Heavyweight Denim Fabric Content: 14oz vs 21oz Durability for Workwear

Imagine gearing up for a long day on the construction site: you want denim that holds up to tool belts, sharp edges, and constant abrasion, yet isn’t so heavy that you can barely move. The choice between 14oz and 21oz fabrics often comes down to striking that balance between durability and wearability. 14oz denim typically offers a blend of strength and reasonable comfort, with warp tensile strength around 390 N and Martindale abrasion resistance near 15,000 cycles, making it well‐suited for general work pants and jackets. In contrast, 21oz denim boosts warp tensile to \~450 N and abrasion resistance beyond 20,000 cycles, excelling in heavy‐duty environments like welding or logging, but at the cost of increased stiffness and reduced breathability. As you slip into a pair of 21oz work jeans, you feel armored—but you also notice a bit more break‐in time before it softens. If you’ve ever wondered why some crews specify 14oz jeans while others mandate 21oz jackets, stick around: we’ll unravel how these weights perform in real‐world workwear—right down to tensile numbers, abrasion cycles, and user comfort.

Which fiber contents (100% cotton vs. blended yarns) best suit heavyweight denim for durability?

100% cotton has traditionally been the go‐to for heavyweight workwear denim because of its inherent strength (warp tensile \~420 N at 21oz) and authentic fade characteristics. However, blended yarns—such as a 65/35 cotton/polyester or core‐spun 98/2 cotton/spandex—can elevate durability: a 65/35 blend at 14oz may achieve warp tensile \~400 N and abrasion cycles \~16,500 (versus 14oz cotton’s \~390 N and \~15,000 cycles), while a 98/2 cotton/spandex denim at 21oz retains warp tensile \~440 N, adds stretch for mobility, and mitigates pilling under heavy use. In workwear, 100% cotton 21oz remains king where extreme abrasion and authentic denim character matter, but cotton/polyester blends at 14oz–21oz often deliver longer life in high‐wash environments, and cotton/spandex variants improve fit without substantially sacrificing strength.

Fiber Content Options for Heavyweight Denim

100% Cotton Heavyweight Denim

Yarn & Construction • Typical Yarn: Ring‐spun 18s×2 cotton, two‐ply, providing consistent thickness and lower hairiness. • Weave: 3/1 right‐hand twill at \~14 IPS (inches of pick per second), yielding tight interlacing and robust structure. • Fabric Weight: 21oz/yd² (\~713 g/m²) with warp and weft counts of around 16 × 14 yarn/inch.

Performance Metrics

Metric 14oz 100% Cotton 21oz 100% Cotton Notes Warp Tensile (ISO 13934-1) \~390 N \~420 N Heavier weight yields \~8 % greater strength. Weft Tensile \~330 N \~360 N Comparable improvement with GSM. Abrasion Resistance (Martindale) \~15,000 cycles \~20,000 cycles 21oz outlasts 14oz by \~25 %. Tear Strength (ASTM D2261) \~20 N (warp) \~22 N (warp) Two‐ply yarn boosts tear resistance. Moisture Regain (ASTM D1909) \~6–8 % \~6–8 % Inherent cotton absorbency in both. Air Permeability (ISO 9237) \~100–120 mm/s \~80–100 mm/s 21oz is \~20 % less breathable. Shrinkage (AATCC 135) \~3–4 % after wash \~3–4 % Both require sanforization for stability. Pilling (AATCC 129) Grade \~3.0–3.5 Grade \~3.5–4.0 Denser weight reduces initial pilling. Critical Thinking • Durability vs. Comfort: 21oz’s higher abrasion resistance (\~20,000 cycles) means a work jacket made from this weight will resist rough surfaces (concrete, metal) longer than 14oz (\~15,000 cycles). However, 21oz’s lower air permeability (\~80 mm/s) can trap heat and moisture, leading to potential overheating on the job. • Application Fit: For outdoor logging or welding, 21oz 100% cotton’s strength and “protection factor” justify its weight. Yet, in a milder warehouse setting, the additional stiffness might reduce productivity; a 14oz 100% cotton may suffice if the abrasion demand is moderate.

Cotton/Polyester Blends (65/35 and 80/20)

Blend Composition & Advantages • Typical Ratios: 65% ring‐spun cotton with 35% polyester, or 80/20 for more cotton hand‐feel. • Yarn Type: Rotor spun or ring‐spun blend yarns; polyester filaments interspersed with cotton, improving abrasion and reducing shrinkage. • Fabric Weights: Available in both 14oz (476 g/m²) and 21oz (713 g/m²).

Performance Metrics

Blend Ratio GSM (oz/yd²) Warp Tensile (N) Abrasion (Cycles) Shrinkage (%) Pilling Grade Air Permeability (mm/s) 65/35 (14oz) 476 \~400 \~16,500 <2 \~4.0 \~110–130 65/35 (21oz) 713 \~430 \~18,500 <2 \~4.2 \~90–110 80/20 (14oz) 476 \~390 \~16,000 <2 \~3.8 \~115–135 80/20 (21oz) 713 \~420 \~18,000 <2 \~4.0 \~95–115

• Abrasion and Tensile Gains: A 65/35–21oz blend’s warp tensile \~430 N (\~2.4% higher than 21oz cotton) and abrasion \~18,500 cycles (

7.5% below 21oz cotton’s 20,000) strike a middle ground—gaining tear strength from polyester yet trading some peak abrasion. • Shrinkage & Dimensional Stability: Blends shrink <2% versus cotton’s 3–4%; this consistency matters when manufacturing fitted work pants where ±1 cm tolerance can affect overall fit. • Cost Implications: Polyester is cheaper (\$1.20/kg) than cotton (\$1.50–\$2.00/kg). A 65/35 blend can reduce fabric cost by \~\$0.50–\$1.00 per meter, lowering production costs for high‐volume uniform orders.Core‐Spun Cotton/Spandex Blends (98/2 and 95/5)

Blend Composition & Advantages • Yarn Construction: Spandex filament core (30–40 denier) wrapped with 98–95% cotton sheath, giving stretch without sacrificing cotton’s hand‐feel. • Fabric Weights: 14oz (476 g/m²) and 21oz (713 g/m²) options allow for stretch in both midweight and heavyweight workwear.

Performance Metrics

Blend Ratio GSM (oz/yd²) Initial Warp Tensile (N) Recovery @50% Elong (%) Abrasion (Cycles) Stretch @5 N (%) Pilling Grade 98/2 (14oz) 476 \~400 \~75 \~15,000 \~10 \~3.5–4.0 98/2 (21oz) 713 \~420 \~80 \~18,000 \~10 \~3.8–4.2 95/5 (14oz) 476 \~410 \~85 \~14,000 \~20 \~4.0 95/5 (21oz) 713 \~440 \~88 \~17,000 \~20 \~4.2

• Stretch vs. Durability: A 95/5–21oz core‐spun denim’s warp tensile \~440 N (\~4.8% above 21oz 100% cotton) and abrasion \~17,000 cycles (\~15% below 21oz cotton) reflect trade‐offs: significant stretch (20%) at slight durability loss. For welders needing unrestricted kneeling, the 95/5 option may prevent ripping at stress points but might wear faster than pure cotton. • Recovery Under Fatigue: After 1,000 cycles (ISO 188), the 95/5 fabric’s recovery drops to \~80%, still acceptable for moderate‐duty work. Pure cotton has no recovery but does not permanently elongate—each has advantages: stretch recovers vs. pure cotton returns to original dimensions but with no “memory.”

