In the world of textile sourcing, the weight of a fabric is more than just a number—it defines product performance, durability, and customer satisfaction. Especially in Oxford cloth, GSM (grams per square meter) plays a critical role in determining whether a fabric is suitable for a breathable hotel shirt or a rugged industrial work bag. But despite its importance, many buyers overlook the differences in GSM standards between apparel and industrial applications.

Oxford cloth GSM standards vary drastically depending on the intended use—typically ranging from 100–150 GSM for shirts and uniforms, to 200–600 GSM for outdoor gear, backpacks, and industrial covers. Understanding how to select the right GSM ensures product quality, cost control, and compliance with performance expectations.

Let’s begin with a deep dive into what GSM actually means in Oxford cloth, why it matters, and how brands can align their product goals with the right material specifications.

What Does GSM Mean in Oxford Cloth and Why Does It Matter?

GSM stands for grams per square meter—a unit of measurement that quantifies fabric weight. In Oxford cloth, GSM directly influences the fabric’s thickness, breathability, drape, and tensile strength. For buyers, GSM is often the first indicator of whether a fabric is designed for lightweight comfort or heavy-duty endurance.

GSM is the technical baseline that distinguishes a dress shirt from a tent fabric.

For example:

- A 110 GSM Oxford fabric feels crisp and airy—ideal for premium dress shirts.

- A 420 GSM Oxford fabric is densely woven with PU backing—ideal for luggage, fireproof bags, or military-grade applications.

How GSM Impacts Performance

| Application Type | Typical GSM Range | Fabric Behavior | Common Use Case |

|---|---|---|---|

| Casual Apparel | 100–140 GSM | Lightweight, breathable, soft | Oxford shirts, uniforms |

| Outerwear | 150–200 GSM | Slightly stiffer, better wind barrier | Jackets, workwear |

| Industrial Use | 300–600 GSM | Thick, durable, water-resistant | Luggage, tents, heavy-duty bags |

How Is GSM Measured for Oxford Fabric in Apparel vs Industrial Settings?

The GSM of Oxford fabric is typically measured using a digital GSM cutter and weighing scale under standardized lab conditions. But in practice, apparel and industrial fabric manufacturers often follow different testing protocols due to the varying expectations of end-use.

In apparel factories, GSM testing focuses on fabric feel, drape, and skin contact. In contrast, industrial suppliers focus on abrasion resistance, tear strength, and weight uniformity.

Measurement Procedures and Factors Affecting Accuracy

1. Sample Size & Cut Method:

- Apparel: Cut from center panel to reduce warp variation.

- Industrial: Larger cut to account for coating irregularities.

2. Coatings & Lamination Impact:

- PU or PVC coatings may increase GSM by 20–40% depending on thickness.

3. Moisture & Humidity Influence:

- Fabric should be conditioned in 20°C and 65% RH for 24 hours before measurement (per ISO 3801).

Lab Comparison Table: Apparel vs Industrial Testing Focus

| Category | Apparel Testing Priority | Industrial Testing Priority |

|---|---|---|

| Weight Uniformity | Moderate (focus on comfort) | High (affects load-bearing capacity) |

| GSM Precision | ±3 GSM acceptable range | ±1–2 GSM often required |

| Additional Layers | Usually single-layer woven | May include coatings, linings |

| Standards Used | ASTM D3776, ISO 3801 | ISO 2286-2, DIN EN 12127 |

Which GSM Range Is Ideal for Different Types of Oxford Garments?

The ideal GSM for Oxford cloth garments depends on the intended function of the clothing—whether it’s for luxury, utility, or durability. Understanding the correct GSM can help reduce returns, improve comfort, and boost brand loyalty for both hospitality and fashion sectors.

For shirts and uniforms, the sweet spot is typically between 110–150 GSM. For jackets, outerwear, or heavy-duty apparel, GSM can go up to 200.

