From cozy knitwear to durable outdoor upholstery, acrylic fabric has earned a place in nearly every textile category. But while it often mimics wool or blends with cotton, few buyers truly understand its synthetic roots and performance profile. And for international sourcing teams, that knowledge gap can lead to misaligned expectations in softness, durability, and sustainability.

Acrylic textile is a synthetic fabric made from acrylonitrile-based polymer fibers. It is lightweight, soft, colorfast, and highly resistant to sunlight and weathering, making it a common alternative to wool and a go-to for outdoor and high-performance textiles.

Unlike cotton or wool, acrylic doesn’t come from nature—it’s engineered for consistency, volume, and color retention. But with its strengths also come trade-offs: environmental concerns, pilling, and heat sensitivity.

Let’s unpack what acrylic really is, how it compares to natural fibers, and how fabric buyers—from fashion labels to furniture brands—can choose the right variant for their end product.

What Is Acrylic Textile Made From and How Is It Manufactured?

Acrylic textile is produced by synthesizing acrylonitrile, a petroleum-derived chemical, into long-chain polymer fibers through a process called wet or dry spinning. These fibers are then crimped, cut, and spun into yarns, which are woven or knitted into fabric.

How Acrylic Is Engineered from Chemistry to Cloth

1. Core Raw Material: Acrylonitrile

| Source Material | Chemical Name | Derivative Product |

|---|---|---|

| Petrochemical | Acrylonitrile (C3H3N) | Polyacrylonitrile (PAN) |

- Acrylonitrile is a volatile compound derived from propylene, which comes from crude oil refining.

- It’s polymerized to form polyacrylonitrile, which forms the basis of acrylic fibers.

2. Spinning Process: From Liquid to Fiber

Acrylic fibers are typically spun using:

- Wet spinning: Polymer is dissolved in a solvent and extruded into a coagulation bath (most common method)

- Dry spinning: Solvent evaporates in heated chambers after extrusion (used for more delicate fiber types)

Once fibers are created, they’re:

- Washed and neutralized

- Crimped to add bulk (mimicking wool)

- Cut into staple lengths for spinning

- Blended or twisted into yarns

3. Fabrication: Yarn to Finished Textile

Acrylic can be:

- Knitted (sweaters, scarves, leggings)

- Woven (blankets, upholstery)

- Needle-punched (non-woven felt)

- Brushed to create fleece-like surfaces

4. Variants and Blends

| Type of Acrylic Fiber | Features | Example Applications |

|---|---|---|

| Standard Acrylic | Soft, wool-like, easy to dye | Knitwear, blankets, scarves |

| Modified Acrylic (modacrylic) | Flame-resistant, more stable | Wigs, faux fur, protective apparel |

| Blended Acrylic | Mixed with wool, polyester, cotton | Sweaters, technical workwear |

5. Production Geography

Main acrylic fiber producers include:

| Country | Notable Producers |

|---|---|

| China | Jilin Chemical Fiber, Sinopec |

| India | Indian Acrylics Limited |

| Turkey | Aksa Akrilik |

| Mexico | CYDSA |

At SzoneierFabrics, we source acrylic yarns from both domestic China suppliers and imported modacrylic lines from Japan for specialty knits and flame-retardant applications.

How Does Acrylic Fabric Compare to Wool, Cotton, and Polyester?

Acrylic fabric is often compared to wool for softness and warmth, to cotton for comfort, and to polyester for durability and moisture resistance. While it excels in affordability and colorfastness, it lacks breathability and is prone to pilling.

