In today’s fast-paced textile industry, polyester remains one of the most in-demand fabrics for fashion, upholstery, activewear, and industrial applications. Behind its global reach are manufacturers constantly pushing the envelope in quality, sustainability, and customization. But how do you identify the top players in a crowded field? The best polyester fabric manufacturers in 2025 are identified by their innovation in fiber technology, eco-certifications, flexible MOQ policies, advanced machinery, and strong export capabilities. Leading suppliers are based in China, India, South Korea, Turkey, and Taiwan, offering both standard and custom solutions tailored to diverse industry needs.

Understanding which suppliers deliver consistent quality, meet global compliance standards, and offer scalable solutions is key to choosing the right partner. Whether you’re sourcing for a performance sportswear brand or luxury interior label, the decision shapes your product success.

To illustrate this, a European fashion startup once struggled with delayed shipments and inconsistent quality until switching to a certified Chinese polyester mill that offered low-MOQ custom printed fabrics and ISO-controlled processes. This pivot led to a 40% increase in customer retention and reduced return rates. Curious which mills made our list and why? Let’s dive in.

What Are the Key Qualities of the Best Polyester Fabric Manufacturers?

In 2025, polyester fabric manufacturers aren’t just evaluated by the meter—they’re measured by their adaptability, commitment to innovation, and how well they serve brand-specific needs in an ever-evolving marketplace. Whether you’re creating functional sportswear or luxury home furnishings, the best mills today operate as strategic partners who contribute to product success, not just as material suppliers. The best polyester fabric manufacturers in 2025 consistently deliver premium-quality fabrics enhanced with performance finishes, flexible custom development, globally recognized certifications, and smart supply chain systems. What sets them apart is their ability to combine industrial scale with boutique-level responsiveness, offering low MOQs, fast sampling, and technical collaboration from concept to final roll.

What Sets Leading Polyester Mills Apart?

To fully understand how elite polyester fabric manufacturers differ from average suppliers, let’s explore the key differentiators across technology, certifications, R&D, and production agility.

Advanced Production Technology

Manufacturers at the top of the industry are defined by their machinery and how they use it.

- Air-Jet and Rapier Looms: Enable precise high-density weaving, especially important for microfiber polyester, sheer curtains, and soft-touch fashion fabrics.

- Heat-Setting Machines: Improve dimensional stability and shape retention in garments and technical polyester fabrics.

- Digital Printing: Provides exact color mapping and eliminates screen costs, essential for small runs, promotional designs, and brand-specific pantones.

| Technology | Benefit | Usage Example |

|---|---|---|

| Air-Jet Looms | High-speed and consistent fabric width | Performance wear, suiting |

| Digital Print Machines | Low-MOQ customization, vivid detail | Fashion collections, promotional fabric |

| Infrared Heat Setting | Shrinkage and crease control | Drapery, uniforms |

Certifications and Compliance

Buyers today demand not just good fabric—but proof that it’s ethically and safely produced.

- OEKO-TEX Standard 100: Ensures no harmful substances are present in finished polyester fabrics.

- GRS (Global Recycled Standard): Verifies that the yarn comes from verified post-consumer PET waste or industry off-cuts.

- ISO 9001 & 14001: Show a manufacturer’s operational control and commitment to quality and environmental management.

Pro Tip: Always ask for the scope certificate for GRS—not just a mention on the website.

Customization & Fabric Engineering

Innovation isn’t just about looks—it’s about fabric performance. Top manufacturers work closely with clients to co-develop:

- Moisture-Wicking Polyester: For sportswear and outdoor apparel.

- UV-Blocking Fabrics: For tents, shade structures, or sun-protective clothing.

- Antibacterial & Anti-Pilling Treatments: Increasingly common in workwear and reusable bags.

- Mechanical Stretch & Soft-Finish Polyester: Replacing elastane in some markets for recyclability and cost.

| Custom Feature | Application | Sample Use Case |

|---|---|---|

| Moisture-Wicking Finish | Sports T-shirts | Activewear brands |

| UV Resistant Finish | Outdoor textiles | Tents, parasols |

| Brushed Surface Finish | Cozy texture | Blankets, loungewear |

| Antibacterial Coating | Hygiene-critical textiles | Masks, uniforms |

MOQ Flexibility & Sampling Support

Flexibility is the new standard. Whether you’re testing new markets or refreshing SKUs, small-batch capability matters.

- Top-tier factories often support MOQs as low as 100–300 meters for new collections or printed fabrics.

- Sampling Lead Times are typically under 10 days for pre-approved substrates, allowing brands to move quickly from concept to display.

Buyer Tip: Factories offering free or low-cost swatch sets and CAD previews save you time and money in development cycles.

Comparative Overview Table

| Attribute | High-Performing Mills | Average Mills |

|---|---|---|

| R&D Capabilities | Dedicated in-house labs with testing chambers | Limited testing, outsourced innovation |

| Certification Coverage | OEKO-TEX, GRS, ISO9001, ISO14001 | May lack traceability or proof |

| MOQ Range | 100–500 meters for customized fabrics | Usually 1000–3000 meters minimum |

| Design Support | CAD previews, free swatches, custom dye lab dips | Basic prints, no sample support |

| Production Speed | 7–15 days sampling, 15–25 days bulk | 20–30 days sampling, longer production lead |

Real Case Study

A European interior furnishing company sourcing brushed polyester velvet for hotel decor faced consistent color discrepancies and slow response times from a South Asian mill. They switched to a Turkish manufacturer offering OEKO-TEX-certified polyester with tight batch-to-batch shade matching and a low MOQ of 300m per color. The result? A 70% reduction in fabric return rates, on-time hotel installation, and improved client satisfaction—without increasing cost.

Which Countries Dominate the Polyester Fabric Manufacturing Landscape?

