In the ever-evolving world of sportswear, the battle between Lycra Spandex fabric and Polyester blends continues to shape how brands design performance gear. From high-stretch yoga leggings to ultra-durable cycling shorts, understanding the differences between these two fabric types can help buyers, designers, and sourcing agents make informed decisions tailored to user needs and market trends.

Lycra Spandex excels in elasticity, comfort, and flexibility, making it ideal for high-stretch activewear like yoga pants. Polyester blends offer better durability, moisture-wicking, and cost-efficiency, which suits team sports, uniforms, and mass-market activewear. Choosing the right fabric depends on your use-case priorities: stretch vs performance balance.

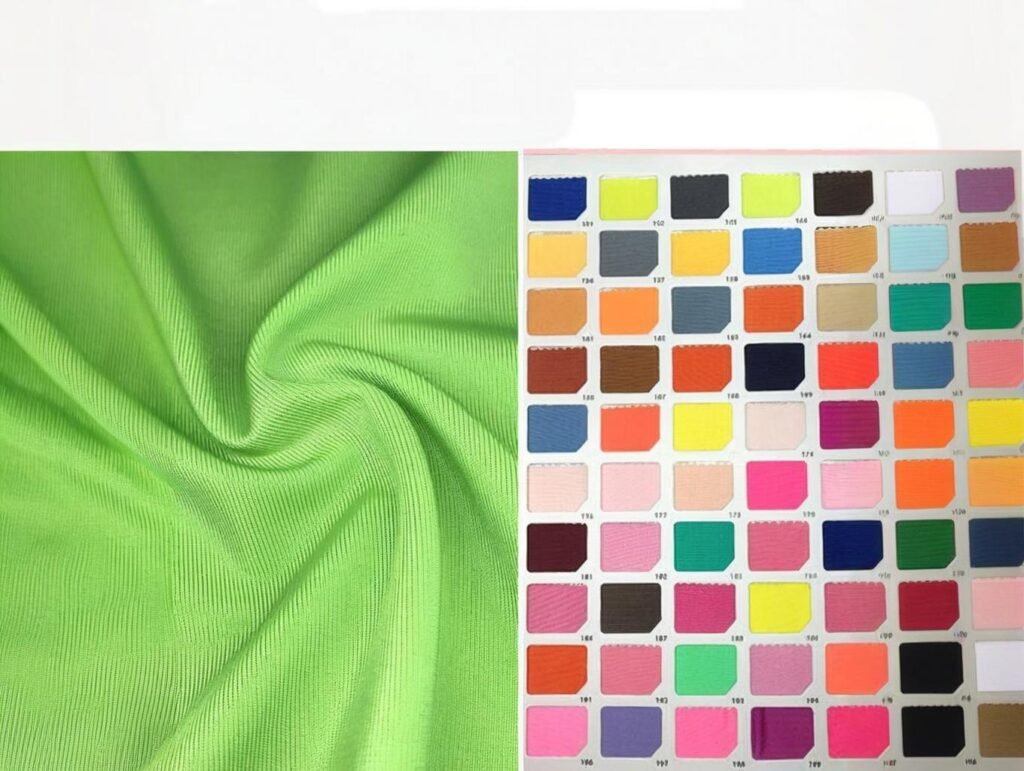

Now picture this: you’re a growing brand preparing for your next activewear launch. You’re evaluating fabric samples—one with a luxurious stretch, hugging every curve; the other crisp, structured, and moisture-repellent. Which do you go for? This guide will walk you through every technical and commercial aspect—backed by real data and brand strategies.

What Are Lycra Spandex and Polyester Blends Made Of?

Lycra Spandex is a synthetic fiber made primarily from polyurethane, known for its extraordinary stretch and recovery. Polyester blends, on the other hand, are typically a mixture of polyester with spandex, cotton, nylon, or rayon, balancing durability and flexibility at a lower cost.

Lycra Spandex is made from polyurethane and is known for 4-way stretch and flexibility. Polyester blends mix polyester with spandex or other fibers to improve durability, structure, and moisture management.

Fiber Composition Comparison

1. Lycra Spandex Composition & Performance

- 85–95% polyether-based polyurethane (PU)

- Often blended with nylon or cotton

- 4-way stretch (expands in all directions)

- High shrinkage control (returns to shape)

- Ultra-fine denier fiber (soft to touch)

2. Polyester Blends Composition

- 50–90% polyester base

- Blended with:

- Spandex (for stretch)

- Cotton (for softness)

- Nylon (for abrasion resistance)

- Rayon or modal (for breathability)

| Fabric Type | Fiber Content | Stretch | Softness | Typical Use |

|---|---|---|---|---|

| Lycra + Nylon | 80% Nylon / 20% Lycra | 4-way | High | Yoga, performance wear |

| Polyester + Spandex | 90% Polyester / 10% Spandex | 2-4-way | Medium | Teamwear, gym shorts |

| Polyester + Cotton | 60% Polyester / 40% Cotton | 1-2-way | Medium-High | T-shirts, uniforms |

| Polyester + Rayon | 50% Polyester / 50% Rayon | Low | High | Casual athleisure |

3. Key Differences in Feel and Function

- Lycra blends feel more body-conforming and breathable.