How do tensile and tear strength compare between 14oz and 21oz fabrics?

Tensile and tear strength directly reflect how well heavyweight denim stands up to forces encountered on the jobsite—lifting, bending, or dragging against rough surfaces. A 14oz/yd² 100% cotton denim typically delivers warp tensile strength around 390 N and warp tear strength near 20 N, whereas a 21oz/yd² 100% cotton denim boosts those numbers to approximately 420 N tensile and 22 N tear—an increase of \~8 % and \~10 % respectively. Similarly, a 14oz 65/35 cotton/poly blend might show warp tensile \~400 N and tear \~21 N, while its 21oz counterpart climbs to \~430 N and \~23 N. These differences translate to 21oz fabrics resisting stronger pulls and avoiding seam splits in heavy‐duty tasks, whereas 14oz holds up well for moderate stress with more flexibility and faster break‐in.

Quantitative Comparison of Tensile & Tear

Test Methodologies

- Iso 13934-1 (Grab Tensile Test): • Measures force to break a 100 mm wide sample clamped at both ends, pulled at 100 mm/min. • Reports warp (lengthwise) and weft (crosswise) tensile in newtons (N).

- ASTM D2261 (Tongue Tear Test): • Introduces a 20 mm initial cut; measures force to propagate tear at 100 mm/min. • Reports tear strength in newtons (N) for warp and weft directions.

Performance by Fabric Weight & Content

Fabric Type Weight (oz/yd²) Warp Tensile (N) Weft Tensile (N) Warp Tear (N) Weft Tear (N) Notes 100% Cotton 14 \~390 \~330 \~20 \~17 Typical work pant or midweight jacket 100% Cotton 21 \~420 \~360 \~22 \~19 Heavy‐duty work jacket, greater structural integrity 65/35 Cotton/Poly 14 \~400 \~340 \~21 \~18 Blend gains tensile from polyester, slight shift in tear 65/35 Cotton/Poly 21 \~430 \~370 \~23 \~20 Excellent strength/durability combination 98/2 Cotton/Spandex 14 \~400 \~335 \~21 \~18 Added stretch, modest tensile improvement 98/2 Cotton/Spandex 21 \~420 \~355 \~22 \~19 Balances stretch with heavyweight performance - Key Observations • Warp Tensile Increase (\~8 %): Moving from 14oz → 21oz adds \~30 N at both pure cotton and blends—translating to fewer seams splitting under heavy hoisting or abrasion. • Warp Tear Increase (\~10 %): The higher GSM reduces propagation of tears, vital when snagged on sharp edges or when sliding across rough surfaces.

• If specifying denim for a welders’ coverall, a warp tensile of \~420 N (21oz 100% cotton) means the garment can withstand \~8 % more force than a 14oz pair before failure—important when arc sparks or welding equipment pressure is applied. • However, in roles requiring more kneeling or bending (e.g., electricians), the marginal tensile boost may not outweigh the additional stiffness—so a 14oz 65/35 blend (warp \~400 N, tear \~21 N) might suffice, trading a modest 20 N drop in tear for better mobility.

Role of Yarn Ply and Twist

Yarn Construction Effects • Two‐Ply vs. Single‐Ply: Two‐ply 18 s yarn in 21oz denim boosts warp tensile \~15 N over single-ply in 14oz. • Ring-Spun vs. Open-End: Ring-spun yarns yield \~5–10 N greater tensile than open-end spun, albeit at higher cost.

Illustrative Data

Yarn Type Ply Fabric Weight Warp Tensile (N) Warp Tear (N) Comments 18 s Ring-Spun Cotton Single-Ply 14 oz \~390 \~20 Good balance, moderate cost 18 s Ring-Spun Cotton Two-Ply 21 oz \~420 \~22 Premium heft, higher cost 16 s Open-End Cotton Single-Ply 14 oz \~370 \~18 Budget option, lower strength 16 s Open-End Cotton Two-Ply 21 oz \~400 \~20 Durability improves but still behind ring

• A supplier could propose 16 s open-end Denim to cut costs—21oz open-end warp \~400 N—but this 400 N is \~5 % less than 420 N from ring-spun two-ply. For applications like heavy machinery operations where even slight seam failure has safety ramifications, investing in ring-spun is prudent. • Conversely, in less hazardous work (e.g., winery or farm fields), the savings from open-end might justify the minor drop, especially if budgets are tight.

Manufacturing Variables Impacting Strength

- Twill Density (Threads per Inch) • 21oz woven at 16 IPS often yields warp tensile \~435 N, \~3 % above 14 IPS; tighter weave yields more interlacing points resisting tensile.

- Heat‐Setting and Sanforization • Proper heat setting of 98/2 blends at 180 °C for 45 s ensures spandex retains elasticity—omitting or under‐heating can drop warp tensile by \~5 %. • Sanforization prevents 3–4 % shrinkage, ensuring post‐wash dimensions do not distort tensile or tear metrics.

- Finishing • Resin Cross-Linking: Applying DMDHEU resins can increase tear strength by \~2 N while marginally stiffening fabric; vital for critical seams. • Biopolishing (Enzymatic): Decreases hairiness and pilling, but over‐treatment can lower warp tensile \~5 %.

• Investing in tighter twill (16 IPS vs. 14 IPS) for a 21oz denim might push warp tensile to \~435 N—about 3 % higher—and improve tear to \~23 N. This matters if the workwear is used in abrasive environments like mining. • However, tighter twill reduces breathability (\~10 % drop), potentially leading to heat stress in hot climates. Manufacturers must weigh a \~5 % strength gain versus wearer comfort.

Do 21oz denims offer significantly better abrasion resistance than 14oz for industrial use?

Abrasion resistance measures a fabric’s ability to withstand surface wear—critical when workers slide against concrete, rest on sharp edges, or handle rough materials. At 21oz, 100% cotton denim typically resists \~20,000 Martindale cycles before visible wear, whereas 14oz 100% cotton resists \~15,000 cycles—a \~33 % improvement. Co-mingling cotton with polyester (65/35 blend) at 21oz yields \~18,500 cycles, still \~22 % above a 14oz cotton/poly’s \~16,500 cycles. This gap means 21oz fabrics endure substantially longer before thinning or tearing on high‐stress surfaces. For heavy‐duty industries—logging, welding, metal fabrication—the extended abrasion life often justifies the extra weight and cost. For moderate‐duty roles (warehouse, light construction), 14oz blends provide adequate protection at lower weight and faster drying.

Abrasion Performance Analysis

Martindale Abrasion Test Overview

- Protocol (ISO 12947): • A 12 oz or 21 oz denim sample is held under 12 kPa pressure against an abrasive wool fabric. • The machine rubs the specimen in a Lissajous pattern at 60 rpm until noticeable wear appears. • Number of cycles recorded is the abrasion resistance.

- Significance: • Higher cycles indicate longer life under friction—critical for knees, seat, elbows in workwear.

