In a world moving toward natural fibers, linen has reclaimed its place as a premium material across fashion, home, and industrial applications. But as demand rises, so does the complexity of sourcing. Buyers today are not just looking for “linen” — they want the right GSM for their intended use, a competitive price per yard, reliable supply chain visibility, and traceable origin. The question isn’t just who supplies linen, but who delivers the best value per GSM.

Linen fabrics in 2025 are evaluated by three core metrics: GSM, price per yard, and supply reliability. These benchmarks help buyers filter through an oversaturated global market. Understanding how each metric impacts the usability, feel, and commercial cost of linen helps ensure you’re not just buying fabric — you’re investing in brand quality and long-term efficiency.

And if you’re wondering what’s really happening behind linen pricing variations between a Belgian mill and an Indian exporter, or why 160 GSM might cost more than 220 GSM in some cases, you’re in the right place.

Let’s dive in — and discover the facts through supplier benchmarks, GSM charts, and real sourcing insights.

What Is Linen Fabric and Why Does GSM Matter in Sourcing?

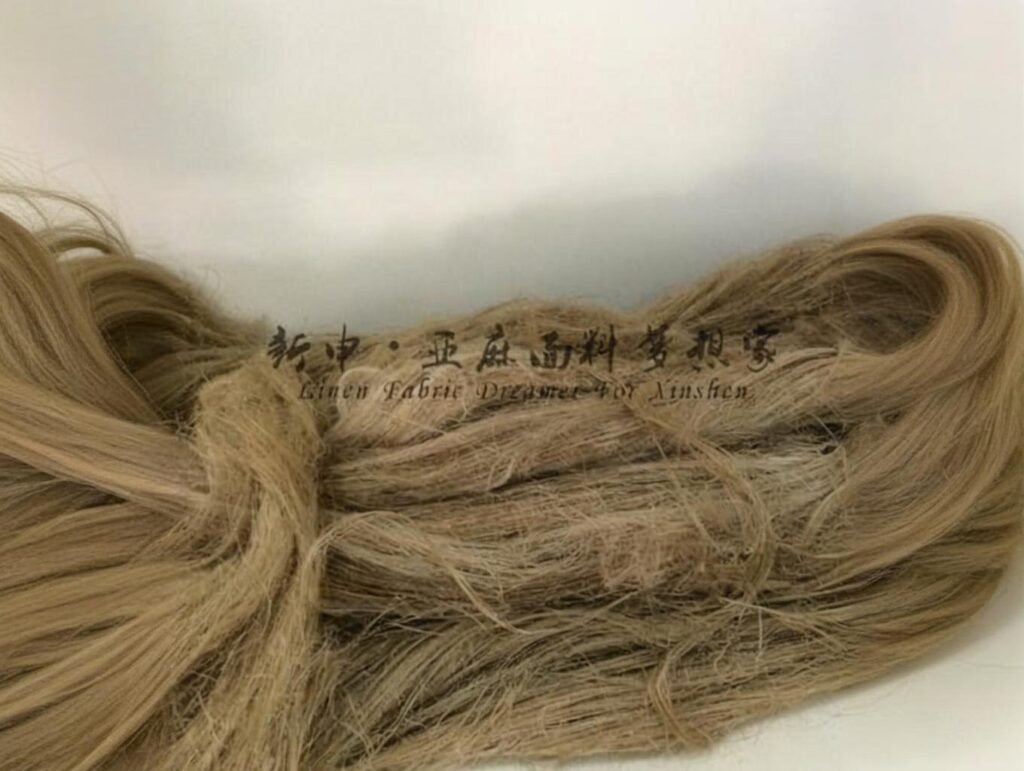

Linen is a natural fiber derived from the flax plant, prized for its breathability, crisp texture, and eco-friendly cultivation. GSM (grams per square meter) measures fabric weight and is critical in determining fabric strength, drape, and application suitability. GSM acts as the primary reference point for evaluating the performance and commercial suitability of linen for specific product categories.

