How Canvas Fabric Material Improves the Performance of Custom Bags and Accessories

Canvas has long been a trusted material in the world of utility. But in 2025, its story goes far beyond simple duffels and backpacks. Now embraced by designers, lifestyle brands, and eco-conscious makers, canvas is being used in everything from streetwear totes to luxury leather-trimmed satchels. Its appeal lies in more than just its rugged charm—canvas performs. And in custom bag manufacturing, performance is everything.

Canvas fabric enhances the performance of custom bags and accessories by delivering high tensile strength, abrasion resistance, excellent printability, and natural sustainability. Its structured weave supports long-term use, branding flexibility, and both fashion and functional applications, making it a top choice for durable and customizable products.

Imagine a startup in Copenhagen launching a vegan bag line. They opted for recycled polyester at first, citing moisture resistance. But after just two production cycles, they pivoted to GOTS-certified canvas, finding customers preferred the tactile feel, breathable build, and timeless aesthetics. Their return rate dropped by 18%, and sales doubled in six months.

In this article, we’ll explore what makes canvas a performance powerhouse—across material science, design applications, and brand identity. Let’s unpack the data behind the texture.

What Are the Key Properties of Canvas Fabric That Benefit Bag Design?

Canvas fabric offers a balance of rigidity, flexibility, and durability that supports both the form and function of custom bags. Unlike softer fabrics, canvas maintains structure, which helps bags keep their shape while carrying heavy contents. Canvas is strong, structured, and breathable, making it ideal for bags that need to hold form, carry weight, and retain a timeless visual appeal. Its high GSM rating and tight weave provide durability, while its natural fiber composition allows customization through dyeing and printing.

Exploring Canvas Benefits in Bag Construction

A. GSM and Strength Balance

| Canvas Type | GSM Range | Application |

|---|---|---|

| Cotton Canvas 10oz | 280–320 | Tote bags, pouches |

| Cotton Canvas 12oz | 360–420 | Backpacks, travel bags |

| Blended Canvas | 380–500 | Tool bags, outdoor gear |

Higher GSM means stronger fabric, ideal for bags with load-bearing needs. SzoneierFabrics regularly provides 12oz canvas for designer-grade backpacks that require strength without excessive weight.

B. Structural Integrity

The plain or duck weave in canvas contributes to its ability to stand upright, reduce sagging, and hold stitching without distortion. Unlike soft polyester or nylon, canvas doesn’t collapse under load.

C. Custom Feel and Appearance

Canvas presents a naturally matte, textured surface that can be easily finished, waxed, or softened to meet specific brand aesthetics. It wears well over time—developing a vintage patina that’s often appreciated by end consumers.

D. Air Permeability

Breathable yet dense, canvas helps reduce moisture buildup inside bags—especially useful in climates with humidity or for bags used to carry produce, clothes, or electronic gear.

How Does Canvas Fabric Enhance Durability in Custom Accessories?

Durability in accessories goes beyond avoiding tears—it’s about surviving friction, bending, exposure to the elements, and even repeated wash cycles. Canvas fabric, when selected and treated properly, excels in all of these categories. Canvas enhances durability in custom accessories by resisting abrasion, supporting reinforced stitching, withstanding moderate weather exposure, and maintaining integrity over extended use. Waxed or coated canvas options further improve weather resistance and longevity.

Understanding the Durability Mechanics of Canvas

A. Abrasion and Tear Resistance

| Test Metric | Canvas (12oz) | Common Synthetic (Polyester 600D) |

|---|---|---|

| Martindale Abrasion Test | 25,000–40,000 cycles | 40,000–60,000 cycles |

| Tear Strength (warp/weft) | 45–65 N | 70–90 N |

While polyester has higher tear resistance, canvas holds up well under friction—especially in urban settings where bags are placed on concrete or tiled floors.

