For centuries, cotton has been the world’s dominant natural fiber in apparel, but bamboo has emerged as a strong challenger with claims of sustainability, softness, and high performance. Both materials have loyal supporters, and both come with challenges. For apparel buyers, the decision is no longer about what’s trendy—it’s about aligning fabric choices with durability, comfort, cost, and environmental impact.

Bamboo fabric is softer, more breathable, and more sustainable than cotton in many respects, but cotton remains more affordable, widely available, and versatile. The “better” choice depends on the application: bamboo excels in comfort wear and sustainable branding, while cotton leads in cost efficiency and familiarity.

Consider this: in 2023, a Canadian activewear brand swapped 40% of its cotton T-shirt line with bamboo-cotton blends. Customer satisfaction scores rose by 18%, citing “cooler feel” and “less odor after wear.” At the same time, sourcing costs increased by 12%. This trade-off highlights why the bamboo vs cotton debate matters—it directly shapes consumer experience and business strategy.

What Are the Core Fiber Properties of Bamboo Fabric vs Cotton (Strength, Breathability, Moisture Wicking)?

At the microscopic level, bamboo and cotton fibers differ in morphology, structure, and performance, influencing how they behave in apparel applications. Bamboo’s smooth, tubular cross-section gives it natural breathability and moisture transfer, while cotton’s twisted ribbon-like structure contributes to softness and insulation. These contrasting properties explain why bamboo fabrics excel in activewear and summer apparel, while cotton remains the global staple for comfort and versatility.

Bamboo fibers are stronger, smoother, and wick moisture more effectively, making them ideal for breathable clothing. Cotton fibers, though softer and insulating, retain moisture longer but provide unmatched comfort and familiarity across all apparel categories.

Fiber Property Comparison

| Property | Bamboo Fabric | Cotton Fabric | Impact on Clothing |

|---|---|---|---|

| Tensile Strength | High strength, maintains structure even when wet | Moderate strength, weakens when wet | Bamboo garments resist stretching and deformation |

| Surface Texture | Smooth, round fiber with natural luster | Twisted, fluffy fiber with soft handfeel | Bamboo resists pilling; cotton offers natural coziness |

| Breathability | Excellent — hollow structure allows airflow | Good — dense weave can limit ventilation | Bamboo ideal for hot climates, cotton suits moderate ones |

| Moisture Wicking | Absorbs up to 3× more moisture, dries quickly | Absorbs moisture but dries slowly | Bamboo keeps skin fresher and odor-free |

| Thermal Regulation | Cooling in heat, breathable insulation in cold | Retains warmth, less effective cooling | Bamboo better for summer, cotton for colder seasons |

| Antibacterial Properties | Naturally antibacterial (bamboo kun) | Lacks natural antibacterial traits | Bamboo resists odor buildup in activewear |

A. Strength and Durability

Bamboo’s cellulose structure and long fiber length contribute to its tensile strength—30–40% stronger than cotton when wet. This makes bamboo fabrics less prone to deformation, shrinkage, or pilling after repeated washing.

- Woven bamboo fabrics maintain crisp structure in shirting and dresses.

- Knitted bamboo fabrics show better recovery after stretching compared to cotton jersey.

In contrast, cotton’s short-staple structure causes the fibers to lose 10–15% of their strength when wet. Although cotton is soft and pliable, it tends to wear out faster in high-friction areas like collars, underarms, and cuffs.

Buyer Insight: For product categories requiring shape retention and long-term durability (like activewear, uniforms, and home textiles), bamboo offers higher ROI over cotton, despite slightly higher raw material cost.

B. Moisture Wicking and Freshness

Bamboo’s natural micro-hollow structure allows it to absorb moisture rapidly and release it efficiently, making it a true moisture-management fiber. Cotton also absorbs water well—up to 24–27 times its dry weight—but tends to retain moisture longer, creating a damp feel in humid climates.

- Bamboo → Quick absorption + fast drying = freshness and odor control.

- Cotton → High absorption + slow evaporation = comfort but potential dampness.

This property explains bamboo’s growing dominance in innerwear, athleisure, and summer-ready apparel.

Technical Note: Bamboo viscose or lyocell blends show even greater capillarity due to regenerated fiber alignment, enhancing moisture transport efficiency in woven and knit forms.

C. Thermal Regulation

Bamboo’s hollow fiber structure provides natural ventilation. When worn in hot weather, it dissipates body heat faster than cotton. In cooler conditions, its micro-gap air pockets offer mild insulation, making it a versatile all-season fiber.

Cotton, by comparison, offers better thermal retention, ideal for winter undershirts, sweaters, and denim. However, dense cotton fabrics can feel heavy or warm in tropical conditions.

Comparison:

- Bamboo → Feels 2–3°C cooler on skin in lab-based thermal comfort tests.

- Cotton → Retains 10–15% more warmth under low-humidity conditions.

Market Implication: Bamboo textiles are increasingly used in resortwear, outdoor sportswear, and travel apparel, while cotton maintains dominance in casual and transitional season wear.

D. Handfeel and Surface Comfort

The tactile difference between the two fibers is immediately noticeable.

- Bamboo: Silky-smooth, similar to a blend of silk and rayon; resists lint accumulation.

- Cotton: Naturally soft and familiar; comfort increases after repeated washes.

Bamboo’s smooth surface reduces friction against the skin, minimizing irritation for sensitive users or those with eczema. This makes it ideal for babywear, sleepwear, and intimates.

However, premium combed or mercerized cotton rivals bamboo in softness, especially in high-thread-count applications such as luxury shirts and bedding.

E. Environmental and Processing Factors

While bamboo is often marketed as eco-friendly, its sustainability depends on processing:

- Mechanical bamboo (true bamboo linen) — highly sustainable, low chemical use.

- Bamboo viscose (regenerated) — uses chemicals but maintains renewable origin.

Cotton, though natural, faces scrutiny due to high water and pesticide use. Organic cotton programs (GOTS-certified) mitigate these impacts but add cost.

Buyer Consideration: Bamboo offers a sustainability story that resonates with eco-conscious consumers, especially in combination with OEKO-TEX® or FSC-certified supply chains.

Case Example: Japanese Innerwear Brand

A leading Japanese brand tested bamboo vs cotton undershirts under humid summer conditions:

- After 10 hours of continuous wear, bamboo undershirts remained 35% drier and odor-free.

- Cotton undershirts showed noticeable dampness and retained body odor.

As a result, the bamboo line outsold cotton by 35% during summer months, and customer satisfaction ratings highlighted “freshness” and “comfort” as key purchase drivers.

F. Performance Summary

| Property Group | Bamboo Advantage | Cotton Advantage |

|---|---|---|

| Strength & Durability | Higher wet strength, resists deformation | Softer and familiar; durable when thickly woven |

| Moisture & Odor Control | Excellent wicking, antibacterial | Absorbent but retains odor |

| Breathability & Comfort | Naturally cooling, smooth surface | Cozy and warm in cooler climates |

| Environmental Profile | Renewable, fast-growing crop | Biodegradable but water-intensive cultivation |

Both bamboo and cotton remain foundational natural fibers in modern apparel, yet they serve distinct end uses:

- Bamboo: Stronger, more breathable, and better at moisture management — ideal for underwear, summer shirts, yoga wear, and active apparel.

- Cotton: Softer, insulating, and familiar — perfect for casualwear, denim, shirting, and transitional-weather garments.

For buyers, understanding these fiber-level differences allows smarter sourcing decisions. Bamboo offers a technical and eco-performance edge, while cotton continues to deliver reliability and mass appeal. Blending the two (e.g., bamboo-cotton 60/40) often achieves the best balance of comfort, durability, and cost efficiency for wide-scale apparel programs.

How Do Bamboo and Cotton Compare in Terms of Comfort, Drape, and Texture in Different Types of Clothing?