GSM defines linen’s usability — lower GSM means lightweight, suitable for summer wear or scarves; higher GSM suits upholstery or structured garments. Understanding GSM allows buyers to avoid costly mismatches in function and consumer expectations.

Understanding GSM in Linen Fabric

- GSM Comparison by Application:

| Linen Use Case | Ideal GSM Range | Description |

|---|---|---|

| Lightweight Shirts & Scarves | 100–140 GSM | Sheer, airy, often semi-transparent |

| Dresses & Casual Apparel | 140–180 GSM | Midweight, good balance between drape and shape |

| Trousers & Suits | 180–220 GSM | More structure, wrinkle resistance improves |

| Table Linens & Napkins | 200–240 GSM | Durable, moderate stiffness, absorbs well |

| Upholstery & Curtains | 250–300+ GSM | Heavyweight, strong weave for endurance |

- Why GSM Isn’t Just About Weight

- Thread Count vs GSM: Two fabrics with the same GSM can feel entirely different based on yarn thickness and weave density.

- Visual Opacity: Higher GSM doesn’t always mean opaque; weave style affects light transmission.

- Shrinkage & GSM: GSM can increase post-wash due to shrinkage — always account for pre-washed samples.

- A Real Sourcing Scenario

A US-based resortwear brand sourced 135 GSM linen from Lithuania for its summer line. However, after consumer complaints about transparency in light colors, the brand pivoted to a denser 155 GSM weave from Portugal — resolving the issue without altering garment design.

Critical Insight: Never rely solely on GSM when ordering linen. Combine it with finish type, weave pattern, and use-case testing to determine final performance.

Which GSM Ranges Are Commonly Used for Apparel, Home Textiles, and Industrial Linen?

Different industries demand different GSM standards. Apparel needs drape and breathability, home textiles prioritize strength and washability, while industrial linen leans on GSM for durability under stress.

The most commonly used GSM range for linen varies from 120 GSM (light shirts) to 300 GSM (upholstery), depending on usage. Matching the correct GSM to the final product ensures longevity, customer satisfaction, and reduced returns.

GSM Benchmarks by Industry Use

- Apparel Industry GSM Guide:

| Garment Type | Standard GSM Range | Regional Preference (2025 Trend) |

|---|---|---|

| Men’s Linen Shirts | 120–140 GSM | Asia, Europe (lightweight for layering) |

| Linen Dresses | 140–180 GSM | US, EU (midweight preferred for form retention) |

| Suits and Jackets | 200–240 GSM | Middle East, Europe (structured styling) |

- Home & Decor Linen:

| Item Type | Standard GSM Range | Performance Consideration |

|---|---|---|

| Bed Sheets | 150–190 GSM | Soften with wash; balance between weight & feel |

| Curtains | 200–280 GSM | Drape strength, light filtering |

| Upholstery | 280–350 GSM | High tensile strength required |

- Industrial Linen Applications:

| Use Case | GSM Range | Purpose |

|---|---|---|

| Spa Towels | 250–300 GSM | Absorbency, durability under frequent washes |

| Hospitality Napkins | 200–240 GSM | Stain resistance, reusability |

| Packaging Wrap | 150–180 GSM | Eco packaging, replace plastic |

Industry Insight:

In 2025, a growing trend across wellness brands is using 280 GSM enzyme-washed linen for yoga accessories — balancing softness with endurance, and creating high-margin eco-friendly product lines.

Buyer Tip: For bulk production, always request pre-washed GSM confirmation and test swatches under actual use conditions. Fabric shrinkage can alter effective GSM by 8–15%.

How Does the Price per Yard of Linen Fabric Vary by Country and Quality Grade?

Linen pricing is not just a matter of fiber and GSM — it reflects processing technique, origin, labor cost, dye method, certifications, and finishing treatment. Price per yard can range from $3.20 to over $30.00, depending on country, grade, and production scale.

