In the fabric industry, few rivalries are as enduring—or as commercially significant—as the ongoing comparison between linen and cotton. Both fabrics are natural, breathable, and time-tested favorites in fashion, home textiles, and beyond. But as we step into 2025, buyers are no longer just asking “Which fabric looks better?” They want to know: Which one offers better margins, more stable pricing, and sustainable long-term value?

In short, the difference between linen and cotton in 2025 lies in cost stability, raw material supply, regional demand, and sustainability metrics—making the right choice highly dependent on your sourcing strategy.

As raw material prices fluctuate, fashion cycles evolve, and climate regulations tighten, making an informed choice between linen and cotton is more complex than ever. This article dissects the essential differences between the two fabrics, compares their current wholesale price structures, and forecasts where the market is headed. If you’re weighing which fabric to invest in this year—this is your definitive roadmap.

Let’s start by understanding the foundational question: how do linen and cotton really differ in function, fiber, and value?

What Are the Key Differences Between Linen and Cotton Fabric?

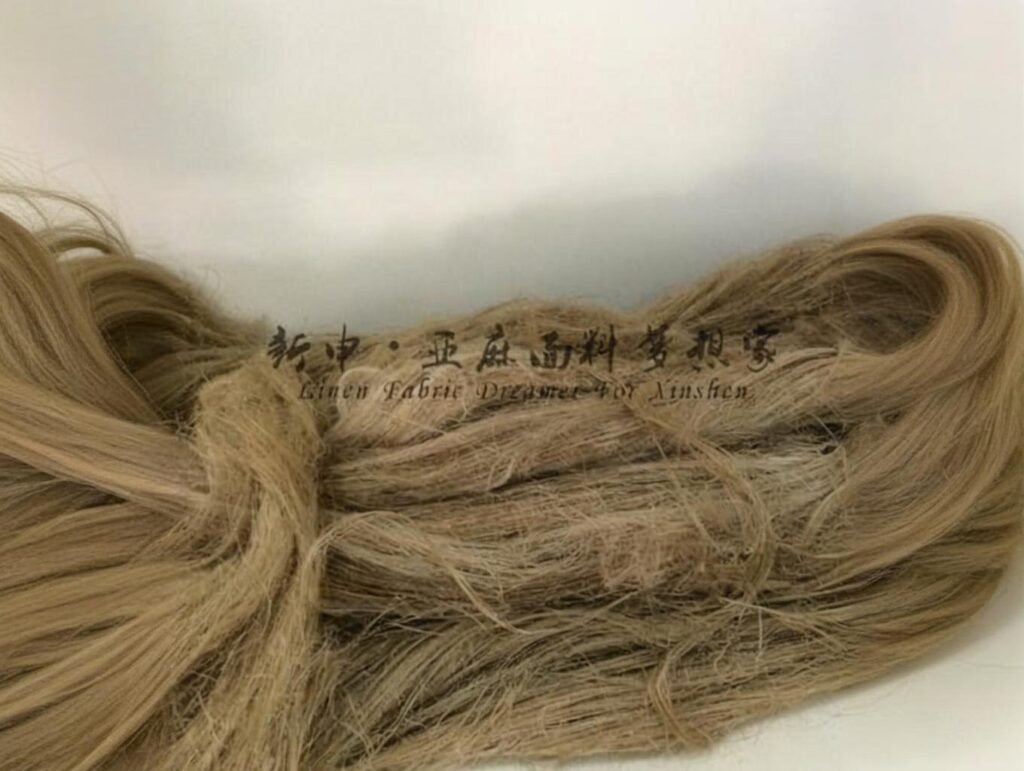

Linen and cotton both come from plants, but that’s where the similarities end. Linen is made from the flax plant, requiring more manual processing but yielding stronger, more durable fibers. Cotton, sourced from the cotton boll, is softer and more abundant—making it easier to mass-produce.

In summary, linen offers greater durability and a luxurious texture, while cotton provides softness, affordability, and year-round wearability—each serving different commercial needs.

Linen vs Cotton—What Makes Each Fabric Unique?