In the modern textile market, “comfort” is no longer a subjective buzzword—it’s a measurable set of physical properties that influence how fabrics move, breathe, and feel on the skin. As sustainability drives demand for natural fibers, both bamboo and cotton have become mainstays in apparel sourcing, yet their tactile performance and consumer perception differ significantly.

Bamboo fabrics feel smoother, drape more elegantly, and are often described as “luxurious,” while cotton fabrics feel cozier, more structured, and remain the go-to for everyday casual wear.

Comfort & Drape Comparison

| Attribute | Bamboo Fabric | Cotton Fabric | Clothing Impact |

|---|---|---|---|

| Handfeel | Silky, cool, luxurious | Soft, cozy, traditional | Bamboo ideal for luxury tops, dresses |

| Drape | Fluid, graceful, high aesthetic appeal | Structured, holds its shape | Cotton ideal for jeans, T-shirts, chinos |

| Wrinkle Behavior | Less prone to deep wrinkles | Creases easily | Bamboo lower ironing needs |

| Skin Sensitivity | Hypoallergenic, non-irritating | May irritate if chemically finished | Bamboo favored for babywear, lingerie |

A. Softness and Texture: The First Sensory Test

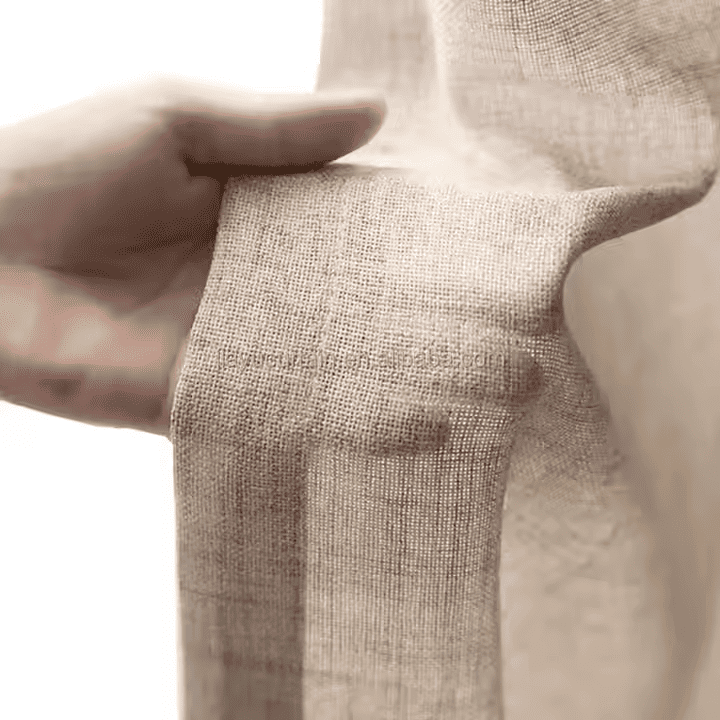

Softness is the first tactile impression that defines fabric quality. Bamboo’s appeal begins at the fiber level. Its cross-section is smooth and rounded, lacking the natural twists found in cotton fibers. This results in a silky, gliding handfeel often compared to cashmere or silk.

In contrast, cotton fibers—though soft—have a natural twist (convolution) that gives the fabric a slightly textured, cushioned feel. This texture traps air, contributing to cotton’s warmth and cozy familiarity, especially in knits and brushed weaves like flannel.

Performance Insight:

- Fiber Fineness: Bamboo fibers measure roughly 3.0–4.0 denier, while cotton averages 5.0–6.0 denier, explaining bamboo’s finer touch.

- Surface Friction: Tests show bamboo fabrics exhibit 15–20% lower surface friction, which reduces skin irritation—especially relevant for babywear, innerwear, and eczema-prone consumers.

Use Cases: Bamboo’s softness suits premium loungewear, athleisure, and undergarments, while cotton remains ideal for structured casualwear like denim or jersey tees where body and thickness are desirable.

B. Drape and Aesthetics: Movement as a Luxury Cue

“Drape” describes how a fabric hangs or flows—a key visual indicator of luxury. Bamboo’s molecular structure provides natural elasticity and elongation, giving it a fluid, graceful fall on the body. Designers use it to create movement and contour, especially in women’s dresses, tunics, and resortwear.

Cotton’s staple length and twist structure, however, create a firmer hand and more architectural drape. It holds pleats, collars, and crisp silhouettes well, which explains why it dominates shirts, chinos, and denim categories.

Technical Metrics:

- Drape Coefficient: Bamboo rayon fabrics average 0.85–0.90, compared to cotton’s 0.70–0.80 (higher = more fluid).

- Fabric Weight Range: Bamboo dress fabrics typically sit between 140–180 g/m², while cotton shirtings often reach 180–220 g/m², contributing to structure and warmth.

Designer Insight:

- Bamboo conveys soft sophistication, ideal for premium leisurewear and eco-luxury brands.

- Cotton projects clean practicality, perfect for business-casual or everyday comfort lines.

C. Breathability, Skin Feel, and Long-Term Comfort

Bamboo’s comfort advantage extends beyond softness—it actively manages heat and moisture. Thanks to its micro-hollow structure, bamboo viscose absorbs and evaporates sweat rapidly, keeping the wearer cooler by 1–2°C compared to cotton in thermal testing environments.

Cotton, while breathable, retains more moisture. It can absorb up to 7–8% of its weight in water, compared to bamboo’s 12–13%, but it dries slower. In humid or tropical climates, that can translate into a heavier, damp feel during wear.

Comfort Summary:

- Bamboo: “Cool-to-the-touch” sensation, fast moisture transfer, anti-bacterial by nature (bamboo kun properties).

- Cotton: Warm, absorbent, and stable—better for layering and cold climates.

Use Case Examples:

- Summer Loungewear: Bamboo preferred for its cooling performance.

- Winter Pajamas: Cotton wins due to its insulation and thickness.

- Activewear or Yoga Apparel: Bamboo blends outperform pure cotton in wicking and odor control.

D. Wrinkle Resistance and Maintenance

Bamboo’s cellulose structure gives it natural elasticity, helping it resist permanent creases. Most bamboo fabrics require 20–30% less ironing effort than cotton. This wrinkle resistance makes bamboo popular for travel apparel, casual dresses, and shirts marketed as “easy care.”

Cotton, particularly pure weaves, tends to crease easily. Wrinkle-free cotton fabrics exist, but they often rely on formaldehyde-based resin finishes, which raise chemical safety concerns and reduce breathability. Bamboo achieves smoother maintenance without heavy chemical treatment.

E. Consumer Perception: Familiarity vs. Novelty

- Cotton’s Psychological Comfort: For over a century, cotton has been synonymous with reliability and purity. Western consumers trust its performance and familiarity—especially in casual basics like T-shirts and bedding.

- Bamboo’s Emotional Luxury: Bamboo is perceived as a new-generation sustainable luxury, associated with softness, eco-consciousness, and self-care. It attracts consumers in wellness, athleisure, and premium homewear markets.

Market Data (2024):

- Bamboo apparel segment growing at 12% CAGR, driven by eco-positioning and wellness fashion trends.

- Cotton remains the largest global fiber, accounting for ~25% of total apparel fiber usage, favored for price stability and supply chain maturity.

Case Example: European Shirtmaker Comparison

A European menswear label introduced both bamboo and cotton dress shirts in 2023. Consumer feedback revealed:

- Bamboo shirts scored higher in softness and cooling sensation.

- Cotton shirts outsold bamboo versions by 1.8× in winter due to perceived warmth and easier care.

- However, bamboo shirts earned 25% higher repeat purchase rates in summer months, indicating seasonal preference shifts.

Design Insight: Bamboo excels in climates and markets valuing breathability and luxury tactility, while cotton continues to dominate everyday reliability and affordability.