GSM Guide by Apparel Type

| Garment Type | Ideal GSM Range | Key Features | Notes |

|---|---|---|---|

| Hotel Staff Shirts | 110–130 GSM | Breathable, soft, wrinkle-resistant | Often blended with polyester for easy care |

| Casual Button-Downs | 120–150 GSM | Crisp texture, elegant drape | Heavier GSM creates a premium, tailored feel |

| Uniform Workwear | 150–180 GSM | Durable, thicker weave | Reinforced stitching often accompanies higher GSM |

| Light Jackets & Windbreakers | 170–200 GSM | Moderate protection, good structure | Needs PU/TPU finish for water resistance |

- Low GSM (<110) is prone to sheerness and lacks structure—suitable only for inner linings or tropical wear.

- High GSM (>180) can overheat the wearer if used inappropriately in hot climates—great for cold-weather hospitality uniforms.

Real-World Example: A 4-star hotel in Singapore switched from 140 GSM poly-cotton to 120 GSM cotton-rich Oxford for their concierge shirts—resulting in a 35% drop in guest complaints about staff appearance and comfort.

What GSM Specifications Are Common in Industrial-Grade Oxford Fabric?

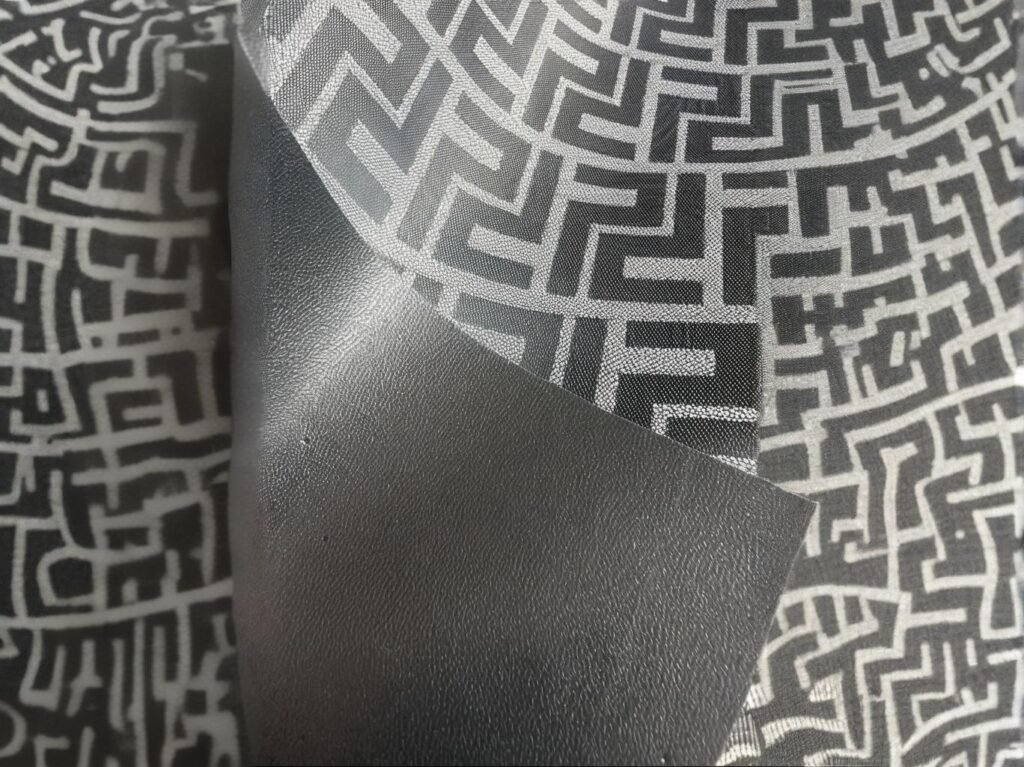

Industrial Oxford fabrics prioritize durability, load-bearing strength, and resistance to environmental wear. Therefore, the GSM values are significantly higher, often enhanced with coatings or multiple layers.

