Few garments symbolize global culture like denim jeans. From American workwear to Italian runways, jeans are as much about engineering as they are about style. Yet behind every pair is a meticulous process: selecting the right fabric, cutting with precision, stitching under industrial machines, and finishing with washes or distressing techniques that define fashion trends. The denim jeans manufacturing process begins with choosing denim fabrics such as raw, stretch, or selvedge. Fabric is prepared through sanforization, cutting, and stitching, followed by washing and finishing. This combination of textile science, machinery, and craftsmanship transforms basic cotton fabric into durable, stylish jeans.

Imagine a roll of indigo-dyed cotton arriving at a factory. Within weeks, that same fabric will reappear in a retail store as neatly folded jeans with fading on the thighs and reinforced seams at stress points. To see how this transformation happens is to understand why denim remains both a technical marvel and a cultural icon.

What are the main types of denim fabrics used in jeans production?

The journey of jeans begins with fabric selection, a decision that shapes not only the aesthetic but also the performance, longevity, and even the retail positioning of the product. Different denim types serve very different buyer needs, ranging from rugged workwear that prioritizes durability to high-end fashion jeans emphasizing authenticity and storytelling. The most widely used fabrics are raw denim, selvedge denim, stretch denim, and specialty denims such as slub, ring-spun, and organic or recycled blends. Each category carries distinct technical features and consumer perceptions. The main types of denim fabrics are raw denim, selvedge denim, stretch denim, and specialty blends like slub, ring-spun, or organic. Each fabric type influences the strength, comfort, sustainability, and branding potential of jeans, defining their target market from heritage lines to mass-market fashion.

Denim Fabric Categories

Raw Denim

- Characteristics: Unwashed, stiff, often dark indigo with a crisp hand feel.

- Performance: Fades and creases develop uniquely with wear, producing a “personalized” look.

- Weight Range: Typically 12–16 oz/yd²; heavier weights above 15 oz are favored in premium heritage lines.

- Market Use: Common in premium brands and niche enthusiasts who value authenticity.

- Data Insight: According to a 2023 survey by Denim Dudes, raw denim accounts for less than 5% of global jeans sales but commands higher margins because of its artisanal appeal.

Selvedge Denim

- Characteristics: Produced on vintage shuttle looms, resulting in a tightly woven fabric with a clean “self-edge” (often white with a red line).

- Performance: Denser and more durable due to lower loom tension, GSM typically 13–16 oz/yd².

- Market Use: Associated with Japanese and U.S. mills; collectors and luxury denim houses favor it.

- Consumer Psychology: Buyers often equate selvedge with “authenticity” and “slow fashion.”

- Data Insight: Selvedge denim production represents under 1% of total denim output worldwide, but Japanese mills like Kaihara and Kurabo have built reputations for exports worth >$300 million annually in high-end markets.

Stretch Denim

- Characteristics: Usually 97–99% cotton blended with 1–3% elastane, spandex, or Lycra.

- Performance: Provides flexibility and shape retention, essential for slim, skinny, and comfort fits.

- Market Use: Dominates the women’s and youth denim sectors; over 60% of global jeans sold in 2022 contained stretch fibers (Statista).

- Challenges: Lower-quality stretch denim can lose recovery after ~50 washes. Dual-core yarns (cotton wrapped around elastane + polyester) are now used to improve lifespan.

- Weight Range: 9–12 oz/yd², making it lighter and more flexible than raw or selvedge.

Specialty Denims

- Slub Denim:

- Features irregular yarn thickness, producing a textured surface and natural fading.

- Popular in vintage-inspired collections.

- Ring-Spun Denim:

- Stronger and softer than open-end yarn denim.

- Produces better color retention and natural fades.

- Widely used in mid- to high-end jeans.

- Organic & Recycled Denim:

- GOTS-certified organic cotton, recycled polyester blends, and post-consumer recycled cotton are gaining traction.

- The eco-denim segment has grown at 8% CAGR globally from 2018–2023 (Textile Exchange), especially in Europe.

Fabric Data Table

| Fabric Type | Composition | Weight (oz/yd²) | Key Features | Market Positioning |

|---|---|---|---|---|

| Raw Denim | 100% cotton | 12–16 | Stiff, unwashed, fades uniquely | Premium heritage, niche collectors |

| Selvedge Denim | 100% cotton, shuttle-loom woven | 13–16 | Dense, durable, clean edges | High-end, luxury, Japanese denim |

| Stretch Denim | 97–99% cotton + 1–3% elastane | 9–12 | Flexible, comfort fit | Mass-market, women’s & youth lines |

| Slub Denim | Cotton with irregular yarns | 10–14 | Textured, vintage aesthetic | Fashion-forward casual wear |

| Ring-Spun Denim | Ring-spun cotton yarns | 11–14 | Stronger, softer, vibrant fades | Mid- to premium market |

| Organic/Recycled | Organic cotton/recycled fibers | 10–14 | Eco-friendly, sustainable | Europe/US eco-conscious brands |

Critical Perspective

Raw and selvedge denim represent heritage craftsmanship, often attracting enthusiasts who see denim as a lifestyle rather than a commodity. Their higher weights and longer break-in times limit them to niche markets but support strong brand storytelling. Stretch denim, by contrast, fuels the mainstream fashion engine, but poses long-term durability concerns unless reinforced with advanced yarn technology. Sustainability is reshaping the equation: Europe reports 15–20% of denim production in 2024 using organic or recycled inputs, and brands like Levi’s and H&M have committed to 100% sustainable cotton sourcing by 2030.