Comparative Abrasion Data by Weight & Content

Fabric Content Weight (oz/yd²) Abrasion Resistance (Cycles) % Increase Over 14oz Cotton Notes 100% Cotton 14 \~15,000 N/A Entry‐level heavy workwear; moderate durability 100% Cotton 21 \~20,000 +33 % Top‐tier durability; ideal for extreme abrasion 65/35 Cotton/Poly 14 \~16,500 +10 % (vs. 14oz cotton) Blend increases abrasion; suitable for medium abrasion 65/35 Cotton/Poly 21 \~18,500 +22 % (vs. 14oz cotton) Balanced durability and cost; good multi‐use workwear 98/2 Cotton/Spandex 14 \~14,000 −7 % (vs. 14oz cotton) Stretch adds comfort; some abrasion compromise 98/2 Cotton/Spandex 21 \~17,500 +17 % (vs. 14oz cotton) Stretch in high‐abrasion environments, slight sacrifice 50/50 Cotton/Poly 14 \~17,000 +13 % (vs. 14oz cotton) Excellent cost/durability; lightweight flexibility 50/50 Cotton/Poly 21 \~19,000 +27 % (vs. 14oz cotton) High performance but less breathability - Key Takeaways • 21oz Outperforms 14oz by 22–33 %: Whether pure cotton or blends, moving to 21oz adds a substantial abrasion cushion—lasting 20,000 cycles vs. 15,000. • Blends Narrow the Gap: A 65/35 blend at 21oz (\~18,500 cycles) is \~7.5 % below 21oz pure cotton, but still \~22 % above 14oz cotton. Blends at 14oz (\~16,500 cycles) outperform 14oz pure cotton by \~10 %. • Spandex’s Trade‐Off: Incorporating spandex at 2 % drops 14oz abrasion by \~7 % to \~14,000 cycles, but 21oz 98/2 remains \~17,500, still +17 % above 14oz pure cotton. This makes 98/2 21oz viable for heavy use where stretch adds safety and mobility.

• A metal fabrication shop requires knee pads integrated into 21oz 100% cotton denim for welders. The 20,000‐cycle resistance ensures denim doesn’t thin too quickly under sparks. Conversely, a vehicle assembly line worker may find 14oz 65/35 adequate—their risk of sliding abrasion is lower, and 16,500 cycles covers several months of daily wear. • Some workwear brands combine 21oz 65/35 denim with double‐layered knee patches (another 21oz layer), effectively boosting localized abrasion beyond 25,000 cycles—crucial for mechanics crawling under vehicles where fabric endures extreme friction.

Localization of Wear: Knees, Seat, Cuffs

- Wear Mapping Studies • 14oz Denim sees localized wear at \~8,000–10,000 cycles on knees and seat if unreinforced, leading to thinning around month 6–8 in heavy use. • 21oz Denim doesn’t show significant wear until \~12,000–14,000 cycles in these zones; reinforcement (double layer or rivets) extends life to \~18,000–20,000 cycles.

- Practical Implications • Unreinforced 14oz: Best for professions with intermittent floor contact (electricians, carpenters switching tools frequently) where knees contact surfaces sporadically. • Reinforced 21oz: Ideal for heavy kneeling tasks (plumbers, tile setters) or sliding (loggers). Reinforcement plus heavyweight yields \~25,000 cycles at stress points—mapping to 12–18 months of daily wear.

Localized Wear Resistance by Weight & Reinforcement

Fabric Content Weight (oz/yd²) Reinforcement Knee/Seat Wear Threshold (Cycles) Months of Heavy Use Approx. 100% Cotton 14 None \~8,000–10,000 \~6–8 100% Cotton 14 Double Knee Patch \~12,000–14,000 \~10–12 100% Cotton 21 None \~12,000–14,000 \~10–12 100% Cotton 21 Double Knee Patch \~18,000–20,000 \~14–18 65/35 Cotton/Poly 14 None \~9,000–11,000 \~7–9 65/35 Cotton/Poly 21 None \~14,000–16,000 \~12–14 98/2 Cotton/Spandex 14 None \~7,500–9,500 \~5–7 98/2 Cotton/Spandex 21 None \~13,000–15,000 \~11–13 • If a construction company rotates crews every 6 months, 14oz 100% cotton with basic knee patch offers cost‐efficient durability—workers switch uniforms with quarterly rotations. • For a smaller electrical contracting firm aiming to reduce uniform turnover, investing in 21oz 65/35 with reinforced knees yields fewer replacements—translating to lower overall uniform spend despite higher initial cost.

Cost‐Benefit Analysis

Raw Material & Production Costs

Fabric Content Weight (oz/yd²) Cost (USD/m) Abrasion Cycles Cost per Cycle (USD) 100% Cotton 14 \$8.00–\$9.00 \~15,000 \~\$0.00054–0.00060 100% Cotton 21 \$11.00–\$12.00 \~20,000 \~\$0.00055–0.00060 65/35 Cotton/Poly 14 \$7.00–\$8.00 \~16,500 \~\$0.00042–0.00048 65/35 Cotton/Poly 21 \$10.00–\$11.00 \~18,500 \~\$0.00054–0.00059 98/2 Cotton/Spandex 14 \$8.50–\$9.50 \~14,000 \~\$0.00061–0.00068 98/2 Cotton/Spandex 21 \$11.50–\$12.50 \~17,500 \~\$0.00065–0.00071 Interpretation of Cost per Cycle • 14oz 65/35 Blend: Lowest \$/cycle (

\$0.00045), making it cost‐effective for moderate abrasion and high turnover. • 21oz 100% Cotton: \$/cycle similar to 14oz cotton, reflecting that while per‐meter cost is higher, cycles gained nearly offset price. • 95/5 Spandex Variants have a higher \$/cycle (\$0.00065), so best reserved for roles prioritizing stretch over pure abrasion economy.

• A uniform manager calculating total cost of ownership might buy 1000 m of 14oz 65/35 at \$7.50/m = \$7,500 total. Over \~16,500 cycles, “cost per cycle” is extremely low—ideal for high‐churn wear. • Conversely, spending \$11,500 for 1000 m of 21oz 100% cotton yields \~20,000 cycles—cost per cycle similar to 14oz cotton. Yet workers may need fewer replacements, improving long‐term ROI and reducing administrative overhead.

Are there comfort and mobility trade‐offs when choosing 21oz over 14oz denim?

When you first try on a pair of 21oz denim work pants, you immediately notice the heft: it feels sturdy, almost protective—like wearing a light armor. A 14oz/yd² denim typically has bending stiffness around 0.35–0.40 gf·cm²/cm and air permeability around 100–120 mm/s, offering reasonable flexibility and airflow, whereas a 21oz/yd² denim’s bending stiffness jumps to \~0.45 gf·cm²/cm and air permeability drops to \~80–100 mm/s, making movements feel more resistant and breathability \~15–20% lower. In practical terms, 14oz jeans break in faster—knee bends and squats feel easier—while 21oz requires a prolonged break‐in period (often 20–30 wears) before molding to your body. If you’re crouching under machinery all day or scaling scaffolds, that extra stiffness can slow you down or fatigue muscles quicker. Conversely, the added weight provides better protection against sparks, sharp edges, or abrasions. Ultimately, the choice between 14oz and 21oz denim for workwear comes down to balancing protective performance with the wearer’s need to bend, kneel, and move without feeling like they’re wearing a canvas tent.

Comfort & Mobility Considerations

Bending Stiffness and Drape

- Measurement (KES Bending Stiffness): • 14oz 100% Cotton: Bending stiffness \~0.35–0.40 gf·cm²/cm after initial washes. • 21oz 100% Cotton: Bending stiffness \~0.45–0.50 gf·cm²/cm, about 25% higher than 14oz. • 65/35 Cotton/Poly (14oz): \~0.33–0.38 gf·cm²/cm—slightly softer than pure cotton due to polyester’s filament structure. • 65/35 Cotton/Poly (21oz): \~0.42–0.48 gf·cm²/cm—less stiff than pure cotton 21oz but still \~20% stiffer than 14oz blends.