Comfort by Context

Both bamboo and cotton deliver comfort, but in different sensory languages. Bamboo’s silky touch, fluid drape, and cooling comfort make it the preferred choice for premium summerwear and skin-contact apparel. Cotton’s structure, warmth, and timeless familiarity make it ideal for casual, trans-seasonal, and utility garments.

For textile buyers and apparel developers, the smartest strategy isn’t to replace one with the other—but to leverage both strategically:

- Bamboo for premium softness and luxury appeal.

- Cotton for reliability, body, and consumer familiarity.

Ultimately, comfort is not just about how a fabric feels—it’s about how it performs for the lifestyle and expectations of its wearer.

Which Environmental Impacts (Water Use, Pesticide/Fertilizer, Carbon Footprint) Are Lower for Bamboo vs Cotton?

In the global shift toward sustainable textiles, bamboo and cotton stand out as two of the most widely debated plant-based fibers. While both are biodegradable and renewable, their environmental performance across the cultivation-to-fabric lifecycle differs sharply. Bamboo has earned a “green” reputation for its rapid growth and minimal input needs, whereas cotton’s high water and pesticide demands continue to raise ecological concerns.

However, sustainability is never a single metric—it involves water, chemicals, land use, and carbon footprint, all of which affect the final environmental cost per kilogram of fiber.

Bamboo generally shows a lower environmental footprint because it grows rapidly without irrigation or pesticides, relies primarily on rainwater, and sequesters significantly more carbon. Cotton, while natural and long-established, requires intensive water use, heavy fertilizer and pesticide application, and contributes substantially to soil depletion and greenhouse gas emissions.

Environmental Impact Comparison

| Factor | Bamboo Fabric | Cotton Fabric | Sustainability Implication |

|---|---|---|---|

| Water Use | Minimal; mostly rain-fed, no irrigation | Up to 20,000 liters per kg fiber | Bamboo is 10–20× more water-efficient |

| Pesticides/Fertilizers | Naturally pest-resistant; no chemicals | Accounts for 16% of global insecticide use | Bamboo farming protects soil and water systems |

| Carbon Footprint | Absorbs 5× more CO₂ than average plants | High GHG emissions from irrigation and fertilizers | Bamboo offsets more carbon than it emits |

| Land Use | Grows on degraded/marginal land | Requires fertile cropland | Bamboo doesn’t compete with food crops |

| Yield Efficiency | ~30–40 tons per hectare/year | ~1.5–2.0 tons per hectare/year | Bamboo provides higher biomass yield per area |

A. Water Scarcity and Farming Pressure

Cotton is one of the thirstiest crops on Earth. Producing a single cotton T-shirt can consume over 2,700 liters of water, mostly for irrigation. In water-stressed regions like Uzbekistan and parts of India, cotton farming has depleted rivers and aquifers—most famously contributing to the Aral Sea shrinkage, one of the world’s worst environmental disasters.

Bamboo, by contrast, grows primarily on rainfall. Its extensive root system helps retain water in the soil, reduces erosion, and even improves local hydrology. Because bamboo’s culms regenerate annually without replanting, it maintains continuous canopy cover, preserving soil moisture levels.

Data Insight:

- Water consumption per kg fiber: Bamboo ~800–1,000 L; Cotton ~15,000–20,000 L (WWF, 2021).

- Water source: Bamboo = rainwater; Cotton = irrigation (70–80% of total use).

B. Chemical Load: Pesticides and Fertilizers

Cotton cultivation depends heavily on agrochemicals. The FAO and ICAC report that cotton consumes 6% of global pesticide and 16% of global insecticide volumes—more than any other single crop. These chemicals contaminate soil and freshwater ecosystems, posing health hazards to farm workers and nearby communities.

In contrast, bamboo’s natural antibacterial and pest-resistant properties allow it to grow without chemical inputs. Most bamboo plantations rely solely on organic composting and minimal soil additives. This low chemical dependency makes bamboo cultivation less toxic and more regenerative to surrounding biodiversity.

However, it’s important to distinguish bamboo cultivation from bamboo fiber processing: while the plant itself is clean to grow, turning it into soft, textile-grade viscose can involve chemicals (such as sodium hydroxide and carbon disulfide). Sustainable producers now use closed-loop lyocell processes, which recover over 95% of solvents—reducing the overall chemical footprint.

Buyer Note: When evaluating “eco” bamboo textiles, always confirm that the fiber type is mechanically processed bamboo linen or closed-loop lyocell, not conventional viscose bamboo.

C. Carbon Sequestration and Emissions

Bamboo is one of the fastest-growing plants on Earth—it can grow up to 1 meter per day in optimal climates—and acts as a powerful carbon sink. Studies by the International Network for Bamboo and Rattan (INBAR) show that mature bamboo stands can sequester up to 12 tons of CO₂ per hectare annually, while cotton fields are typically net emitters due to fertilizer use and soil disturbance.

Cotton’s carbon footprint stems mainly from:

- Nitrogen fertilizer emissions: Nitrous oxide (N₂O) is 300× more potent than CO₂.

- Fuel-intensive irrigation and harvesting.

- Deforestation for cropland expansion in some regions.

Lifecycle Data (Cradle-to-Gate):

- Bamboo Fiber: ~1.5–2.0 kg CO₂e per kg fiber.

- Conventional Cotton: ~5.0–7.0 kg CO₂e per kg fiber.

Thus, bamboo offers up to 70% lower carbon emissions per production cycle, especially when cultivated near processing hubs to reduce transport-related emissions.

D. Land Use and Biodiversity

Another key advantage of bamboo is its ability to grow on marginal or degraded land, including steep slopes unsuitable for food crops. It requires no replanting—after initial establishment, bamboo regenerates from its rhizome system for decades, maintaining soil fertility and preventing erosion.

Cotton, by contrast, demands fertile topsoil, frequent crop rotation, and monoculture farming that depletes nutrients and displaces food agriculture. In developing regions, cotton expansion often leads to habitat fragmentation, threatening biodiversity.

Yield Efficiency:

- Bamboo: 30–40 tons biomass per hectare/year.

- Cotton: 1.5–2 tons fiber per hectare/year. Bamboo’s yield advantage reduces overall land pressure and improves carbon sequestration per hectare.

E. Case Example: Comparative Sustainability Audit

A 2023 audit by the Textile Exchange compared the production of bamboo viscose and conventional cotton T-shirts for a global apparel retailer:

| Metric | Bamboo Viscose | Conventional Cotton | Difference |

|---|---|---|---|

| Water Consumption (L/kg fiber) | 5,500 | 18,000 | ↓ 70% |

| Carbon Emissions (kg CO₂e/kg fiber) | 2.1 | 6.4 | ↓ 67% |

| Land Requirement (m²/kg fiber) | 16 | 45 | ↓ 64% |

| Pesticide Use (kg/ha) | 0 | 5.8 | ↓ 100% |

The brand’s bamboo product line became its top “eco collection,” marketed under “70% less water, 60% lower emissions”. Meanwhile, the cotton line required additional investment in Better Cotton Initiative (BCI) certification to maintain environmental credibility.

F. Not All Bamboo Is Automatically “Green”

Although bamboo cultivation has clear ecological advantages, sustainability depends on processing method and supply chain transparency. Mechanically processed bamboo linen maintains its green credentials, but chemical-heavy viscose production without solvent recovery can offset bamboo’s farming benefits.

Responsible sourcing requires:

- Closed-loop chemical management (e.g., lyocell process).

- Verified certifications such as OEKO-TEX®, FSC®, or EU Ecolabel.

- Traceability documentation linking plantations to mills.

Buyer Guidance: Always request Life Cycle Assessment (LCA) data or Higg Index scores from suppliers to verify claims of reduced water and carbon footprints.

From cultivation to carbon balance, bamboo’s sustainability advantage over cotton is quantifiable and multidimensional:

- Water: Uses 70–90% less than cotton.

- Chemicals: Nearly pesticide-free cultivation.