- Polyester blends feel structured and provide more resilience to daily wear and sweat.

4. Manufacturing Note

Lycra is a branded fiber owned by The LYCRA Company. While “spandex” is generic, fabrics labeled “Lycra” often carry a higher quality and price tag due to licensing and testing standards.

How Do Lycra Spandex and Polyester Blends Perform in Stretch and Recovery?

When it comes to stretch and recovery, Lycra Spandex fabrics outperform most polyester blends due to their higher elastic content and engineered 4-way elasticity. However, newer polyester-spandex hybrids have significantly closed the gap.

Lycra Spandex offers superior 4-way stretch and recovery, making it ideal for body-hugging activewear. Polyester blends provide moderate stretch, often with better shape retention over time in structured designs.

Stretchability in Action

1. Stretch Range Comparison (Lab-Tested)

| Fabric | Stretch (%) Horizontal | Stretch (%) Vertical | Recovery Rate (%) |

|---|---|---|---|

| 90% Nylon / 10% Lycra | 120–150% | 90–120% | 95–98% |

| 90% Polyester / 10% Spandex | 80–100% | 60–90% | 85–90% |

| 100% Polyester | 20–30% | 10–20% | 30–40% |

- Lycra fabrics can stretch up to 5x their original size and still snap back with minimal deformation.

- Polyester blends rely more on the knit construction than on fiber elasticity.

2. Use-Case Relevance

- Yoga leggings require Lycra-level elasticity for deep stretches and motion.

- Team jerseys prefer controlled stretch—Polyester blends prevent sagging over time.

3. Industry Example

- Lululemon primarily uses high-percentage Lycra blends in its Align™ series, ensuring a second-skin fit.

- Adidas and Nike often choose polyester-spandex blends for soccer kits and basketball uniforms, balancing stretch with durability.

4. Consumer Feedback

In reviews, Lycra-rich products are favored for activities that involve dynamic motion, compression, and flexibility, whereas polyester blends are appreciated for durability and consistent structure.

Which Fabric Offers Better Moisture-Wicking and Breathability for Athletes?

When it comes to performance in hot and sweaty environments, polyester blends often surpass Lycra Spandex in moisture-wicking and quick-drying properties. However, breathability is more nuanced—Lycra can be more breathable depending on the blend and knit structure.

Polyester blends offer superior moisture-wicking and faster drying, making them ideal for high-sweat activities. Lycra blends, while breathable, retain more moisture and may feel damp longer after intense workouts.

Moisture Management and Airflow

1. Moisture-Wicking Capability Table

| Fabric Type | Wicking Speed (g/m²·s) | Drying Time (minutes) | Air Permeability (mm/s) |

|---|---|---|---|

| Polyester + Spandex | 0.65–0.90 | 15–20 | 300–500 |

| Nylon + Lycra | 0.40–0.60 | 20–30 | 350–700 |

| Polyester + Cotton | 0.30–0.50 | 25–35 | 200–400 |

- Polyester’s hydrophobic nature allows moisture to pass through quickly.

- Lycra, being a denser and more elastic material, can trap sweat near the body in tight zones.

- Knit patterns (e.g., mesh vs jersey) significantly affect breathability.

2. Application-Specific Use

- Running shirts and soccer jerseys typically favor polyester for rapid evaporation.

- Compression wear for yoga or dance may use Lycra for its soft-touch and body heat retention.

3. Technology Integration

- Moisture-wicking polyesters often come treated with finishes like Coolmax®, Dri-FIT, or Climalite®.

- Lycra is less often treated for wicking but excels in airflow when used in open-weave constructions.

4. Athlete Insights

Elite runners often prefer polyester-blend tanks in races due to the fabric’s ability to stay dry and light. In contrast, gym-goers focused on body-sculpting workouts may opt for Lycra-heavy garments for a snug, performance-enhancing fit—even if it holds more moisture.

Are Lycra Spandex or Polyester Blends More Durable for Repetitive Use?

Durability is where polyester blends often dominate, especially in applications involving abrasion, frequent washing, and outdoor exposure. Lycra spandex, while stretchier, tends to degrade faster under UV light, heat, or harsh detergent cycles unless protected.