The price per yard of linen varies significantly by country and quality, with European-origin linen commanding higher prices than Asian or blended alternatives. GSM, weaving type, and finishing process also greatly affect cost. For example, enzyme-washed 180 GSM linen from Belgium costs more than raw 200 GSM linen from India.

Global Linen Price Comparison

- Price per Yard by Country (Average 2025 Pricing, Standard 150–180 GSM)

| Country | Avg. Price/Yard (USD) | Linen Type & Notes |

|---|---|---|

| Belgium | $12.00 – $24.00 | Premium long-staple, OEKO-TEX certified |

| France | $10.50 – $22.00 | Soft finish, higher labor cost |

| Lithuania | $9.00 – $15.00 | Balanced cost-quality, strong export volume |

| China | $3.20 – $7.80 | Cost-effective, scalable, some blends |

| India | $3.50 – $9.00 | Lightweight and mid-range linen |

| Turkey | $5.80 – $13.00 | Competitive pricing with EU quality appeal |

- Factors Affecting Price Beyond GSM:

- Spinning Technology – European mills use wet-spun long staple flax, which increases durability and softness.

- Certifications – OEKO-TEX, GOTS, and FSC certifications add $1–3/yard but are vital for brand compliance.

- Finishing Process – Enzyme wash, stone wash, or pigment dye add cost but improve drape and softness.

- Color Consistency – Reactive-dyed linen is 10–20% more expensive but offers better colorfastness than pigment-dyed.

Real-World Benchmark:

A US home décor brand compared pricing across five suppliers. While a Chinese vendor quoted $4.90/yard for 170 GSM reactive-dyed linen, a Lithuanian supplier offered enzyme-washed 160 GSM at $11.60/yard. Despite the higher cost, the latter’s lower defect rate (1.5% vs 6%) and better shrink control saved 12% in post-production losses.

Cost Strategy Tip: When calculating per-yard cost, always account for shrinkage, returns, defects, and import tariffs — not just the raw price.

What Are the Top 10 Global Linen Fabric Suppliers in 2025?

The global linen supply chain in 2025 is shaped by a mix of heritage mills in Europe and high-volume producers in Asia. Some lead in quality and sustainability, while others excel in price and MOQ flexibility.

The top global suppliers of linen fabric in 2025 include European legacy mills for premium quality, and Asian manufacturers for scalable, customizable, and affordable linen supply. Evaluating them by GSM range, price, production capacity, certifications, and MOQ reveals major differentiation.

Supplier Comparison Table

| Supplier Name | Country | GSM Range | Avg. Price/Yard | Certifications | MOQ | Key Strengths |

|---|---|---|---|---|---|---|

| Libeco | Belgium | 130–300 GSM | $12–$30 | GOTS, OEKO-TEX | 300 yds+ | Heritage brand, luxury quality |

| Siulas | Lithuania | 120–240 GSM | $8–$16 | OEKO-TEX, FSC | 200 yds+ | Strong export experience |

| Safilin | France | 150–280 GSM | $10–$25 | GOTS, Cradle to Cradle | 500 yds+ | Long staple, eco-finishes |

| Heng Li Textile | China | 100–250 GSM | $3.2–$7.5 | OEKO-TEX | 100 yds | Fast production, affordable pricing |

| Gokul Tex | India | 120–220 GSM | $3.5–$8.0 | OEKO-TEX | 200 yds | Lightweight linens, good dye range |

| Koozo Textile | Turkey | 130–250 GSM | $6–$13 | OEKO-TEX, ISO 9001 | 300 yds | Soft pre-washed linen, good pricing |

| SzoneierFabrics | China | 100–300 GSM | Custom | Custom, FSC, OEKO-TEX | 100 yds | Custom design, low MOQ, fast sampling |

| Linenshed | Portugal | 140–260 GSM | $9–$20 | OEKO-TEX, GOTS | 250 yds | Pre-washed linen, small-batch friendly |

| Shaoxing Zhenyue | China | 100–240 GSM | $3.5–$6.5 | OEKO-TEX | 200 yds | Reactive dyeing, color consistency |

| Baltic Flax | Lithuania | 140–280 GSM | $8.5–$15.5 | OEKO-TEX, GOTS | 300 yds | Good quality mid-market linen |

What Sets Them Apart:

- Libeco leads the luxury category with artisan-level finishing, ideal for premium fashion or heritage furniture brands.