The most common GSM range for industrial-grade Oxford is between 300–600 GSM, depending on the application such as tarpaulin, tenting, or luggage fabric.

GSM Requirements by Industrial Use

| Product Type | Common GSM | Additional Treatments | Application Examples |

|---|---|---|---|

| Luggage Fabric | 400–600 GSM | PU/PVC coating, tear-resistant yarns | Duffel bags, travel gear, airline luggage |

| Tool Bags & Backpacks | 300–450 GSM | Reinforced warp weave | Industrial toolkits, outdoor packs |

| Tents & Covers | 500–600 GSM | Waterproof lamination, UV blocking | Camping tents, vehicle covers, military use |

| Fireproof Bags | 400–500 GSM | Flame-retardant additives | Fire document bags, rescue supply carriers |

Coating Effect on GSM:

- A base 210 GSM Oxford fabric laminated with PU coating (180 GSM) becomes 390 GSM total weight, altering both its physical performance and cost structure.

Did You Know? A military-grade Oxford used in bulletproof backpacks for school use was developed with 600 GSM fabric reinforced with Kevlar threading, significantly raising tensile strength without sacrificing pliability.

How Does GSM Impact Fabric Cost and MOQ in Oxford Cloth Production?

GSM (grams per square meter) is a primary cost determinant in Oxford fabric manufacturing. Higher GSM not only means more raw material usage but also implies denser weaving, longer production times, and additional treatments like PU coating or waterproofing—all of which increase costs and affect minimum order quantity (MOQ).

In general, the higher the GSM, the higher the production cost and the MOQ, especially for industrial-grade Oxford cloth.

Cost & MOQ Comparison by GSM Tier

| GSM Range | Avg. Fabric Cost (USD/yard) | MOQ (yards) | Common Application |

|---|---|---|---|

| 100–150 | \$0.80 – \$1.20 | 300 – 500 | Shirts, light uniforms |

| 150–250 | \$1.30 – \$1.80 | 500 – 800 | Durable uniforms, casual bags |

| 250–400 | \$1.90 – \$2.60 | 800 – 1000 | Backpacks, luggage linings |

| 400–600 | \$2.70 – \$4.50 | 1000+ | Tents, military gear, tool bags |

A Canadian luggage startup initially opted for 420 GSM Oxford fabric at \$3.10/yard but had to reduce GSM to 350 to meet their budget under MOQ 500 yards. The compromise slightly reduced tear resistance but allowed quicker market testing with lower financial risk.

Hidden Cost Factors:

- Yarn Type: Cationic-dyed yarns raise the price by 15–20% compared to regular polyester.

- Coating: PU adds 40–100 GSM but also increases price by \$0.30–\$0.60/yard.

- Special Finishes: UV resistance, fireproofing, and water repellency all increase both GSM and final cost.

Does Higher GSM Always Mean Better Quality in Oxford Fabric?

Not always. While GSM is an indicator of density and potential durability, it’s not the sole metric for fabric quality. A 500 GSM Oxford fabric may be structurally strong but could still fail under UV exposure, colorfastness, or water resistance if not properly treated or poorly woven.

True quality lies in the right balance between GSM, yarn quality, weave structure, and functional finish.

When High GSM Isn’t Enough

| Scenario | GSM | Result | Why It Happened |

|---|---|---|---|

| 420 GSM bag failed under rain | 420 GSM | Water soaked through in 20 min | No waterproof PU or TPU backing |

| 380 GSM tent degraded in sunlight | 380 GSM | Color fading, material breakdown | No UV coating despite high weight |

| 160 GSM hotel shirt wrinkled quickly | 160 GSM | Poor brand impression | High GSM but lacked wrinkle-free finish |

Evaluating Quality Beyond GSM:

- Weave Density (DPI/PPI): Threads per inch—tighter weaves outperform looser ones even at the same GSM.

- Yarn Composition: Recycled yarns may lower strength by 10–15% unless blended with virgin fibers.