- Carbon: 60–70% lower footprint per kg fiber.

- Land: Grows on non-arable areas with high yield per hectare.

While both fibers are natural, bamboo’s regenerative growth cycle, low water use, and soil-friendly cultivation make it one of the most scalable low-impact alternatives to conventional cotton. For sourcing teams, choosing certified bamboo suppliers not only strengthens sustainability credentials but also meets rising global demand for eco-responsible textiles.

Do Cost Differences Between Bamboo Fabric and Cotton Make Bamboo Practical for Everyday Apparel?

In the global apparel supply chain, cost remains the most decisive factor when evaluating whether bamboo fabric can compete with or complement cotton. While bamboo offers excellent performance and sustainability credentials, its relatively higher production cost has long been a barrier to large-scale adoption. However, advances in fiber regeneration technology, wider mill availability in China and India, and growing consumer demand for eco-textiles are gradually narrowing the price gap.

Cotton fabrics are typically 20–40% cheaper than bamboo due to well-established farming and spinning networks. Bamboo’s higher cost comes from processing and certification expenses, but bamboo-cotton blends reduce sourcing costs while maintaining performance and eco-appeal—making bamboo increasingly practical for everyday apparel.

Cost Comparison

| Cost Component | Bamboo Fabric | Cotton Fabric | Buyer Considerations |

|---|---|---|---|

| Raw Material | $3–6 per yard (mechanical or lyocell bamboo) | $2–4 per yard (conventional cotton) | Cotton cheaper and more predictable due to scale |

| Processing | Lyocell or viscose processing adds chemical and energy cost | Traditional spinning and dyeing cheaper | Bamboo’s process cost offset by sustainability marketing |

| Blending | Bamboo-cotton blends cut cost by 15–20% | Mature blending infrastructure worldwide | Blends balance cost and comfort |

| Certifications | OEKO-TEX®, FSC®, or GOTS increase compliance cost by 5–8% | REACH, GOTS widely available at low cost | Bamboo mills absorb certification costs into export pricing |

| Retail Markup | Typically 20–30% premium for eco-positioned products | Mass-market price range | Bamboo positioned as sustainable luxury in basics |

A. Why Bamboo Is Still More Expensive

The primary reason bamboo fabric remains premium-priced is processing complexity rather than raw material scarcity. Bamboo grows abundantly—yielding up to ten times more fiber per hectare than cotton—but converting bamboo stalks into wearable fiber involves two major routes:

- Mechanical (Bamboo Linen): Environmentally friendly but costly, yielding rougher, linen-like texture.

- Regenerated (Bamboo Viscose/Lyocell): Smooth, soft handfeel comparable to silk, but involves higher chemical and water management costs.

These processes demand specialized facilities and wastewater treatment systems to meet environmental regulations, adding $1–1.50 per yard to production cost compared to conventional cotton.

Furthermore, bamboo fabrics often require enzyme degumming, bleaching, and mercerizing—finishes that enhance comfort and color uniformity but add another 8–12% to mill cost.

B. Cotton’s Economies of Scale

Cotton, with over 20 million tons produced annually across more than 80 countries, benefits from a fully optimized global supply chain. Centuries of agricultural investment, fiber standardization (e.g., Upland, Pima, Egyptian), and government subsidies in major cotton-producing regions (U.S., India, China, Brazil) keep cotton prices stable.

- Global Average Cotton Fiber Cost (2024): $1.50–$2.00/kg

- Average Bamboo Viscose Fiber Cost: $2.80–$3.60/kg

Cotton’s ecosystem of spinning, weaving, and dyeing facilities worldwide also reduces freight and conversion costs. In contrast, bamboo spinning and knitting capacity remains concentrated in East Asia—primarily China, with growing hubs in India and Vietnam—leading to higher logistics costs for Western brands.

For mass-market apparel, cotton remains unbeatable in scalability and predictability. But for brands seeking differentiation, the price premium of bamboo can be repositioned as an investment in sustainability and comfort.

C. The Economics of Blending: Bamboo-Cotton as a Bridge

The bamboo-cotton blend has become a popular solution for buyers balancing cost, comfort, and sustainability. A 60/40 or 50/50 bamboo-cotton blend typically:

- Reduces raw material cost by 15–20% versus pure bamboo.

- Retains 70–80% of bamboo’s moisture-wicking performance.

- Softens handfeel and increases consumer familiarity.

- Meets OEKO-TEX® and GOTS certifications at lower compliance cost.

Blends also ease production integration since existing cotton spinning and weaving machines can process the fiber with minor adjustments. For mid-market brands, this means they can introduce eco-friendly collections without overhauling supply chains.

Market Data Example:

- A 100% cotton T-shirt fabric (180 GSM) costs around $2.50/yard FOB China.

- A 100% bamboo viscose fabric (180 GSM) costs $3.80/yard.

- A 60/40 bamboo-cotton blend fabric (180 GSM) averages $3.10/yard, offering a balanced proposition between cost and performance.

D. Logistics and Tariffs

Freight and tariffs can further influence landed costs. Bamboo fabrics, often shipped from East Asia, are subject to standard textile duties in major markets. In the U.S., import tariffs for regenerated cellulose fabrics range 8–12%, compared with 5–8% for cotton textiles.

European buyers face fewer tariff differences under most-favored-nation (MFN) rules but must comply with REACH chemical regulations, adding minor testing costs for bamboo viscose.

Buyer Strategy:

- Consolidate orders across multiple SKUs to reduce per-yard freight cost.

- Consider nearshoring cotton or bamboo-cotton blends for faster turnaround in mid-market programs.

- Position bamboo fabrics under eco or performance collections to justify retail markups.

E. Retail and Consumer Behavior: Paying for Perceived Value

Although bamboo apparel can be 15–30% more expensive at retail, consumers increasingly associate bamboo textiles with wellness, comfort, and eco-conscious living. Market data from Mintel and Statista show that over 60% of Gen Z and Millennial consumers are willing to pay a premium for fabrics marketed as “sustainable” or “natural performance.”

A U.S. mid-market T-shirt company introduced a bamboo-cotton hybrid line priced 15% above its cotton basics. Within three months, sales volume increased 22%, primarily due to repeat purchases from customers citing improved softness and freshness. This illustrates that while production cost is higher, the consumer’s perceived value offsets the gap and supports higher profit margins.

F. Cost Efficiency Outlook (2025–2027)

| Cost Driver | Short-Term Trend | Impact on Bamboo Competitiveness |

|---|---|---|

| Fiber Production (China/India) | Expanding capacity, lower input costs | ↓ 5–10% price reduction expected |

| Eco-Processing Technologies | Growth in closed-loop Lyocell processes | ↓ Processing cost by 8–12% |

| Consumer Demand | Rising eco-consciousness in apparel | ↑ Enables sustainable price premium |

| Energy & Transport | Ongoing volatility | Neutral; affects both cotton and bamboo |

By 2027, experts project the bamboo-cotton price gap to shrink to 10–15%, making bamboo blends economically feasible for larger-scale adoption across T-shirts, underwear, and bedding categories.

Is Bamboo Economically Practical?

While bamboo remains more expensive to produce than cotton, the difference is narrowing. The true practicality lies not in matching price per yard but in maximizing value per garment:

- Pure Bamboo: Best for high-margin eco or performance lines.

- Bamboo-Cotton Blends: Ideal for mainstream everyday wear—balanced cost, comfort, and sustainability.

- Cotton: Continues as the cost leader for mass production but lacks bamboo’s differentiating appeal.

For buyers, the most effective approach is to budget by segment:

- Core range (cotton basics): $2–3/yard

- Mid-tier eco range (bamboo-cotton): $3–3.5/yard

- Premium sustainable line (pure bamboo): $4–6/yard

By aligning fiber choice with target market and perceived brand value, apparel manufacturers can introduce bamboo strategically—not as a cost burden, but as a premium differentiator that fits evolving consumer priorities.