Case Example

A European jeans label repositioned its product line in 2022, shifting 40% of production to organic stretch denim sourced from Turkey. Costs increased by 18%, but the move aligned with eco-conscious trends. Within 12 months, the brand reported:

- Sales growth of 22% in Germany and Scandinavia.

- A 15% price premium accepted by customers.

- Stronger brand loyalty, particularly in younger demographics seeking sustainability.

This example highlights how fabric choice is both a technical and a marketing decision, shaping not only the product but also the brand’s global competitiveness.

How is raw denim fabric prepared before cutting and sewing?

Before denim enters the cutting room, it must go through a series of fabric preparation processes designed to stabilize dimensions, remove weaving chemicals, and ensure consistent performance across large production runs. Without these steps, jeans are prone to unpredictable shrinkage, seam twisting, or uneven fading that can undermine both quality and brand reputation. Raw denim fabric is prepared using processes such as singeing, desizing, sanforization, skewing, and sometimes mercerization. These treatments smooth the fabric surface, reduce shrinkage to below 1%, and improve color absorption, ensuring jeans maintain consistent fit and appearance after repeated washing.

Fabric Preparation Steps

Singeing & Desizing

- Singeing:

- A high-temperature flame or heated copper plates burn off surface fuzz.

- Provides a cleaner, smoother face, improving the sharpness of subsequent printing or laser whiskering.

- Industry data shows that singeing reduces fabric hairiness index by 40–60%, improving wash uniformity.

- Desizing:

- Denim is typically woven with starch-based sizing to protect warp yarns.

- Desizing uses enzymes (amylases) to remove starch, reducing stiffness.

- Results in better chemical penetration during later finishing.

- Denim mills report 15–20% fewer streaking issues in washing when proper desizing is performed.

Sanforization

- Controlled Shrinkage: Fabric is moistened with steam and passed through heated rubber blankets that compress it.

- Limits residual shrinkage to 0.5–1%, compared to 8–12% in unsanforized denim.

- A must for mass-market jeans where sizing consistency is crucial.

- Only “shrink-to-fit” heritage jeans intentionally skip this process, relying on customers to break in the fabric.

Technical Benchmark:

- Standard: residual shrinkage ≤1% (ISO 5077 test).

- Without sanforization: shrinkage up to 10%, resulting in ill-fitting jeans after first wash.

Skewing & Mercerization

- Skewing:

- Introduces a deliberate angle (~3–5°) in the weft yarn to counteract torque from twill weaving.

- Prevents side seams from twisting after repeated washing.

- Studies show skewing reduces seam twist complaints by >80% compared to unskewed denim.

- Mercerization (optional):

- Caustic soda treatment under tension improves fiber luster and strength.

- Increases dye uptake, giving indigo denim a richer, deeper shade.

- Mercerized denim is 15–25% stronger and absorbs reactive dyes more evenly, making it popular in premium markets.

Fabric Prep Data Table

| Process | Purpose | Impact on Jeans | Industry Benchmark |

|---|---|---|---|

| Singeing | Burn off surface fibers | Smooth face, prevents pilling | Reduces hairiness index 40–60% |

| Desizing | Remove starch from warp yarns | Improves wash uniformity & softness | 15–20% fewer streaking issues |

| Sanforization | Pre-shrink fabric with steam | Prevents >10% shrinkage; stabilizes sizing | Residual shrinkage ≤1% |

| Skewing | Correct twill torque | Reduces seam twisting after laundering | Cuts twist complaints by >80% |

| Mercerization | Improve dye affinity & strength | Deeper color, higher tensile strength | 15–25% stronger yarns |

Critical Perspective

Skipping preparation may reduce costs in the short term but often leads to quality issues and consumer dissatisfaction:

- Jeans without proper skewing often display seam twisting after 5–6 washes, leading to higher return rates.

- Un-sanforized denim appeals to purists but is unsuitable for mainstream retail, where consistent sizing is a selling point.

- Mercerization increases costs by ~8–10% per meter, but it significantly enhances fabric appearance, making it essential for premium collections.

The trade-off is clear: brands must weigh authenticity vs consistency. Heritage denim makers may skip sanforization or mercerization for storytelling, while large retailers prioritize controlled processes to minimize defects.

Case Example

A North American factory producing 500,000 jeans annually identified that 7% of returns were due to seam twisting and uneven shrinkage. By incorporating skewing and mercerization into their standard prep, they:

- Reduced return rates by 7%, saving ~$600,000 annually in logistics and write-offs.

- Increased average customer satisfaction scores by 15% in post-purchase surveys.

- Successfully marketed the mercerized denim line as “richer indigo tone with premium durability,” allowing a 10% higher retail price point.

This demonstrates that investing in preparation processes is not just about quality control — it directly affects brand profitability and positioning.

Which steps are involved in the denim cutting and stitching process?

Once the fabric has been stabilized, it enters the cutting and stitching phase, where textile rolls transform into recognizable garments. This stage is at the heart of denim manufacturing, blending engineering precision with artisanal skill. Cutting determines material efficiency and consistency, while stitching ensures jeans can withstand years of wear, laundering, and stress at high-tension points like pockets and belt loops. The denim cutting and stitching process includes marker making, fabric spreading, precision cutting, and assembly using techniques like chain-stitching, overlocking, and bartack reinforcement. Together, these steps reduce fabric waste, improve fit accuracy, and strengthen high-stress areas of jeans.