B. Double-Stitching Compatibility

Canvas’s tight weave allows for:

- Double and triple stitching

- Reinforced corners and stress points

- Strong handle anchoring with minimal fabric distortion

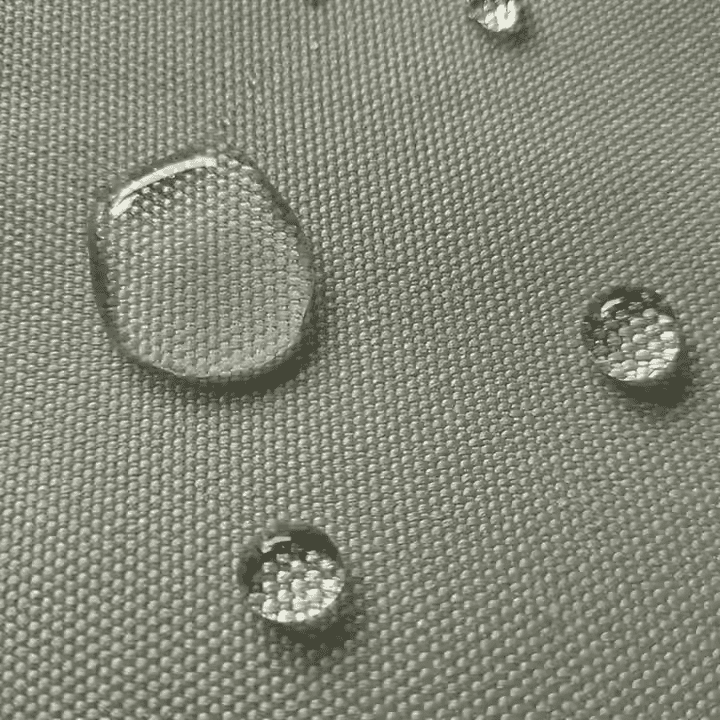

C. Coating for Extra Weather Resistance

SzoneierFabrics offers canvas with various finishes:

- Waxed Canvas: Repels water and adds vintage appeal

- PU-Coated Canvas: Increases weather resistance

- Anti-Mildew Finishing: Ideal for tropical markets

D. Long-Term Shape Retention

Custom accessories such as pencil cases, camera bags, and zipper wallets require structural integrity to maintain function and appearance. Canvas holds up even when packed tightly or placed under compression.

Real-World Example: A Korean tech brand used canvas for custom tablet sleeves. After 12 months of use, customer feedback showed less than 5% reported fraying or edge wear—compared to 19% on a previous polyester model.

E. Resistance to Heat and Friction

Canvas does not melt under high temperatures, making it ideal for accessories like:

- Tool pouches

- Apron-based organizers

- Firefighter gear bags (when flame-retardant treated)

Is Canvas Better Than Other Materials for Bag Structure and Form?

When it comes to bags and accessories, structure defines perception. A bag that stands upright, maintains its silhouette, and feels substantial gives the impression of quality—even before it’s used. Canvas, known for its density and flexibility, offers excellent form retention without compromising comfort or aesthetic. Canvas is generally superior to soft synthetic materials in terms of form retention and structural design. Its naturally rigid weave supports reinforced paneling, compartment construction, and elegant draping, making it an ideal material for structured fashion and utility bags.

Why Canvas Wins on Structure

A. Comparative Form Support

| Material | Form Retention Rating (1–5) | Notes |

|---|---|---|

| Canvas (12oz) | 5 | Excellent for box-shaped or upright bags |

| Polyester (600D) | 4 | Good shape, but less tactile rigidity |

| Nylon (420D) | 3 | Lightweight, collapses easily |

| Denim | 4 | Durable, but heavier and stiffer |

B. Ideal for Multi-Compartment Construction

Canvas holds top-stitching well, allowing for:

- Internal dividers

- Flat bottom gussets

- Reinforced zipper lines

- Handle inserts and padded shoulder panels

C. Clean Lines Without Plastic Inserts

Canvas provides structure naturally, so designers often avoid bulky reinforcements like plastic boards or foam panels. This lowers production costs while maintaining aesthetic integrity.

D. Tactile Perception of Quality

Shoppers often judge bag quality by feel. Canvas communicates strength and natural value, especially in minimalist or heritage-style designs. Its ability to “stand” without filler material elevates it above droopy synthetics.

Case Study: A Danish fashion label switched from bonded faux leather to cotton canvas for its crossbody collection. Customers cited the cleaner shape and “more honest” feel of the canvas version as key reasons for repurchase.

E. Shape Recovery Post-Fold or Wash

After compression (such as shipping or flat-packing), canvas bags bounce back better than synthetics due to fiber memory and weave tightness—especially important for e-commerce brands.

Which Coatings or Treatments Improve Canvas for Outdoor Use?

