Linen is no longer just a seasonal favorite—it’s a fabric of rising strategic value for manufacturers worldwide. From its breathable elegance to its eco-friendly credentials, linen’s demand has surged across fashion, home, and wellness sectors. But when it comes to bulk purchasing, buyers quickly discover that navigating linen’s price tiers, order quantities, and origin-based variances is far more complex than expected.

In short, bulk linen cloth material refers to high-volume linen fabric orders, typically above 100 meters, with pricing and minimum order quantities (MOQs) determined by fiber type, GSM, blend ratio, country of origin, and any special finishes or certifications.

Understanding how to benchmark MOQ and price per yard (or meter) is essential for cost control, especially as the linen market grows more segmented by quality level, sustainability requirements, and finish options. The good news? With a bit of strategic planning—and the right supplier—you can dramatically improve your margins without compromising on quality.

Let’s start by understanding what counts as “bulk” linen in today’s global textile trade.

What Is Considered Bulk Linen Material in the Textile Industry?

“Bulk” in linen sourcing doesn’t have a universal definition. It varies depending on the manufacturer, region, and even the fabric type. For commodity-grade linen, “bulk” may begin at 100–300 meters, while for custom blends or specialty-finished linen, the threshold could rise to 500–1000 meters. Volume pricing generally kicks in once you exceed the supplier’s production efficiency threshold.

Bulk linen material is generally defined as an order of 100 meters or more of raw or finished linen fabric, supplied in continuous rolls or bolts, with quantity-based pricing advantages and production efficiencies built into the transaction.

Defining Bulk in Context

1. By Quantity

- Small-Batch Linen Orders: 30–99 meters — Often used for sampling, prototyping, or boutique runs. Usually priced at retail or near-wholesale levels.

- Mid-Level Bulk: 100–300 meters — Where most volume pricing starts for general-purpose linen.

- High-Level Bulk: 500–5000+ meters — Reserved for industrial orders, private label programs, or multi-product campaigns.

2. By Fabric Format

- Greige Linen Rolls: Raw, unbleached, and unfinished—cheaper but requires downstream processing.

- Prepared for Dyeing (PFD): Scoured and bleached, ready for customization.

- Pre-Dyed & Finished Rolls: Ready-to-use linen, often priced 15–20% higher due to added value.