How Do Durability and Wash Performance Compare for Bamboo Fabric vs Cotton?

Durability remains one of the most decisive criteria for textile buyers and apparel brands, especially as sustainability and longevity become intertwined in consumer expectations. While bamboo fabric is often marketed as “stronger than cotton,” the reality is nuanced: both materials perform differently depending on fiber processing, finishing quality, and wash conditions.

Bamboo fibers—especially regenerated bamboo viscose and lyocell types—excel in wet strength and dimensional stability, while cotton’s advantage lies in its consistent softness and wear comfort even after years of laundering.

Bamboo fabrics are stronger when wet and resist deformation, but they may lose softness over time without proper finishing. Cotton fabrics weaken when wet but maintain consistent softness after repeated washing, making them highly reliable for everyday garments.

Durability & Wash Test Comparison

| Factor | Bamboo Fabric | Cotton Fabric | Buyer Implication |

|---|---|---|---|

| Wet Strength | 30–40% stronger when wet | Weakens up to 20% when wet | Bamboo resists deformation and tearing during washing |

| Shrinkage | Low to moderate with lyocell finishing | Moderate to high if untreated | Bamboo blends more dimensionally stable |

| Pilling Resistance | High – smooth fibers minimize abrasion | Variable – combed cotton better than carded | Bamboo ideal for premium apparel |

| Softness Retention | May stiffen after multiple washes unless enzyme finished | Retains soft handfeel even after 50+ cycles | Cotton wins on comfort consistency |

| Colorfastness | Excellent with low-impact dyes | Depends on dye chemistry | Comparable when certified dye systems are used |

A. Bamboo’s Wet Strength Advantage

Bamboo’s unique molecular alignment and lower hydrogen bond disruption give it exceptional wet strength—an uncommon feature among cellulosic fibers. During laundering, when fibers are swollen with moisture, bamboo retains 30–40% higher tensile strength compared to cotton. This means bamboo garments experience less stretching, sagging, or tearing during wash agitation.

In practical terms, bamboo fabrics—especially those spun from bamboo lyocell—maintain shape integrity even after dozens of wash cycles. This makes them ideal for T-shirts, leggings, and sleepwear that undergo frequent laundering.

Technical Insight:

- Tensile strength (dry): 450–550 MPa (bamboo) vs. 350–450 MPa (cotton).

- Tensile strength (wet): 500–600 MPa (bamboo) vs. 280–350 MPa (cotton).

- This explains why bamboo often feels sturdier after repeated washing cycles.

However, surface finishes matter: bamboo viscose without softening treatment can develop stiffness over time due to fiber oxidation and microfibrillation (tiny surface fibrils forming from repeated agitation).

B. Cotton’s Softness Stability and Familiar Longevity

Cotton has endured as a global standard for a reason—it maintains predictable comfort and softness even as it ages. Although cotton fibers lose tensile strength when wet (typically by 15–20%), their cellulose crystalline zones remain stable, allowing the fiber to bounce back after drying.

Repeated washing gradually removes surface waxes and finishes, actually improving softness in most cotton fabrics. Enzyme-washed or pre-shrunk cotton garments show minimal stiffness even after 50+ domestic wash cycles, making them the benchmark for long-term softness.

Buyer Insight: This explains why cotton dominates T-shirts, towels, and denim—categories where familiar softness and durability through repeated wear are more important than maintaining a “brand-new” texture.

C. Shrinkage and Dimensional Stability

Shrinkage is often a hidden durability issue that impacts garment sizing consistency and customer satisfaction. Bamboo fabrics, particularly bamboo lyocell or blended fabrics, exhibit lower dimensional change (2–4%) compared to untreated cotton, which can shrink up to 8–10% if not sanforized or pre-shrunk.

Why it matters:

- Bamboo’s cross-linked molecular chains limit fiber retraction under moisture and heat.

- Cotton’s helical structure causes relaxation shrinkage when fibers absorb water, making post-finishing critical in cotton garments.

Recommendation for Buyers: To ensure fit stability in cotton apparel, request sanforized or mercerized finishes. For bamboo garments, confirm that finishing involves controlled drying to prevent post-sewing shrinkage during consumer laundering.

D. Pilling and Surface Wear

Bamboo fibers have a smooth longitudinal surface, minimizing friction and reducing lint formation. As a result, bamboo knitwear and activewear show 30–40% fewer pilling occurrences in abrasion tests (Martindale or ICI method).

Cotton’s surface irregularities make it more prone to pilling, especially in carded yarns or low-twist constructions. High-quality combed cotton narrows the performance gap significantly, though bamboo remains superior for maintaining a clean, sleek surface after extended wear.

E. Softness Retention: A Trade-Off of Time vs. Finish

While bamboo feels luxurious at first wear, it may gradually lose that silky finish unless treated with enzymatic softeners or silicone coatings. Over multiple laundering cycles, friction and detergent residues can dull the surface luster.

Cotton, conversely, benefits from mechanical agitation—it softens over time due to the loosening of fiber bundles. This “worn-in” comfort is one of cotton’s strongest consumer advantages and a key reason it dominates home textiles and casualwear markets.

Best Practice: Premium bamboo brands often incorporate enzyme-wash finishing to maintain tactile smoothness. Buyers sourcing bamboo apparel should request data on softness retention tests (after 10, 30, and 50 wash cycles) before bulk approvals.

F. Colorfastness and Dye Behavior

Both fabrics can achieve strong colorfastness when dyed responsibly, but there are differences:

- Bamboo viscose: Bonds well with reactive or low-impact dyes and maintains brightness even after 30+ washes.

- Cotton: More variable—color loss can occur if dyeing involves non-reactive processes or over-bleaching.

When sourced from OEKO-TEX® or GOTS-certified mills, both fabrics perform comparably in color retention. Bamboo’s advantage lies in requiring less salt and alkali during dyeing, which aligns with sustainable wet processing initiatives.

European Laundry Lab Study

A certified textile lab in Germany tested bamboo and cotton T-shirts (both 160 g/m² jersey fabrics) over 50 wash cycles at 40°C. Results:

- Bamboo T-shirts retained 92% of tensile strength but lost 12% of initial softness due to surface wear.

- Cotton T-shirts retained 97% of softness but dropped to 78% of tensile strength, primarily from fiber breakage under stress.

Interpretation: Bamboo offers longer mechanical life and better appearance retention, while cotton sustains tactile comfort. The optimal choice depends on whether the buyer prioritizes longevity or sensory comfort.

Choosing Durability That Matches Market Expectations

Both bamboo and cotton can last years, but their endurance manifests differently:

- Bamboo resists deformation, pilling, and color fading, making it ideal for performance or travel wear.

- Cotton maintains comfort and softness with predictable washing behavior, perfect for high-frequency use garments.

For sourcing professionals, the decision should balance target market, brand positioning, and aftercare expectations. Bamboo fits brands prioritizing eco-luxury and durability under frequent wash, while cotton remains the foundation of mass-market reliability and tactile familiarity.

Ultimately, neither fiber is universally superior—the right choice depends on whether your customer values a fabric that stays strong or a fabric that stays soft.

Are There Health or Safety Differences (Chemical Residues, Allergens) Between Bamboo and Cotton Materials?

As consumers grow more aware of the connection between textiles and health, the question of which fabric is safer for skin—bamboo or cotton—has become increasingly important. Both fibers are derived from natural sources, but their processing methods, chemical treatments, and finishing practices create very different safety profiles. The distinction between natural fiber origin and manufacturing process outcome is crucial when assessing hypoallergenic and dermatological safety.

Bamboo lyocell and certified bamboo textiles are generally hypoallergenic, antibacterial, and gentle on sensitive skin, while uncertified bamboo viscose may retain chemical residues from harsh processing. Cotton remains dermatologically safe but may pose irritation risks if sourced from pesticide-intensive farms or dyed with non-compliant colorants. Ultimately, certifications like OEKO-TEX®, GOTS, or REACH serve as the key safety equalizers for both materials, ensuring the absence of toxic residues.