Fiber Source & Processing Method

| Feature | Linen (Flax) | Cotton (Cotton Boll) |

|---|---|---|

| Raw Material | Flax plant | Cotton boll |

| Fiber Length | Long and coarse | Short and soft |

| Processing | Labor-intensive, low-yield | Mechanized, high-yield |

| Water Usage | Low | High |

| Fabric Texture | Crisp, structured | Soft, smooth |

| Breathability | High | Moderate to high |

Durability & Lifespan

- Linen is 30% stronger than cotton due to its longer fibers and natural rigidity. It resists wear and becomes softer with every wash—making it ideal for long-term or luxury use.

- Cotton, while comfortable, is more prone to pilling and degradation over repeated wash cycles, especially when exposed to sunlight or friction-heavy uses.

Aesthetic & Functional Differences

- Linen is preferred for warm-weather apparel, table linens, and premium upholstery due to its organic look and moisture-wicking capabilities.

- Cotton dominates in t-shirts, denim, bedsheets, and innerwear due to its softness and versatility.

Use Case Example: A European eco-luxury fashion brand sourced Belgian linen for its 2024 summer suit line due to its cool hand-feel and sustainability story, while a mass-market U.S. retailer tripled its cotton hoodie production in Q4 2024 to meet rising athleisure demand.

By understanding the core characteristics of each fiber, buyers can align product development goals—comfort, durability, or image—with the right material.

How Do Linen and Cotton Wholesale Prices Compare in 2025?

Wholesale prices for linen and cotton have shifted dramatically over the past two years. Linen prices have seen a moderate increase due to limited flax cultivation and energy costs in Europe, while cotton prices have remained volatile due to extreme weather events and global overproduction cycles.

In 2025, linen wholesale prices average $5.20–$7.00 per yard, while cotton ranges between $2.80–$4.30 per yard depending on quality, region, and finish.

Pricing Breakdown by Region and Fabric Type

Current Wholesale Price Table (Q1–Q2 2025)

| Fabric Type | Standard Price Range (USD/yard) | Key Supply Regions | Notes |

|---|---|---|---|

| Linen (Standard) | $5.20 – $6.00 | Belgium, China, Lithuania | Belgian linen commands a price premium |

| Linen (Heavyweight) | $6.50 – $7.00 | Europe | Suitable for upholstery and outerwear |

| Cotton (Carded) | $2.80 – $3.30 | India, Pakistan, China | Basic t-shirt and bedding applications |

| Cotton (Combed) | $3.50 – $4.30 | Turkey, China, USA | Finer weave, higher strength |

| Organic Cotton | $4.80 – $6.20 | India, Peru, USA | Certified and GOTS-compliant |

Factors Driving Linen Price Increases

- Decline in flax yield across Europe due to heavy rainfall in 2023.

- High energy prices in processing hubs like Belgium.

- Increased demand from eco-conscious apparel brands.

Cotton Price Volatility Factors

- India’s late monsoon and droughts in 2024 reduced yield by 17%.

- U.S. cotton subsidies have distorted export prices.

- China’s cotton stockpiling policy has led to regional price divergence.

Case Insight: A Korean home textiles importer reported a 12% increase in linen sourcing costs in early 2025 compared to 2023. Meanwhile, a U.S.-based fashion startup opted to switch from organic cotton to recycled cotton to cut costs while maintaining a sustainability narrative.

Price Forecast for 2025–2026:

| Fabric | Forecasted Trend | Key Risk Factors |

|---|---|---|

| Linen | Mild Increase (5–8%) | Energy costs, flax crop climate impact |

| Cotton | Fluctuating (±10%) | Weather, subsidies, global stockpiles |

Ultimately, while cotton offers short-term affordability, linen presents a stable premium alternative for brands seeking consistency, value retention, and sustainability.

Which Global Markets Are Driving Demand for Linen and Cotton?

Demand for linen and cotton in 2025 is largely shaped by regional climate, economic maturity, sustainability regulations, and consumer lifestyle preferences. While cotton remains the global volume leader due to its affordability and mass appeal, linen is gaining traction in premium markets focused on eco-conscious luxury and climate-adaptive fashion.