- Tear & Abrasion Resistance: Often measured by Martindale or Taber tests—critical for workwear and industrial fabrics.

Expert Tip: Ask your supplier not just for GSM data, but for supporting test reports like Martindale abrasion cycles, tear strength (ISO 13937), and hydrostatic head pressure for waterproof testing. These reflect real-world performance far better than GSM alone.

What Are the International GSM Benchmarks for Oxford Cloth?

GSM standards for Oxford cloth vary slightly by region, based on climatic requirements, garment classification, and industrial safety norms. These benchmarks help ensure consistency across procurement channels and are often referenced in technical specifications or RFQs.

In summary: While the GSM values themselves are similar globally, their classification and recommended use differ by region.

Global GSM Classifications for Oxford Fabric

| Region | GSM Benchmark Categories | Application Focus |

|---|---|---|

| USA | 150–250 (light), 300–600 (heavy) | Uniforms, tactical gear, outerwear |

| EU | 140–240 (light), 250–500 (heavy) | Workwear, medical, industrial PPE |

| Japan | 120–180 (light), 200–400 (heavy) | Hospitality, electronics, hygiene garments |

| China | 100–200 (light), 220–500 (heavy) | Fashion, schoolwear, mid-weight utility bags |

| Australia | 160–250 (light), 300–550 (heavy) | Outdoor gear, agriculture, industrial textiles |

Certification Considerations:

- EU (EN 343, EN ISO 20471): Requires minimum GSM levels for visibility and protection.

- USA (NFPA 1977, ASTM F903): Higher GSM often required for fire resistance and fluid penetration resistance.

- Japan: Focus on lightness and antibacterial coatings; GSM rarely exceeds 300.

A French automotive interior brand rejected a 180 GSM Oxford submission in favor of 320 GSM to meet abrasion and fire retardant norms under EN 1021-1 testing. This adjustment secured compliance and long-term sourcing contracts.

How Can Szoneier Help You Customize Oxford Fabric GSM for Your Needs?

At SzoneierFabrics, we understand that GSM isn’t just a number—it’s a strategic decision. Our factory in China works with a wide range of GSM standards, offering buyers custom blends, finishings, and sustainable options like rPET Oxford cloth.

Our GSM range spans from 100 to 600+, suitable for everything from fashion to fireproof applications—customized based on your use case, budget, and compliance needs.

What We Offer:

- ✅ GSM Customization: From lightweight 120 GSM apparel-grade Oxford to rugged 600 GSM industrial variants.

- ✅ Free Design & Sampling: Send your spec sheet—we’ll prepare GSM-matched prototypes within 5–7 days.

- ✅ rPET Certification Support: We provide GRS and OEKO-TEX® certified yarn sourcing with full rPET % documentation.

- ✅ Low MOQ Flexibility: Start from just 300 meters per GSM specification.

- ✅ Quick Turnaround: 7–15 days lead time based on GSM and finishing.

How We Customized GSM for a US-Based Travel Gear Brand

| Requirement | Solution Provided |

|---|---|

| Ultralight daypack | 150 GSM PU-coated Oxford |

| Water-resistant coating | TPU lamination on 320 GSM Oxford |

| Sustainable request | 220 GSM rPET Oxford (100% GRS) |

| MOQ needed < 500m | Supplied 350m per GSM variation |

We didn’t just supply a fabric—we built a GSM-based product matrix with the client’s sourcing team to plan future scale-up needs with consistency and compliance in mind.

Ready to Tailor GSM Specifications to Your Project?

If you’re a brand, designer, or buyer looking to source Oxford fabric that meets your exact GSM requirements, Szoneier is your go-to manufacturing partner.

From technical apparel to military-grade materials, our team provides:

- 🎯 Real-time GSM calibration

- 📦 Free swatches & matching

- 🌍 Export-ready compliance

- 💬 Multilingual support

👉 Contact Szoneier today for a free consultation, custom GSM sampling, and exclusive B2B pricing.