3. By Buyer Intent

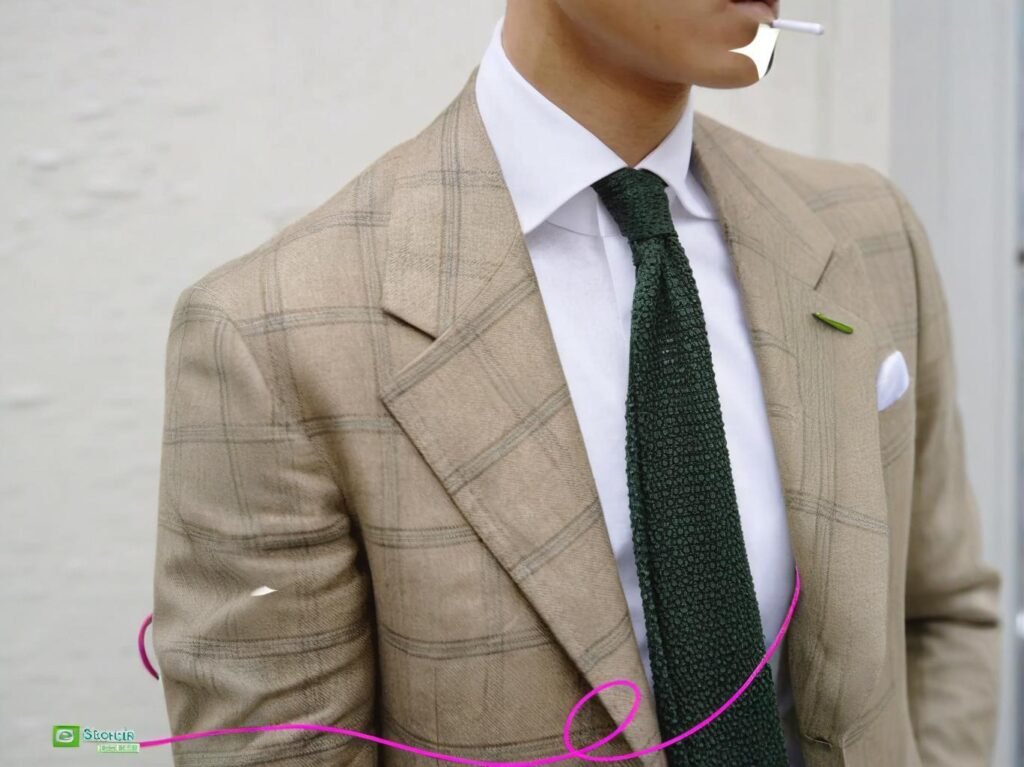

- Apparel Manufacturers may bulk order lighter GSM linen (130–180 GSM) in hundreds of meters per color.

- Home Textile Producers might seek heavier, pre-treated linen (200–300 GSM) in bulk for upholstery or curtains.

Linen Bulk Volume Classification Table

| Order Volume (Meters) | Classification | Typical Use Cases | Price Range (USD/yard) |

|---|---|---|---|

| 30–99 | Small-Batch | Sampling, boutique production | $12–$24 |

| 100–300 | Entry-Level Bulk | Garments, tableware, small series | $8–$16 |

| 500–1000 | Standard Bulk | Multi-style manufacturing, stock fabrics | $6–$13 |

| 1000+ | Industrial Bulk | Mass production, OEM/ODM projects | $5–$11 |

Real-World Insight: An Indian linen shirt maker purchases 250 meters of OEKO-TEX® certified 145 GSM French flax per color. Their average price drops by 18% compared to 80-meter batch purchases, and their mill provides complimentary lab dips after 300 meters.

How Do Minimum Order Quantities (MOQ) for Linen Vary by Supplier?

MOQ refers to the smallest quantity a supplier is willing to produce or sell in a single order. With linen, MOQs vary widely depending on the supplier’s machinery setup, fabric finishing capacity, dyeing method, and whether the fabric is stock or made-to-order.

Minimum Order Quantities (MOQ) for linen typically range from 100 to 1000 meters, influenced by whether the fabric is in-stock, requires custom dyeing or finishing, or comes from a specialized mill or vertical factory.

MOQ Factors That Matter

1. Stock vs. Custom Production

- Stock Linen: Pre-made, warehouse-ready fabrics often have low MOQs (as low as 30–100 meters).

- Custom Linen (Color/Finish): Mills usually require 150–500 meters per color to justify dye machine setup and run efficiency.

2. Dyeing and Finishing Technique

- Piece Dyeing MOQ: ~150 meters per color

- Yarn Dyeing MOQ: ~500–1000 meters per shade due to higher setup time

- Digital/Reactive Printing: Some suppliers now offer digital prints with MOQs as low as 100 meters

3. Blend and Composition Complexity

- 100% Linen: Generally lower MOQ, widely available

- Linen-Cotton, Linen-TENCEL™, Linen-Viscose Blends: Often require higher MOQ (300–600 meters) due to custom spinning or weaving

4. Regional Differences

| Country/Region | MOQ for Solid Colors | MOQ for Custom Blends | Notes |

|---|---|---|---|

| China | 100–300 meters | 300–600 meters | Lower MOQ for in-stock greige |

| India | 150–400 meters | 500+ meters | Strong yarn-dye capacity, higher MOQ |

| Lithuania | 100–200 meters | 250–500 meters | Flexible but slower in delivery |

| Turkey | 300–600 meters | 600–1000 meters | Premium finishing, moderate MOQ |

Case Insight: A California-based kidswear brand looking for 180 GSM linen-viscose blend was initially quoted a 600-meter MOQ by a Turkish supplier. After requesting greige stock and offering flexible dye lots, the MOQ was negotiated down to 300 meters with a 12% surcharge—still well within their margin.