In today’s global textile economy, polyester remains the most widely used synthetic fabric—and its manufacturing is highly concentrated in specific countries that offer the right combination of volume capacity, cost-efficiency, environmental compliance, and innovative textile technologies. As of 2025, the five countries that dominate polyester fabric manufacturing are China, India, South Korea, Taiwan, and Turkey. Each holds a unique advantage: China and India for mass production and cost-effective blending; South Korea and Taiwan for cutting-edge polyester technologies and functional textiles; Turkey for premium quality and proximity to the European market. Together, these regions shape the bulk of global polyester sourcing strategies.

Regional Strengths and Strategic Supplier Differentiation

Understanding the capabilities of each country helps buyers select the right sourcing location based on quality expectations, compliance needs, customization demands, and budget.

1. China – The Customization Giant with Unmatched Scale

- Key Hubs: Zhejiang (Shaoxing), Jiangsu (Suzhou), and Guangdong (Guangzhou)

- Specialties: Printed polyester, suede-like polyester, velvet, peach skin, brushed, satin, oxford polyester, and coated fabrics

- Strengths:

- Thousands of polyester mills offering diverse price points

- Fast sampling (5–7 days) and low MOQ custom orders (as low as 100m)

- Strong expertise in digital printing, coating, laminating, and composite polyester

- Large pool of suppliers holding OEKO-TEX, ISO, and GRS certifications

Real-World Insight: A U.S. bag brand reduced its lead time by 35% by shifting to a Shaoxing-based mill offering digital-printed polyester canvas with waterproof PU coating, low MOQ (200m), and 12-day turnaround.

2. India – The Global Hub for Blends and Economical Supply

- Key Hubs: Surat (Gujarat), Erode and Karur (Tamil Nadu)

- Specialties: Polyester-cotton blends, dyed polyester shirting, saree fabrics, and spun polyester

- Strengths:

- Competitive pricing due to lower labor and energy costs

- Strong finishing capabilities, especially for dyed and plain-woven polyester

- Expanding eco-compliance focus with rising GRS and OEKO-TEX certifications

- Beneficial for large bulk orders with simplified logistics and flexible payment terms

Data Insight: India’s polyester output is projected to grow 7.6% YoY through 2026, driven by demand for blended fabrics and technical wear across Asia and the Middle East.

3. South Korea – The R&D Leader in Functional Polyester

- Key Hubs: Daegu, Gumi, and Seoul region

- Specialties: High-tenacity polyester, recycled PET (rPET), breathable mesh, sportswear fabrics, and smart textiles

- Strengths:

- Advanced functional finishing: UV-resistance, moisture management, odor control

- In-house R&D for developing proprietary fabric solutions

- Fast prototyping with low MOQs for innovative apparel launches

- Excellent communication and supply reliability

| Innovation | Typical MOQ | Certification Status |

|---|---|---|

| rPET Activewear Knit | 200m | GRS, bluesign® |

| Air Mesh for Sportswear | 300m | OEKO-TEX |

| Antibacterial Warp Knit | 150m | ISO9001, ISO14001 |

Buyer Tip: South Korea is ideal for performance fashion, yoga wear, and functional uniforms where technical specs and traceability matter more than cost alone.

4. Taiwan – Technical and Eco-Responsible Polyester Textiles

- Key Hubs: Tainan, Taichung, and New Taipei

- Specialties: Warp-knitted polyester, spacer fabrics, mesh, industrial polyesters, medical textiles

- Strengths:

- Long-standing expertise in warp knitting and 3D structures

- Among the highest adoption of bluesign® and GRS certification in Asia

- Factories focus on performance, stability, and batch uniformity

- Reliable supply for sectors like medical, automotive, filtration, and industrial apparel

Case Study: A German PPE supplier collaborated with a Taiwanese mill for warp-knitted polyester treated with flame-retardant coating, which passed EN ISO 11612 standard. The quality consistency resulted in a 40% reorder increase in under 6 months.

5. Turkey – High-End Polyester for EU Buyers

- Key Hubs: Bursa, Istanbul, and Gaziantep

- Specialties: Fashion-grade polyester, woven stretch, suitings, dyed chiffon, technical apparel fabrics

- Strengths:

- Fast delivery to Europe (7–12 days by road/rail)

- High dye precision and finishing standards

- Strong quality control systems with ISO, GRS, and OEKO-TEX certification

- Competitive alternative to EU mills, offering lower pricing with comparable compliance

Stat Snapshot: Turkey exported over $4.6 billion in manmade fiber-based textiles in 2024, 58% of which were polyester-dominant.

Country-by-Country Comparison Table

| Country | Core Strengths | Best For | MOQ Range | Certification Focus |

|---|---|---|---|---|

| China | Mass production, customization, print & coating | Bags, outdoor gear, promotional textiles | 100–1000m | OEKO-TEX, GRS, ISO |

| India | Cost-effective blends, dyed polycotton | Casualwear, workwear, uniform fabrics | 300–2000m | OEKO-TEX, GRS (growing) |

| South Korea | High-tech development, low MOQ | Sportswear, innovation brands | 100–500m | GRS, bluesign®, ISO |

| Taiwan | Technical fabrics, industrial use | Automotive, medical, eco-performance | 300–1000m | bluesign®, ISO, OEKO-TEX |

| Turkey | Premium dyeing, fast EU access | Fashion, high-end apparel | 200–1000m | OEKO-TEX, ISO, GRS |

What Certifications Do Top Polyester Fabric Manufacturers Hold?

In today’s compliance-driven market, certifications are more than just badges—they’re powerful assurances of safety, sustainability, and quality. As polyester remains the backbone of various textile products from athleticwear to industrial use, buyers across the globe are no longer willing to compromise on transparency and traceability. Top polyester fabric manufacturers in 2025 typically hold OEKO-TEX Standard 100, GRS (Global Recycled Standard), bluesign®, ISO 9001, and ISO 14001 certifications. These credentials serve as key indicators that fabrics are free from harmful chemicals, environmentally responsible, and manufactured under a consistent and traceable quality system. Certifications are now a strategic necessity—not just for compliance, but also for brand reputation and consumer trust.

