagging, seat sagging, and waist gaping—especially in fitted silhouettes.

Elastane dramatically improves fit retention by introducing elastic recovery. Even small percentages help denim snap back after movement, preserving garment proportions throughout the day. This is why slim-fit, skinny, and body-contoured jeans almost always rely on cotton-elastane blends.

Polyester improves dimensional stability but does not provide true elasticity. It helps garments hold size through washing but does less to address deformation during active wear. Multi-fiber blends allow designers to fine-tune this balance, combining stability and recovery as needed.

Washing Behavior and Long-Term Shape

Repeated washing is where fiber weaknesses become most visible. Heat, moisture, and mechanical agitation expose differences between fibers.

| Fiber-Related Risk | Typical Outcome |

|---|---|

| Elastane degradation | Loss of stretch recovery |

| Polyester stiffness | Reduced softness over time |

| Cotton swelling | Shrinkage and relaxation |

Cotton fibers swell when wet and relax under heat, leading to shrinkage if not properly controlled. Polyester resists swelling but can stiffen if finishes break down. Elastane can lose elasticity when exposed to high temperatures or aggressive washing.

Balanced blends are designed to minimize these extremes. By limiting elastane content, stabilizing cotton with polyester, or softening structure with regenerated fibers, manufacturers aim to create denim that survives repeated laundering with minimal shape loss.

This balance is one of the most difficult aspects of denim engineering—and one of the most commercially important.

Comfort Over Time Versus Comfort at First Wear

One of the key distinctions between pure cotton denim and blends is when comfort is delivered.

- Pure cotton denim often feels better over time as it adapts to the wearer.

- Blended denim feels better immediately but may change less dramatically with age.

Neither approach is inherently superior. The choice depends on target customer expectations. Enthusiasts and heritage consumers often accept initial stiffness in exchange for long-term character. Mainstream consumers generally prioritize immediate comfort and consistency.

Fiber composition is how brands signal which experience they are offering.

A Real-World Case

A mid-rise women’s jean was initially produced using 100% cotton denim. Customer feedback highlighted a recurring issue: after several hours of wear, the waistband relaxed, leading to visible gaping at the back.

Rather than increasing fabric weight or altering pattern grading, the brand switched to a 98/2 cotton-elastane blend. The fabric’s appearance and weight remained unchanged, but fit retention improved significantly. Waist gaping complaints dropped, and overall satisfaction increased—without altering the garment’s visual identity.

This example illustrates how small fiber adjustments can solve real-world problems more effectively than structural changes alone.

Manufacturing Perspective: Control Versus Character

From a production standpoint, blended denim offers greater predictability. It allows mills and factories to manage shrinkage, fit, and performance across large volumes with fewer surprises. Pure cotton denim, while rich in character, introduces more variability and demands tighter quality control.

Neither approach is wrong. They serve different product philosophies.

Critical Takeaway

Fiber composition is not about choosing “better” fibers in isolation. It is about choosing the right mix for how a garment will actually be worn, washed, and lived in.

Cotton delivers comfort, breathability, and aging character. Performance fibers deliver control, stability, and repeatability. The most successful denim fabrics balance these forces deliberately—aligning fiber choices with real-world use rather than abstract ideals.

In modern denim manufacturing, performance begins at the fiber level. Everything else follows.

What Trade-Offs Should Buyers Consider When Choosing Cotton vs Blended Denim Fabrics?

Choosing between 100% cotton denim and blended denim is less about right versus wrong, and more about deciding which compromises you are willing to live with. Every denim fabric—no matter how well engineered—sits on a spectrum between authenticity and control, character and consistency, emotion and predictability.

Cotton delivers what many people instinctively recognize as “real denim”: a fabric that starts stiff, softens slowly, fades unevenly, and records the wearer’s habits over time. Blended denim, by contrast, is designed to behave. It stretches when expected, recovers when needed, and looks largely the same from the first wear to the fiftieth.

There is no perfect denim—only appropriate denim. The challenge for buyers is understanding which trade-offs matter for their product, their customer, and their market.

Understanding the Real Compromises

In sourcing discussions, cotton versus blended denim is often framed as a philosophical debate. In reality, it is a functional decision driven by how garments are worn, sold, returned, and reviewed. The trade-offs are predictable once priorities are made explicit.