Comparing Acrylic with Popular Alternatives

1. Visual and Textural Similarity to Wool

| Property | Wool | Acrylic |

|---|---|---|

| Texture | Natural crimp | Artificial crimp (engineered) |

| Warmth | High | Medium–High |

| Moisture Wicking | Good | Poor |

| Elastic Recovery | Good | Moderate |

| Price | High | Low |

- Acrylic mimics wool’s loft and softness at a fraction of the cost

- Ideal for vegan or allergy-conscious consumers who can’t wear animal fibers

2. Compared to Cotton

| Feature | Cotton | Acrylic |

|---|---|---|

| Origin | Natural plant | Synthetic fiber |

| Breathability | High | Low |

| Drying Time | Slow | Fast |

| UV Resistance | Poor | Excellent |

- Acrylic dries faster and is more colorfast than cotton

- But lacks cotton’s skin breathability and biodegradability

3. Compared to Polyester

| Property | Polyester | Acrylic |

|---|---|---|

| Strength | High | Moderate |

| Heat Tolerance | High | Low |

| Softness | Low–Moderate | High |

| UV Stability | Moderate | Excellent |

Sourcing Application Insight: For outdoor upholstery, buyers often choose acrylic over polyester because it retains color after long-term UV exposure and doesn’t become brittle in the sun—ideal for patio cushions, marine fabrics, or awnings.

4. Overall Summary Comparison Table

| Feature | Acrylic | Wool | Cotton | Polyester |

|---|---|---|---|---|

| Cost | Low | High | Medium | Low |

| Warmth | Medium | High | Low | Medium |

| Softness | High | High | Medium | Low |

| UV Resistance | Excellent | Poor | Poor | Good |

| Breathability | Low | High | High | Low |

| Sustainability | Low | High | High | Low |

What Are the Main Properties of Acrylic Textile in Apparel and Home Use?

Acrylic textile is lightweight, soft, colorfast, and insulating. It resists fading, wrinkling, and UV damage, making it suitable for apparel, blankets, and outdoor fabrics. However, it is prone to pilling and can melt under high heat.