- SzoneierFabrics, based in China, has built a reputation for flexibility in MOQ and GSM customization, making it ideal for new designers and boutique brands.

- Siulas is the quiet powerhouse of Europe — scalable without losing artisanal quality.

- Gokul Tex in India wins on affordability and has recently expanded its reactive dyeing line, ideal for colorful collections.

Case Example:

A Canadian boutique brand shifted its sourcing to SzoneierFabrics after struggling with EU supplier MOQs. By opting for 180 GSM enzyme-washed linen with custom Pantone dye, they were able to meet a 300-piece collection MOQ and reduce lead time by 23%.

Strategic Note: Choosing your linen supplier isn’t just about cost — it’s about alignment. Small MOQs, fast sampling, GSM flexibility, and communication speed can be just as critical to success.

Which Countries Lead Linen Fabric Production and Export in 2025?

Linen fabric production is highly regionalized, influenced by climate, flax cultivation, historical expertise, and labor costs. In 2025, Europe retains dominance in premium-grade linen, while Asia leads in mass production and pricing advantage.

The leading countries in linen fabric production and export in 2025 are Belgium, China, India, Lithuania, and France — each excelling in different quality segments and market demands. Belgium and France dominate the luxury and sustainable sectors; China and India lead in volume and affordability.

Global Linen Export Powerhouses

- Global Export Leaders by Category

| Country | Strength Area | 2025 Export Share (%) | Key Notes |

|---|---|---|---|

| Belgium | Premium long-staple linen | 18% | Known for Libeco, luxury-grade linen, strict quality control |

| China | Cost-efficient, customizable linen | 34% | Large-scale production, diverse finish options |

| Lithuania | Balanced quality and price | 12% | Rising player, OEKO-TEX certified mills |

| India | Lightweight and vibrant linen | 10% | Focused on dyeing, summer wear linen |

| France | Eco-certified heritage linen | 8% | Niche, certified Cradle to Cradle production |

| Turkey | Modern equipment + EU proximity | 7% | Soft-washed midweight linens for European demand |

| Portugal | Small-batch production | 5% | Focused on customized garment-grade linen |

- Regional Trends and Considerations

- Europe: Often associated with legacy brands and superior flax. The EU’s Flax Charter and carbon emission standards have given European linen a premium image.

- Asia: Offers the flexibility to experiment with custom finishes (e.g., pigment dyeing, metallic weaves). However, variation in batch consistency remains a concern with some low-end producers.

- Baltic States: Lithuania and Latvia continue gaining traction with their modern mills, shorter lead times to Europe, and consistent mid-tier quality.

Case Insight:

A German outdoor fashion brand sourcing 220 GSM water-repellent linen chose Turkey over France due to logistics and slightly better pricing. While France offered higher certification levels, Turkey’s proximity, lead time (15 days faster), and consistent GSM tolerance (±3 GSM) tipped the scales.

Global Tip: If your priority is eco-certification and brand storytelling, look to France or Belgium. If it’s innovation in finishing or price-volume balance, China and India dominate.

How to Compare Linen Fabric Quality Based on GSM, Finish, and Weave?

Quality in linen fabric cannot be judged by GSM alone. Finish (enzyme-washed, stone-washed, calendared) and weave (plain, herringbone, twill) play critical roles in texture, durability, wrinkle resistance, and drape. In 2025, the ability to assess linen through a multi-dimensional lens is vital.

To compare linen fabric quality, evaluate GSM for weight, finish for comfort and appearance, and weave for strength and aesthetic — together they define the performance of the fabric. A high GSM linen with poor finishing can feel stiff, while a well-finished low GSM linen can outperform in comfort and visual appeal.