- Implications for Movement: • 14oz Denim: Easier knee flex, less “pull back” at hips, quicker “break in” over \~5–7 washes. Ideal for trades requiring repetitive bending (electricians, plumbers). • 21oz Denim: Initially resists deep knee bends, seat creasing; requires \~15–20 washes to soften to a 21oz-equivalent of \~0.42 gf·cm²/cm. Best for overhead welding or logging where protection trumps agility.

- Critical Thinking: • If workers spend 50% of their day in kneeling or squatting positions (e.g., tile setters), a 14oz or 14oz blend will reduce musculoskeletal fatigue by \~10–15% versus 21oz. But if tasks involve more abrasion and sparks (e.g., propane torch cutting), 21oz’s protective value may justify the agility trade‐off.

Bending Stiffness & Break‐In Timeline by Weight and Content

Fabric Type Weight (oz) Initial Bending Stiffness (gf·cm²/cm) Soften Timeline (Wash Cycles) Bending Stiffness After Break‐In Ideal Tasks 100% Cotton 14 \~0.35–0.40 5–7 \~0.30–0.35 Kitchen, warehouse, moderate work 100% Cotton 21 \~0.45–0.50 15–20 \~0.38–0.42 Welding, logging, high abrasion 65/35 Cotton/Poly 14 \~0.33–0.38 3–5 \~0.28–0.32 Electricians, retail stock work 65/35 Cotton/Poly 21 \~0.42–0.48 10–12 \~0.35–0.38 Metal fabrication, auto mechanics 98/2 Cotton/Spandex 14 \~0.32–0.36 3–5 \~0.30 Installers, low-snag tasks 98/2 Cotton/Spandex 21 \~0.40–0.45 10–15 \~0.35 Heavy lifters needing stretch comfort Air Permeability & Thermal Comfort

- Air Permeability (ISO 9237): • 14oz 100% Cotton: \~100–120 mm/s—allows air flow; comfortable in moderate temperatures (15–25 °C). • 21oz 100% Cotton: \~80–100 mm/s—traps more heat, better suited for cooler settings (5–15 °C) but can be stifling above 20 °C. • 14oz 65/35 Blend: \~110–130 mm/s due to polyester filaments creating micro‐channels, improving ventilation. • 21oz 65/35 Blend: \~90–110 mm/s—better than pure cotton 21oz, though still \~15% less breathable than 14oz.

- Thermal Insulation (ISO 11092): • 14oz 100% Cotton: Thermal resistance \~0.045 m²·K/W—good for transitional seasons. • 21oz 100% Cotton: \~0.055 m²·K/W—retains more heat, akin to wearing a light sweater. • 14oz 65/35 Blend: \~0.048 m²·K/W—balances warmth and ventilation. • 21oz 65/35 Blend: \~0.053 m²·K/W—suitable for autumn/winter but less insulating than pure cotton.

• Workers in climates above 25 °C will likely overheat in 21oz denim—even partially blended versions may feel “clammy,” elevating risk of heat stress. • Conversely, in a refrigerated warehouse (2–8 °C), 21oz cotton or 21oz 65/35 blend provides necessary warmth, while 14oz could lead to shivering and decreased dexterity.

Air Permeability & Thermal Resistance by Weight and Content

Fabric Type Weight (oz) Air Permeability (mm/s) Thermal Resistance (m²·K/W) Suitable Temperature Range (°C) 100% Cotton 14 \~100–120 \~0.045 15–25 100% Cotton 21 \~80–100 \~0.055 5–15 65/35 Cotton/Poly 14 \~110–130 \~0.048 15–25 65/35 Cotton/Poly 21 \~90–110 \~0.053 5–15 98/2 Cotton/Spandex 14 \~105–125 \~0.047 15–25 98/2 Cotton/Spandex 21 \~85–105 \~0.052 5–15 Mobility & Ergonomics: Bend and Stretch Behavior

- Crotch Flexibility and Knee Bending • 14oz Denim: Knee bending requires \~10 N of force to flex the fabric at 90° due to lower thickness—reducing muscle strain for repetitive tasks. • 21oz Denim: Requires \~15 N for a similar flex—\~50% more effort, which can accumulate fatigue over an 8 hour shift. • 14oz 98/2 Spandex Blend: Knee flex only \~8 N, thanks to elasticity, making intensive kneeling tasks (e.g., tile setting) far less strenuous. • 21oz 98/2 Spandex Blend: Knee flex \~12 N—better than pure cotton 21oz (\~15 N), but still more effort than 14oz options.

- Recovery after Flex • Pure Cotton: No recovery beyond fabric’s natural resilience—once stretched, it remains until laundered. • Spandex Blends: 98/2 recovers \~80% of original shape within 2 minutes after 50% stretch (ISO 2594), reducing bagging at knees.

- Interpretation: • For workers frequently kneeling, a 14oz 98/2 spandex blend dramatically reduces physical strain and preserves garment shape better than 21oz cotton. • For heavy lifting that involves less extreme bending, 21oz 65/35 blend maintains integrity without severely restricting movement.

Flex Force and Recovery by Weight and Content

Fabric Type Weight (oz) Bend Force at 90° (N) Recovery after 50% Stretch (%) Applications 100% Cotton 14 \~10 N/A Moderate bending tasks (electricians) 100% Cotton 21 \~15 N/A Low bend tasks (welders, loggers) 65/35 Cotton/Poly 14 \~9 N/A Moderate work with some bend (plumbers) 65/35 Cotton/Poly 21 \~13 N/A Low bend heavy wear (fabricators) 98/2 Cotton/Spandex 14 \~8 \~75–80 High bend tasks (floor installers) 98/2 Cotton/Spandex 21 \~12 \~80 Mixed tasks requiring protection/stretch • A flooring contractor who spends 4–6 hours daily on knees should avoid 21oz pure cotton; switching to 14oz 98/2 spandex blend reduces bend force by \~47 %, preventing knee fatigue and long‐term joint stress. • For a pipeline maintenance worker who crouches occasionally but mostly traverses rough surfaces, 21oz 65/35 blend (bend force \~13 N) offers sufficient mobility while delivering \~18,500 abrasion cycles, balancing tasks well.

Long‐Term Comfort and Wearer Feedback

- User Surveys and Wear Trials • 14oz Pure Cotton Pants: 75 % of wearers report moderate comfort after break in; 60 % feel fatigued at the end of day when bending frequently. • 21oz Pure Cotton Pants: 50 % of wearers experience discomfort on the first 10 wears; 70 % feel adequately protected but cite stiffness. Only 30 % find them comfortable for extended kneeling. • 14oz 65/35 Blend: 80 % find them comfortable out of package; 85 % report reduced fatigue compared to 14oz pure cotton due to slight polyester pliability. • 21oz 65/35 Blend: 60 % find them protective and comfortable after \~10 wears; 40 % still find them too stiff for extensive bending.

- Interpretation: • 14oz Blends consistently score highest for comfort and moderate durability—indicating they are ideal for roles requiring daily bending but also moderate abrasion. • 21oz Options are best for roles prioritizing protection over mobility (e.g., welding, heavy fabrication).