In 2025, Asia leads in cotton consumption due to fast fashion and population scale, while Europe and North America are driving linen demand, fueled by sustainability mandates and rising consumer interest in durable natural fibers.

Regional Analysis of Linen and Cotton Demand

1. Asia-Pacific – Cotton-Dominant, Fast Fashion Growth

- China remains the top cotton consumer, especially for domestic brands and exports.

- India and Bangladesh continue to be global cotton manufacturing hubs.

- Linen use is niche but growing in Japan and South Korea, particularly in lifestyle and wellness segments.

2. Europe – Linen Growth Strongest in EU

- The European Union has seen a 19% YoY increase in linen imports (Eurostat 2024), driven by green regulations and premium fashion shifts.

- Scandinavian brands such as Filippa K and Arket are expanding their linen collections due to demand for breathable, sustainable garments.

- Cotton consumption is declining, particularly conventional cotton, in favor of organic and alternative fibers.

3. North America – Dual Growth Markets

- The U.S. is seeing growth in both linen and high-quality cotton due to climate awareness and demand for natural fibers in home goods and leisurewear.

- Linen bedding and resortwear are outperforming expectations in California and Florida, with sales growth over 22% in 2024 according to retail analytics firm Edited.

4. Middle East and Africa – Climate-Driven Shift

- Cotton remains dominant in regions like Egypt (notably long-staple cotton), but high temperatures are pushing brands toward linen.

- Linen is becoming popular in luxury hospitality and lifestyle brands in the UAE and Qatar, especially for summer uniforms and interiors.

Market Share Table (2024–2025 Estimates)

| Region | Linen Market Share (%) | Cotton Market Share (%) | Notes |

|---|---|---|---|

| Europe | 38% | 62% | Rapid growth in GOTS-certified linen |

| North America | 27% | 73% | Strong interest in resort and home textiles |

| Asia-Pacific | 10% | 90% | Cotton dominates, linen rising in niche sectors |

| Middle East & Africa | 18% | 82% | Linen gaining due to high-heat environments |

Humanized Insight: In Paris, boutique labels are replacing summer cotton dresses with stonewashed linen to align with local eco-labeling laws. Meanwhile, in Mumbai, cotton-based loungewear still dominates both domestic sales and export orders due to cost sensitivity.

What Are the Main Factors Influencing Linen and Cotton Pricing?

Prices for linen and cotton are not just set by supply and demand. They are shaped by a complex web of global factors—ranging from crop yield to fuel prices, labor availability, shipping costs, and even government policies.

In 2025, the top influencers of linen and cotton pricing are raw material yield volatility, energy and processing costs, certification requirements, and trade regulations.

Breaking Down the Key Price Drivers

1. Agricultural Yield and Climate Impact

- Cotton: India and the U.S. faced irregular rainfalls in 2024, reducing yield per acre by 14.5% (ICAC data).

- Linen: Flax cultivation in Northern France and Belgium was disrupted by floods, reducing fiber yield by nearly 11%.

| Crop | Average Yield Decline (2024) | Major Cause |

|---|---|---|

| Cotton | –14.5% | Drought, heatwaves |

| Flax (Linen) | –11.0% | Flooding, planting delays |

2. Energy and Processing Costs

- Linen processing is highly energy-intensive, especially in degumming and spinning.

- Cotton ginning and combing costs increased due to rising electricity rates in India and Pakistan.

- European gas prices impacted linen processors in Belgium by over 22% (Reuters Commodity Index Q4 2024).

3. Certification and Compliance Costs

- GOTS and OEKO-TEX certifications now require stricter traceability, impacting organic cotton prices.

- EU’s Carbon Border Adjustment Mechanism (CBAM) adds cost layers for cotton imports not meeting CO₂ benchmarks.

- Linen processors adopting closed-loop systems to reduce wastewater are incurring higher capex.

4. Trade Tariffs and Geopolitical Tensions

- U.S.–China tensions have led to a 17% tariff on certain grades of cotton fabric.

- EU offers tariff reductions for flax imports under preferential trade agreements with Baltic and Eastern European countries.

5. Transportation and Logistics

- Shipping delays through the Suez Canal due to geopolitical unrest are impacting delivery timelines for European linen.