Buyer Tip: Suppliers like SzoneierFabrics specialize in low-MOQ, high-quality bulk linen offerings. When sourcing, always ask whether quoted MOQ applies to greige, dyed, or finished fabric—this can significantly affect both cost and planning flexibility.

Which Factors Influence the Price Per Yard or Meter of Bulk Linen Fabric?

Linen’s price tag is affected by far more than just raw material. From fiber origin to finishing technique, and from certifications to logistical terms, every stage in the linen supply chain adds a layer to the final cost.

The price per yard or meter of bulk linen fabric is primarily influenced by fiber quality, GSM (grams per square meter), country of origin, weaving density, certification costs, and finishing treatments such as enzyme washing, dyeing, or antimicrobial application.

Key Price Drivers Explained

1. Fiber Origin (French, Belgian, or Eastern Europe)

- Belgian and French flax command a premium for longer staple length and consistent color.

- Lithuanian, Romanian, or Chinese flax offers a lower-cost alternative with slightly coarser fibers.

| Origin | Avg. Base Price (USD/yard) |

|---|---|

| Belgian | $18–$28 |

| French | $16–$25 |

| Lithuanian | $10–$18 |

| Chinese | $8–$14 |

2. Fabric GSM (Weight per m²)

- Lower GSMs (130–160) are lighter and cost less, but may lack opacity or structure.

- Heavier GSMs (200–280) suitable for upholstery or jackets are more expensive to produce and ship.

| GSM Range | Typical Use | Avg. Price Range (USD/yard) |

|---|---|---|

| 130–150 GSM | Shirts, dresses | $7–$12 |

| 160–190 GSM | Pants, tunics, aprons | $9–$14 |

| 200–250 GSM | Blazers, home textiles | $11–$18 |

| 250+ GSM | Upholstery, bags | $13–$20+ |

3. Dyeing & Finishing Methods

- Piece-dyed linen is more affordable than yarn-dyed or printed versions.

- Special finishes like enzyme softening, stone washing, or flame retardant treatments add 10–25% per yard.

4. Certification Fees

- OEKO-TEX®, GOTS, or European Flax® certifications increase cost due to stricter input and processing standards.

- Expect an added $0.50–$1.50 per yard depending on the level of compliance.

5. Order Volume & Currency Conditions

- Buying over 500 meters per color often yields 8–15% price reductions.

- Euro-dollar or RMB-dollar exchange rate fluctuations affect imported linen pricing month to month.

Case Snapshot: A small-run textile label in Australia requested 150 GSM OEKO-TEX® certified dyed linen with enzyme finish. The base price was $10.80/yard for 200 meters. After negotiating for 500 meters across three colors, they secured $9.65/yard pricing with consolidated shipping—saving over $1,000 in total.

What Are the Average Price Ranges for Bulk Linen by Type and GSM?

Prices for bulk linen fabric in 2025 vary based on fiber composition, weaving complexity, treatment level, and origin. However, industry-standard ranges can provide helpful benchmarks when budgeting and negotiating with suppliers.

The average price for bulk linen ranges from $6 to $20 per yard, with lightweight untreated linen being the most affordable and premium dyed or certified blends reaching the higher end of the scale.

Bulk Linen Price Benchmarks by Category

1. 100% Linen (Greige or Scoured)

- No dyeing, no finish

- Suitable for garment-dyeing or reactive printing

- Best for cost-sensitive projects

Avg. Price: $6–$10/yard

2. 100% Linen (Pre-dyed, Softened)

- Enzyme-washed, softened, or yarn-dyed

- Ideal for fashion and home textiles with color variation

- Usually includes pre-shrinking

Avg. Price: $9–$15/yard

3. Linen Blends (Linen-Cotton, Linen-Viscose, Linen-TENCEL™)

- Improve softness, drape, or elasticity

- Some blends like TENCEL™ carry brand royalty fees

| Blend Type | Price Range (USD/yard) | Notes |

|---|---|---|

| Linen-Cotton 55/45 | $8–$13 | Softer feel, lower wrinkle factor |

| Linen-Viscose 60/40 | $9–$14 | Smooth, glossy finish |

| Linen-TENCEL™ 50/50 | $11–$18 | Premium eco blend, highly breathable |

4. Special Finishes (Antimicrobial, Flame Retardant, Digital Print)

- Used in medical, hospitality, or kidswear markets

- Requires specialized mills with ISO/REACH compliance

Add-on Cost: $1.50–$3.50/yard (on top of base price)