The most common areas of tension include authenticity versus performance control, immediate comfort versus long-term durability, cost perception versus total cost, and sustainability narratives versus material reality.

Authenticity Versus Performance Control

Pure cotton denim offers the traditional denim experience. It begins with a crisp, rigid handfeel, gradually relaxes with wear, and develops distinctive fades that reflect the wearer’s movements and habits. This behavior is highly valued in heritage, raw, and premium denim categories.

At the same time, 100% cotton denim brings inherent limitations:

- Higher and less predictable shrinkage

- Low elastic recovery, leading to shape relaxation

- Greater size variation after extended wear

Blended denim moderates these variables by introducing fibers that stabilize behavior. Elastane improves recovery, polyester limits shrinkage, and regenerated fibers soften the handfeel. The result is a fabric that behaves consistently—but ages more quietly.

| Priority | Better Choice |

|---|---|

| Heritage appearance | 100% cotton |

| Consistent fit | Cotton blends |

| High-contrast fades | 100% cotton |

| Everyday wear comfort | Blended denim |

For buyers, the key question is whether character or control is more important to the product’s identity.

Comfort Today Versus Durability Tomorrow

Comfort is often the first thing customers notice—and the first reason they return a garment. Blended denim, especially cotton-elastane or cotton-lyocell constructions, tends to feel better immediately. Stretch and softness reduce pressure points, making garments more forgiving in daily wear.

Durability, however, unfolds over time. It includes abrasion resistance, seam stability, and fiber fatigue.

| Fiber Choice | Initial Comfort | Long-Term Risk |

|---|---|---|

| Cotton only | Moderate, improves over time | Shrinkage, deformation |

| Cotton + Elastane | High, immediate | Recovery loss if overused |

| Cotton + Polyester | Medium, firm | Reduced breathability |

Pure cotton denim may feel demanding at first, but it often maintains structural integrity longer in a natural way. Elastane improves comfort and fit retention, but it introduces sensitivity to heat and mechanical stress. Polyester enhances durability but can reduce breathability and tactile warmth.

Excessive stretch content can solve short-term comfort complaints while creating long-term shape issues if yarn construction and finishing are not carefully controlled. Buyers must decide whether immediate comfort or extended wear resilience is the primary value driver.

Fit Consistency Versus Organic Variation

Fit retention is one of the most practical reasons brands move toward blended denim. Pure cotton stretches mechanically and rarely returns fully to its original shape. Over time, this leads to knee bagging, seat sagging, and waist relaxation—issues that are especially visible in fitted silhouettes.

Blended denim improves fit consistency:

- Elastane provides elastic recovery during movement

- Polyester stabilizes dimensions during washing

- Multi-fiber blends allow fine-tuning of behavior

For e-commerce-driven brands, fit predictability is often more valuable than fade character. Fewer fit-related complaints translate directly into fewer returns and better reviews.

In contrast, organic variation is part of the appeal for heritage-focused customers. They accept—and often expect—fit changes as part of the denim’s lifecycle. For these consumers, predictability can feel sterile rather than reassuring.

Cost Per Yard Versus Total Cost of Ownership

On paper, 100% cotton denim often appears more affordable. Fewer fibers, simpler yarns, and traditional processes keep material costs lower. Blended denim, especially with elastane or specialty regenerated fibers, typically costs more per yard.

However, initial fabric cost tells only part of the story.

Blended denim can reduce downstream costs by lowering:

- Return rates due to fit issues

- Alteration requests

- Customer complaints related to comfort

Pure cotton denim may be cheaper to buy, but it can generate higher costs after garments reach consumers—particularly in mass-market or online retail environments.

For buyers managing large volumes, total cost of ownership often matters more than raw material price.

Sustainability Trade-Offs Are Not Binary

Sustainability is frequently cited as a reason to prefer one fiber over another, but the reality is nuanced. Each fiber choice carries its own environmental implications.

- Cotton is natural and biodegradable, but water- and resource-intensive

- Recycled polyester reduces waste, but remains synthetic

- Regenerated fibers are renewable, but require chemical processing

Blended denim can support sustainability goals through recycled or responsibly sourced fibers, yet it may complicate recyclability at end of life. Pure cotton denim is easier to recycle mechanically, but its environmental footprint depends heavily on farming and processing practices.