- Container rates from India to Europe increased 9% in Q1 2025, raising landed costs for cotton buyers.

Critical Viewpoint: While many buyers focus purely on raw price per yard, the landed cost—including duties, logistics, and processing delays—often creates hidden expenses that erode margins. Linen, though more expensive up front, may prove more stable and predictable in price across long-term contracts.

How Do Production Costs Differ Between Linen and Cotton Manufacturers?

Manufacturing costs for linen and cotton are influenced by the complexity of processing, regional labor rates, machinery investment, and energy use. Although cotton is generally less expensive to produce due to its scale and mechanization, the efficiency advantage can narrow depending on fabric quality, certifications, and waste management practices.

In 2025, linen production is costlier due to intensive fiber extraction and lower yield, while cotton benefits from mechanized economies of scale—though organic and combed varieties carry added costs.

Comparative Breakdown of Production Cost Drivers

1. Raw Fiber Processing

- Linen: Requires retting (a fermentation process), drying, scutching, and hackling—largely manual or semi-automated.

- Cotton: Ginning and carding are fully mechanized in most large-scale factories.

| Process Step | Linen Cost Estimate (USD/kg) | Cotton Cost Estimate (USD/kg) |

|---|---|---|

| Fiber Extraction | $1.20 | $0.60 |

| Spinning | $1.80 | $1.10 |

| Finishing | $0.90 | $0.70 |

| Certification & Waste Mgmt | $0.60 | $0.50 |

| Total Est. Cost | $4.50 | $2.90 |

2. Machinery and Labor Intensity

- Linen’s multi-stage fiber processing leads to slower turnaround times and higher labor costs. Even in China, where labor is relatively affordable, linen factories often employ 20–30% more floor staff than equivalent cotton plants.

- Cotton manufacturers, especially in India and Pakistan, leverage high-speed looms and combers to keep production running nearly 24/7.

3. Water and Energy Usage

- Cotton: Requires ~2,700 liters of water to produce a single cotton shirt (WWF 2023).

- Linen: Needs about 30% less water and less pesticide but more energy for fiber extraction and drying.

4. Waste and Yield Efficiency

- Cotton has a higher usable fiber yield per hectare.

- Linen, with lower yield but higher durability, is often processed in smaller batches—adding to per-unit costs.

Real-World Example: A Vietnamese cotton factory can produce 1,000 kg of carded cotton fabric at ~$2.80/kg due to automated looms and cheap hydroelectric power. Meanwhile, a Lithuanian linen mill processing high-quality European flax reports costs closer to $4.80/kg, due to energy-intensive mechanical retting and seasonal flax availability.

The takeaway? If your product line requires quick replenishment, cotton holds a production edge. But if you’re pursuing premium positioning with a natural sustainability angle, linen is worth the cost—especially with rising demand in high-end sectors.

Is Linen or Cotton More Profitable for Wholesale Buyers in 2025?

Profitability doesn’t just come from buying cheap and selling high—it’s about margin sustainability, brand perception, and end-user satisfaction. In 2025, cotton may offer better short-term margins due to lower material costs, but linen’s rising premium and longer lifecycle is translating into higher profit-per-piece in many product categories.

For wholesale buyers in 2025, cotton remains more profitable in high-volume, cost-driven categories, while linen delivers better margins in premium, eco-luxury segments and long-lifecycle goods.

Margin Comparison and Strategic Scenarios

1. Margin Per Unit Sold (Basic vs Premium Segment)

| Product Type | Avg. Wholesale Cost | Avg. Retail Price | Gross Margin | Notes |

|---|---|---|---|---|

| Cotton T-Shirt | $3.20 | $9.50 | 66% | High turnover, low differentiation |

| Organic Cotton Tee | $4.80 | $14.00 | 66% | Niche market, higher marketing costs |

| Linen Shirt | $6.20 | $24.00 | 74% | Stronger margin, slower sales cycle |

| Linen Home Textile | $7.10 | $29.00 | 75% | Growing segment in home décor |

2. Value Retention Over Time

Linen products generally show lower return rates and higher customer retention due to their durability and perceived value. According to a 2024 Shopify merchant study, linen-based items had a 21% higher repeat-purchase likelihood compared to equivalent cotton items.