Bulk Linen Price Comparison Table

| Type & Treatment | GSM | Avg. Price (USD/yard) |

|---|---|---|

| Greige Linen (undyed) | 140 | $6.00–$8.50 |

| Enzyme-washed French Linen | 160 | $10.00–$14.00 |

| Yarn-dyed Belgian Linen | 180 | $14.00–$18.00 |

| Linen-Cotton Blend, dyed | 190 | $9.00–$13.00 |

| Linen-TENCEL™, eco-certified | 200 | $13.00–$18.00 |

| Digital-printed Linen-Viscose | 160 | $12.00–$16.00 |

Trend Note (2025): Increased demand for sustainable blends and digital-ready linen has created a price gap between untreated and value-added fabrics—expect a 12–18% premium if you’re sourcing certified, pre-treated linen from Europe.

How Does Country of Origin Affect Linen Fabric Cost and MOQ?

Country of origin plays a pivotal role in both the pricing structure and minimum order requirements of bulk linen fabric. Geography impacts everything—from flax cultivation techniques and textile heritage to labor costs, factory technology, and environmental regulations.

Linen from Western Europe typically carries a higher price and stricter MOQs due to labor costs and certification systems, while Eastern Europe and Asia offer lower prices, more flexible MOQs, and increasing production quality through upgraded technology.

Regional Impact on Cost and MOQ

1. Western Europe (France, Belgium, Italy)

- Produces high-grade flax with long staple lengths

- Most mills are vertically integrated, with in-house retting, combing, dyeing

- Higher wage standards and environmental compliance costs

| Region | Typical MOQ | Avg. Price (USD/yard) | Lead Time (Days) | Notes |

|---|---|---|---|---|

| Belgium | 300–600 m | $18–$28 | 30–45 | Masters of Linen® certified |

| France | 200–500 m | $16–$25 | 30–40 | GOTS and OEKO-TEX® ready |

| Italy | 250–500 m | $17–$24 | 35–50 | High-end finishes, longer lead |

2. Eastern Europe (Lithuania, Romania, Ukraine)

- Offers more flexible MOQs with decent mid-range quality

- Some mills are semi-automated, keeping overhead low

- Growing adoption of sustainability and traceability programs

| Region | Typical MOQ | Avg. Price (USD/yard) | Lead Time (Days) | Notes |

|---|---|---|---|---|

| Lithuania | 100–300 m | $10–$15 | 20–35 | OEKO-TEX® common, slower scaling |

| Romania | 150–400 m | $9–$13 | 25–35 | Good for rustic or heavier GSM styles |

| Ukraine | 300–600 m | $8–$12 | 30–45 | May face logistics risk in some zones |

3. Asia (China, India)

- Asia’s advantage is scaling capacity, customization, and low production cost

- Many Chinese mills now import European flax and process it in-house

- Indian mills are growing in yarn-dyed and printed linen offerings

| Region | Typical MOQ | Avg. Price (USD/yard) | Lead Time (Days) | Notes |

|---|---|---|---|---|

| China | 100–300 m | $7–$12 | 15–30 | Strong greige stock, fast turnarounds |

| India | 200–500 m | $8–$13 | 25–40 | Color-rich, handloom and machine looms |

Buyer Insight: A South African home décor company split their sourcing between France (for organic table linen at $22/yard) and China (for printed linen napkins at $9/yard)—balancing brand prestige with mass affordability.

Strategic Consideration: For projects requiring certification and brand positioning, opt for Europe. For seasonal products, fast fashion, or cost-sensitive campaigns, Asia and Eastern Europe offer better pricing with decent consistency—especially when working with suppliers like SzoneierFabrics who manage blended sourcing channels.