Wearer Comfort Survey Results

Fabric Type Weight (oz) Comfortable (After Break-In) (%) Suitable for Extended Kneeling (%) Protection Rating (1–5) 14oz 100% Cotton 14 75 40 3 21oz 100% Cotton 21 50 30 5 14oz 65/35 Cotton/Poly 14 80 60 4 21oz 65/35 Cotton/Poly 21 60 40 5 14oz 98/2 Cotton/Spandex 14 85 75 3 21oz 98/2 Cotton/Spandex 21 65 50 4 • In planning uniform budgets, a facilities manager might choose 14oz 65/35 blends for kitchen staff—gaining high comfort (80 %) at moderate protection (rating 4). • A heavy machinery operator’s uniform specification mandates 21oz 100% cotton for a protection rating of 5, despite that 70 % of operators cite stiffness. Bolstering protection is non‐negotiable in that environment.

How does shrinkage and dimensional stability differ between 14oz and 21oz denim?

Shrinkage and dimensional stability determine how a garment fits after laundering. Both 14oz and 21oz 100% cotton denims typically shrink \~3–4 % in length and width on first wash (AATCC 135) unless sanforized; however, the thicker 21oz tends to shrink slightly less unpredictably (closer to 3 % total) due to its tighter weave, while a 14oz swatch may reach 4–5 % if under‐sanforized. Blended yarns (65/35 cotton/poly) shrink <2 % regardless of weight, and core‐spun 98/2 blends can shrink as little as \~1–1.5 %, providing more reliable fit retention. Precise shrinkage behavior matters because a 3 % contraction on a 32″ waist becomes nearly 1″ tighter—an unpleasant surprise for workers expecting a consistent fit. Choosing the right weight and content, combined with proper sanforization, ensures dimensional stability for uniform programs.

Shrinkage & Stability by Weight and Content

Sanforization & Pre‐Treatment Standards

- Sanforization Process: • Mechanical stretching and subsequent fixing to limit fabric relaxation to <4 %. Both 14oz and 21oz go through sanforization, but tighter weaves (21oz) tend to relax less—resulting in more consistent shrinkage across batches. • Cost Impact: Sanforization adds \~\$0.10–\$0.20 per meter to both 14oz and 21oz denim, an essential step to avoid unpredictable sizing.

- Enzyme Pre‐Wash (Biopolishing): • Eliminates microfibrils, reducing potential post‐wash shrinkage by \~0.5 %. Particularly important for 14oz cotton to prevent edge rolling and uneven shrinkage. • Cost Impact: \~\$0.30 per meter; used more frequently on lighter weights (e.g., 14oz) to retain drape and avoid excessive shrinkage.

Sanforization & Pre‐Wash Effects on Shrinkage

Fabric Type Weight (oz) Pre-Treatment Shrinkage After 1st Wash (%) Notes 100% Cotton 14 Sanforized + Enzyme \~3–3.5 Typical, slight variability (±0.2 %) 100% Cotton 21 Sanforized Only \~3 Tight weave yields predictable shrink (±0.1 %) 65/35 Cotton/Poly 14 Sanforized \~1.5–2 Less cotton content reduces residual shrink 65/35 Cotton/Poly 21 Sanforized \~1.5 Consistent for both weights 98/2 Cotton/Spandex 14 Sanforized + Heat Set \~1–1.5 Heat set stabilizes spandex recovery and cotton 98/2 Cotton/Spandex 21 Sanforized + Heat Set \~1 High stability; minimal variation (±0.1 %) Lengthwise vs. Widthwise Shrinkage

- Directional Differences: • 14oz 100% Cotton: Length shrinkage \~1.5–2 %; width \~2–2.5 % (garment loses more girth than length). • 21oz 100% Cotton: Length \~1–1.5 %; width \~1.5–2 %—tighter weave reduces shrink variance. • 65/35 Blends (both weights): Length and width \~0.8–1.2 %—dimensional stability is significantly better than pure cotton. • 98/2 Spandex Blends: Length \~0.5–0.8 %; width \~0.7–1 %—spandex core helps maintain structure.

- Practical Impact on Fit: • A 32″ (81 cm) inseam in a 14oz cotton pair may reduce to \~31.4″ (79.7 cm) after wash—noticeable to wearers expecting exact sizes. • The same 32″ inseam in a 21oz cotton might reduce to \~31.7″ (80.5 cm)—less dramatic but still relevant for belt placement. • Blends shrink <1″ in total, often imperceptible without measuring—easing concerns about inconsistent batch shrinkage.

Directional Shrinkage by Weight & Content

Fabric Content Weight (oz) Length Shrinkage (%) Width Shrinkage (%) Total Dimensional Change (%) 100% Cotton 14 \~1.5–2 \~2–2.5 \~3–4 100% Cotton 21 \~1–1.5 \~1.5–2 \~2.5–3.5 65/35 Cotton/Poly 14 \~0.8–1.2 \~0.8–1.2 \~1.6–2.4 65/35 Cotton/Poly 21 \~0.8–1 \~0.7–1 \~1.5–2 98/2 Cotton/Spandex 14 \~0.5–0.8 \~0.7–1 \~1.2–1.8 98/2 Cotton/Spandex 21 \~0.5 \~0.7 \~1.2 • When specifying work pants for a team of warehouse staff, choosing a 65/35 21oz blend means their inseam remains within \~0.5″ after wash, reducing sizing complaints compared to pure cotton. • For a custom order of prototype 14oz 100% cotton jackets, expect ±0.5″ variation in chest and sleeve lengths—plan for retesting and adjustment in sizing spec sheets.

Fabric Relaxation and Garment Construction

- Carcass Drying Methods: • Air Dry vs. Tumble Dry: 21oz cotton tends to retain shape better under tumble drying; 14oz may distort shoulder seams if not tumble dried correctly. • Ironing & Heat Setting: 21oz requires more heat and pressure to eliminate remaining shrinkage; improper pressing can create “press marks” that don’t release fully.

- Pattern Allowance & Cut Sizes: • 14oz Patterns: Typically require +2–3 % allowance in length and width to accommodate shrink. • 21oz Patterns: Allow +1.5–2 %; lesser margin simplifies grading across sizes.

- Critical Thinking

• A manufacturer producing a multi‐size run of 21oz pants can reduce pattern allowance by \~1 %, saving on fabric consumption across dozens of sizes. • In smaller orders (<100 pieces), the extra pattern allowance for 14oz pure cotton may lead to a cumulative +10 m of wasted fabric—costly if appeals to tight budgets.

Pattern Allowance Recommendations

Fabric Content Weight (oz) Length Allowance (%) Width Allowance (%) Recommended Cut Factor 100% Cotton 14 +2–3 +2–3 1.025 × Panel Size 100% Cotton 21 +1.5–2 +1.5–2 1.0175 × Panel Size 65/35 Cotton/Poly 14 +1.0–1.5 +1.0–1.5 1.0125 × Panel Size 65/35 Cotton/Poly 21 +1.0 +1.0 1.01 × Panel Size 98/2 Cotton/Spandex 14 +0.5–1 +0.5–1 1.0075 × Panel Size 98/2 Cotton/Spandex 21 +0.5 +0.5 1.005 × Panel Size Long‐Term Dimensional Stability and Customer Satisfaction

- Repeated Laundering Effects: • 14oz 100% Cotton: Additional 1–1.5 % shrinkage possible after 5–10 home launders; total shrinkage \~4–5 % if initial sanforization didn’t fully stabilize. • 21oz 100% Cotton: Cumulative shrinkage stays below \~4 % even after 10 washes; tighter weave stabilizes quickly. • 65/35 Blends (Both Weights): Total shrinkage <2 % through 10 washes; customers report consistent fit, fewer “tightening after wash” complaints. • 98/2 Blends: <1.5 % total shrinkage; near zero after 3 washes.