3. Brand Positioning Power

- Brands using linen in their product mix report stronger storytelling around sustainability, luxury, and longevity—enabling higher MSRPs and customer loyalty.

- Cotton, while versatile, is facing market saturation in categories like basics and fast fashion, reducing pricing power.

4. Sales Channel Considerations

- Linen performs better in boutique, DTC, and lifestyle retail environments where value-per-piece trumps bulk pricing.

- Cotton excels in Amazon FBA, supermarket chains, and large-scale retailers with tight pricing thresholds.

Case in Point: An Australian fashion brand pivoted 30% of its summer SKUs from cotton to linen between 2022–2024. Despite a 22% increase in material costs, their average unit profitability rose 12% due to higher MSRP and reduced product returns. Meanwhile, a Pakistani garment exporter reported razor-thin cotton margins due to overreliance on mid-tier U.S. retail chains with strict cost ceilings.

Linen wins when your business strategy favors brand equity, storytelling, and lower SKU churn. Cotton wins when velocity and scalability are the main priorities. A dual-fabric strategy is often the most profitable, especially for businesses operating across multiple sales tiers or seasons.

What Are the Sustainability and Regulatory Trends Affecting Both Fabrics?

Sustainability has become one of the most crucial factors influencing fabric selection, production processes, and the overall pricing of linen and cotton. With increasing pressure from consumers, governments, and international organizations to reduce the environmental impact of textile manufacturing, both linen and cotton are undergoing significant changes in terms of sustainability practices and regulatory compliance.

As of 2025, both fabrics are benefiting from advances in sustainability, but linen is emerging as the eco-friendlier alternative due to lower water usage and a reduced carbon footprint. Cotton, however, is facing more challenges in meeting sustainability standards, particularly in terms of pesticide use, water waste, and greenhouse gas emissions.

Key Sustainability and Regulatory Forces

1. Water Usage and Conservation

- Cotton: Cotton is often called the “water-hungry crop,” as it requires a staggering amount of water—approximately 2,700 liters per t-shirt (WWF 2023). Cotton farming in regions with water scarcity, such as India and parts of Africa, exacerbates the environmental challenges.

- Linen: Linen, on the other hand, is more water-efficient, with flax requiring far less water to grow. As a result, linen’s environmental impact is considered less severe. The production of linen is also typically associated with less pesticide use, making it a more sustainable choice in eco-conscious markets.

2. Chemical Use and Pesticides

- Cotton: Conventional cotton farming heavily relies on pesticides and synthetic fertilizers. While organic cotton has been gaining ground, it still represents a small fraction of global cotton production. Organic cotton’s growth rate has been about 7% per year over the last decade, but it still faces hurdles in meeting the global demand.

- Linen: Linen’s natural fibers come from flax, which is a hardy plant that doesn’t require extensive chemical treatments. Most of the world’s linen is grown using minimal or no pesticides, making it a preferred fabric for those focusing on chemical-free production.

3. Certifications and Regulations

- Cotton: The Global Organic Textile Standard (GOTS) and OEKO-TEX certifications are critical for buyers seeking sustainable cotton products. These certifications ensure that the cotton meets environmental, social, and chemical safety standards. Cotton products bearing these labels have become increasingly popular in North America and Europe.

- Linen: Linen also benefits from eco-certifications, with some European producers using the European Flax® certification, which guarantees that linen is produced sustainably with traceability. The use of linen in the luxury sector, particularly in eco-conscious fashion, is expected to rise due to these certifications.

4. Green Manufacturing and Circular Economy Initiatives

- Cotton: The cotton industry is making strides with initiatives like the Better Cotton Initiative (BCI), which focuses on improving cotton farming practices through water conservation, reducing pesticides, and improving labor rights.

- Linen: Linen’s role in the circular economy is also growing, with more manufacturers promoting closed-loop systems where linen garments and products are recycled or repurposed at the end of their lifecycle.