What Certifications or Treatments Add to the Cost of Bulk Linen Orders?

Beyond fiber and weave, value-added certifications and fabric treatments can significantly affect pricing. These are often necessary for brands seeking to meet retail compliance, sustainability targets, or functional performance in industries like hospitality or healthcare.

Common linen certifications like OEKO-TEX®, GOTS, and European Flax® add between 5–15% to raw fabric cost, while treatments such as enzyme washing, antimicrobial finish, or digital printing can increase price per yard by $0.80 to $3.50 depending on method and complexity.

Common Certifications & Treatments That Impact Cost

Certifications That Influence Pricing

| Certification | Purpose | Price Impact per Yard | Common Regions |

|---|---|---|---|

| OEKO-TEX® Standard 100 | Chemical safety (skin contact) | +$0.50–$1.00 | Europe, China, India |

| GOTS | Organic farming + clean processing | +$0.80–$1.50 | France, Romania, Turkey |

| European Flax® | EU-grown flax traceability | +$0.50–$1.00 | Belgium, France |

| Masters of Linen® | Full European production chain | +$1.00–$2.00 | Belgium, Italy |

Popular Linen Finishes and Their Costs

- Enzyme Wash / Stone Wash: +$0.80–$1.50/yard

- Reactive Dyeing: +$0.60–$1.20/yard

- Digital Printing (low MOQ): +$2.00–$3.50/yard

- Antimicrobial / Anti-Odor Finish: +$1.00–$2.50/yard

- Flame Retardant (FR) Finish: +$2.00–$4.00/yard

Use Case Insight: A Canadian medical wear company sources GOTS-certified, antimicrobial-treated linen-viscose blend at $14.80/yard for 300-meter orders. Base fabric cost was $11.00/yard, with $1.50 for certification and $2.30 for silver-ion antimicrobial finish.

Cautionary Note: Not all mills have in-house finishing or certification capabilities. Partnering with vertically integrated suppliers like SzoneierFabrics can help reduce markups, streamline timelines, and ensure compliance documentation is accurate and up-to-date.

How Can Textile Manufacturers Negotiate Better MOQ and Pricing Terms?

In bulk linen procurement, the power to negotiate lies not just in the quantity ordered, but in how strategically the buyer engages with suppliers. Clear planning, flexible delivery, and trust-based relationships are the foundations for unlocking better terms.

To negotiate better MOQ and pricing for linen fabric, manufacturers should offer flexibility in delivery dates, batch colors together, request shared dye lots, and leverage long-term relationships for volume discounts.

Effective Negotiation Strategies for Linen Sourcing

1. Bundle Colors or GSMs Across Styles

- Grouping multiple colors of the same GSM linen in one production run helps mills save on setup costs.

- This can reduce per-color MOQ from 300 meters to 150 meters or less.

2. Opt for Greige Stock + Custom Dyeing

- Mills with greige fabric in inventory can often dye to order with lower MOQ.

- This avoids weaving minimums and accelerates sampling.

3. Agree to Flex Dates or Staggered Delivery

- Offering flexible delivery timelines or taking partial shipments allows the mill to optimize production queues, which they often reward with better unit pricing.

4. Establish Repeat Order Terms

- Suppliers often agree to lower MOQ or pricing if future order potential is confirmed (e.g., seasonal collections).

- Signing a 6-month supply forecast can reduce unit cost by 8–15%.

5. Share Development Costs for Custom Blends

- For special linen-cotton or linen-viscose mixes, offer to co-finance yarn sampling or loom setup if exclusivity is involved.

- This shows commitment and strengthens supplier willingness to customize MOQ.