For buyers, sustainability decisions must balance measurable impact, certification requirements, and performance needs rather than relying on simple narratives.

Market Positioning and Customer Expectations

One of the most overlooked trade-offs is how fiber choice communicates product intent. Fabric composition signals to consumers what kind of experience they should expect.

- 100% cotton often signals authenticity, craftsmanship, and tradition

- Blended denim signals comfort, modernity, and ease of wear

Problems arise when the signal and the experience do not align. A heritage-branded jean that feels overly elastic may disappoint purists. A comfort-driven product that stretches out or shrinks may frustrate mainstream buyers.

Successful denim programs align fiber composition with brand promise.

Washing Behavior and Care Sensitivity

Buyers should also consider how customers actually care for denim. Pure cotton tolerates aggressive washing better in terms of fiber integrity, even though it may shrink. Elastane and regenerated fibers are more sensitive to heat and mechanical stress.

Blended denim often requires clearer care instructions and more controlled finishing to ensure longevity. When care expectations are unrealistic, performance suffers regardless of fiber choice.

A Sourcing Insight

A brand developing two parallel denim lines—a core collection and a heritage capsule—approached fiber selection deliberately. The main collection used blended denim to ensure consistent fit, comfort, and low return rates across high volumes. The heritage capsule returned to 100% cotton to preserve rigid structure and expressive fading.

The success of both lines came not from choosing a “better” fabric, but from matching fiber composition to product purpose. The trade-offs were intentional, not accidental.

Risk Management in Large-Scale Production

From a sourcing perspective, blended denim reduces variability. It allows mills and factories to manage shrinkage, fit, and performance with greater precision across production runs. Pure cotton denim requires tighter raw material control and greater tolerance for variation.

Neither approach is inherently safer, but the risk profiles differ. Buyers must decide whether they prefer to manage variability upstream in sourcing—or downstream through customer service and returns.

Choosing between cotton and blended denim is ultimately a decision about priorities, not ideology. Cotton offers authenticity, breathability, and a rich aging story. Blended denim offers control, comfort, and consistency. Each benefit gained introduces a corresponding trade-off.

The most effective denim buyers do not ask which fabric is better. They ask which fabric is appropriate for how the garment will actually be worn, washed, and evaluated. When fiber choice aligns with real use, the trade-offs stop being problems—and start becoming design decisions.