Cutting & Assembly

Marker Making & Fabric Spreading

- Marker Making:

- CAD (computer-aided design) markers arrange patterns to maximize fabric yield.

- Reduces wastage by 2–4% per garment, which can mean significant savings at scale.

- Example: In a factory producing 500,000 jeans, optimized markers save ~10,000 meters of fabric annually.

- Fabric Spreading:

- Denim is heavy and stiff, so it is layered in stacks of up to 80–100 plies.

- Automated spreaders align fabric with <2 mm deviation, critical for precision cutting.

- Prevents defects such as mismatched seams or uneven leg lengths.

Cutting Techniques

- Manual Cutting:

- Carried out with handheld electric or straight-knife cutters.

- Suitable for small runs and customized production.

- Accuracy deviation: ±5 mm.

- Pros: Low investment cost, flexibility for sampling.

- Cons: Higher waste, slower, risk of human error.

- Automatic CNC Cutting:

- Uses laser-guided or blade-based computerized machines.

- Accuracy deviation: ±1 mm, fabric savings of 3–5%.

- Cuts up to 100 plies simultaneously, dramatically increasing throughput.

- Higher upfront investment (~$250,000–$400,000) but ROI achievable in <2 years for large factories.

Industry Benchmark: Factories producing >1 million jeans annually now report >70% adoption of CNC or laser cutters. Smaller producers remain manual due to capital cost.

Stitching & Reinforcement

- Chain-Stitching:

- Common in waistbands and hems.

- Offers elasticity and strength; survives >50,000 flex cycles in ASTM durability testing.

- Creates a signature “roping effect” fade in hems — prized in premium jeans.

- Overlocking (Serge Stitching):

- Locks raw edges to prevent unraveling.

- Essential for mass production since denim frays easily under abrasion.

- Bartack Reinforcement:

- Concentrated zigzag stitches at pocket corners and belt loops.

- Increases tear strength by 30–40%, preventing pocket failures (a common consumer complaint).

- Modern factories use programmable bartack machines capable of 600–800 cycles/hour.

- Riveting & Hardware Placement:

- Rivets (patented by Levi’s in 1873) remain vital for reinforcing stress points.

- Automated riveting machines now install 400–600 rivets/hour, ensuring uniform quality.

Cutting & Stitching Data Table

| Stage | Description | Performance Impact | Industry Standard |

|---|---|---|---|

| Marker Making | CAD layout for pattern optimization | Saves 2–4% fabric per garment | Digital markers used in 80%+ mills |

| Fabric Spreading | Stacking up to 80–100 plies | Ensures precision, reduces mismatches | Automated spreaders in large plants |

| Manual Cutting | Straight-knife or band-knife cutting | ±5 mm accuracy, slower, more waste | Used in small-batch facilities |

| CNC/Laser Cutting | Automated blade or laser cutting | ±1 mm accuracy, 3–5% fabric savings | 70% adoption in large factories |

| Chain-Stitching | Durable hems & waistbands | Survives >50,000 flex cycles | Standard in mid- to high-end jeans |

| Bartack Reinforcement | Strengthens stress points | Increases tear resistance by 30–40% | 600–800 bartacks per hour |

Critical Perspective

The choice between automation and manual craftsmanship reflects broader strategic positioning:

- Large-scale exporters prioritize CNC cutting and programmable machines to reduce unit costs and ensure consistency.

- Boutique or premium brands may retain manual cutting for smaller batches, where flexibility and “handcrafted” appeal outweigh efficiency.

It’s also important to consider defect economics: a 1% reduction in cutting defects at a factory producing 2 million jeans saves nearly 20,000 garments annually, which can equal $400,000 in lost revenue prevention.

Case Example

A Turkish factory producing 1 million jeans annually transitioned from manual straight-knife cutting to CNC laser cutters in 2021. The results were measurable:

- Fabric wastage reduced by 3.2%, saving ~$1.5 million annually.

- Fit consistency improved, reducing consumer complaints by 18%.

- Return-on-investment achieved in just 18 months.

Meanwhile, a smaller Japanese selvedge denim brand deliberately retained manual cutting and chain-stitch sewing, marketing its products as “authentically hand-crafted.” Although production costs were 25–30% higher, the brand achieved premium pricing and customer loyalty in niche markets.

This contrast illustrates that in denim manufacturing, technology adoption is not one-size-fits-all — it depends on scale, brand story, and buyer expectations.

How do washing, distressing, and finishing techniques affect denim quality?