Canvas is breathable and absorbent by nature, which is wonderful for everyday bags—but potentially problematic in harsh weather or moisture-heavy environments. The right coatings and treatments allow canvas to enter new territories—like camping gear, messenger bags, and courier-grade delivery backpacks. Waterproofing, UV resistance, flame retardancy, and anti-mildew treatments can significantly enhance canvas fabric’s suitability for outdoor use. Waxed canvas and PU-coated options are the most common solutions for extending canvas performance in wet or rugged conditions.

Making Canvas Ready for the Elements

A. Waterproofing Treatments

| Type of Finish | Water Repellency | Feel/Aesthetic | Reusability |

|---|---|---|---|

| Waxed Finish | Moderate–High | Vintage, textured, stiff | Can be rewaxed |

| PU Coating | High | Smooth, slightly glossy | Permanent |

| Acrylic Coating | Moderate | Slight sheen, stiffer hand | Semi-permanent |

| Teflon Nano Finish | Moderate | Soft hand, invisible | Long-lasting |

SzoneierFabrics offers all four options with flexible MOQ. Waxed canvas in particular has become a favorite for heritage-style outdoor bags.

B. UV Resistance

Canvas fades faster than polyester under sunlight. UV treatments can increase resistance from 100 to over 800 hours of sun exposure. This is crucial for:

- Beach totes

- Roof-top cargo bags

- Bicycle panniers

C. Mold and Mildew Prevention

Uncoated canvas can absorb moisture and support bacterial growth. Anti-mildew coatings (often combined with PU) can extend product shelf life in tropical or humid markets.

D. Fire Retardant Application

For bags used in industrial, camping, or military applications, flame retardancy may be required. FR canvas can pass certifications like:

- NFPA 701

- EN 13501-1

Real-World Use Case: A European bicycle courier brand transitioned to PU-coated cotton canvas for their waterproof backpacks. They reported a 40% reduction in customer complaints during rainy seasons, with no significant increase in bag weight or production costs.

E. Layering Canvas with Synthetic Backings

Some technical bags now use dual-layer construction:

- Canvas on the exterior (for look and feel)

- Laminated polyester lining (for waterproof protection)

This approach retains the natural appeal of canvas while delivering synthetic-level protection.

How Does Canvas Handle Printing, Embroidery, and Branding Applications?

One of canvas’s most appealing traits is its compatibility with a wide range of branding techniques. From digital prints to vintage screen methods, to high-density embroidery—canvas is a designer’s playground when it comes to custom bags and accessories. Canvas handles printing, embroidery, and branding exceptionally well due to its tight weave, natural absorbency, and textured surface. It supports various customization methods including screen printing, digital printing, heat transfer, and embroidery, making it ideal for both artistic and commercial branding.

Exploring Branding Compatibility of Canvas

A. Print Method Compatibility

| Branding Method | Canvas Compatibility | Key Notes |

|---|---|---|

| Screen Printing | Excellent | Best for bold designs and solid color areas |

| Digital Printing (DTG) | Good | Works well on pre-treated surfaces |

| Heat Transfer Vinyl | Excellent | Clean edge definition and vivid color |

| Sublimation | Not Compatible | Canvas is not polyester-based |

| Embroidery | Excellent | Strong weave holds stitches tightly |

| Debossing/Stamping | Possible (with waxed) | Gives vintage, tactile impression |

B. Texture Matters

The slightly coarse texture of cotton canvas enhances tactile branding. Logos appear with more definition under natural lighting and the texture helps minimize glare compared to synthetic surfaces.

C. Color Accuracy and Depth

Reactive and pigment dyes work well with canvas. Though polyester allows for brighter sublimated colors, canvas delivers a rich, deep look perfect for earthy or natural aesthetics.

D. Print Longevity

- Canvas: Holds up well under hand-washing or gentle machine cycles

- Polyester: Tends to maintain print longer under abrasion but may peel with poor-quality heat transfer

Use Case Example: An Australian surf lifestyle brand uses screen-printed canvas tote bags as seasonal promotional gifts. After 12 months, print quality held at 95% integrity with only minor fade—far better than their previous nylon models which showed cracking in vinyl logos.

E. Branding Across Canvas Types

| Canvas Type | Best Branding Methods |

|---|---|

| Plain Cotton Canvas | Screen print, digital, embroidery |

| Waxed Canvas | Embroidery, debossing, patch applique |

| Recycled Canvas | Digital print, low-temp heat transfer |

| Blended PE/Canvas | Screen print, embroidery, Teflon-coating |

What Types of Canvas Are Most Suitable for Fashion vs Utility Bags?