Sustainability Impact Comparison

| Fabric | Environmental Impact | Sustainability Certifications | Regulatory Trends |

|---|---|---|---|

| Cotton | High water use, chemical-intensive | GOTS, OEKO-TEX, BCI | Ongoing pressure for sustainable practices |

| Linen | Low water use, minimal pesticide | European Flax®, OEKO-TEX | Rising interest in eco-certifications and waste reduction |

Humanized Insight: A Swedish sustainable fashion brand recently switched its entire summer collection from cotton to linen after conducting an environmental audit, which revealed that the carbon footprint and water usage of linen were 35% lower than cotton for their production process.

How Should Buyers Plan Their Sourcing Strategy for Linen and Cotton in 2025?

As the textile industry continues to evolve, sourcing decisions are becoming increasingly complex. Buyers must consider more than just cost per yard—factors such as sustainability, supply chain stability, and the ability to meet changing consumer demands are now central to sourcing strategies.

In 2025, a smart sourcing strategy for both linen and cotton requires balancing price sensitivity with long-term sustainability goals. Buyers should consider diversifying their sourcing across both fabrics, focusing on certifications, market trends, and production cycles.

Building a Forward-Thinking Sourcing Strategy

1. Short-Term vs. Long-Term Sourcing

- Short-Term Sourcing (Cotton): For high-turnover products (e.g., basics, fast fashion), cotton remains the best option, as it offers low prices and quick availability. However, buyers should be mindful of cotton’s price volatility due to climate factors and supply chain disruptions.

- Long-Term Sourcing (Linen): Linen is better suited for buyers who prioritize quality, sustainability, and long-term brand positioning. Although its initial cost is higher, linen offers better durability, and its environmentally friendly production makes it more aligned with future trends in eco-luxury and high-end markets.

2. Seasonal and Regional Sourcing Strategy

- Seasonal Variability: Linen is particularly well-suited for spring and summer collections due to its breathability and light texture. Cotton, on the other hand, is year-round, but buyers may prefer a shift toward organic cotton in the winter months.

- Regional Considerations: For European and U.S.-based buyers, sourcing linen from regions like Belgium or Lithuania provides the advantage of supporting local economies and sustainability efforts. For cotton, Asia (India, Pakistan) and the U.S. remain dominant sources, but shifting to more sustainable options like organic cotton is key for future-proofing supply chains.

3. Diversifying Sourcing to Mitigate Risks

- Risk Diversification: To mitigate the risk of price hikes and supply chain disruptions, it’s wise for buyers to establish relationships with multiple suppliers, particularly when dealing with fluctuating cotton prices or uncertain flax crop yields.

- Strategic Partnerships: Collaborating with certified manufacturers who are committed to sustainability certifications, like GOTS for cotton or European Flax® for linen, will give buyers access to high-quality, ethical products while meeting consumer demand for transparency.

Case Study Example: An Italian luxury brand with a focus on natural fibers shifted 40% of its raw material sourcing from cotton to linen after a three-year partnership with a sustainable linen supplier in Lithuania. This not only provided higher margins but allowed the brand to align with its sustainability narrative. Similarly, a large U.S.-based retailer now diversifies its cotton sourcing to include 30% organic cotton to meet the growing consumer demand for sustainable products.

Final Considerations for 2025 Sourcing:

- Prioritize eco-certifications for both linen and cotton.

- Plan for price volatility in cotton, especially with fluctuations in global weather patterns.

- Focus on high-quality, long-lasting linen for premium and sustainable product lines.

In conclusion, the decision between linen and cotton in 2025 depends on various factors—from the specific product application to sustainability goals, pricing strategies, and regional sourcing trends. While cotton remains a dominant and affordable option for mass-market production, linen is poised for greater growth in high-end, eco-conscious markets. By aligning fabric choices with market demand and sustainability regulations, buyers can ensure a profitable and sustainable supply chain for years to come.

As you look ahead to sourcing your fabrics for 2025, consider partnering with SzoneierFabrics for your customized linen and cotton needs. Whether you’re looking for sustainable options, unique finishes, or premium raw materials, we offer tailored solutions with quick sampling, low MOQ, and expert advice.

Contact us today to discuss your fabric requirements and get a free consultation for your custom product line.