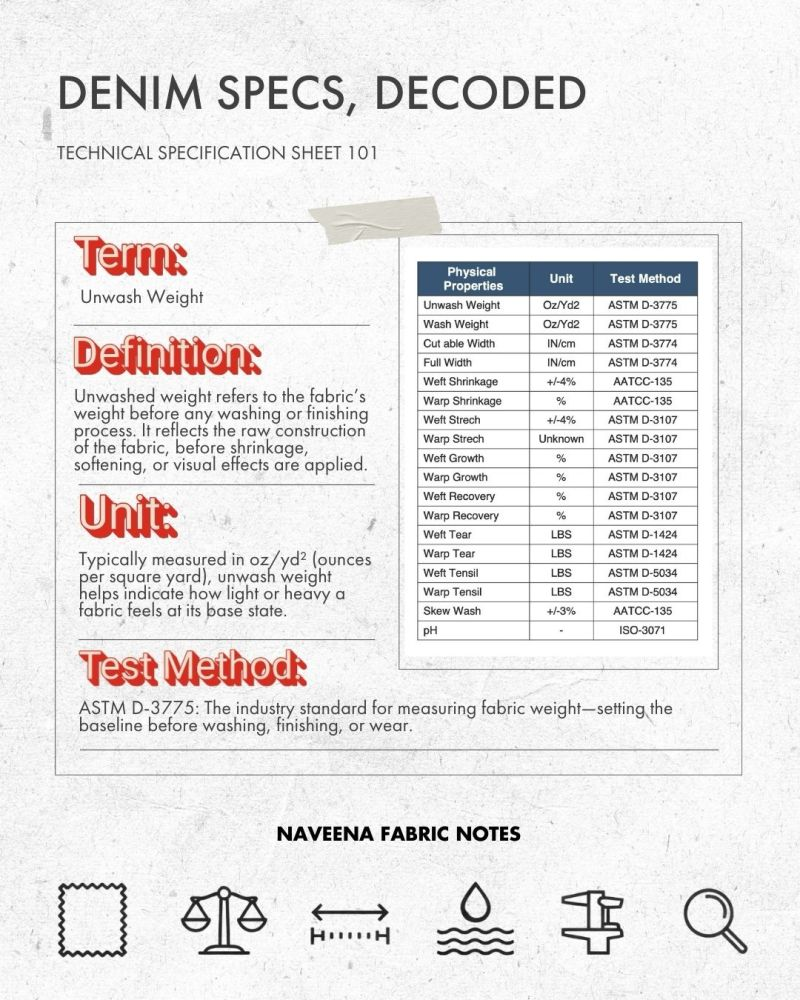

How Should Manufacturers and Buyers Specify Denim Fiber Composition for Consistent Production and End Use?

In denim manufacturing, inconsistency rarely starts on the factory floor. It usually starts on paper.

Many performance issues—unexpected shrinkage, poor fit retention, color variation, or comfort complaints—can be traced back to unclear or incomplete fiber specifications. When fiber composition is described loosely rather than defined precisely, mills are forced to interpret intent. Over time, those interpretations drift, and so does product performance.

For manufacturers and buyers aiming for repeatable quality, fiber composition must be treated as a measurable engineering input, not a marketing phrase. Consistency does not come from good intentions. It comes from clear numbers, defined tolerances, and performance criteria tied to how the denim will actually be worn and washed.

Consistency starts on paper.

Writing Fiber Specifications That Actually Work

Effective denim specifications do not rely on brand language or shorthand. They translate design intent into parameters that can survive multiple production cycles, raw material fluctuations, and factory changes.

A working fiber specification answers three questions:

- What exactly is in the fabric?

- How much variation is acceptable?

- What performance must this composition deliver in real use?

If any of these are missing, consistency becomes accidental rather than designed.

Move From Names to Numbers

Terms like “stretch denim,” “comfort denim,” or “stable denim” may be useful in marketing decks, but they are not actionable for mills. Different suppliers will interpret these labels differently, often leading to inconsistent outcomes across batches.

Clear specifications replace subjective language with objective composition and process requirements.

| Vague Term | Clear, Actionable Specification |

|---|---|

| Stretch denim | 98% cotton / 2% elastane |

| Stable denim | Maximum shrinkage ≤3% after wash |

| Soft denim | Enzyme wash + softener, defined recipe |

Numbers eliminate interpretation. When fiber percentages are stated explicitly, spinning, dyeing, and finishing decisions become aligned automatically.

For buyers managing multiple suppliers, this clarity is essential. Without it, the same “stretch denim” can behave very differently depending on elastane type, placement, or percentage.

Specify Tolerances, Not Absolutes

Natural fibers vary. Cotton crop quality changes by season, region, and harvest. Expecting absolute consistency is unrealistic—and often counterproductive. Well-written specifications acknowledge variability while keeping it under control.

| Parameter | Recommended Tolerance Range |

|---|---|

| Cotton content | ±1% |

| Elastane content | ±0.3% |

| Shrinkage | ±1% |

Tolerances protect both sides of the supply chain. They give mills flexibility to manage raw material realities while protecting buyers from performance drift. Specs without tolerances either fail in production or encourage silent substitutions when exact numbers cannot be met.

For blended denim, elastane tolerance is particularly critical. A difference of even 0.5% can noticeably alter stretch, recovery, and long-term shape retention.

Tie Fiber Composition to Performance Tests

Fiber percentages alone do not guarantee performance. Two fabrics with identical compositions can behave very differently depending on yarn construction, finishing, and fabric structure. This is why fiber specs must be paired with performance criteria.

At a minimum, composition should align with:

- Stretch and recovery testing

- Wash durability and shrinkage testing

- Abrasion resistance or fatigue testing

Without testing, specifications remain theoretical. With testing, they become predictive.

For example, a 98/2 cotton-elastane denim spec should not only state fiber content, but also define expected recovery after stretch, acceptable shrinkage after multiple washes, and resistance to deformation at stress points.

This approach shifts the conversation from “what fibers are used” to “what the fabric must do.”

Align Fiber Specs With End Use, Not Samples

One of the most common mistakes in denim development is approving fiber composition based solely on sample performance. Samples are worn briefly, washed minimally, and evaluated visually. Real garments are worn repeatedly, washed aggressively, and judged by consumers over time.