Functional Strengths and Weaknesses of Acrylic

1. Strengths That Make Acrylic Popular

| Property | Benefit in Use |

|---|---|

| Lightweight | Comfortable for layering, travel-friendly |

| Soft Texture | Ideal for wool substitutes in knits |

| UV Resistance | Excellent for outdoor or marine fabrics |

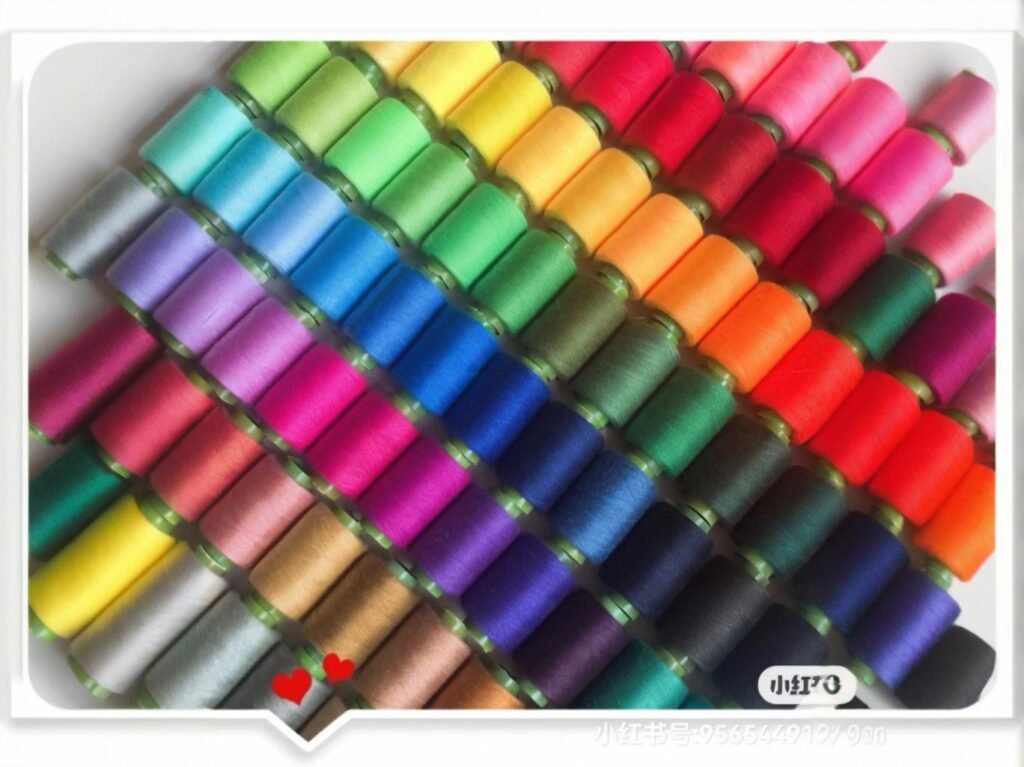

| Colorfastness | Holds dye extremely well—no fading |

| Moisture-Resistant | Quick drying and hydrophobic |

| Moth/bug Resistant | Synthetic structure repels natural pests |

2. Common Applications

- Apparel: Sweaters, hats, scarves, gloves, leggings

- Home Textiles: Upholstery, blankets, throws

- Outdoor Use: Awning fabric, boat covers, cushion covers

- Medical/Fashion Accessories: Wigs, faux fur, insulation layers

3. Weaknesses to Consider

| Limitation | Real-World Impact |

|---|---|

| Pilling | Surface fuzz in high-friction areas (e.g., cuffs, elbows) |

| Static Retention | Prone to cling and spark without treatment |

| Heat Sensitivity | Can melt or distort when ironed |

| Low Breathability | Traps body heat in humid climates |

4. Treatment and Finishing Options

| Additive/Treatment | Effect |

|---|---|

| Anti-pilling finish | Reduces fiber breakage during wear/wash |

| Softening agents | Enhances hand feel and drape |

| Blending with wool/cotton | Balances breathability and natural feel |

| UV absorbers | Increases outdoor lifespan further |

Factory Perspective – SzoneierFabrics: When producing acrylic-based fleece blankets for a Canadian brand, we applied both anti-pilling and anti-static finishes, achieving a 4.5-star average customer review score and 16% fewer returns compared to their previous cotton-poly blend line.

Is Acrylic Fabric Breathable, Warm, or Water-Resistant?

Acrylic fabric is warm and water-resistant but not breathable. It retains heat well in cold conditions, repels moisture to a degree, but does not allow airflow, which may lead to discomfort in humid environments.

How Acrylic Performs in Climate-Control Applications

1. Warmth Performance Thanks to its wool-like loft and hollow fiber structure, acrylic traps air efficiently.

- Thermal insulation is comparable to wool at equal thickness

- Ideal for cold-weather products like scarves, gloves, and beanies

| Insulation Rating (1–5) | Material |

|---|---|

| 5 | Wool |

| 4.5 | Acrylic |

| 3 | Cotton Fleece |

| 2 | Polyester Mesh |

2. Breathability Limitations

- Acrylic fibers are hydrophobic (don’t absorb moisture)

- Lack of moisture wicking = clamminess in hot or high-exertion conditions

- Poor airflow makes it less suitable for summerwear or activewear

3. Water Resistance Properties

| Feature | Performance |

|---|---|

| Liquid Repellency | Moderate–High |

| Vapor Permeability | Low |

| Dry Time | Fast |

4. Key Use Cases Based on Thermal and Moisture Profile

| Product Type | Acrylic Suitability |

|---|---|

| Winter Scarves | ✅ Excellent—insulating and soft |

| Summer Dresses | ❌ Not ideal—poor airflow |

| Outdoor Blankets | ✅ Great—weather-resistant and colorfast |

| Sportswear Tops | ❌ Avoid—traps sweat, low stretch comfort |

Blending acrylic with cotton or viscose can improve breathability, while mixing with polyester enhances strength. At SzoneierFabrics, we often create custom-blended fleece knits (50% acrylic / 50% cotton) for B2B clients needing year-round weight-adjustable products.

What Types of Products Commonly Use Acrylic Textile?

Acrylic textile is commonly used in sweaters, blankets, upholstery, faux fur, outdoor fabrics, wigs, and socks due to its soft texture, vibrant dyeability, and resistance to UV and weathering. It is often chosen as a lightweight alternative to wool and as a color-stable option for outdoor environments.

Category-by-Category Breakdown of Acrylic Usage

1. Apparel

| Product | Why Acrylic Works |

|---|---|

| Sweaters & Cardigans | Warmth, bulk, color options, wool substitute |

| Gloves & Scarves | Soft feel, light insulation, stretch recovery |

| Beanies & Leggings | Elasticity, easy knitting, retains shape |

| Socks | Low cost, colorfastness, lightweight comfort |

Blended acrylic (with spandex, cotton, or wool) is often used to improve elasticity or moisture balance.