Understanding What These Certifications Actually Guarantee

OEKO-TEX Standard 100 – Certified Safety You Can Feel

OEKO-TEX is arguably the most recognized textile certification globally, and it’s vital for any polyester fabric that comes into direct contact with the skin.

- What it Means: The fabric has been tested for over 100 regulated and non-regulated harmful substances, including azo dyes, formaldehyde, heavy metals, and pesticides.

- Verification: Annual re-testing ensures consistency. Every certified batch carries a control number that can be validated online.

- Who Needs It: Brands in fashion, children’s apparel, underwear, bedding, and even accessories can’t skip this certification.

Example: A children’s rainwear company based in Sweden requires all polyester suppliers to show OEKO-TEX certification to meet strict EU health standards and consumer safety laws.

GRS – The Standard for Verified Recycled Polyester

As recycled PET (rPET) takes center stage in sustainable fashion and industrial design, GRS is the go-to certification to ensure legitimacy and integrity in recycled materials.

- What it Covers:

- Recycled content validation (minimum 20% recycled fibers)

- Supply chain traceability across every tier

- Social and environmental practices including restricted substance lists (RSL)

- Why It Matters: Greenwashing is common. GRS certification proves your polyester truly comes from recycled sources and wasn’t simply labeled as such.

Real Buyer Story: A Canadian sports brand increased online conversions by 22% after highlighting its products used GRS-certified rPET polyester from South Korean suppliers. Customers responded strongly to verified eco-claims.

bluesign® – End-to-End Process Transparency

bluesign® is about clean input and responsible output—it starts before the polyester yarn is even spun.

- What It Requires:

- Chemical management of every input (fibers, dyes, auxiliaries)

- Responsible water, energy, and emissions usage

- Worker safety and transparent environmental impact

- Industry Preference: bluesign® is favored by brands like Patagonia, Puma, and Nike, and is mandatory for many outdoor and lifestyle brands targeting eco-aware markets.

Insider Insight: bluesign® suppliers often provide digital dashboards for buyers to monitor CO₂, H₂O, and chemical savings by fabric batch—helping you meet ESG reporting goals and connect with conscious consumers.

ISO 9001 – The Backbone of Quality Control

ISO 9001 ensures that the manufacturing plant has standardized processes, documented controls, and continuous improvement protocols.

- What It Covers:

- Procurement, sampling, and production consistency

- Real-time inspection and testing

- Clear corrective action tracking

- Why It’s Important: ISO 9001-certified polyester manufacturers usually have lower defect rates, faster sampling, and better communication, reducing risk for buyers.

Procurement Tip: Ask for the factory’s most recent ISO 9001 audit report—it often includes non-conformance logs and corrective measures you can review.

ISO 14001 – Environmental Compliance with Global Recognition

This environmental management system certification shows that the manufacturer is actively reducing waste, emissions, and energy consumption.

- What It Includes:

- Emission tracking and reduction targets

- Responsible chemical handling

- Energy-saving plans and audits

- Market Impact: Especially relevant for buyers in Europe, Australia, and North America, where governments increasingly demand green procurement policies.

Certification Comparison Table

| Certification | Focus Area | Verifiable Through | Best For |

|---|---|---|---|

| OEKO-TEX 100 | Chemical & safety compliance | Unique control number | Apparel, bedding, accessories |

| GRS | Recycled content & traceability | Transaction certificates (TCs) | rPET, eco brands, ESG sourcing |

| bluesign® | Environmental + worker safety | bluesign® system partner ID | Technical & sustainable products |

| ISO 9001 | Quality management systems | Audit reports | Consistent QC & defect control |

| ISO 14001 | Environmental management systems | Public declaration | Green procurement alignment |

What Certifications Really Mean for Buyers

In 2025, certifications are not just a checkbox—they’re becoming a sourcing advantage. Here’s how:

- Brand Protection: Certifications like OEKO-TEX and GRS protect you from consumer lawsuits or backlash tied to chemical content or greenwashing.

- Market Access: Many retail chains and platforms (e.g., Zalando, Amazon Conscious) require GRS or bluesign® as part of vendor onboarding.

- Marketing Edge: Eco-claims backed by bluesign® or GRS outperform generic green statements in ads and social media.

Stat Snapshot: According to McKinsey’s 2025 Apparel Sourcing Report, 74% of fashion buyers now require at least two major certifications in all new supplier relationships.

How Do Minimum Order Quantities (MOQs) Differ Among Polyester Suppliers?

Whether you’re launching a new product line or scaling up for global distribution, one number often determines supplier fit before anything else—the MOQ. Minimum order quantities affect pricing, customization options, inventory risk, and production timelines. And in 2025, with more agile supply chain strategies and diversified product lines, sourcing with the right MOQ is more strategic than ever. MOQs for polyester fabric manufacturers in 2025 vary widely—from as low as 100 meters for digital prints and off-the-shelf stock to 3000+ meters for specialty coatings or complex woven fabrics. Factors like fabric type, printing or dyeing method, finish requirements, and supplier capabilities all play key roles. Balancing your project scale with the supplier’s MOQ flexibility is crucial for cost-effectiveness and product viability.

MOQ by Fabric Type, Production Process & Region

To help you source smarter, let’s break it down by category.

1. Stock Polyester Fabrics – Lowest MOQs with Fast Turnaround

These are ready-to-ship rolls of solid-color or basic printed polyester fabrics.

- Typical MOQ: 50–300 meters

- Pros: No dyeing setup needed; perfect for samples and small drops

- Cons: Limited in colors and finishes; no custom branding

Use Case: A niche U.S. bag brand sourced 200m of stock water-resistant polyester from a Guangzhou supplier to create a small-run Kickstarter campaign. The low MOQ allowed testing without inventory burden.