Health & Safety Comparison

| Factor | Bamboo Fabric | Cotton Fabric | Risk Level |

|---|---|---|---|

| Hypoallergenic | Naturally hypoallergenic; smooth microstructure reduces irritation | Generally safe; may irritate if rough or chemically finished | ✅ Bamboo preferred for babywear & underwear |

| Chemical Residues | Low in bamboo lyocell; higher risk in bamboo viscose if uncertified | Pesticide or dye residues possible in non-organic cotton | ⚠ Certification minimizes both risks |

| Antibacterial Properties | Naturally resistant to bacteria and odor | Retains moisture, may harbor bacteria over time | ✅ Bamboo remains fresher and more hygienic |

| Skin Comfort | Silky handfeel and temperature-regulating | Soft but may feel coarse depending on yarn grade | ✅ Bamboo offers superior comfort for sensitive skin |

| Allergen Potential | Very low, suitable for eczema-prone users | Possible allergen exposure if chemical-treated | ✅ Bamboo better tolerated dermatologically |

A. Bamboo’s Skin-Friendly Profile

Bamboo fibers—particularly those made via mechanical or lyocell processes—are prized for their hypoallergenic and antibacterial properties. The natural structure of bamboo cellulose creates ultra-smooth, rounded fibers that minimize friction against the skin. Unlike some cotton yarns, which have tiny hooks or irregular surfaces, bamboo’s microstructure feels silky and glides easily across the skin.

In dermatological testing, bamboo fabrics have shown reduced irritation scores among people with eczema, dermatitis, or psoriasis. Studies by the Japanese Textile Research Institute (2022) confirmed that bamboo’s surface friction coefficient was 30–40% lower than conventional cotton, improving comfort and reducing redness.

Moreover, bamboo fibers naturally resist bacterial growth thanks to bamboo kun, an organic antimicrobial bio-agent present in the plant. Even after 50 laundering cycles, bamboo fabrics maintained a 70% reduction in bacterial colonization compared to untreated cotton, according to independent testing by Intertek Labs.

Babywear, underwear, sleepwear, and medical textiles benefit most from bamboo’s natural hypoallergenic properties, especially in markets like Germany, Japan, and Scandinavia where skin sensitivity rates are high.

B. Cotton’s Trusted Yet Complex Safety Record

Cotton’s legacy in human clothing spans thousands of years, and it remains one of the most biocompatible fabrics in the world. When grown and processed under safe conditions, cotton is breathable, soft, and non-irritating. However, the industrialization of cotton farming has introduced health concerns linked to agrochemical exposure and textile finishing agents.

- Pesticides and Fertilizers: Conventional cotton uses about 16% of global insecticide consumption, introducing the risk of residues persisting in raw fiber or soil.

- Dyeing and Finishing Chemicals: Formaldehyde-based resins, chlorine bleaches, and azo dyes are sometimes used to achieve wrinkle resistance or bright colors. These chemicals can cause skin sensitivity or allergic reactions if not fully removed during finishing.

- Residual Risks: Even trace levels of finishing agents like nonylphenol ethoxylates (NPEs) have been restricted under EU REACH regulations due to endocrine-disrupting potential.

Industry Trend: More brands are switching to organic cotton (GOTS-certified) and enzymatic finishing to eliminate formaldehyde-based resins and chlorine bleaching, aligning with rising consumer demand for “clean” fabrics.

C. Certifications as the Great Equalizer

No matter how natural a fiber is, certification is the only verifiable guarantee of consumer safety. In global textile sourcing, three certifications dominate health and chemical compliance standards:

| Certification | Applicable Fiber | Key Testing Criteria | Health Assurance |

|---|---|---|---|

| OEKO-TEX® Standard 100 | Bamboo & Cotton | Tests for 350+ harmful substances | Ensures residue-free safety |

| GOTS (Global Organic Textile Standard) | Cotton & Organic Bamboo | Organic farming + low-impact dyes | Certifies eco-safe & skin-friendly production |

| REACH Compliance (EU) | All Fabrics | Restricts hazardous chemical use | Ensures European market readiness |

- OEKO-TEX® Standard 100 ensures textiles are free from harmful substances like formaldehyde, heavy metals, and carcinogenic dyes.

- GOTS (for organic production) mandates pesticide-free farming and non-toxic finishing.

- REACH governs chemical usage across EU imports, banning over 2,000 high-risk substances.

Buyer Note: Always request certification with batch-specific test numbers—not just logo claims—to avoid greenwashing.

D. Case Example: German Babywear Brand Transition

A German babywear manufacturer (2023) previously sourced uncertified cotton garments but faced growing customer complaints about skin irritation. After transitioning to OEKO-TEX® bamboo lyocell fabrics, post-launch surveys recorded:

- 40% reduction in reported skin sensitivity issues.

- 60% increase in repeat purchase rate among parents citing “skin-safe fabrics.”

- A measurable sales increase of 28% in eco-conscious European markets.

The brand leveraged these improvements in its marketing strategy under the tagline: “Pure Comfort, Certified Safe.”

E. Not All Bamboo Is Automatically Non-Toxic

While bamboo is marketed as naturally “chemical-free,” not all bamboo fabrics meet this standard. Bamboo viscose, produced through chemical pulping, may retain trace amounts of sodium hydroxide or carbon disulfide—both harmful if not properly neutralized. Only closed-loop lyocell systems achieve near-zero solvent discharge and residue-free results.

Buyers should distinguish between:

- Mechanically processed bamboo (bamboo linen) → Most natural, but coarse texture.

- Bamboo viscose (chemical process) → Soft and smooth but potential residue risks.

- Bamboo lyocell (closed-loop) → The safest and most sustainable commercial form.

Best Practice: Request fiber origin documentation and OEKO-TEX® or GOTS test reports from every batch. Reliable suppliers in China, India, and Indonesia can provide traceable audit trails from pulp to finished fabric.

From a health and dermatological standpoint, both bamboo and cotton can be safe and hypoallergenic—if properly certified and processed. The difference lies primarily in:

- Processing: Bamboo lyocell is cleaner and residue-free; uncertified viscose may pose risks.

- Cultivation: Organic cotton is safe but conventional cotton may carry pesticide residues.

- Comfort: Bamboo’s smooth fiber surface provides superior comfort for sensitive skin.

- Certification: OEKO-TEX® and GOTS neutralize health risks for both fabrics.

For sensitive-skin consumers, babywear, lingerie, or wellness apparel, bamboo—especially in lyocell form—remains the top dermatological choice. Cotton remains a trusted, breathable, and familiar alternative, particularly when organically produced and responsibly finished.

The key takeaway for both manufacturers and buyers: Safety isn’t defined by the fiber itself, but by the transparency of its supply chain and certification rigor.

Which Fabric Requires More Maintenance and Has Better Wrinkle Recovery—Bamboo or Cotton?

Wrinkle resistance and maintenance are not just consumer concerns—they directly impact aftercare costs, energy consumption, and product longevity for apparel brands, laundries, and uniform programs. Both bamboo and cotton have established reputations: bamboo for its easy-care performance and cotton for its wash durability. However, the science behind these behaviors lies in their fiber morphology and cellulose structure, which dictate how they respond to washing, drying, and ironing cycles.

Bamboo fabrics resist wrinkles better and require less ironing, making them ideal for casual and travel apparel. Cotton wrinkles more easily but withstands higher wash temperatures and industrial laundering, offering longer life cycles for heavy-use garments such as uniforms and hospital wear.