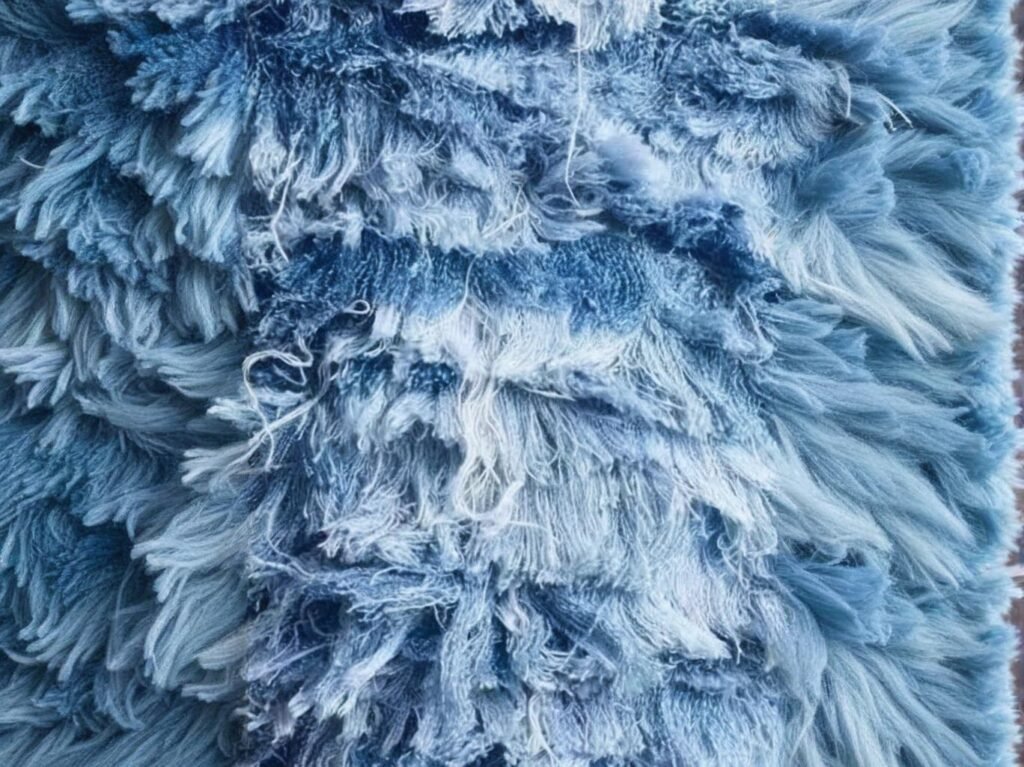

The washing and finishing stage is often described as the “soul of denim” because it transforms stiff indigo cloth into expressive garments. This is where fabric science intersects with fashion — creating whiskers, fades, and textures that communicate lifestyle and identity. However, every washing method has consequences: it can soften or weaken fibers, add or subtract years of life to the garment, and significantly alter the environmental footprint of jeans. Washing and finishing techniques such as stone washing, enzyme treatments, sandblasting, laser finishing, and ozone or e-flow technologies define the look and feel of denim jeans. These methods influence aesthetics, durability, cost, and sustainability, making finishing one of the most decisive stages in denim production.

Washing & Finishing Methods

Stone Washing

- Process: Denim is tumbled with pumice stones to abrade the surface, producing faded and uneven patterns.

- Aesthetic: Classic vintage look, irregular fading, softer hand feel.

- Drawback: Causes fiber loss, reducing tensile strength by 15–20%. Average jean lifespan shortens from ~5 years (raw) to ~3.5–4 years (stone washed).

- Water Use: Up to 70 liters per garment, plus pumice waste disposal challenges.

- Market Note: Still popular in mid-market jeans due to its strong consumer recognition.

Enzyme Washing

- Process: Uses cellulase enzymes to break down cellulose fibers, softening fabric and enhancing fades.

- Aesthetic: Subtle, natural fade with a smoother finish.

- Durability: Gentler than stone washing, with only 5–8% strength loss.

- Eco Impact: Biodegradable enzymes reduce chemical load; water use ~40 liters/garment.

- Market Note: Favored by sustainable brands as an alternative to pumice stones.

Sandblasting & Hand Abrasion

- Process: High-pressure sand or manual abrasion creates whiskers, honeycombs, and faded thigh areas.

- Aesthetic: Highly distressed look, iconic in the 1990s–2000s.

- Drawback: Health risks — sandblasting dust causes silicosis, leading to restrictions in the EU and US.

- Market Note: Many brands have banned sandblasting, replacing it with laser distressing for ethical compliance.

Laser Finishing

- Process: Digitally controlled CO₂ lasers etch patterns (whiskers, abrasions, fades) directly onto denim.

- Aesthetic: Precise, repeatable, and programmable for different collections.

- Durability: Minimal fiber damage, preserves >95% of original fabric strength.

- Eco Impact: Cuts water consumption by 50–70% compared to stone washing; eliminates pumice use.

- Cost: Higher initial investment but scalable for large-volume production.

Ozone & E-Flow Technology

- Ozone Fading: Uses ozone gas to oxidize indigo dye, producing authentic fades without harsh chemicals.

- E-Flow Nanobubbles: Sprays nano-sized bubbles to deliver finishing chemicals more efficiently.

- Eco Impact: Both methods save 70–90% water and reduce chemical use by 50%.

- Durability: No significant fiber loss, maintaining garment strength.

- Market Note: Adopted by eco-leaders like Levi’s, H&M, and Inditex in their sustainable denim programs.

Washing & Finishing Data Table

| Technique | Aesthetic Effect | Durability Impact | Water Use (per jean) | Environmental Impact |

|---|---|---|---|---|

| Stone Washing | Vintage fade, rough texture | -15–20% fiber strength | ~70 liters | High pumice + sludge waste |

| Enzyme Washing | Soft touch, subtle fade | -5–8% fiber strength | ~40 liters | Biodegradable enzymes, lower load |

| Sandblasting | Whiskers, heavy distressing | Surface weakening | ~20 liters | High health risks, largely banned |

| Laser Finishing | Precise, programmable effects | Minimal loss (<5%) | ~20–30 liters | Saves 50–70% water, no pumice waste |

| Ozone/E-Flow | Clean eco-friendly fades | No major strength loss | ~10–20 liters | Saves 70–90% water, low chemicals |

Critical Perspective

Buyers must balance fashion demand, durability, and sustainability:

- Durability vs Aesthetics: Heavily distressed jeans look stylish but weaken fibers, increasing product returns.