Effective specifications anticipate end use, not just first impression.

For example:

- A slim-fit jean sold online requires strong fit retention and predictable sizing.

- A heritage jean sold to enthusiasts prioritizes rigid structure and expressive fading.

- A workwear garment needs abrasion resistance and dimensional stability over comfort.

Fiber composition should be written to support these realities. When specs are aligned with real wear scenarios, downstream problems decrease significantly.

Lock Reference Samples as Physical Anchors

Written specifications are essential, but they are not sufficient on their own. Physical references translate numbers into reality.

Approved fabric swatches, lab-dip references, and washed garment samples serve as anchors for future production. They provide a tangible benchmark against which new batches can be evaluated.

At SzoneierFabrics, fiber composition specifications are typically paired with performance test data and approved reference samples. Future production is checked not only against written specs, but also against how the reference fabric behaves after washing and wear simulation.

This dual system—documentation plus physical reference—dramatically reduces subjective disagreements.

Preventing Specification Drift Over Time

Even well-written specs can erode if communication breaks down. Over multiple seasons, subtle changes may creep in: a slightly different elastane source, a minor cotton substitution, a revised finishing recipe. Individually, these changes may seem harmless. Collectively, they alter fabric behavior.

Preventing this drift requires clear communication across:

- Design teams defining intent

- Development teams translating intent into specs

- Production teams executing those specs

When any link in this chain works from assumptions rather than documentation, consistency suffers.

Centralized specification documents, version control, and regular review of test results help ensure that fiber composition remains stable across seasons and suppliers.

Balancing Precision With Manufacturability

Overly rigid specifications can be as problematic as vague ones. If specs demand unrealistic precision or ignore manufacturing realities, suppliers may struggle to comply—or quietly deviate.

Effective fiber specs strike a balance:

- Precise enough to protect performance

- Flexible enough to accommodate natural variation

This balance encourages transparency. Mills are more likely to flag potential issues early when specs allow for controlled adjustment rather than absolute pass/fail thresholds.

Cost and Risk Considerations

Specifying fiber composition accurately also helps buyers manage cost and risk. Clear specs reduce sampling cycles, minimize rework, and prevent costly post-production corrections.

They also simplify supplier comparisons. When multiple mills quote against the same detailed specification, pricing differences reflect real cost structures rather than hidden assumptions.

Over time, this clarity builds trust and shortens development timelines.

Documentation Is a Performance Tool

Fiber specifications are often treated as administrative paperwork. In reality, they are performance tools. They determine whether a denim program behaves consistently across production runs, markets, and seasons.

Well-written specs reduce reliance on individual expertise and institutional memory. They allow consistency to survive staff changes, supplier shifts, and scaling pressures.

A Practical Perspective

Manufacturers and buyers who struggle with inconsistent denim performance often discover that the fabric itself is not the problem. The problem is how the fabric was defined—or not defined—at the outset.

When fiber composition is written clearly, tested realistically, and communicated consistently, denim behaves predictably. When it is not, performance becomes a matter of luck.

Critical Takeaway

Specifying denim fiber composition is not about adding complexity. It is about removing ambiguity.

Move from names to numbers. Define tolerances instead of absolutes. Tie fiber content to performance tests and lock physical references. Most importantly, align specifications with how garments will actually be worn and washed.

In denim manufacturing, consistency is not achieved through tighter control at the end of the process. It is achieved through clear decisions at the beginning.

Denim fibers define behavior, not just composition

Asking “What is denim fabric made of?” in modern manufacturing means asking a deeper question: How should this denim behave once it leaves the cutting table and enters real life?

Cotton gives denim its soul—breathability, texture, and aging. Blends give it discipline—stretch, recovery, and control. Performance fibers extend its capabilities, but only when used intentionally.

The best denim programs don’t chase purity or novelty. They choose fibers that serve the garment, the wearer, and the lifecycle honestly.

SzoneierFabrics supports denim development with deep fiber knowledge, flexible sampling, and performance-driven specifications. Whether you’re building pure cotton heritage denim or engineering modern blended denim for comfort and consistency, the focus is on making fiber choices that work—not just on paper, but in wear.

If you’re developing denim products and need guidance on fiber composition, testing, or custom manufacturing, reach out to SzoneierFabrics to start a tailored quotation and sampling discussion.