2. Home Textiles

| Product | Advantage |

|---|---|

| Blankets & Throws | Lofty warmth, machine washable, fast drying |

| Cushion Covers | Fade resistance under window or sun exposure |

| Curtains | Drape well, hold vibrant prints |

In decorative applications, acrylic is praised for its bright colors and clean weaves.

3. Outdoor & Industrial Textiles

| Use Case | Performance Needs | Why Acrylic Works |

|---|---|---|

| Awning fabric | UV exposure, rain | High UV stability, fast dry |

| Marine upholstery | Salt, mildew, sunlight | Low absorption, anti-fade |

| Camping blankets | Lightweight + insulating | Great thermal retention |

| Workwear liners | Thermal base under abrasion fabric | Affordable and insulating |

4. Faux Fur & Fashion Accessories

- Acrylic fibers are modacrylic (modified for flame resistance and softness)

- Common in wigs, hairpieces, plush toys, and high-pile faux fur coats

5. Niche Technical Products

| Niche Application | Details |

|---|---|

| Filter media | Acrylic felt used in air/water filtration |

| Insulating filler | Used as an alternative to polyester batting |

| Sound-absorbing panels | Non-woven acrylic used in acoustic materials |

Case Study – SzoneierFabrics Client: A European sports brand approached us to develop UV-stable, water-resistant picnic rugs. We blended 70% acrylic / 30% polyester, achieving fade resistance over 300 hours in a QUV test and strong water repellency with post-treatment coating. The collection now retails across 20+ countries.

How Do You Care for and Maintain Acrylic Fabrics Over Time?

Acrylic fabrics are generally easy to maintain—machine-washable, quick-drying, and wrinkle-resistant. However, they require low heat settings, careful storage, and anti-pilling care to maintain their appearance and structure over time.

Acrylic Fabric Care – What B2B Buyers Should Know

1. Washing Guidelines

| Care Factor | Acrylic Response |

|---|---|

| Machine Washable | ✅ Yes – gentle or normal cycles |

| Shrinkage Risk | ❌ Low – but avoid high heat |

| Fabric Softeners | ⚠️ Caution – may increase static buildup |

- Recommended wash temperature: 30–40°C

- Avoid harsh agitation on loosely knitted acrylics

2. Drying & Ironing

| Drying Type | Recommendation |

|---|---|

| Tumble Dry | ❌ Avoid – heat may distort fibers |

| Line Dry | ✅ Best method – preserves shape |

| Ironing | ⚠️ Use low heat or steam only |

Acrylic has a low melting point (\~190°C). Ironing without protection can cause permanent damage.

3. Pilling Control

- Acrylic is prone to pilling, especially in high-friction areas

- Anti-pilling treatments or tight knitting reduce risk

- Regular de-pilling or brushing extends garment life

4. Storage Tips

- Fold, don’t hang knitwear (to prevent stretching)

- Avoid direct sunlight during long-term storage

- Store with anti-static sheets if prone to clinging

5. Blended Care Considerations

When acrylic is blended with:

- Wool – Follow lowest-temperature washing instruction

- Cotton – More breathable but may shrink slightly

- Spandex/Elastane – Avoid hot water, tumble drying

Retail Insight from SzoneierFabrics: We provide custom wash care labeling services for acrylic garment orders, ensuring brand clients offer accurate guidance and reduce post-sale customer complaints—particularly for pilling, ironing, and shrinkage misunderstandings.

Are There Environmental Concerns or Sustainability Issues with Acrylic?

Yes—acrylic textiles raise sustainability concerns due to their fossil fuel origins, low biodegradability, microplastic shedding, and energy-intensive production process. However, some manufacturers are adopting recycling technologies and improved production practices to reduce impact.