Canvas is not a one-style-fits-all fabric. It comes in multiple grades, finishes, and fiber blends—each better suited to specific types of bags and accessories. Whether you’re building rugged utility pouches or minimalist fashion totes, choosing the right canvas is key. For fashion bags, lighter-weight cotton or blended canvas offers a soft feel and elegant drape, supporting detailed finishes and printing. For utility bags, heavier GSM, waxed, or synthetic-blend canvas provides strength, water resistance, and structural integrity.

Matching Canvas Types to Bag Categories

A. Fashion and Lifestyle Canvas

| Feature | Preferred Canvas Type |

|---|---|

| Lightweight Totes | Cotton canvas (8–10oz) |

| Printed Satchels | Pre-treated cotton canvas |

| Embellished Clutches | Blended canvas (PE/CO, 9oz) |

| Foldable Backpacks | Recycled cotton canvas |

These types emphasize:

- Comfort and flexibility

- Visual appeal

- Soft hand feel

- Lightweight handling

Fashion bags often require canvas that works well with color and print fidelity, and doesn’t add unnecessary bulk.

B. Utility and Technical Bags

| Feature | Preferred Canvas Type |

|---|---|

| Tool Bags | 12–16oz cotton duck canvas |

| Courier Backpacks | Waxed or PU-coated canvas |

| Laptop Sleeves | 14oz blended or padded canvas |

| Military Rucksacks | 16oz FR-treated canvas |

Here, the focus shifts to:

- Abrasion resistance

- Reinforced seams

- Load-bearing capacity

- Water or stain repellency

C. Weight vs Performance Trade-Off

| Canvas Weight | Fashion Use | Utility Use |

|---|---|---|

| 8–10oz | Excellent | Limited |

| 12oz | Balanced | Good |

| 14–16oz | Too heavy | Ideal |

D. Finish Options for Both Categories

- Fashion bags: Pre-washed canvas for softness, eco-dyed, pastel tones

- Utility bags: Waxed, PU-coated, FR/anti-mold treated, darker colorways

Case Example: A Canadian outdoor equipment brand uses 16oz waxed canvas for their camping tool rolls, while their urban accessory line uses 10oz cotton canvas in earth-tone shades. This dual approach helps meet both ruggedness and aesthetics across two distinct customer segments.

Do Canvas Bags Offer Better Sustainability and Reusability Performance?

Sustainability has become a non-negotiable criterion for many brands and consumers alike. As bags shift from disposable utility items to reusable fashion statements, the environmental profile of the fabric plays a critical role. Canvas, especially organic or recycled, stands out as a top contender in this space. Canvas bags offer superior sustainability and reusability compared to many synthetic alternatives. Made from natural fibers like cotton or hemp, canvas is biodegradable, durable, and supports multiple reuse cycles. When responsibly sourced or blended with recycled content, canvas becomes a standout option for environmentally conscious brands.

Evaluating Canvas Through the Sustainability Lens

A. Lifecycle and Reuse Capacity

| Metric | Canvas Bag | Polyester Tote |

|---|---|---|

| Average Reuse Cycles | 50–200 uses | 30–100 uses |

| Biodegradability (uncoated) | 5–12 months | Not biodegradable |

| Compostable (unprinted) | Yes | No |

| End-of-life recyclability | Moderate | High (if rPET) |

Canvas outlasts many cheap promotional bags and is often reused for years, especially when constructed with quality stitching and strong handles.

B. Material Source and Impact

| Canvas Type | Environmental Impact |

|---|---|

| Organic Cotton Canvas | Low water, pesticide-free, GOTS certified |

| Recycled Canvas | Low carbon footprint, circular supply chain |

| Standard Cotton | Moderate impact (water + chemicals) |

Brands looking to align with conscious consumerism increasingly prefer organic or recycled versions. SzoneierFabrics, for instance, offers GOTS-certified organic canvas and rCanvas (from post-consumer textile waste) with low-MOQ support.