Polyester blends are more durable for repetitive wear and washing, offering better abrasion resistance. Lycra spandex excels in elasticity but is more prone to fiber fatigue over time.

Comparing Fabric Longevity and Resistance

1. Abrasion & Tensile Strength Comparison

| Test Type | Polyester + Spandex | Lycra + Nylon |

|---|---|---|

| Martindale Abrasion Cycles | 20,000–50,000 | 10,000–30,000 |

| Tensile Strength (MPa) | 0.40–0.60 | 0.25–0.35 |

| UV Degradation Resistance | High | Moderate–Low |

| Chlorine/Salt Resistance | Medium–High | Low–Medium |

- Martindale tests show that polyester blends maintain surface integrity significantly longer.

- Lycra, although soft and flexible, can start showing signs of fiber thinning after repeated wear and stretch.

2. Washing Durability

- Polyester blends withstand over 50+ washing cycles without major structural change.

- Lycra-based items often require cold-water cycles and air drying to maintain longevity.

3. Industrial and Commercial Use

- Sports teams, fitness chains, and school uniforms tend to prefer polyester for low maintenance and long-lasting wear.

- Premium leggings, shapewear, and dancewear—often containing Lycra—require gentler care routines.

4. Brand Example: Nike vs Alo Yoga

- Nike often uses polyester blends for durability and consistent fit in team sportswear lines.

- Alo Yoga relies heavily on high Lycra content for performance yoga gear—knowing its audience prioritizes fit over rough-use longevity.

What Are the Differences in Care, Washability, and Shrinkage Between the Two?

Caring for activewear materials is critical not only for the consumer but also for the brand reputation. Polyester blends are easier to wash and more shrink-resistant, while Lycra Spandex requires gentler handling to maintain elasticity and structure over time.

Polyester blends are machine-washable, quick-drying, and shrink-resistant, making them low-maintenance. Lycra Spandex needs cold washing and air-drying to avoid fiber damage and shrinkage.

Real-Life Maintenance Comparison

1. Care Instruction Table

| Fabric Type | Machine Wash | Shrinkage Risk | Ironing Required | Drying Method |

|---|---|---|---|---|

| Polyester + Spandex | Yes (Warm/Cold) | Very Low (<2%) | No | Tumble or Line Dry |

| Lycra + Nylon | Yes (Cold Only) | Medium (3–5%) | No | Line Dry Preferred |

| Polyester + Cotton | Yes | Medium (2–4%) | Light Ironing | Tumble Dry |

- Polyester blends withstand hotter water and longer cycles, making them ideal for mass laundering (e.g., gyms, teams).

- Lycra Spandex is prone to thermal damage—heat causes the elastic fibers to lose their stretch and snap.

2. Consumer Complaints & Returns

Many apparel brands report that returns due to warping or “stretch loss” are more common in Lycra-based products that weren’t properly washed. Labels with clear care instructions help reduce this issue.

3. Packaging and Storage

- Polyester garments can be compressed or vacuum-sealed without damage.

- Lycra garments are better stored folded, not tightly rolled, to avoid stress on elasticity.

4. Retail Shelf Life

In warehouses or showrooms, polyester holds structure better over time, resisting creases and UV damage. Lycra, while initially appealing in appearance, may degrade in direct light or heat environments.

Do Lycra Spandex or Polyester Blends Provide Better UV and Odor Resistance?

Polyester blends—especially those treated with technical finishes—outperform Lycra in both UV resistance and odor control. Lycra’s polyurethane base is more sensitive to sunlight and prone to odor absorption without added treatments.

Polyester blends offer stronger UV resistance and better odor control, especially when treated with antimicrobial finishes. Lycra Spandex is more vulnerable to UV degradation and sweat retention.

Outdoor Use & Smell Management

1. UV Protection Performance

| Fabric Type | UPF Rating (Untreated) | Degradation After 20hrs UV |

|---|---|---|

| Polyester + Spandex | UPF 30–50 | <5% structural change |

| Lycra + Nylon | UPF 20–30 | 10–15% loss in elasticity |

- Polyester naturally blocks UV better than Lycra, thanks to its tight molecular structure.

- Lycra requires added UV inhibitors or dyeing processes to improve outdoor performance.

2. Odor Resistance (Sweat Absorption Tests)

| Test | Polyester Blend | Lycra Blend |

|---|---|---|

| Sweat Retention (After 60min Workout) | Low to Medium | Medium to High |

| Odor After 4 Hours | Mild | Noticeable |

| Bacteria Growth Rate | Low (with finish) | High (untreated) |

3. Finishing Technologies

- Polyester garments may be treated with silver ions, polygiene, or anti-odor finishes during production.