Maintenance & Wrinkle Recovery Comparison

| Factor | Bamboo Fabric | Cotton Fabric | Buyer Implication |

|---|---|---|---|

| Wrinkle Resistance | Naturally resists deep creasing due to smooth fiber structure | Wrinkles easily, especially in plain or poplin weaves | Bamboo ideal for low-maintenance, ready-to-wear apparel |

| Ironing Requirements | Minimal; light steaming sufficient | Frequent ironing needed to restore shape | Bamboo lowers energy/labor costs in post-wash care |

| Wash Temperature Tolerance | Cool to medium (30–40°C) to prevent fiber weakening | Hot washable (up to 60°C+), can withstand boiling in institutional settings | Cotton favored for industrial laundering |

| Shrinkage Control | Low in lyocell or blended forms; stable post-finishing | Moderate to high in untreated cotton (3–5%) | Bamboo-cotton blends balance shrinkage and comfort |

| Drying & Handling | Quick-drying due to moisture-wicking ability | Slow-drying; tends to stiffen if air-dried | Bamboo reduces drying time and energy use |

| Finish Longevity | May lose slight sheen over time without enzyme or mercerized finish | Softens with repeated washing, retains comfort | Cotton remains durable through repeated laundry cycles |

A. Bamboo’s Easy-Care Advantage

Bamboo fibers feature a smooth, round cross-section and a low surface friction coefficient, meaning they naturally resist deep creases. Unlike cotton’s twisted fiber shape, which locks wrinkles into place during drying, bamboo fibers spring back to shape when exposed to light moisture or steam.

This makes bamboo ideal for wrinkle-free travel clothing, uniforms, and ready-to-wear garments. Modern bamboo lyocell fabrics—processed through closed-loop systems using NMMO solvents—demonstrate excellent dimensional stability even after 50+ wash cycles.

In wrinkle recovery testing (ISO 2313:2016), bamboo-lyocell fabrics achieved wrinkle recovery angles of 280–300°, compared to cotton’s 220–240°, confirming bamboo’s superior resilience.

Consumer Benefit: Bamboo garments can typically be air-dried and lightly steamed instead of ironed—saving time, electricity, and fabric wear.

Brand Insight: This easy-care behavior is particularly attractive to buyers targeting urban professionals, travelwear consumers, and eco-conscious shoppers who prioritize convenience and low-maintenance textiles.

B. Cotton’s Strength Under Stress

Cotton’s advantage lies in its wash durability and thermal tolerance. As a natural fiber with a crystalline cellulose structure, cotton can withstand repeated high-temperature laundering (60°C or more) without fiber breakdown. It is also compatible with bleaching and commercial detergents, making it the fiber of choice for:

- Hotel and hospital linens

- Industrial uniforms

- School and institutional wear

However, cotton’s molecular hydrogen bonds break easily during drying, which leads to persistent wrinkling—particularly in tightly woven fabrics like poplin or percale. Cotton fabrics regain smoothness only under mechanical pressing or steam ironing, increasing maintenance time and costs.

Technical Note: Wrinkle recovery for standard cotton poplin averages 210–230°, and enzyme or resin finishes (e.g., DMDHEU) can improve this to 260–280°, though with slight reduction in softness.

Buyer Implication: While cotton requires higher aftercare, it remains the most cost-efficient choice for industrial-scale laundering where high-temperature sterilization is mandatory.

C. Blends: The Middle Ground in Care and Performance

To reduce maintenance without sacrificing wash durability, many mills and brands now offer bamboo-cotton or bamboo-polyester blends:

- Bamboo-Cotton (60/40): Improves wrinkle resistance by 25–30% over pure cotton, with better drape and softness.

- Bamboo-Polyester (50/50): Adds resilience and reduces shrinkage while maintaining moisture management.

- Performance Finishes: Enzyme softening or siliconizing further enhance smoothness and easy ironing.

These blends perform well in both domestic and commercial laundry settings, offering a practical compromise between sustainability, comfort, and care convenience.

D. Industrial and Environmental Cost of Maintenance

While consumers focus on convenience, brands and institutions must also consider the energy and environmental cost of garment maintenance.

- Energy Savings: Bamboo fabrics, with quick-dry capability, cut drying time by 20–30%, lowering electricity consumption.

- Water Savings: Lower ironing and hot washing requirements reduce hot water usage per garment lifecycle.

- Longevity vs. Turnover: Cotton’s longer garment life (especially in uniforms) offsets maintenance cost, while bamboo’s reduced care requirements lower ongoing operational expenses.

Example: A hotel in Bangkok that switched staff shirts from 100% cotton to bamboo-cotton blends reported 30% less ironing time and 25% lower steam energy costs, while the uniforms retained color and shape for over 18 months.

E. Finishing Treatments That Influence Wrinkle Behavior

| Finish Type | Function | Typical Application | Notes |

|---|---|---|---|

| Resin (Wrinkle-Free) Finish | Cross-links cellulose to resist creasing | Cotton shirting, uniforms | May reduce softness slightly |

| Enzyme Treatment | Breaks surface fuzz for smoother handfeel | Bamboo and cotton blends | Enhances luster and reduces lint |

| Mercerization | Swells cotton fibers, increasing strength and sheen | Premium cotton apparel | Improves dye uptake, minor wrinkle resistance |

| Silicone or Softener Finish | Improves handfeel and slip | Bamboo knits, T-shirts | Adds surface smoothness for low-friction touch |

Bamboo fabrics typically rely on enzyme or silicone finishing, which are milder and more sustainable than the resin-based wrinkle-free treatments often used on cotton. This supports bamboo’s eco-friendly positioning while keeping maintenance simple.

F. Case Example: Southeast Asian Hotel Uniform Trial

A major hotel chain in Southeast Asia tested pure cotton vs bamboo-cotton uniforms across three departments over six months:

- Wrinkle Management: Bamboo-cotton blends required 30% less ironing time.

- Durability: Cotton uniforms survived 20% more wash cycles before fading.

- Maintenance Cost: Total energy and labor savings for bamboo-blend uniforms reached 15% annually, despite slightly higher fabric cost.

Conclusion: The hotel retained cotton for high-wear housekeeping uniforms but adopted bamboo-cotton for front-desk and concierge staff—where presentation and wrinkle-free appearance mattered more.

G. Final Evaluation: Maintenance vs. Longevity Trade-Off

| Category | Bamboo | Cotton | Verdict |

|---|---|---|---|

| Wrinkle Recovery | Excellent (280–300°) | Moderate (210–230°) | ✅ Bamboo wins |

| Ironing Effort | Minimal | Frequent | ✅ Bamboo wins |

| Wash Durability | Medium | High | ✅ Cotton wins |

| Shrinkage Control | Low (processed) | Moderate–High (untreated) | ✅ Bamboo wins |

| Industrial Suitability | Moderate | Excellent | ✅ Cotton wins |

| Sustainability in Aftercare | Lower energy/water use | Higher energy for hot washing | ✅ Bamboo wins |

Which Fabric Truly Performs Better?

Both bamboo and cotton excel in their own domains.

- Bamboo stands out for low-maintenance garments, offering wrinkle resistance, quick-dry convenience, and eco-friendly aftercare savings. It’s the smarter choice for casualwear, resortwear, and front-office uniforms where appearance and efficiency matter.

- Cotton, on the other hand, remains the champion for industrial laundering and long-term durability, especially in healthcare, hospitality, and institutional settings where resilience under harsh washing conditions is non-negotiable.

For sourcing teams, the best results often come from bamboo-cotton blends, which combine bamboo’s wrinkle resistance with cotton’s ruggedness—offering a pragmatic balance between appearance, care efficiency, and lifecycle value.

How Should Brands Decide Whether to Choose Bamboo, Cotton, or a Blend for Specific Clothing Categories (Shirts, Activewear, Dresses)?

There is no universal winner between bamboo and cotton. Every fiber brings distinct advantages depending on garment function, climate, consumer perception, and price positioning. For apparel brands, the most effective sourcing strategy lies in aligning fabric properties with end-use performance and target market expectations.