C. Packaging and Waste Reduction

Canvas bags:

- Reduce single-use plastics in packaging and transport

- Are often used as dual-purpose (e.g., dust bags, gift bags)

- Can support minimalist branding for zero-waste presentations

D. Brand Positioning Advantage

A Swedish skincare brand replaced printed poly gift bags with natural canvas pouches. Within one campaign cycle, they reported:

- 3x increase in social media shares of unboxing content

- 40% increase in “eco-aware” customer segmentation

Canvas bags do more than carry—they communicate.

How Can You Source High-Quality Canvas for Custom Bag Manufacturing?

Knowing what kind of canvas you want is only part of the equation. Finding the right supplier—one that understands customization, quality control, and global logistics—is what transforms an idea into a reliable, profitable product line. To source high-quality canvas for custom bags, look for suppliers with experience in canvas finishing, customization capability, certifications, and a track record of meeting short lead times and low MOQ requirements. Reliable sourcing includes material transparency, performance testing, and flexible production services.

Sourcing Strategy for Canvas Fabric

A. Supplier Checklist

| Criteria | Why It Matters |

|---|---|

| Material Testing Provided | Ensures GSM, tear strength, colorfastness |

| Certifications Available | GOTS, OEKO-TEX, REACH for compliance |

| Low MOQ Capability | Enables pilot testing or small launches |

| Sampling Speed | Shortens development timelines |

| Customization Support | Coatings, colors, dyeing, branding prep |

B. Lead Time & Logistics

| Sourcing Region | Average Sample Time | Bulk Production Time |

|---|---|---|

| China (e.g. Szoneier) | 5–7 days | 20–25 days |

| India | 7–10 days | 25–35 days |

| Turkey | 7–10 days | 30–40 days |

Faster sampling = faster go-to-market = higher seasonal revenue opportunities.

C. Customization Capabilities

A premium supplier should offer:

- GSM range selection (8oz to 16oz)

- Pre-washing, waxing, coating

- Pantone color matching

- Digital or screen printing services

- Edge cutting (laser, ultrasonic)

D. Communication & Quality Control

Ask if your supplier provides:

- Batch QC reporting

- Pre-shipment swatch confirmation

- Lot number tracking

- After-sales support

SzoneierFabrics Advantage:

- 100% quality guarantee with photo and video proofing

- Free design mockups and labeling assistance

- Support for blended and recycled canvas options

- International shipping with multi-language support

Let Canvas Carry Your Brand Further

From tactile elegance to structural endurance, and from sustainability to scalable production—canvas fabric checks all the right boxes when it comes to bags and accessories that perform. Whether you’re building a conscious lifestyle brand, launching a custom campaign product, or adding a rugged new line to your collection, canvas helps you do it with authenticity, strength, and beauty.

SzoneierFabrics has helped hundreds of global brands turn ideas into bestsellers—providing custom canvas fabrics that match not only your functional needs but your brand story. From waxed vintage textures to modern digital prints, and from small test runs to full-scale production—we’ve got you covered.

Let’s Build Your Custom Canvas Collection Together

- ✅ Free canvas swatches & expert design consultation

- ✅ Flexible low MOQ with fast global shipping

- ✅ GOTS, OEKO-TEX, and performance-tested fabric options

- ✅ Support for fashion, utility, promo, and luxury bag brands

Contact SzoneierFabrics today to request a quote or start your custom sampling. Let’s craft canvas materials that elevate your bag product line—with confidence and character.

canvas fabric for bags, custom canvas bag material, best fabric for tote bags, durable canvas for accessories, canvas fabric supplier China, waxed canvas for backpacks, printed canvas bag fabric, canvas fabric for embroidery, canvas vs polyester bags, waterproof canvas fabric, cotton canvas for custom bags, heavy duty canvas material, eco friendly canvas fabric, canvas material for fashion bags, wholesale canvas fabric, canvas fabric for branding, types of canvas fabric, bag manufacturing fabric options, custom bag fabric sourcing, coated canvas for outdoor bags, canvas for tool bags, sustainable bag fabric, canvas fabric for pouches, GOTS certified canvas fabric, reusable canvas bag material, high GSM canvas for bags, canvas bag customization fabric, canvas for promotional bags, fabric for structured handbags, fashion bag fabric trends,

Can't find the answers?

No worries, please contact us and we will answer all the questions you have during the whole process of bag customization.

Make A Sample First?

If you have your own artwork, logo design files, or just an idea,please provide details about your project requirements, including preferred fabric, color, and customization options,we’re excited to assist you in bringing your bespoke bag designs to life through our sample production process.