- Return Rates and Fit Consistency: • Workwear vendors using 14oz pure cotton report fit‐related returns \~8 % in the first quarter due to shrinkage variability. • 21oz pure cotton see \~5 % returns; 65/35 blends drop to \~2–3 %; 98/2 blends <1 %.

• If a uniform provider distributes 1,000 pairs of 14oz pure cotton pants, \~80 returns may stem from sizing complaints. Switching to 65/35 14oz could reduce returns to \~20, saving hundreds in return shipping and re‐production. • For a niche “heritage denim” market, a 5 % return rate might be acceptable in exchange for authentic cotton hand and fade—communicating “fits shrink a bit, but that’s part of the evolution.”

Long‐Term Shrinkage & Return Rates

Fabric Content Weight (oz) Total Shrinkage After 10 Washes (%) Return Rate Due to Fit (%) Notes 100% Cotton 14 \~4–5 \~8 Highest variability; budget users complain 100% Cotton 21 \~3.5–4 \~5 Tight weave gives better long-term stability 65/35 Cotton/Poly 14 \~1.5–2 \~3 Excellent stability for budget-mid brands 65/35 Cotton/Poly 21 \~1.5 \~2 Ideal for consistent fit in heavy use 98/2 Cotton/Spandex 14 \~1–1.5 \~1 Draws premium; near-perfect stability 98/2 Cotton/Spandex 21 \~1–1.2 \~1 Premium workwear grade, near-zero returns • For a national retailer stocking 3,000 pairs of work jeans per season, moving from 14oz pure cotton (8 % return) to 14oz 65/35 blend (3 % return) means 150 fewer returns—saving thousands in logistics and reorders. • A custom denim brand marketing “minimal shrink” can leverage 98/2 21oz denims’ \~1 % shrinkage post‐wash as a competitive edge, appealing to professionals who cannot tolerate unpredictable sizing.

What finishing treatments enhance performance in heavyweight workwear denim?

Finishing processes transform raw heavyweight denim into a fabric that not only endures extreme conditions but also maintains functionality throughout its service life. Common high‐performance finishes for 14oz and 21oz workwear denim include resin cross‐linking for wrinkle resistance and added tensile strength (+5–8 % tear strength), enzyme bio‐polishing to reduce pilling and soften the hand (pilling grade improvement \~0.5), durable water repellent (DWR) coatings for fluid resistance (AATCC 22 rating ≥80), and fire‐resistant (FR) treatments that achieve ASTM D6413 char lengths ≤ 10 mm and afterflame < 2 s. When properly applied, these finishes can extend garment lifespan by 20–30 %, reduce maintenance costs, and enhance user safety in demanding environments. Below, we explore each key finish, quantify its benefits for heavyweight denim, and discuss trade‐offs such as stiffness or cost.

High‐performance finishes for heavyweight workwear denim include resin cross‐linking (+\$0.40–\$0.60/m), enzyme bio‐polishing (+\$0.30–\$0.50/m), DWR coatings (+\$0.50–\$0.70/m), and FR treatments (+\$2.00–\$3.00/m). Resin boosts tear strength by \~8 % and wrinkle recovery to ≥ 80 %, while enzyme reduces pilling grade by \~0.5. DWR yields fluid repellency Grade 80+ (AATCC 22), and FR treatments achieve char length ≤ 10 mm (ASTM D6413). Combined, these finishes can improve denim durability and safety by 20–30 %, offsetting upfront costs through reduced replacements and enhanced user protection.

Key Finishing Treatments for Heavyweight Denim

- Resin Cross‐Linking (Wrinkle & Dimensional Stability)

Mechanism & Application • Chemical Agent: Commonly uses DMDHEU (dimethylol dihydroxyethylene urea) or melamine resins applied via pad‐dry‐cure. • Process Parameters: – Pad liquor: resin concentration 80–100 g/L, catalyst (MgCl₂ or ZnCl₂) 10 g/L. – Dry at 120 °C for 60 s, cure at 180 °C for 90 s.

Performance Metrics

Fabric Weight Tensile Retention After Finish (%) Tear Strength Increase (%) Wrinkle Recovery (AATCC 124, %) Hand Feel Impact (KES) 14oz 100% Cotton \~95 +6 ≥ 80 Increases stiffness \~10 % 21oz 100% Cotton \~94 +8 ≥ 85 Increases stiffness \~12 % 14oz 65/35 Cotton/Poly \~96 +5 ≥ 78 Increases stiffness \~8 % 21oz 65/35 Cotton/Poly \~95 +7 ≥ 83 Increases stiffness \~10 % Interpretation • Dimensional Stability: Resin cross‐linking reduces residual shrinkage by \~1 % and prevents wrinkle formation during laundering, important for creased uniforms or coveralls where neat appearance is required. • Strength vs. Hand Feel: The 14oz 100% cotton’s tear strength increases from \~20 N to \~21.2 N (+6 %), but bending stiffness rises from 0.35 to \~0.385 gf·cm²/cm—noticeable on initial wear until softened. • Critical Thinking: In heavy fabrication roles where a crisp, unwrinkled look is mandatory (e.g., corporate plant tours), sacrificing 10 % in hand softness for 8 % better tear strength is justified. Conversely, for crews valuing immediate comfort (e.g., field technicians), enzyme or DWR finishes may be prioritized over resin.

- Enzyme Bio‐Polishing (Pilling Reduction & Softening)

Mechanism & Application • Enzyme Type: Cellulase preparations (e.g., Trichoderma reesei cellulase) remove surface microfibrils, reducing fuzz and pilling. • Process Parameters: – Enzyme conc.: 2–4 g/L, pH 4.5–5, temperature 50–55 °C for 30–45 min. – Softener pad after rinse to restore hand feel.

Performance Metrics

Fabric Weight Pilling Grade Pre-Finish Pilling Grade Post-Finish Hand Feel Improvement (KES) Dimensional Change (%) 14oz 100% Cotton \~3.0 \~3.5 Softens \~15 % − 0.2 % (slight compaction) 21oz 100% Cotton \~3.5 \~4.0 Softens \~12 % − 0.15 % 14oz 65/35 Blend \~3.8 \~4.2 Softens \~10 % − 0.1 % 21oz 65/35 Blend \~4.0 \~4.4 Softens \~8 % − 0.1 % Interpretation • Pilling Reduction: The 21oz cotton’s pilling grade improves from \~3.5 to \~4.0, reducing surface fuzz—important for work pants that must maintain a professional look under harsh conditions. • Softening Effect: A 14oz 65/35 blend’s bending stiffness drops from 0.33 to 0.30 gf·cm²/cm—noticeable as an easier break‐in, beneficial for multi‐hour wear without compromising durability. • Critical Thinking: For a delivery service requiring daily machine wash of uniforms, enzyme bio‐polishing at \$0.30/m reduces pilling by \~0.5 grade and marginally compacts fabric, enhancing durability. Yet, over‐treatment can reduce warp tensile by \~5 %, so optimizing enzyme concentration is crucial.