2. Custom-Dyed or Printed Polyester – Medium-Range MOQs

If your design requires Pantone matching, digital prints, or heat-transfer graphics, MOQ climbs due to machine prep and ink usage.

- Typical MOQ:

- Digital Print: 300–500 meters

- Rotary Screen Print: 800–1500 meters

- MOQ Drivers: Color count, fabric width, print technique

Tip: Digital printing allows the lowest MOQs because there are no screens to prepare. Great for brands experimenting with colorways or seasonal prints.

3. Functional Finishes – Higher MOQs for Coating Consistency

These include flame retardants, UV resistance, water repellency (DWR), PU/PVC coatings, or anti-bacterial treatments.

- Typical MOQ: 1000–3000 meters

- Why High?: Chemical coating tanks must be filled in bulk, and testing protocols are more complex

| Finish Type | Typical MOQ | Application Examples |

|---|---|---|

| Waterproof PU Coating | 1000–1500m | Backpacks, outerwear, tents |

| FR Treatment (NFPA/EN) | 2000–3000m | Workwear, uniforms, upholstery |

| Antibacterial Treatment | 1000–2000m | Sportswear, healthcare, lifestyle bags |

Real Insight: A Swiss medical textile company shared that sourcing flame-retardant coated polyester below 1500m was nearly impossible without paying a 40% surcharge on setup costs.

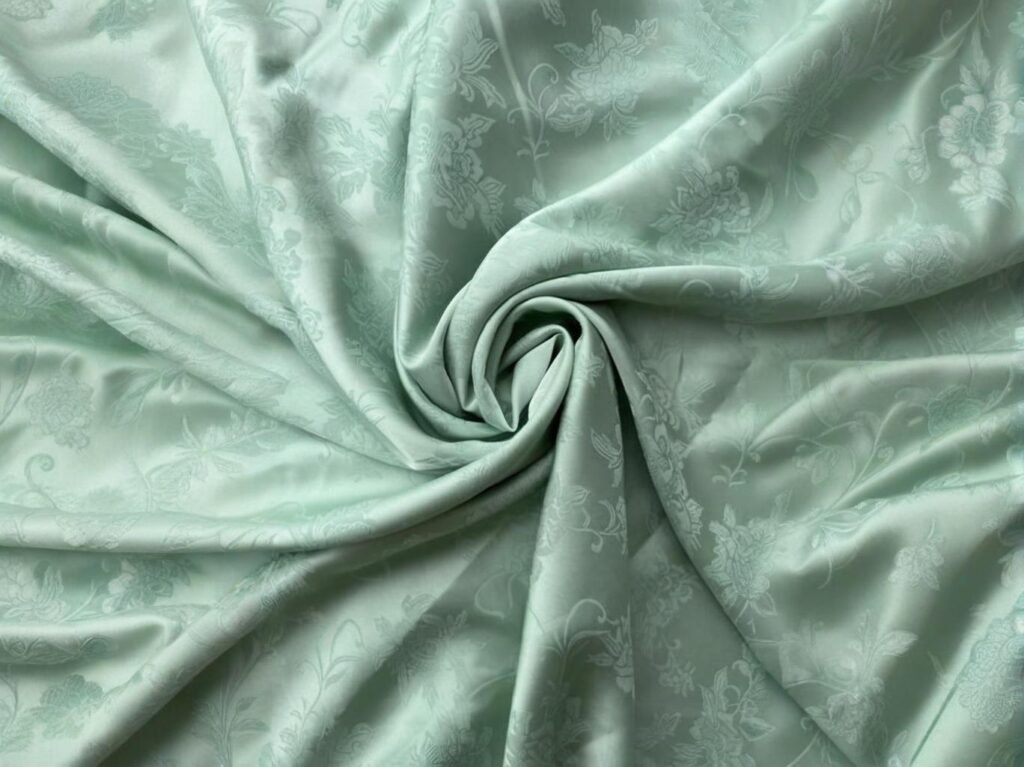

4. Jacquard, Yarn-Dyed & Complex Weaves – Highest MOQs

Custom looms, color setup, and slow production speeds push these products into high-volume territory.

- Typical MOQ: 1500–4000 meters

- Considerations: Often used for high-end apparel, home textiles, and decorative upholstery

- Setup Costs: High loom changeover costs mean mills prefer large batch runs

Buyer Note: Some Turkish and Taiwanese mills now offer 1000m MOQ for yarn-dyed polyesters—but only if you agree to exclusive use of the pattern for a limited time.

MOQ Comparison Table by Fabric Type

| Fabric Type | MOQ Range | Best For |

|---|---|---|

| Stock Solid-Dyed Polyester | 50–300m | Prototypes, small brand launches |

| Digital Printed Polyester | 300–800m | Fashion collections, custom graphics |

| Functional Polyester (Coated) | 1000–3000m | Outdoor gear, workwear, protective |

| Jacquard / Yarn-Dyed Polyester | 1500–4000m | High-end woven designs, upholstery |

Global MOQ Landscape: Which Countries Are More Flexible?

| Country | Average Custom MOQ | Flexibility Notes |

|---|---|---|

| China | 100–1000m | Highly flexible for digital, coated, brushed or velvet polyesters |

| South Korea | 200–600m | Strong support for eco & functional knits, great for MVPs |

| India | 500–2000m | Lower price, but may require higher MOQ due to batch dyeing logistics |

| Taiwan | 300–1000m | More rigid MOQ, but top-tier functional and tech polyesters |

| Turkey | 200–1500m | Negotiable for EU buyers with long-term agreements |

Sourcing Insight: In 2025, Chinese and Korean mills lead the way in flexible MOQs and short-run capabilities, especially in digitally printed polyester and small-batch functional coatings.