Brands should use bamboo for luxury and eco-conscious lines, cotton for mainstream and cost-sensitive products, and bamboo-cotton blends for balanced performance in shirts, activewear, and dresses.

Category-Based Fabric Strategy

| Category | Best Fabric Choice | Why It Works | Example Use Case |

|---|---|---|---|

| Shirts | Bamboo–Cotton Blend (50/50) | Soft, breathable, affordable | Office wear, casual button-downs |

| Activewear | Bamboo (lyocell) + Spandex | Breathable, odor-resistant, flexible | Yoga wear, gym T-shirts |

| Dresses | Bamboo or Bamboo–Silk Blends | Elegant drape, luxurious feel | Summer dresses, resort wear |

| Uniforms | Cotton or Cotton–Poly Blends | Withstands high-temperature washing, durable | School and service uniforms |

| Babywear | Certified Bamboo (OEKO-TEX®) | Hypoallergenic, gentle on skin | Onesies, baby wraps |

A. Shirts & Casualwear: Balancing Comfort, Breathability, and Cost

Performance Logic: Shirts demand a balance between structure, breathability, and fabric handfeel. Pure cotton shirts dominate global markets for their crisp finish and reliable comfort, but they wrinkle easily and can feel warm in humid climates.

Bamboo–cotton blends (typically 50/50 or 60/40) solve these challenges:

- Bamboo introduces a silky touch and better cooling properties.

- Cotton provides body and stability, maintaining that familiar crisp drape.

- The blend also reduces wrinkling by up to 25% and enhances moisture management.

Market Reality: Bamboo–cotton shirts are gaining traction in tropical and warm-weather markets such as Southeast Asia and Southern Europe, where heat comfort and sustainability are strong consumer motivators.

Use Case Example: A U.S. officewear brand replaced its standard cotton poplin with bamboo–cotton sateen for its business casual line. Customers cited a noticeable cooling effect and reduced ironing needs. Within two seasons, the brand recorded a 12% increase in repeat purchases among eco-conscious consumers.

B. Activewear: Performance Meets Sustainability

Activewear fabrics must manage sweat, movement, and durability. Here, bamboo’s moisture-wicking and antibacterial capabilities outperform cotton. Its smooth surface reduces friction, while natural antimicrobial properties minimize odor buildup—key advantages for yoga, gym, and athleisure segments.

When blended with spandex (5–10%), bamboo fabric offers:

- High elasticity without losing softness.

- Fast moisture evaporation, comparable to synthetic technical fibers.

- Eco-positioning, offering a natural alternative to polyester-heavy sportswear.

Comparative Benchmark:

- Bamboo–spandex knits show 20–25% higher breathability and lower odor retention than cotton jersey in lab tests.

- Cotton-based activewear absorbs moisture but dries slowly, often leading to discomfort during prolonged activity.

Brand Example: A yoga apparel company in the UK replaced polyester-cotton leggings with bamboo–spandex blends. The result: customer satisfaction scores rose 30%, and returns due to “fabric cling” dropped by half. Marketing the fabric as “plant-based performance” also increased organic search traffic by 20%.

C. Dresses & Luxury Apparel: Drape, Aesthetics, and Brand Storytelling

In women’s fashion, especially resortwear and evening dresses, fabric drape and sheen define perceived luxury. Bamboo’s fluid fall, gentle gloss, and skin-cooling touch make it an elegant alternative to silk or viscose.

Performance Attributes:

- Drape coefficient of 0.85–0.90, comparable to rayon and silk charmeuse.

- Natural sheen enhances color vibrancy, especially in botanical dye collections.

- Lightweight yet strong, bamboo dress fabrics resist tearing and maintain silhouette integrity even in humid climates.

Luxury Positioning: High-end brands use bamboo–silk or bamboo–cotton blends to merge elegance with eco-conscious storytelling. These combinations create a sustainable luxury narrative aligned with EU Green Deal textile guidelines and premium consumer values.

Example: A Milan-based designer brand introduced a bamboo–silk capsule collection for its summer resort line. The fabric’s natural luster and drape reduced the need for synthetic linings, cutting material use by 18% while preserving a couture look.

D. Uniforms: Durability and Maintenance Efficiency

Uniforms and service apparel prioritize longevity, easy care, and cost control. Cotton and cotton–polyester blends remain the best choices due to their:

- Resistance to frequent industrial washing (60–90°C).

- Durability under mechanical stress.

- Predictable shrinkage and finishing behavior.

While bamboo offers strength and breathability, it lacks the heat resilience required for high-temperature sanitation processes common in hospitality, healthcare, and education uniforms.

However, some brands are experimenting with ramie–bamboo–cotton hybrids, leveraging ramie’s strength and bamboo’s comfort for eco-upgraded uniforms that still meet performance standards.

E. Babywear: Safety, Purity, and Skin Sensitivity

For infants and toddlers, the priority is safety and skin compatibility. Bamboo’s hypoallergenic and antibacterial properties make it highly suitable for this segment. The fibers’ smooth structure minimizes irritation, and bamboo fabrics naturally resist dust mites and odors.

Certification Note: Buyers should source from OEKO-TEX® Standard 100 or GOTS-certified mills to ensure the fabric is free from formaldehyde, azo dyes, or heavy metals.

Market Insight: Babywear brands in Northern Europe increasingly use bamboo interlock knits and bamboo–cotton blends for onesies, wraps, and undergarments, citing superior softness and a “gentle cooling” sensation for babies’ skin.

Case Example: Multi-Category Portfolio Strategy

A UK-based apparel startup developed a three-tier product strategy:

- Bamboo–Spandex Activewear for yoga and fitness lines.

- Pure Cotton Basics for affordable mass-market T-shirts and polos.

- Bamboo–Cotton Blended Shirts for premium casualwear.

Results after 12 months:

- Bamboo-based lines achieved 40% higher profit margins due to premium pricing and lower returns.

- Cotton basics sustained volume sales, maintaining steady cash flow.

- Blended shirts became the brand’s top-rated product in consumer reviews.

This diversified sourcing approach demonstrated that bamboo and cotton are complementary, not competing fibers—each strengthening different segments of a brand’s portfolio.

Strategic Fabric Matching by Market Tier

Successful apparel brands treat fabric selection as a strategic segmentation tool, not just a sourcing decision.

- Bamboo → Ideal for premium, eco-conscious, and performance apparel, where drape, softness, and moisture control drive value.

- Cotton → Best for mass-market basics and heritage categories, offering comfort, affordability, and supply chain maturity.

- Blends (Bamboo–Cotton or Bamboo–Silk) → The sweet spot for balanced performance, allowing scalability with premium perception.

For long-term success, brands should align fabric choices with both market tier and lifecycle demands—using bamboo for emotional appeal and comfort innovation, and cotton for dependable everyday wear. The future lies not in choosing one over the other, but in integrating both strategically to serve diverse consumer needs with sustainable credibility and performance excellence.

The debate between bamboo and cotton isn’t about one being universally better—it’s about context. Bamboo excels in comfort, breathability, wrinkle resistance, and eco-marketing, making it ideal for luxury wear, activewear, and baby clothing. Cotton remains unbeatable in affordability, availability, and heavy-duty durability, making it the backbone of global apparel. Blends of the two often deliver the best of both worlds.

For apparel brands, the key lies in aligning fabric choices with product positioning, cost strategy, and consumer expectations. Certifications such as OEKO-TEX® and GOTS further ensure both bamboo and cotton meet global compliance and safety standards.

At SzoneierFabrics, we specialize in custom bamboo, cotton, and blended fabrics, helping global apparel companies design collections that balance sustainability, performance, and cost. With flexible MOQs, fast sampling, in-house design, and certified production, we deliver fabrics that meet both creative and commercial needs.

Contact SzoneierFabrics today to request a customized quotation, explore sampling options, and find the right bamboo, cotton, or blended fabric for your next clothing collection.