- Cost vs Compliance: Stone washing is cheaper upfront but poses waste management costs. Eco-tech like lasers or ozone require capital investment but lower operating costs long term.

- Sustainability Pressure: With water scarcity and chemical regulations tightening, brands risk reputational damage if they rely on outdated methods. By 2030, it is expected that >60% of global denim finishing will use eco-technologies (Textile Exchange).

Case Example

A Spanish denim manufacturer producing 5 million pairs annually phased out stone washing in 2022, replacing it with laser finishing and ozone technology:

- Water savings: 1.2 million liters per year (a 65% reduction).

- Chemical savings: 50 tons fewer pumice stones and bleaching agents annually.

- Retail positioning: Partnered with two global fashion retailers to launch a “sustainable denim” collection.

- Market outcome: Sales grew by 18% YoY, proving that eco-finishing can be both an ethical and commercial advantage.

What machinery and technology are essential in denim jeans manufacturing?

Behind every pair of denim jeans lies not just sewing labor, but an ecosystem of industrial machinery and digital tools. Unlike lightweight garments, denim’s density, twill structure, and finishing complexity require machines built for power, precision, and repeatability. From spreading 100 layers of fabric with millimeter accuracy to etching whiskers with lasers, technology defines efficiency, quality, and sustainability in modern denim manufacturing. Key machinery in denim manufacturing includes automatic spreaders, CNC or laser cutters, heavy-duty lockstitch and chain-stitch machines, bartack and rivet machines, industrial washers, and advanced finishing systems like laser and ozone machines. Together, they reduce fabric waste, increase durability, and support sustainable production.

Core Machinery in Denim Production

Cutting & Preparation

- Automatic Fabric Spreaders & CNC Cutters

- Spreaders lay up to 80–100 fabric plies evenly.

- CNC machines cut stacks with ±1 mm accuracy, saving 3–5% fabric waste compared to manual cutting.

- A factory producing 1 million jeans annually can save >50,000 meters of denim per year.

- Laser Cutters

- Used for precision pocket shapes, labels, or small-batch production.

- Adoption growing in premium brands where accuracy and design flexibility outweigh cost.

Stitching & Assembly

- Heavy-Duty Lockstitch Machines

- Backbone of jeans assembly; speeds of 3,000–5,000 stitches per minute.

- Required to penetrate heavy denim without needle breakage.

- Chain Stitch Machines

- Used for waistbands and hems, creating the distinctive “roping effect” fade after washes.

- Survives >50,000 flex cycles in durability tests.

- Overlock Machines

- Seal raw edges against fraying, critical for extending garment life.

- Bartack Machines

- Apply dense zigzag reinforcement at stress points like pocket corners.

- Increases tear resistance by 30–40%, cutting pocket failure complaints dramatically.

- Rivet & Button Machines

- Pneumatic or servo machines install 400–600 rivets/hour.

- Automates what was once a manual bottleneck.

Washing & Finishing

- Rotary Stone Wash Machines

- Still used for pumice stone treatments; batch sizes of 150–200 pairs.

- Water use can reach 70 liters per jean, creating sustainability concerns.

- Enzyme Washers

- Controlled enzyme baths, reducing fiber damage compared to stones.

- Growing as a “greener” choice.

- Laser Finishing Machines

- CO₂ lasers digitally etch whiskers and fades with repeatable precision.

- Water savings: 50–70% compared to stone washing.

- Popular in factories serving EU/US buyers with strict sustainability targets.

- Ozone & E-Flow Systems

- Ozone gas oxidizes indigo, creating fades without bleach.

- E-flow nanobubble systems deliver chemicals with minimal water.

- Together, they cut water use by 70–90% and reduce chemicals by ~50%.

Automation & Digitalization

- CAD Software for Marker Planning

- Optimizes pattern layouts to maximize yield.

- Typically saves 2–4% fabric per garment.

- AI-Driven Quality Control

- Real-time defect detection in seams and fabric spreading.

- Reduces human error, ensuring consistent QC.

- Robotics in Material Handling

- Increasing use of robotic arms for fabric movement in large-scale factories.

- Cuts manual labor needs, but requires high upfront investment.

Machinery Benchmark Table

| Process | Machine Type | Output Efficiency / Impact |

|---|---|---|

| Cutting | CNC cutter, laser cutter | ±1 mm accuracy, 3–5% less waste vs manual |

| Fabric Spreading | Automatic spreader | Aligns 80–100 plies with <2 mm deviation |

| Stitching | Heavy-duty lockstitch | 3,000–5,000 stitches/min, reduces downtime |

| Reinforcement | Bartack machine | Increases stress resistance by 30–40% |

| Hardware Attachment | Rivet & button pressers | 400–600 rivets/hour, fully automated |

| Washing/Finishing | Laser / Ozone / E-Flow systems | Water savings 50–90%, fewer chemicals |

Critical Perspective

The denim industry is experiencing a technology divide:

- Large-scale manufacturers (e.g., Bangladesh, Vietnam, Turkey) are heavily investing in CNC cutters, AI QC, and eco-finishing machines to meet compliance for global retailers.

- Smaller workshops in Japan or Italy still prioritize manual cutting and vintage shuttle looms, marketing the handcrafted appeal as a premium differentiator.

- While advanced machinery reduces operating costs long term, high upfront investment (e.g., $250,000+ for a CNC cutter or $500,000+ for a laser finishing system) makes it challenging for small factories.