Case Study: From MOQ Barrier to Brand Breakthrough

A Canadian yoga brand wanted to test-market a new line of eco polyester leggings with antibacterial treatment. Most suppliers asked for over 2000m MOQ. However, a South Korean mill offered 200m MOQ for their in-stock recycled base with custom anti-bacterial finish.

The result?

- The brand launched quickly without financial risk

- Validated demand in 3 months

- Reordered with 5000m in Season 2

- Saved over $25,000 in initial inventory costs

Buyer Tips: How to Manage MOQ Challenges

- Batch Orders Across SKUs: Many suppliers allow mixing colors or styles in the same order to meet MOQ (e.g., 100m per color, 500m total)

- Use Supplier Stock Base: Customize prints or finishes on their in-stock greige polyester to reduce MOQ

- Negotiate Scale-Ups: Ask for a lower MOQ on first order with commitment to reorder based on sales performance

- Consider Group Buying: Collaborate with other brands or buying agents to meet volume requirements for specialty finishes

Which Polyester Fabric Manufacturers Offer the Best Customization Services?

In today’s saturated product landscape, customization isn’t a luxury—it’s a necessity. For fashion, outdoor, medical, and industrial brands alike, custom polyester fabric allows for product distinction, performance alignment, and brand authority. Manufacturers in 2025 that lead the field offer not just customization—but collaborative innovation, where technical consultation, design integration, and fast development cycles are the norm. Top-tier polyester fabric manufacturers in 2025 offer customization services including GSM variation, yarn blending, functional finishes (like waterproof, flame-retardant, UV-resistant), Pantone dye matching, digital/rotary printing, embossed textures, and private label branding. They often support low MOQs, provide free lab dips or swatches, and offer rapid prototyping to help brands launch with agility.

A Full Spectrum of Polyester Customization Services

Let’s unpack what “customization” really means in 2025—and which services truly differentiate top manufacturers.

1. Fabric Weight and Weave Customization (GSM Control)

The GSM (grams per square meter) directly affects the drape, strength, and opacity of polyester fabric.

| GSM Range | Applications | Sample Use Case |

|---|---|---|

| 80–120 GSM | Linings, scarves, fashion shells | A Bali-based resort wear label used 110 GSM chiffon for airy dresses |

| 130–200 GSM | T-shirts, leggings, athletic wear | A UK fitness brand sourced 180 GSM brushed polyester for gym tops |

| 200–300+ GSM | Jackets, bags, industrial textiles | A German auto supplier used 250 GSM PU-coated polyester for seat covers |

Sourcing Insight: Good manufacturers offer not only GSM ranges but also custom weave types such as twill, satin, ripstop, or dobby, adjusting yarn size, density, and finish to match your product vision.

2. Functional Coatings & Performance Enhancements

Performance polyester has moved far beyond basic water repellency. Today’s best mills integrate multi-functional coatings directly into the fabric matrix or apply advanced chemical finishes for targeted results.

| Functionality | Description & Compliance | Best For |

|---|---|---|

| Waterproofing (PU/TPU) | Durable water resistance via coatings or lamination | Jackets, bags, tents |

| FR Treatment | Fire resistance per EN11612, NFPA701 | Uniforms, curtains, PPE |

| UV Blocking | Up to UPF 50+ via treatment or yarn choice | Outdoor apparel, beachwear |

| Antibacterial/Antiviral | Embedded silver/zinc oxide nanoparticles | Hospital garments, sportswear |

| Anti-static / Conductive | Fiber-level modification or carbon yarn blending | Industrial, electronics packaging |

Real-World Example: A Japanese electronics brand required anti-static packaging made from black conductive polyester. A Chinese mill provided yarn-integrated conductive fabric at just 500m MOQ with IEC certification, beating Korean and European competitors on price and lead time.

3. Digital & Rotary Print Customization

Print technologies are becoming increasingly vibrant, durable, and fast. Today’s polyester mills offer full-spectrum printing solutions, often in as little as 7–12 days.

- Digital Printing:

- Best for short runs, detailed graphics, variable designs

- Ideal for swimwear, leggings, activewear, promotional banners

- Eco-friendly with water-based inks

- Rotary Screen Printing:

- Better for larger volumes and fewer colors

- High-speed production but requires setup charges

- Suitable for fashion polyesters and upholstery prints

| Printing Type | MOQ Range | Setup Fees | Ideal Use |

|---|---|---|---|

| Digital Sublimation | 100–300m | Low | Activewear, signage, capsule |

| Rotary Screen | 800–1500m | High | Large fashion drops, curtains |

Buyer Insight: If you need variable SKUs or seasonal collections, choose digital over rotary. It’s faster and allows greater design flexibility without committing to high MOQs.

4. Dyeing and Color Matching Options

Polyester dyeing is a science. Top mills offer:

- Pantone Matching: With lab dips and approval cards

- Dope Dyeing (Solution Dyed): Color added at yarn stage = excellent colorfastness

- Disperse Dyeing: Most common for standard polyester

- Cationic Dyeing: Used in poly-blends like poly-viscose

Case Study: A Spanish bag company wanted desert-camo polyester in four Pantone-matched tones. A Taiwanese mill offered dope-dyed yarns with lab dips in 5 days and delivered 2000m in 18 days—outpacing Indian and Vietnamese competitors.

5. Custom Branding & Private Label Support

More than ever, product identity begins at the fabric level.

Top manufacturers offer:

- Custom printed or embroidered selvage edges

- Logo-printed wrapping or labeling on rolls

- Brand-specific barcoding, woven tags, and spec sheets

- Fabric header cards with logo for marketing purposes

Pro Tip: Ask your supplier if they can provide sample books with your logo—great for direct-to-store sales or private presentations.