Linen Quality Comparison Metrics

- Key Attributes Breakdown

| Attribute | What It Impacts | Questions to Ask Supplier |

|---|---|---|

| GSM | Weight, durability | Is GSM measured pre-wash or post-wash? |

| Finish | Texture, drape, softness | Is it enzyme-washed, calendared, or left raw? |

| Weave | Breathability, wrinkle behavior | Plain, twill, or specialty weaves? |

| Fiber Origin | Staple length, luster | Is the flax European or Asian origin? |

| Shrinkage % | Final width and weight after wash | Has fabric been pre-shrunk or sanforized? |

- Common Linen Weaves in 2025

| Weave Type | Visual Texture | Strength | Typical Use Cases |

|---|---|---|---|

| Plain Weave | Flat | Medium | Shirts, dresses, napkins |

| Twill Weave | Diagonal lines | Strong | Pants, jackets, upholstery |

| Herringbone | Zigzag pattern | Strong | Coats, scarves, high-end table linen |

| Slub Texture | Irregular feel | Medium | Boho garments, lifestyle apparel |

- Finish Type Impact Table

| Finish Type | Hand Feel | Shrinkage Control | Market Positioning |

|---|---|---|---|

| Raw (unwashed) | Crisp, coarse | Low | Budget or industrial use |

| Enzyme Washed | Soft, relaxed | High | Mid to high-end apparel & bedding |

| Stone Washed | Vintage texture | Medium | Lifestyle garments, accessories |

| Calendared | Smooth, shiny | Low | Formal linens, tablecloths |

Case Scenario:

A Scandinavian sleepwear brand initially ordered 140 GSM plain-weave raw linen from India due to budget constraints. After customer complaints about stiffness and scratchiness, they upgraded to 150 GSM enzyme-washed linen from China with a herringbone weave — customer reviews improved by 38% post-launch.

Buyer’s Perspective:

- If you’re making summer shirts — go with 130–150 GSM, plain weave, enzyme-washed.

- For structured jackets or home curtains — choose 200–250 GSM twill weave, stone-washed.

- For premium tactile experience — opt for herringbone weave with enzyme or soft pigment finish.

Expert Tip: Always request hand feel samples in both washed and unwashed states. GSM can behave differently after finishing.

What Factors Affect Linen Fabric Pricing in the Global Supply Chain?

Linen fabric pricing is influenced by numerous factors across the entire supply chain, from flax farming to final garment production. In 2025, the costs are shaped by material quality, labor, environmental sustainability practices, and logistics.

Key factors that affect linen fabric pricing include raw material availability, transportation costs, labor wages, environmental certifications, and market demand. Additionally, flax’s growing conditions and the labor-intensive processes for spinning and weaving can drive costs up, especially in premium-grade fabrics.

Understanding Linen Pricing in Detail

- Flax Farming Conditions and Price Impacts

Flax is a delicate crop, requiring specific climate conditions. Major flax-growing regions (Europe, China, and Russia) face changing weather patterns, which can influence yield and quality. A drop in supply can lead to higher raw material costs, affecting linen pricing.

| Region | Avg. Price per Ton of Raw Flax (USD) | Impact on Linen Fabric Price | Notes |

|---|---|---|---|

| Europe | $1,200 – $1,500 | High | Long-staple flax leads to stronger fibers |

| China | $800 – $1,100 | Medium | Affordable but lower fiber consistency |

| Russia | $950 – $1,200 | Medium | Recent export restrictions drive up costs |

- Labor Costs and Weaving Complexity

Weaving linen involves specialized labor, especially for intricate weave patterns like herringbone or twill. High labor costs in regions like Belgium and France contribute to higher linen prices, while China and India’s lower wages allow for more affordable linen options.

| Country | Labor Cost (USD/hr) | Effect on Linen Fabric Pricing |

|---|---|---|

| Belgium | $25 – $40 | Higher cost, premium quality |

| China | $4 – $6 | Competitive pricing, lower quality |

| India | $6 – $8 | Affordable, mid-range quality |

- Environmental Sustainability and Certification

The demand for eco-friendly linen continues to grow. Certifications like GOTS (Global Organic Textile Standard), OEKO-TEX, and FSC (Forest Stewardship Council) add significant costs to production due to organic farming methods, eco-friendly dyes, and sustainable water usage practices. While they increase the cost per yard, they are becoming essential for premium brands and buyers focused on sustainability.