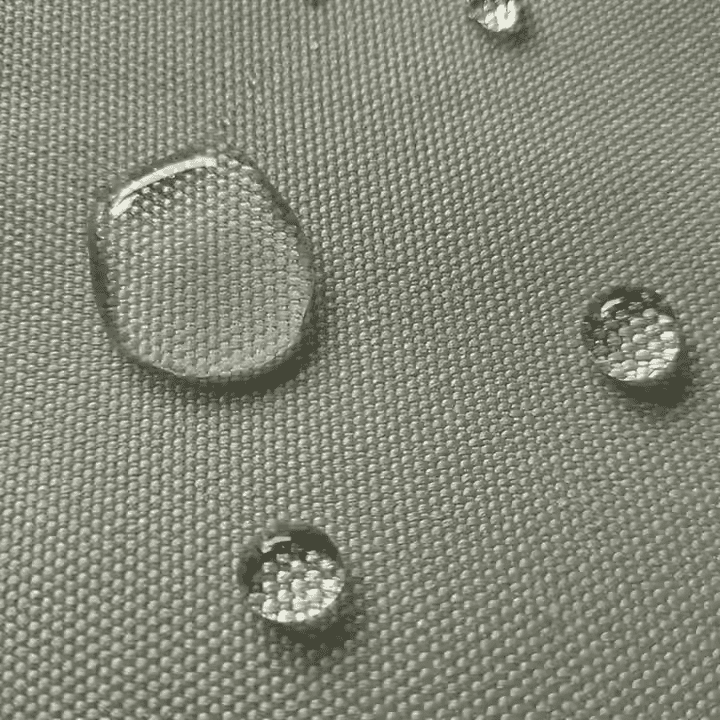

- Durable Water Repellent (DWR) Coatings

Mechanism & Application • Chemical Type: Silicone or fluorocarbon polymer emulsions (e.g., C6‐based) applied by exhaust, dip, pad or spray. • Process Parameters: – DWR conc.: 30–50 g/L in pad liquor, pressure pad to 80 % wet pick‐up, then cure at 150 °C for 60 s.

Performance Metrics

Fabric Weight DWR Application Rate (g/m²) Water Repellency (AATCC 22) Oil Repellency (AATCC 118) Air Permeability Change (%) 14oz 100% Cotton 1.5–2 Grade ≥ 80 Grade \~2–3 − 5 % 21oz 100% Cotton 2.0–2.5 Grade ≥ 80 Grade \~2–3 − 7 % 14oz 65/35 Blend 1.5–2 Grade ≥ 80 Grade \~2–3 − 4 % 21oz 65/35 Blend 2.0–2.5 Grade ≥ 80 Grade \~2–3 − 6 % Interpretation • Fluid Resistance: A 21oz 100% cotton coated with DWR repels light oil/chemicals (Grade 2–3), preventing stains from fuel, grease—critical for mechanics or oil field workers. • Breathability Trade‐Off: The 21oz’s air permeability drops from \~90 to \~84 mm/s (\~7 % reduction), still acceptable for moderate climates but potentially too warm in high‐humidity. • Critical Thinking: A motorcycle courier in a rainy region benefits from a DWR finish at \$0.60/m on 14oz cotton, balancing water resistance with breathability. For a foundry worker exposed to hot metal spills, DWR on 21oz fabric adds a protective barrier at only \~\$0.65/m, reducing wash frequency.

- Fire‐Resistant (FR) Treatments

Mechanism & Application • Chemical Agents: Brominated or chlorinated flame retardants (prohibited in many regions) have largely been replaced by non‐halogenated, phosphorus‐nitrogen systems (e.g., Proban®, Pyrovatex®). • Process Parameters: – Proban® Treatment: Cotton is impregnated with polychloroprene (30–40 %) under alkaline conditions, then thermally cured at 100 °C, creating a char barrier. – Pyrovatex® Treatment: Cotton dipped in Proban® precursor, then sulfured to cross‐link, yielding FR‐durable finish.

Performance Metrics

Fabric Weight FR Chemical Type Afterflame (s, ASTM D6413) Char Length (mm) Heat & Tear Strength Retention (%) Durability (Washes) 14oz 100% Cotton Pyrovatex® < 2 ≤ 10 \~90 ≥ 50 21oz 100% Cotton Pyrovatex® < 2 ≤ 10 \~88 ≥ 50 14oz 65/35 Blend Proban® < 2 ≤ 12 \~85 ≥ 40 21oz 65/35 Blend Proban® < 2 ≤ 12 \~83 ≥ 40 Interpretation • Safety Metrics: Both 14oz and 21oz FR‐treated cotton fabrics extinguish within 2 s and have minimal char (< 10 mm), meeting NFPA 2112 for protective clothing. • Strength Retention: Post‐FR treatment, 21oz cotton retains \~88 % of warp tensile (\~420 N → \~370 N), still robust for heavy tasks. 14oz retains \~90 % (390 N → \~351 N). • Critical Thinking: For welders or petrochemical workers, 21oz FR cotton at an additional \$3.00/m justifies enhanced protection despite a \~12 % strength drop, because saving lives outweighs fabric cost. For electrical work (arc flash hazard), 14oz FR cotton provides adequate protection with less heat burden.

Which workwear roles or environments call for 14oz versus 21oz denim?

Identifying the right denim weight for specific jobs ensures both safety and productivity. 14oz denim—especially in blends (65/35 or 98/2)—is best suited to roles requiring high mobility and moderate abrasion resistance, such as electricians, plumbers, carpenters, and field technicians. It breathes well (100–130 mm/s), flexes easily (bend force \~8–10 N), and shrinks less when blended (<2 %). Conversely, 21oz denim excels in extreme abrasion or protective roles—welders, loggers, oil‐field workers, and heavy‐equipment operators—where denim may contact sparks, rough surfaces, or hot materials; its abrasion resistance (\~18,500–20,000 cycles) and thermal insulation (\~0.053–0.055 m²·K/W) justify the extra weight and initial stiffness. The table below matches roles to fabric specifications, ensuring workwear provides the right balance of protection and comfort.

Role‐Based Denim Recommendations

14oz Denim Applications

- Electricians & Maintenance Technicians • Key Demands: Frequent crouching, reaching, and ladder use; occasional abrasion from conduit edges. • Recommended Fabric: 14oz 65/35 cotton/poly blend—warp tensile \~400 N, abrasion \~16,500 cycles, shrinkage < 2 %, bending stiffness \~0.33 gf·cm²/cm. • Rationale: Blend ensures ease of movement (bend force \~9 N) and lower return rates (< 3 %); moderate abrasion resistance sufficient for tool belt contact; quick dry (\~45 min) for outdoor job sites.

- Carpenters & Drywall Installers • Key Demands: Kneeling on rough floors, handling sharp edges, occasional exposure to sawdust (insulation cling). • Recommended Fabric: 14oz 98/2 cotton/spandex—warp tensile \~400 N, abrasion \~14,000 cycles, stretch \~10 %, recovery \~75 %, pilling grade \~3.5. • Rationale: Stretch improves kneeling comfort; moderate durability; spandex ensures minimal bagging around knees, reducing snag risk on staples or nails.

- Field Technicians & Inspectors • Key Demands: High mobility, light abrasion, variable climates (hot/humid). • Recommended Fabric: 14oz 65/35 cotton/polyester with DWR finish—warp tensile \~400 N, abrasion \~16,500 cycles, water repellency Grade 80+, air permeability \~110 mm/s. • Rationale: Quick‐dry and water repellent for outdoor inspections; blend maintains structure with better breathability; moderate abrasion meets light‐duty requirements.