Customization Capabilities Comparison Table

| Service Area | Top Manufacturer Capability | Average Supplier Limitation |

|---|---|---|

| GSM & Yarn Control | Precise tolerance ±5 GSM | ±15 GSM variance |

| Custom Print | Digital, rotary, transfer | Limited to screen or heat press |

| Functional Finishes | Multi-function + certifications | Basic DWR only |

| Dyeing & Lab Dips | 3–5 day Pantone match lab dips | 10+ days with limited correction |

| Branding / Labeling | Full-service private label | Generic packaging only |

Case Spotlight: All-in-One Custom Solution

A Netherlands-based uniform brand needed a 240 GSM polyester twill that met EU FR compliance, had oil-repellent treatment, featured a sublimated camouflage print, and carried their logo-printed roll wrapping. A Turkish supplier delivered:

- Pre-production samples in 9 days

- Lab test certifications in 4 days

- Bulk delivery of 1500m in 3 weeks

The brand used these benefits to land a contract with a national railway company—beating three competitors with stock solutions.

Buyer Recommendations: How to Navigate Custom Fabric Development

- Start with Your End Use: List all fabric performance requirements upfront—this reduces iteration and cost.

- Request a Technical Customization Checklist: Good suppliers will offer a matrix of options for weave, GSM, finish, dyeing, and branding.

- Insist on Lab Dips & Swatches: Test for wash fastness, pilling, waterproofing before committing.

- Negotiate MOQ by Process: You can often get low MOQs on GSM changes if printing is stock or finish is standard.

- Audit Sample to Bulk Consistency: Ensure that the final production matches the swatch exactly—some mills cut corners.

How Do Leading Polyester Fabric Mills Incorporate Sustainability?

For decades, polyester has been synonymous with petroleum-based textiles and environmental harm. But in 2025, a new generation of fabric manufacturers is rewriting that narrative—turning polyester into a smart, circular, and low-impact solution through cutting-edge technology, responsible sourcing, and transparent certification systems. The world’s top polyester fabric manufacturers are embracing sustainability by shifting to recycled inputs (rPET), low-impact dyeing technologies (like dope dyeing), water reuse systems, renewable energy integration, and verified third-party certifications such as GRS, OEKO-TEX, bluesign®, and ISO 14001. These efforts make polyester fabrics more planet-friendly while preserving the performance and affordability buyers expect.

Greener Practices in Polyester Production

Let’s examine exactly how leading mills are making polyester fabrics greener—without compromising on quality or performance.

1. Recycled Polyester (rPET): The Foundation of Circularity

Recycled polyester is no longer niche. In 2025, it accounts for nearly 25% of all polyester fiber production globally, thanks to scalable recycling innovations and growing brand demand.

Primary rPET Sources:

- Post-Consumer Bottles: PET beverage bottles collected, cleaned, shredded, and re-spun.

- Textile Cutting Waste: Off-cuts from factories are recovered and reprocessed.

- Ocean Salvage Plastics: Fishing nets and marine waste, transformed into usable fibers.

| Recycled Source | Sustainability Impact | Common Applications |

|---|---|---|

| PET Bottles | Keeps plastic out of landfill & oceans | Activewear, linings, fleece |

| Cutting Waste | Reduces industrial scrap and waste | Fashion poly-blends, accessories |

| Ocean Waste | Supports marine cleanups, circular use | Premium swimwear, bags |

Real-World Example: Taiwan’s Far Eastern New Century recycles over 200,000 metric tons of PET bottles annually, supplying GRS-certified rPET to global brands like Adidas and Uniqlo.

2. Dope Dyeing Technology: Less Water, More Color Fastness

Dope dyeing, also known as solution dyeing, is one of the most transformational technologies for polyester sustainability.

Instead of dyeing fabric after weaving, color pigments are added during the fiber-making process, resulting in deeply colored yarns with exceptional fastness and minimal resource use.

| Benefit Area | Dope Dyeing Result | Compared to Traditional Dyeing |

|---|---|---|

| Water Use | Up to 80% reduction | 100–150L per kg saved |

| Energy Use | 30–60% less | No need for high-temp water baths |

| Color Fastness | Higher UV and wash resistance | Ideal for outdoor or uniforms |

| Chemical Use | Nearly eliminated | No dye-bath wastewater |

Notable Mills Using Dope Dye:

- Toray Industries (Japan)

- Huvis (Korea)

- FENC (Taiwan)

- Reliance (India)

Case Study: A Belgian home textile company switched to dope-dyed polyester from India for blackout curtains. The fabric retained color for 5+ years of sun exposure, and reduced their dyeing water usage by 88%.

3. Closed-Loop Water Recycling and Zero Liquid Discharge (ZLD)

Water scarcity is a critical global issue. Leading mills are investing in closed-loop water systems and ZLD technology, which filter and reuse water instead of discharging it into rivers or land.

| Water Practice | Description | Key Countries Using It |

|---|---|---|

| Closed-Loop System | Filters & reuses dye bath water | China, India, Turkey |

| ZLD | No wastewater is released externally | Vietnam, Bangladesh, Pakistan |

| Biological Treatment | Treats with microbes before reuse | Korea, Taiwan |

Insight: India’s Textile Policy 2025 mandates ZLD for all mills above a certain capacity in Tamil Nadu and Gujarat—two polyester-rich states. This has spurred innovation and compliance across the region.

4. Renewable Energy Integration in Polyester Production

From solar panels on factory roofs to biomass boilers for heating dye tanks, many mills are reducing carbon footprints by sourcing cleaner energy.

| Renewable Source | Application | Countries Leading Adoption |

|---|---|---|

| Solar PV | Powering looms, lighting, offices | Turkey, Vietnam, India |

| Biomass Boilers | Heating dye baths | China, Thailand |

| Wind Power | Offset grid energy | Netherlands, parts of Korea |

Example: A Turkish mill reduced its CO2 emissions by nearly 40% after installing solar arrays that now power 60% of its polyester production capacity.