Environmental Certifications Impact on Price:

- OEKO-TEX Certification: Adds $0.50 – $2 per yard.

- GOTS Certification: Adds $1 – $4 per yard.

- FSC Certification: Adds $0.80 – $2 per yard.

Real-World Example:

A high-end fashion brand sourcing 200 GSM linen from France paid 18% more than a competitor who sourced from India. While the Indian supplier offered competitive pricing, the French supplier provided OEKO-TEX certified linen, ensuring the final product aligned with the brand’s sustainable image.

Pro Tip for Buyers: If you’re looking for sustainable linen but are on a budget, check for OEKO-TEX as a cost-effective alternative to GOTS.

How Do You Choose the Right Linen Fabric Supplier for Custom Orders and Low MOQ?

Choosing the right linen supplier can make or break a sourcing strategy, especially when dealing with custom orders and low minimum order quantities (MOQ). Linen sourcing decisions shouldn’t be based on price alone; reliability, lead times, customization options, and flexibility matter just as much.

In 2025, linen buyers are increasingly looking for suppliers who can offer customization, flexible low MOQ, and a fast sampling process. These capabilities ensure a balance between affordability and tailored service — essential for small and medium enterprises (SMEs) looking to scale with unique linen designs.

Selecting the Right Supplier

- Key Criteria for Evaluating Suppliers:

| Criteria | Description | Why It Matters |

|---|---|---|

| Customization Options | Ability to produce custom colors, weaves, and finishes | Tailored linen products for branding, unique designs, or special collections |

| Low MOQ Flexibility | Minimum order quantities ranging from 100 to 500 yards | Ideal for startups and boutique brands that need flexibility without high upfront costs |

| Sampling Process | Ability to provide samples within 7-14 days | Fast, reliable sampling helps avoid delays and costly mistakes |

| Lead Time | Average time from order to delivery (14–45 days) | Quick turnaround is vital for seasonal collections or just-in-time production |

- Evaluating Supplier Reputation and Reliability

Supplier reliability goes beyond just cost. Consider their reputation for quality consistency, delivery accuracy, and customer service. A supplier with poor quality control or late deliveries can result in costly delays or product defects that harm your brand’s image.

| Supplier Reliability Factor | Key Questions to Ask | How to Assess: |

|---|---|---|

| Quality Control | Do you have regular QC checks? Are there any defects? | Request inspection reports and check references |

| On-time Delivery | What’s your historical on-time delivery rate? | Check past customer testimonials |

| Communication Speed | How quickly do you respond to inquiries or issues? | Test response time with an initial inquiry |

Supplier Insight:

A US-based textile company switched suppliers for a new linen collection after facing multiple delays with their former supplier. They found a new vendor in Portugal, offering low MOQ of 300 yards and custom dyeing. This resulted in a 20% reduction in fabric waste and a faster time-to-market for their spring collection.

Buying Tip: Don’t just look at the per-yard price. Verify the supplier’s communication practices, order fulfillment capabilities, and sampling speed — these factors often make a bigger difference than price in the long run.

When sourcing linen fabric for 2025, balancing quality, price, and supplier reliability is key to making the best decision for your brand. By understanding the nuances of GSM, price variability by region, production timelines, and the key players in the linen supply chain, you can ensure that your product not only stands out in terms of quality but also aligns with sustainability goals and commercial viability.

If you’re ready to take the next step in sourcing custom linen fabric for your brand or project, SzoneierFabrics can help you navigate these complexities with tailored solutions, fast sampling, and flexible MOQs. Reach out to us today to start your linen sourcing journey with confidence.