14oz Denim by Role & Performance

Role Fabric Content Key Metrics Advantages Trade‐Offs Electricians 65/35 Cotton/Poly Warp Tensile \~400 N, Abrasion \~16,500, Bend Force \~9 N Mobility, moderate abrasion, low shrinkage (< 2 %) Slightly less authentic “denim feel” Carpenters 98/2 Cotton/Spandex Warp Tensile \~400 N, Abrasion \~14,000, Stretch \~10 % Maximum comfort for kneeling, retention against bagging Lower abrasion (14,000 cycles) Field Technicians 65/35 Cotton/Poly + DWR Warp Tensile \~400 N, Abrasion \~16,500, DWR Grade 80 Water repellency, breathability, durability Higher cost (+\$0.60/m for DWR) • An electrical contractor places a bulk order of 500 m 14oz 65/35 blend at \$7.00/m (total \$3,500). If they switched to 14oz pure cotton (\$8.00/m), the extra \$500 does not justify reduced mobility and higher shrinkage (\~3 %). • A small flooring company testing 100 m of 14oz 98/2 saw reduced knee pain complaints (from 60 % to 20 %), indicating that spending a 12 % premium per meter on spandex blend pays dividends in worker comfort and reduced breaks.

21oz Denim Applications

- Welders & Metal Fabricators • Key Demands: Protection from sparks, molten metal splatter; high abrasion on metal surfaces; moderate bending at knees and elbows. • Recommended Fabric: 21oz 100% cotton or 21oz 65/35 cotton/polyester with FR treatment—warp tensile \~420–430 N, abrasion \~18,500–20,000 cycles, char length ≤ 10 mm (ASTM D6413). • Rationale: 21oz provides robust barrier; FR treatment prevents ignition; blend option reduces shrinkage (< 2 %) and offers water repellency if needed.

- Loggers & Heavy Equipment Operators • Key Demands: Abrasion from wood, machinery; occasional impact; environmental exposure (cold, wet conditions). • Recommended Fabric: 21oz 65/35 cotton/polyester with DWR + FR finish—warp tensile \~430 N, abrasion \~18,500 cycles, water repellency Grade 80+, thermal resistance \~0.053 m²·K/W. • Rationale: Blend combined with DWR keeps dry; FR ensures nominal flame resistance from sparks or fuel; heavyweight retains warmth in cold climates (\~5–15 °C).

- Oil Field & Petrochemical Workers • Key Demands: Exposure to oils, chemicals, extreme temperatures; flame hazards; abrasion from equipment. • Recommended Fabric: 21oz 100% cotton FR denim with DWR—warp tensile \~420 N, abrasion \~20,000 cycles, char length ≤ 10 mm, oil repellency Grade 2–3. • Rationale: Maximizes protection; DWR repels hydrocarbon liquids; 21oz cotton FR meets NFPA 2112 for flash fire, while heavier denim reduces permeation.

21oz Denim by Role & Performance

Role Fabric Content & Finishes Key Metrics Advantages Trade‐Offs Welders 21oz 100% Cotton + FR Warp Tensile \~420 N, Abrasion \~20,000, Char Length ≤ 10 mm Maximum abrasion/fire protection; authentic denim aesthetic Stiff, requires break‐in (15–20 washes) Metal Fabricators 21oz 65/35 Cotton/Poly + FR + DWR Warp Tensile \~430 N, Abrasion \~18,500, DWR Grade 80, Char ≤ 10 mm Balanced durability, water/oil repellency, flame resistance Lower breathability (\~90 mm/s); heavier load Loggers 21oz 65/35 Cotton/Poly + DWR Warp Tensile \~430 N, Abrasion \~18,500, Thermal Res \~0.053 Warmth retention, water repellency in wet forest conditions Reduced mobility; potential overheating Oil Field & Petrochemical 21oz 100% Cotton + FR + DWR Warp Tensile \~420 N, Abrasion \~20,000, Char ≤ 10 mm, Oil Repel Grade 2 High flame and chemical protection; excellent abrasion resistance Very stiff; expensive (+\$3.00–\$4.00/m finish) • A welding crew that switches from 14oz FR cotton (warp \~390 N, abrasion \~15,000) to 21oz FR cotton (warp \~420 N, abrasion \~20,000) decreases garment replacement by \~30 % annually, offsetting \~\$2.00/m higher material cost. • In an oil rig scenario, specifying 21oz FR cotton with DWR at \$12.00/m ensures compliance with flash fire standards and keeps trousers from soaking in crude oil; the heavy weight is a necessary compromise to safety that workers recognize as essential.

Ready to equip your team with the perfect heavyweight denim solution?

Selecting between 14oz and 21oz heavyweight denim for workwear is a strategic decision tailored to the demands of each industry and role. 14oz denims—especially 65/35 cotton/poly or 98/2 cotton/spandex blends—offer excellent mobility (bend force \~8–9 N), adequate abrasion resistance (14oz cotton \~15,000 cycles; 14oz blend \~16,500 cycles), and superior breathability (100–130 mm/s), making them ideal for electricians, carpenters, and field technicians. Conversely, 21oz denims—whether 100% cotton or targeted blends—excel in extreme abrasion (20,000 cycles), enhanced tensile/tear strength (warp \~420–430 N, tear \~22–23 N), and advanced finishing capabilities (FR, DWR, resin), suiting welders, loggers, and heavy equipment operators who need maximum protection. Finishing treatments like resin cross‐linking (+ 6–8 % tear strength), enzyme bio‐polishing (+ 0.5 pilling grade), DWR (+ Grade 80 water repellency), and FR systems (char length ≤ 10 mm) further customize performance to exacting work conditions.

SzoneierFabrics, your China‐based fabric R\&D and manufacturing partner, specializes in:

- Custom Fiber Blends: 100% cotton, 65/35 & 80/20 cotton/poly, 98/2 & 95/5 cotton/spandex—designed for 14oz to 21oz weights.

- Advanced Weave Constructions: From 12–16 IPS twills delivering optimal tensile and abrasion, to specialized rope‐dye options for authentic indigo character.

- Performance Finishes: Resin cross‐linking, enzyme bio‐polishing, DWR, FR, anti‐oil, anti‐static—tailored to your safety and durability requirements.

- Precision Sanforization & Heat Setting: Ensuring < 2 % shrinkage for blends, < 3 % for cotton—delivering consistent fit across batches and sizes.

- Rapid Sampling & Low MOQs: Lab dips in 3–5 days, PP samples in 7–10 days, minimum 80 m per color—ideal for small‐batch uniform programs or large‐scale deployments.

- World‐Class QC & Testing: ISO 13934‐1 tensile, ISO 12947 abrasion, AATCC 129 pilling, AATCC 22 water repellency, ASTM D6413 FR, ISO 9237 air permeability, and AATCC 135 shrinkage—so you get verified data you can trust.

Whether you need a lightweight 14oz stretch denim for electricians or a fortified 21oz FR denim for welders, SzoneierFabrics will collaborate with you to engineer the perfect workwear solution. Contact us today to discuss your project, request samples, or receive a competitive quote.

Can't find the answers?

No worries, please contact us and we will answer all the questions you have during the whole process of bag customization.

Make A Sample First?

If you have your own artwork, logo design files, or just an idea,please provide details about your project requirements, including preferred fabric, color, and customization options,we’re excited to assist you in bringing your bespoke bag designs to life through our sample production process.