This divide reflects a wider sourcing question: buyers must decide if they value scale and sustainability or heritage and craftsmanship.

Case Example

A Bangladesh factory producing 2 million jeans annually invested $1.2 million in ozone and laser finishing systems in 2021. Within two years:

- Water usage dropped by 70%, saving 200 million liters annually.

- Chemical costs fell by 25%, equivalent to ~$500,000 in savings per year.

- Compliance with European sustainability standards enabled new contracts with two leading fast-fashion retailers.

- ROI achieved in less than 3 years — a strong case for the financial viability of eco-tech in denim.

In contrast, a small Japanese mill producing 50,000 selvedge jeans annually still uses manual cutting and vintage Union Special chain-stitch machines. While output efficiency is lower, their handcrafted branding allows retail prices 2–3x higher, sustaining profitability.

Do compliance standards and certifications matter in denim production?

Yes — compliance standards are no longer optional; they are a gateway to international markets. From chemical safety regulations in Europe to labor practice audits in the U.S., denim manufacturers must meet multiple layers of certification. Compliance not only protects consumers but also shields brands from costly shipment rejections, fines, and reputational damage. For buyers, working with compliant suppliers is a safeguard against hidden risks in the supply chain. Compliance standards such as REACH, OEKO-TEX, GOTS, WRAP, and ZDHC are crucial in denim production, ensuring safety, sustainability, and ethical practices. Non-compliance can result in shipment rejections, legal penalties, and brand reputation loss, while compliance opens access to premium global markets.

Denim Compliance Framework

Chemical & Material Safety

- REACH (EU Regulation 1907/2006)

- Restricts use of >2,000 hazardous substances including azo dyes, lead, cadmium, and formaldehyde.

- For denim, azo dye restrictions are especially critical; violations can lead to shipment rejections at EU ports.

- Testing cost: ~$300 per chemical batch.

- OEKO-TEX Standard 100

- Certifies that fabrics are free from harmful levels of pesticides, heavy metals, and allergenic dyes.

- A must-have for denim suppliers selling to large EU and US retailers.

- Over 16,000 textile companies worldwide are certified.

- GOTS (Global Organic Textile Standard)

- Applies to organic denim made with certified cotton.

- Covers both environmental (organic farming, wastewater treatment) and social criteria.

- Essential for brands selling into eco-conscious markets such as Germany, Scandinavia, and California.

Environmental Standards

- ZDHC (Zero Discharge of Hazardous Chemicals)

- Mandates elimination of toxic chemicals in textile wastewater.

- Denim mills are particularly targeted because indigo dyeing and finishing historically produce heavy effluent loads.

- By 2023, over 150 global apparel brands signed onto ZDHC Roadmap.

- Higg Index

- Developed by the Sustainable Apparel Coalition.

- Measures energy, water, and chemical footprint across the denim supply chain.

- Many retailers now request Higg Facility Environmental Module (FEM) scores before approving vendors.

Social & Ethical Standards

- WRAP (Worldwide Responsible Accredited Production)

- Covers labor rights, wage compliance, and safe working conditions.

- Especially relevant in denim hubs like Bangladesh, Vietnam, and Mexico where labor practices are under scrutiny.

- SEDEX/SMETA Audits

- Evaluate social compliance on wages, health & safety, and environmental impact.

- Accepted by many UK and EU buyers.

- California Transparency in Supply Chains Act (2010)

- Requires disclosure of efforts to eliminate slavery and human trafficking — critical for U.S. market entry.

Compliance Data Table

| Standard | Focus Area | Relevance to Denim | Testing/Certification Cost |

|---|---|---|---|

| REACH (EU) | Chemical restrictions | Azo dyes, heavy metals, formaldehyde in denim dyes/finishes | $300–$500 per batch |

| OEKO-TEX 100 | Fabric safety | Certifies safe jeans for EU/US consumers | $1,500–$3,000/year (cert audit) |

| GOTS | Organic certification | Organic cotton denim; growing in EU/US eco markets | +20–30% fabric cost premium |

| WRAP | Ethical labor practices | Needed for global retailers sourcing from Asia | $2,000–$5,000 audit cycle |

| ZDHC | Wastewater chemical compliance | Critical for denim dyehouses & finishing plants | Ongoing wastewater audits |

Critical Perspective

Compliance is often seen as a cost burden, but data shows it creates long-term commercial advantage:

- Cost Impact: Testing and certifications typically add 3–5% to production costs.

- Market Access: Non-compliant suppliers risk exclusion from EU and US supply chains.

- Brand Value: A 2022 McKinsey report found 72% of consumers in Europe consider certifications important when buying apparel.

Non-compliance can be catastrophic: In 2021, over 20,000 jeans shipments were flagged at EU ports due to azo dye violations, leading to losses exceeding $50 million across suppliers.

Case Example

A Scandinavian retailer importing jeans from South Asia faced delays when azo dye content exceeded REACH limits. The shipment of 20,000 jeans (worth ~$800,000) was detained at customs, causing missed retail deadlines.

The company switched to an OEKO-TEX and ZDHC-certified supplier in Turkey. While costs rose by 10%, the brand leveraged certification to market the jeans as “safe and sustainable”, leading to:

- 18% sales growth in Northern Europe.

- Improved trust with retail partners.

- Reduced compliance risk exposure.

This case illustrates that compliance is not just a technical requirement — it is a strategic differentiator in denim sourcing.

How do lead times, MOQs, and supply chain factors impact denim sourcing?