5. Certification-Backed Supply Chain Transparency

Without third-party verification, sustainability is just a promise. The best mills invest in globally recognized certifications that prove eco-performance, traceability, and ethical compliance.

| Certification | What It Covers | Buyer Benefit |

|---|---|---|

| GRS | Recycled content, traceability, ESG | Widely trusted by global brands |

| bluesign® | Chemical safety, energy, emissions | Ideal for premium, eco buyers |

| OEKO-TEX | Human and ecological textile safety | Must-have for fashion or bedding |

| ISO 14001 | Environmental management systems | Corporate ESG alignment |

| Higg Index | Lifecycle, labor, and sustainability data | For public CSR and benchmarking |

Case Study: A Canadian athleisure brand used GRS-certified polyester fleece from a Korean mill to pass an ESG audit for a major U.S. retail chain. It resulted in a $1.2M annual contract for “green-certified activewear.”

Sustainability Scorecard: Comparing Standard vs. Green Polyester Mills

| Feature | Conventional Mill | Sustainable Mill |

|---|---|---|

| Recycled Input (%) | <10% | 50–100% |

| Water Use / kg | 150–200L | <40L |

| Emissions Control | Minimal | Advanced filters |

| Renewable Energy Use | <5% | 40–80% |

| Certifications | None or ISO only | GRS, bluesign®, OEKO-TEX |

| Transparency | Low | Full traceability |

| ZLD Compliance | Rare | Common in India/China |

Buyer Recommendations: What to Ask When Evaluating Sustainability

- What percentage of your production is rPET-based?

- Do you offer dope-dyed or waterless dyeing options?

- Can you provide GRS, bluesign®, or LCA documentation?

- What energy sources power your looms and dyeing?

- How do you handle chemical disposal and wastewater?

How Do Polyester Mills Maintain Consistent Quality Across Batches?

In a competitive sourcing environment, quality isn’t just a feature—it’s a promise. Polyester fabric buyers, whether in fashion, upholstery, or industrial sectors, require materials that behave predictably across production runs. A 5% variation in GSM, color shade, or shrinkage can result in brand-damaging inconsistencies. That’s why leading polyester mills in 2025 are investing heavily in smart quality assurance (QA) frameworks, combining automated inspection, ISO-certified processes, and digitized traceability.

Top-tier polyester mills achieve batch-to-batch consistency through ISO 9001-certified systems, AI-powered in-line monitoring, routine lab testing, and digital roll traceability. These elements ensure that every meter of fabric meets defined specifications for weight, color, strength, and durability, while also enabling fast resolution of any quality deviation.

Inside the Quality Control Pipeline

1. ISO 9001:2015 – The Backbone of Consistency

The ISO 9001:2015 standard enforces uniform documentation and procedural compliance, ensuring that mills follow rigorous Standard Operating Procedures (SOPs) across all production stages. Key components include:

- Raw Yarn Inspection: Moisture content, denier, and filament integrity verified before warping

- Machine Calibration Logs: Looms, heat setters, and dyeing units recalibrated per schedule

- Fabric Inspection Reports: Visual and machine-led inspections logged with timestamps

- CAPA System (Corrective Action/Preventive Action): Structured response system for quality failures

Why It Matters: Mills without ISO often rely on manual spot checks, increasing the risk of undetected defects in high-volume runs.

2. Real-Time, Automated In-Line Monitoring

Advanced mills use AI-integrated technology for non-stop monitoring of critical metrics in real-time:

| Parameter | Equipment Used | Common Defects Caught |

|---|---|---|

| Weave Density | Optical Sensors | Float skips, broken picks |

| Dye Consistency | Spectrophotometers | Shade banding, underdye |

| Surface Quality | Vision Cameras | Snags, pilling, lint |

| Coating Uniformity | Ultrasonic Gauges | Uneven thickness |

These tools reduce human error and allow immediate correction, minimizing second-grade output and rework costs.

3. Comprehensive Laboratory Testing Per Production Batch

Top mills operate in-house textile labs aligned with global test standards, validating that every batch meets buyer specifications and industry benchmarks.

| Test Type | Standard Used | Fabric Type | Target Values |

|---|---|---|---|

| Colorfastness to Wash | ISO 105-C06 | Apparel, home | Grade 4–5 |

| Tensile Strength | ISO 13934-1 | Outdoor, bags | >500N |

| Abrasion Resistance | ISO 12947 (Martindale) | Workwear, upholstery | >20,000 cycles |

| Dimensional Stability | ISO 5077 | Fashion, lining | ≤ 3% shrinkage |

| Flame Resistance | EN11612, NFPA701 | Industrial, decor | Meets Class 1 or 2 |

Real Use Case: A European transit company requires each polyester seating fabric roll to pass Martindale >30,000 rubs and tensile >600N. Only a few ISO-compliant mills in Taiwan and South Korea qualify consistently.

4. Digital Roll-Level Traceability

Digitalization is now standard for quality tracking. Each fabric roll is assigned a QR code or barcode at the greige stage and tracked through:

- Loom or machine ID

- Yarn batch and supplier

- Dye lot and lab dip ID

- QA results and personnel involved

- Shipping and inspection record

Benefit: Enables precise defect tracing, repeat reorders, and transparent reporting for audits or brand claims.

5. Visual & Tactile Checks with Grading Protocols

While machines catch most flaws, human QC teams still perform:

- 4-point fabric inspection system (penalizing by defect size)

- Hand-feel (drape and stretch) assessments for apparel buyers

- Luster and sheen consistency checks on fashion fabrics

- Fold and crease recovery for upholstery polyester

Some mills also offer video reports or live factory quality audits for transparency.

Case Insight: Boosting Buyer Confidence Through QC Innovation

A French hospitality linen brand partnered with a Korean polyester mill known for its digital QC dashboards. Each roll came with a real-time PDF report showing weaving variance, tensile test data, and shade control chart. As a result, the brand cut its quality rejection rate from 7.5% to under 2% in just two quarters.