- Lycra products often skip antimicrobial coatings due to the focus on elasticity, which makes them more odor-prone over time.

4. Outdoor Performance Case Study

Brands like Patagonia and Columbia Sportswear use polyester blends with UV coatings for hiking and running gear. These products maintain color and structure over months of outdoor use—something Lycra garments struggle with unless heavily engineered.

5. Branding & Marketing Implications

If your activewear line is targeting outdoor enthusiasts or performance athletes, highlighting UV and odor control features can offer real differentiation—especially in tropical or high-altitude markets.

Is Lycra Spandex or Polyester Blend More Cost-Effective for Bulk Production?

From a manufacturer’s perspective, polyester blends offer better cost-efficiency for bulk production due to lower material costs, easier handling, and faster production cycles. Lycra Spandex, while premium in performance, generally leads to higher per-unit costs and longer lead times.

Polyester blends are more cost-effective for bulk orders due to lower raw material costs and simpler production. Lycra Spandex is more expensive due to fiber quality, licensing, and handling complexity.

Price Breakdown and MOQ Considerations

1. Estimated Cost Table (Based on 2025 Market Averages)

| Fabric Type | Cost per Meter (USD) | MOQ (Meters) | Lead Time (Days) | Wastage Risk |

|---|---|---|---|---|

| Polyester + Spandex | \$2.00 – \$3.50 | 500 – 1,000 | 10–15 | Low |

| Lycra + Nylon | \$3.80 – \$6.00 | 300 – 800 | 15–20 | Medium |

| High-Lycra Content (30%+) | \$6.50 – \$10.00 | 200 – 500 | 20–25 | High |

2. Production Efficiency

- Polyester blends are easier to cut, sew, and print on industrial machines.

- Lycra Spandex requires specialized needles and slower cutting speeds to maintain fiber integrity—raising labor costs.

3. Return on Investment

- Polyester is favored for fast fashion and large-scale sportswear retailers due to low COGS and high turnover.

- Lycra fits niche, premium activewear brands that focus on high-margin, specialized apparel (e.g., shapewear, performance leggings).

4. MOQ Flexibility

At Szoneier, custom orders can start as low as:

- 50 meters for polyester blends

- 100 meters for Lycra-rich fabric blends

This allows both startup and mid-size brands to test small runs without overstocking.

Which Fabric Is Preferred by Top Sportswear Brands in 2025?

In 2025, the leading global brands are strategically blending both Lycra and polyester, based on use-case and product line. Lycra dominates in high-performance bodywear, while polyester blends remain the king in teamwear, mass-market fitness clothing, and environmentally optimized supply chains.

Top brands like Nike, Lululemon, and Adidas use both fabrics strategically—Lycra for premium flexibility and fit, and polyester blends for durability, cost-efficiency, and mass production.

Real-World Brand Fabric Strategies

1. Brand-by-Brand Breakdown

| Brand | Primary Fabric Choice | Use Case |

|---|---|---|

| Lululemon | High Lycra content (20–30%) | Premium yoga pants, Align series |

| Nike | Polyester-Spandex blends (90/10) | Soccer kits, basketball apparel |

| Adidas | Recycled polyester blends | Mass-market gym wear & eco lines |

| Under Armour | Polyester + elastane | Compression and sweat-wicking tops |

| Gymshark | Mixed Lycra & polyester | Sculpting leggings, training gear |

2. Sustainability Trends

- Recycled polyester (rPET) blends are seeing huge adoption, reducing environmental impact while keeping performance.

- Lycra has launched EcoMade®, a recycled Lycra fiber—but adoption is slower due to cost.

3. Trend Analysis for B2B Buyers

- Buyers in North America and Europe increasingly request dual-function fabrics: stretch + sustainability.

- In Southeast Asia, price-per-piece is still a dominant factor—driving polyester-heavy orders.

4. What Should B2B Buyers Consider When Choosing?

- Performance priority? Go with Lycra Spandex (especially for yoga, dancewear, sculpting apparel).

- Cost + scale focus? Choose Polyester blends (ideal for uniforms, team kits, budget-conscious ranges).

- Hybrid approach? Work with suppliers like Szoneier to develop custom polyester-Lycra blends, optimizing both price and performance.

Ready to Customize Your Fabric Orders?

Whether you’re launching a premium athleisure collection or need a cost-efficient fitnesswear line, SzoneierFabrics can help you develop the perfect material solution. With over 18 years of experience, we offer:

- Custom polyester, Lycra, and hybrid fabric blends

- Free sampling and quick prototyping

- Low MOQs (starting from 50 meters)

- Guaranteed quality and fast lead times

Contact SzoneierFabrics today to request a sample pack or get a free custom quote tailored to your business goals.