For global denim buyers, sourcing decisions rarely revolve around fabric texture or wash effects alone. Behind every pair of jeans lies a delicate balance of time-to-market, production scale, and supply chain resilience. Lead times, MOQs (minimum order quantities), and external risks such as cotton price swings or port congestion shape whether a brand can hit seasonal deadlines, maintain margins, and stay competitive in fast-moving fashion cycles. Lead times for denim usually range 45–90 days, while MOQs fall between 500–2,000 pieces depending on the mill or full-package supplier. Reliability is shaped by global cotton price volatility (which can spike costs by 30–40%), trade tariffs, and logistics bottlenecks, all of which directly influence sourcing flexibility and profitability.

Lead Times

Lead times in denim are complex because the process involves multiple stages of fabric and garment production:

- Fabric preparation (3–5 weeks): Weaving, dyeing (often indigo rope dyeing), and finishing require 20–35 days depending on capacity and machinery.

- Garment production (4–6 weeks): Cutting, sewing, washing, and finishing usually add another 30–45 days.

- Total timeline: On average, 45–90 days from fabric booking to delivery of finished jeans.

In competitive markets like fast fashion, a 2-week delay can mean missing a retail season. Some Turkish and Mexican suppliers market themselves as “speed-to-market” partners, offering 30–45 day cycles, nearly half the time of traditional South Asian supply chains.

Minimum Order Quantities (MOQs)

MOQ thresholds vary by supplier type and denim quality:

- Fabric mills: Mid-sized Asian mills typically set MOQs at 500–1,000 meters per fabric/color.

- Full-package suppliers: Garment manufacturers require 500–2,000 pieces per style, balancing efficiency with manageable inventory levels.

- Premium denim (selvedge/organic): Often 2,000+ meters or higher because of smaller, more specialized production runs.

For smaller brands, these numbers can be prohibitive. Some Bangladesh suppliers now advertise “low MOQ programs” of 200–300 pieces per style to attract independent labels and online retailers.

Supply Chain Risks

Denim sourcing is deeply tied to global supply dynamics:

- Cotton price volatility: In 2022, cotton prices surged by 40% year-on-year, hitting a decade high of $1.50 per pound (ICE Cotton Index). This volatility directly impacted FOB denim prices, which rose 15–25% across suppliers in Pakistan and India.

- Geopolitical factors: U.S.–China trade tensions and EU REACH chemical compliance add cost layers. For instance, compliance with EU chemical restrictions adds $0.20–0.40 per yard for mills that need extra testing or alternative chemicals.

- Logistics bottlenecks: Port congestion in South Asia can add 2–4 weeks delay. During the 2021 Suez Canal blockage, denim shipments faced rerouting delays of up to 6 weeks, costing some U.S. brands an estimated $50,000+ in missed sales opportunities per week.

Denim Supply Chain Data Table

| Factor | Denim Fabric Supply | Canvas Fabric Supply |

|---|---|---|

| Lead Time | 45–90 days (avg.) | 30–60 days (mass orders) |

| MOQ (garments) | 500–2,000 pcs per style | 1,000–3,000 pcs for niche fabrics |

| Price Risk | Cotton volatility (up to +40%/yr) | Organic certification premiums |

| Logistics Risk | Port congestion, container shortages | Higher airfreight costs for rush |

This table illustrates that denim is more vulnerable to raw material price swings, while canvas tends to be more affected by certification and shipping cost structures.

Critical Perspective

Large retailers like Inditex and Levi’s mitigate sourcing risk by:

- Dual sourcing: Splitting orders across suppliers in different geographies (e.g., Bangladesh + Turkey). This reduces dependency on one region and shortens replenishment times.

- Forward booking: Locking cotton prices through futures contracts, allowing them to stabilize input costs for 6–12 months.

- Nearshoring: Using Turkey, Mexico, or Morocco for smaller replenishment orders with shorter lead times.

Meanwhile, small to mid-sized brands often prioritize suppliers that offer:

- Lower MOQs for reduced inventory risk.

- Flexible shipping options such as air-sea combined freight, which is 30% faster than pure sea freight but 70% cheaper than air.

- Shared capacity programs, where multiple smaller brands share production runs to reach MOQ thresholds.

Case Example

A mid-sized U.S. denim label sourcing exclusively from Pakistan faced a 6-week shipment delay in 2021 due to Karachi port congestion and container shortages. The company reported lost sales worth $200,000 during the peak back-to-school season.

By adopting a dual-sourcing strategy with Vietnam and Turkey, the brand cut its average lead time exposure by 30%. Vietnam covered bulk orders at competitive prices, while Turkey handled urgent replenishment in 35 days, ensuring the label could react quickly to fast-moving trends.

This shift not only reduced risk but also helped the brand expand into European distribution, leveraging Turkey’s proximity to the EU for faster logistics.

In summary, denim sourcing is not only about securing fabric at the right price but also about balancing time, flexibility, and supply chain resilience. Buyers who integrate lead time management, MOQ negotiation, and multi-country sourcing strategies are better positioned to avoid costly disruptions and remain competitive.

What should buyers consider when choosing a denim jeans manufacturing partner?

In today’s denim supply chain, the right manufacturing partner can define the success of an entire collection. A great design or premium fabric may never reach its full potential if the partner lacks capacity, compliance, or reliability. For buyers — whether global retailers or niche fashion startups — the evaluation goes far beyond unit cost. It involves trust in delivery, expertise in fabric, adherence to regulations, and the ability to innovate in finishing and sustainability. When selecting a denim jeans manufacturing partner, buyers must evaluate fabric expertise, compliance certifications, production capacity, MOQ flexibility, lead times, and innovation services such as eco-washes and design support. These factors directly influence brand positioning, market access, and long-term profitability.