Negotiation Leverage Table

| Strategy | Cost Benefit Potential | MOQ Impact | Supplier Incentive |

|---|---|---|---|

| Batch similar colors | 5–10% reduction | 50% lower per color | Less dye machine setup time |

| Use greige stock | 10–15% savings | Lowers MOQ to 100 m | Immediate base fabric availability |

| Accept staggered shipments | 3–6% reduction | Faster slot booking | Warehouse balancing for supplier |

| Confirm 2+ future orders | 8–12% reduction | MOQ exceptions possible | Predictable revenue |

Case Insight: A Brazilian fashion label negotiated a 9% discount by accepting a staggered linen delivery in 200-meter batches over two months, instead of one large shipment. The supplier offset the lower cash flow risk by lowering the MOQ per color to 150 meters.

What Are the Best Practices for Sourcing Bulk Linen Material in 2025?

In 2025, sourcing bulk linen means more than just comparing price lists—it requires alignment with global logistics trends, certification shifts, and new sustainability standards. Whether you’re buying for fashion, upholstery, or hospitality, applying strategic best practices will reduce risk and improve margin retention.

The best practices for sourcing bulk linen in 2025 include choosing certified suppliers, validating GSM and shrinkage through lab tests, forecasting volume for better terms, and diversifying sources across regions for cost and lead time balance.

Strategic Sourcing Framework

1. Define Use Case Before Contacting Suppliers

- Know the end application (e.g., garments, home textiles, medical).

- Specify the desired GSM range, composition (100% linen vs. blend), and finish (PFD, enzyme, reactive dyed).

2. Prioritize Certified Mills

- Work with suppliers who can provide OEKO-TEX®, GOTS, or European Flax® certificates.

- Ask for ISO lab testing on shrinkage, colorfastness, and tensile strength—particularly for apparel or hospitality applications.

3. Request Swatches + Technical Data

- Swatches reveal hand-feel, color depth, and drape.

- A good supplier will provide spec sheets with GSM, weave type, dye type, shrinkage %, and treatment process.

4. Use a Tiered Supplier Strategy

- Combine one premium supplier (e.g., France or Belgium) for flagship styles and one cost-efficient mill (e.g., China, Lithuania) for volume pieces.

- This balances price volatility, risk, and brand positioning.

5. Monitor Currency Trends + Logistics

- Linen prices fluctuate with Euro/RMB/USD rates. Forward-planning purchases can hedge rising prices.

- Ensure your supplier has port access and export history—delays in customs or documentation can erase margin advantages.

6. Build Supplier Relationships, Not Just Orders

- Long-term partners provide better responsiveness, sampling support, and inside access to upcoming fabrics.

- Brands working closely with suppliers often receive early access to limited weaves, cancellations, or overstock.

Sourcing Readiness Checklist (2025)

| Task | Must-Have? |

|---|---|

| Define fabric use and spec sheet | ✅ |

| Ask for OEKO-TEX/GOTS certification | ✅ |

| Request lab shrinkage report | ✅ |

| Confirm MOQ by fabric/color | ✅ |

| Clarify dyeing vs greige pricing | ✅ |

| Check supplier’s export experience | ✅ |

Example Strategy: A Canadian homewares brand uses 100% Lithuanian linen for budget-conscious tea towels at $9.50/yard and imports enzyme-washed French linen at $19.00/yard for premium bedding. Both lines are OEKO-TEX® certified, and the cost balancing enables a competitive retail price while retaining luxury appeal.

Sourcing bulk linen fabric in 2025 is a matter of precision, not guesswork. From understanding MOQ thresholds to benchmarking global prices by origin and GSM, the best decisions are backed by clarity, lab data, and real-world supply chain savvy. Whether you’re producing 200 meters of soft-washed shirting or 5,000 meters of GOTS-certified drapery, every fabric order begins with informed questions.

Let your linen sourcing strategy work smarter—not harder.

Partner with SzoneierFabrics for Custom Bulk Linen Supply

As a trusted Chinese linen manufacturer with years of experience in customized fabric development, SzoneierFabrics helps you:

- Source certified bulk linen (100% or blends)

- Access low MOQ options for custom colors and finishes

- Get free samples and fast sampling turnaround

- Balance pricing, quality, and delivery for global orders

Contact SzoneierFabrics today to request a quote, MOQ breakdown, or a free consultation on your next linen project.