Buyer Tip: What to Request for Quality Assurance

Here’s a quality checklist to request from your polyester supplier before bulk production:

✅ Pre-production lab dip or swatch test ✅ Technical datasheet with fabric specs ✅ AQL (Acceptable Quality Level) system description ✅ In-line QC and final roll inspection report ✅ Batch traceability documentation ✅ Return policy for quality failures

Pro Tip: For large-volume orders, negotiate a third-party QC audit or request video inspection access to boost transparency.

What Are the Top 20 Polyester Fabric Manufacturers in 2025?

The global polyester fabric supply chain in 2025 is increasingly defined by sustainability, innovation, and agility. While mega-corporations continue to lead in scale, small-to-mid-size manufacturers offering low MOQs, customization, and digital responsiveness are becoming equally critical—especially for private label brands, DTC businesses, and technical textile buyers.

Whether you’re sourcing for sportswear, workwear, upholstery, flags, or fashion, choosing the right supplier can impact your product quality, cost efficiency, and market entry speed.

The top 20 polyester fabric manufacturers in 2025 include a diverse range of global leaders—Toray (Japan), Hyosung (Korea), Unifi (USA)—as well as high-agility innovators like SzoneierFabrics (China). These suppliers stand out for their certified production, advanced textile engineering, fast sampling, and responsiveness to customization needs.

Global Manufacturer Benchmarking Table

| Rank | Manufacturer Name | Country | Core Strengths | Key Certifications |

|---|---|---|---|---|

| 1 | Toray Industries | Japan | High-tech fabrics, sustainability | ISO 9001, bluesign®, GRS |

| 2 | Hyosung TNC | South Korea | creora® spandex-polyester, durability | GRS, OEKO-TEX |

| 3 | Teijin Limited | Japan | Performance polyesters for industrial use | ISO 14001, bluesign® |

| 4 | Far Eastern New Century (FENC) | Taiwan | rPET, dope-dyed innovation | GRS, bluesign®, ISO 50001 |

| 5 | Zhejiang Hailide | China | Industrial-grade polyester yarns and fabric | REACH, ISO 9001 |

| 6 | Reliance Industries | India | World’s top PET producer, rPET scaling | OEKO-TEX, GRS |

| 7 | Unifi Inc. (REPREVE®) | USA | Recycled polyester market leader | GRS, ISO 9001 |

| 8 | Sarla Performance Fibers | India | Blended yarns for fashion & function | OEKO-TEX, ISO 9001 |

| 9 | Formosa Taffeta | Taiwan | Waterproof/PU polyesters | REACH, bluesign® |

| 10 | Sonear Industries | Vietnam | Sublimation-ready fabric, responsive MOQ | OEKO-TEX, ISO 14001 |

| 11 | Shinkong Textile | Taiwan | Stretch woven polyester, fashion-forward | OEKO-TEX, GRS |

| 12 | Indorama Ventures | Thailand | Vertical PET/polyester supply chain | GRS, ISO 14001 |

| 13 | Sefar AG | Switzerland | Technical polyester for industrial filtration | ISO 9001, GMP |

| 14 | Weiqiao Textile | China | Low-cost, high-volume polyester fabric | ISO 9001, ISO 14001 |

| 15 | Shaoxing Keqiao Yiding | China | Quick sample turnaround, digital print | GRS, OEKO-TEX |

| 16 | ECLAT Textile Co. | Taiwan | Sportswear supply chain integration | WRAP, bluesign® |

| 17 | NILIT Fibers | Israel | Functional yarns and thermal poly-blends | ISO 9001, GRS |

| 18 | Hengdian Group DMEGC | China | Dope-dyed yarns, advanced colorfastness | ISO 14001, OEKO-TEX |

| 19 | Première Vision Supplier (France) | France | Jacquard & luxury polyester | OEKO-TEX, REACH |

| 20 | SzoneierFabrics | China | Custom development, fast sample lead time, low MOQ | Internal QC, digital proofing, OEM-ready |

Strategic Insights: What Makes These Suppliers Stand Out?

- Toray, Hyosung, Teijin: Best for technical textiles, activewear, and large-scale contracts

- Unifi & FENC: Go-to options for recycled polyester (rPET) and sustainable supply chains

- Shaoxing Keqiao & Sonear: Ideal for digital print polyester and fast lead times

- SzoneierFabrics: Best for small-to-mid buyers needing customization, flexibility, and OEM development support

Real-World Buyer Application:

A California swimwear startup needed low-MOQ, sublimation-ready polyester with antibacterial coating. They chose Sonear Industries (Vietnam) for fast delivery and sampling, then moved to SzoneierFabrics (China) for scale-up thanks to its faster prototyping and free design support.

Result? The brand launched within 45 days and saved 18% in material costs by negotiating a blended GSM structure.

Final Thoughts: How to Choose Your Best Supplier

Choosing your polyester fabric manufacturer should align with your volume, customization, timeline, and technical requirements. Here’s a simplified decision matrix:

| Buyer Need | Best-Fit Suppliers |

|---|---|

| Sustainability Focus | Unifi, FENC, Teijin, Indorama |

| Low MOQ / Fast Sampling | SzoneierFabrics, Keqiao Yiding, Sonear |

| Technical Textiles | Toray, Teijin, NILIT, Sefar |

| Apparel Brands | Hyosung, Shinkong, ECLAT |

| Cost-Effective Bulk | Weiqiao, Hengdian Group, Reliance |

Need Help Sourcing Polyester Fabric?

At SzoneierFabrics, we specialize in:

- Custom polyester fabric development (GSM, blends, finishes)

- Free sampling and visual mockups

- Low MOQ starting at 100 meters

- Rapid lead times (5–12 days for samples, 15–25 days for bulk)

- Full OEM/ODM and private label services

✅ ISO-like internal QC

✅ Sublimation, PU coating, water resistance

✅ Colorfastness testing & digital lab dips

📩 Contact SzoneierFabrics today to discuss your project needs—we’re here to help global buyers source smarter, faster, and better.