Fabric Expertise & Range

Denim is no longer one-dimensional; the market demands everything from classic 14 oz. rigid indigo to lightweight stretch blends. A capable partner should demonstrate:

- Versatility in fabric sourcing: From selvedge and organic denim to recycled cotton and elastane blends.

- Technical transparency: Swatch books, GSM ranges (8–16 oz. for jeans), and shrinkage/stretch data.

- Customization capability: Yarn count adjustments, indigo shade variation, and special weaves.

Example data: According to a 2024 sourcing survey, 65% of denim brands demanded stretch blends while 30% requested organic cotton fabrics. A supplier unable to cater to these preferences risks losing competitive edge.

Compliance & Certifications

Compliance is no longer optional. Global retailers expect strict certification frameworks to ensure worker safety, chemical safety, and ethical production:

- OEKO-TEX Standard 100: Guarantees no harmful substances in textiles.

- GOTS (Global Organic Textile Standard): Validates organic cotton production across the supply chain.

- WRAP & SEDEX audits: Verify labor practices and environmental responsibility.

Without these, brands face import rejections, reputational risks, and retail bans. For instance, EU regulations on azo dyes caused widespread shipment rejections in 2021, costing importers millions in penalties and product recalls.

Capacity & Lead Times

Manufacturing capacity should match a buyer’s growth ambitions:

- Large-scale suppliers: Facilities producing 50,000+ pcs/month are ideal for global brands requiring consistency.

- Mid- to small-sized suppliers: Perfect for niche collections or test runs with low MOQs (200–500 pcs per style).

Lead times vary widely:

- Bangladesh/Pakistan: 75–90 days typical.

- Turkey/Morocco: 35–50 days, faster replenishment.

- Mexico (for U.S. brands): 30–45 days, nearshoring advantage.

Case in point: In 2023, Zara’s fast-track collections used Turkish suppliers to cut lead times by 40%, allowing them to react to seasonal demand almost in real-time.

Innovation & Value-Added Services

Denim finishing has transformed from manual sandblasting to advanced laser and ozone technologies. Buyers should seek manufacturers offering:

- Sustainable washes: Enzyme, ozone, and laser finishing cut water use by up to 70%.

- Design consultation: Pattern development, wash guides, and trim suggestions.

- Technical R&D support: GSM balancing, shrinkage management, and recovery stretch performance.

Sustainability data: Levi’s Water<Less™ program demonstrated that eco-finishing saved over 3 billion liters of water between 2010 and 2022 — a benchmark every serious supplier should aim for.

Buyer Decision Matrix

| Evaluation Factor | Key Question | Impact |

|---|---|---|

| Fabric Range | Can they supply selvedge, organic, stretch, and recycled blends? | Determines product positioning and versatility |

| Compliance | Are they OEKO-TEX, GOTS, WRAP certified? | Unlocks EU/US premium retail access |

| Capacity & Flexibility | Can they balance MOQs with delivery agility? | Critical for scalability and inventory planning |

| Innovation | Do they provide sustainable washes, laser finishing? | Builds brand value and aligns with ESG goals |

| Support Services | Do they offer sampling, tech packs, and design support? | Speeds up time-to-market, reduces development costs |

Critical Perspective

Some buyers focus narrowly on lowest price per piece, but this short-term thinking often backfires. A 2022 study showed that factories lacking certifications had 18% higher rejection rates at customs compared to certified suppliers. Conversely, slightly higher costs at compliant factories open premium retail channels, reduce legal risks, and enhance consumer trust.

Moreover, in fashion cycles where speed matters, a $0.50 cost saving per pair means little if missed deadlines wipe out an entire season’s profit. The real value lies in resilience, agility, and compliance.

Case Example

A European mid-market retailer once sourced from uncertified South Asian factories, leading to 20,000 jeans rejected in Hamburg in 2020 due to azo dye non-compliance. The financial hit exceeded €300,000 in lost sales and fines.

After switching to a WRAP- and OEKO-TEX-certified Turkish supplier, the same retailer:

- Reduced returns by 12%.

- Secured distribution contracts with two major German department stores.

- Boosted brand reputation, allowing them to charge 10–15% higher retail prices for “eco-certified denim.”

This case highlights how compliance and innovation outweigh purely low-cost sourcing.

Partnering with Szoneier Fabrics

The denim jeans supply chain is a fusion of textile science, skilled craft, and sustainability commitments. Choosing the right partner determines not just fabric quality, but also speed-to-market and long-term brand credibility.

At Szoneier Fabrics, we offer:

- 18+ years of expertise in denim R&D and product development.

- Low MOQs (from 200 pcs per style), fast sampling (7–10 days), and custom wash programs.

- Compliance-ready production with OEKO-TEX, REACH, GOTS, and SEDEX certifications.

- Integrated services from swatch books to full-package design support.

- Global logistics solutions with flexible lead times across Asia, Europe, and North America.

Whether you need rigid selvedge denim for heritage lines, stretch blends for mass retail, or eco-washed denim for sustainable collections, our team ensures your products meet both market demand and regulatory standards.

Contact Szoneier Fabrics today for a tailored denim manufacturing quotation that combines compliance, agility, and innovation.