Evaluating Acrylic’s Environmental Impact

1. Synthetic Origin from Petroleum

- Acrylic is derived from acrylonitrile, a compound made from crude oil

- This places it alongside polyester and nylon as a non-renewable synthetic

2. Biodegradability and Waste Impact

| Material | Biodegradable? | Typical Breakdown Time |

|---|---|---|

| Cotton | ✅ Yes | \~5 months |

| Wool | ✅ Yes | \~1 year |

| Acrylic | ❌ No | 100+ years |

- Once discarded, acrylic persists in landfills or oceans for decades

- Incineration releases harmful gases like hydrogen cyanide if not controlled

3. Microplastic Pollution

- Washing acrylic fabrics releases microfibers into wastewater

- A study by the University of Plymouth (UK) found that acrylic sheds 730,000+ fibers per wash, more than polyester or poly-cotton blends

4. Energy and Chemical Intensity

| Environmental Factor | Acrylic Production Impact |

|---|---|

| Water Usage | Low (compared to cotton) |

| Energy Consumption | High – chemical processing + heat |

| CO₂ Emissions | Moderate to high |

| Chemical Residue Risk | Depends on production standards |

5. What’s Being Done?

| Solution Type | Description |

|---|---|

| Post-consumer Recycling | Acrylic re-spun into low-grade fibers |

| Biodegradable Acrylic | In early R\&D stage |

| OEKO-TEX / REACH Cert | Ensures lower toxic residue in output |

| Circular Programs | Take-back or upcycling in upholstery sector |

6. Buyer Tip: Choose Certified or Blended Options

- Blending acrylic with natural fibers (e.g., cotton, bamboo) can reduce its environmental footprint

- Look for suppliers offering OEKO-TEX®, GRS (Global Recycled Standard), or low-emission dyeing processes

How Can B2B Buyers Choose Reliable Acrylic Textile Suppliers in the Global Market?

To choose reliable acrylic textile suppliers, B2B buyers should evaluate fiber specifications, production certifications, MOQ flexibility, colorfastness guarantees, and post-sale service. Sampling, compliance checks, and supply chain transparency are key to sourcing successfully.

Strategic Sourcing Checklist for Acrylic Textile

1. Confirm Fiber Origin and Composition

- Specify if you need 100% acrylic, modacrylic, or blended yarns

- Request material data sheets and composition breakdowns

2. Evaluate Performance Metrics

| Property to Request | Ideal Specification |

|---|---|

| GSM (grams/sqm) | 180–350 GSM for most garments |

| Pilling Grade (ISO 12945) | 3–5 for good durability |

| UV Resistance (QUV) | >300 hours for outdoor use |

| Colorfastness (ISO 105) | ≥4 rating (on 1–5 scale) |

3. Ask for Certifications

- OEKO-TEX® Standard 100 for safety

- GRS (for recycled blends)

- ISO 9001 / 14001 for factory operations

- REACH compliance for EU market

4. Sample and Test Locally

- Always request swatches or finished samples

- Perform field tests for stretch, wash durability, and shrinkage

5. Evaluate Production Capacity and MOQ

| Buyer Type | MOQ Expectation | What to Look For |

|---|---|---|

| Startup / boutique brand | 50–300 meters | Flexible dye lot batching |

| Mid-size private label | 500–2000 meters | Custom color matching |

| Large retail chain | 5000+ meters | Volume discounts, QA audits |

6. Consider Post-Sale Support

- Inquire about color fastness warranties, replacement policies, and after-shipment defect reporting protocols

Partner with SzoneierFabrics for High-Quality Custom Acrylic Textiles

At SzoneierFabrics, we help B2B buyers worldwide source the right acrylic fabrics—blended or pure—for fashion, home, outdoor, or industrial applications. With years of experience in yarn selection, dye control, finishing, and pattern customization, we ensure your products meet performance, quality, and aesthetic standards.

Why Choose Us:

- ✅ 100% quality assurance & lab-tested specs

- ✅ Free swatches & design consultation

- ✅ OEKO-TEX®, GRS, and REACH-compliant supply chain

- ✅ MOQ from 50 meters, bulk rates for 1000m+

- ✅ Quick sampling: 5–7 days; bulk production: 15–25 days

- ✅ Global logistics & multilingual support

Contact us today to develop your custom acrylic textile collection:

Let’s build fabric solutions that blend performance, color, and confidence—together.