Your Trusted Wholesale And Custom Cotton Fabric Manufacturer

As a specialized neoprene fabric manufacturer, Szoneier Fabric empowers industries with high-performance, customizable materials built for resilience. Leveraging neoprene’s unique properties—waterproof insulation, thermal retention, shock absorption, and stretch durability—we craft fabrics that excel in demanding environments.

Your vision defines our process. From vibrant prints and embossed logos to precision-cut patterns, we integrate designs seamlessly into neoprene through advanced dyeing, laser cutting, or sublimation techniques—without sacrificing its structural integrity.

Choose thickness (1mm to 7mm+), surface textures, or specialty coatings (anti-slip, UV-resistant). We transform raw neoprene into branded, purpose-driven solutions.

Your Design. Neoprene’s Potential. Perfected by Szoneier.

Just Try Us!

You just choose wholesale any Oxford fabric types for your customization, and we will take care of the rest.

Selecting the perfect fabric for your product line has never been easier! As a top rated fabric manufacturer, we offer a wide variety of wholesale Cotton fabrics that can be customized to suit your exact needs. Whether you’re looking for lightweight cotton for clothing, durable options for bags, or specialized fabrics with water-resistant or UV-protective coatings, we’ve got you covered. With endless options in colors, textures, and finishes, our fabrics are perfect for fashion, home textiles, outdoor gear, and more. Partner with us to bring your ideas to life with high-quality materials, competitive prices, and flexible customization options.

90T Oxford Fabric

150D Oxford Fabric

210D Oxford Fabrics

300Dpu Polyester Oxford Fabric

420D Oxford Fabric

600D OXford Fabric

600D Polyester Oxford Fabric

600D waterpoof Oxford Fabric

800D Oxford Fabric

900D OXford Fabric

1000d Oxford Ripstop Fabric

1200d Oxford Fabric

1680D Oxford Fabric

Canvas Poly Oxford Fabrics

Cordura Oxford Fabric

Cotton Solid Yarn Dyed Stripe Oxford Fabric

Denim Oxford Fabric

Dyed Oxford Fabric

Fireproof Coating Oxford Fabric

Fluorescent Oxford Fabric

Heavy Oxford Fabric

Jacquard Oxford Fabric

Oxford fabric with silver coating

oxford shirt material

Polyester Oxford Fabric

PVC Coated Oxford Fabric

Wholesale and Custom Fabric Categories

Renowned for its waterproof insulation, flexibility, and durability, Oxford fabric is a go-to material for performance-driven solutions.

Potential applications of Oxford fabric

Bags and Backpacks

Oxford fabric is highly favored for making bags, backpacks, and luggage due to its exceptional durability and resistance to abrasion. Typically crafted from polyester or nylon Oxford, these bags can withstand rough handling and heavy loads, making them perfect for outdoor adventures, travel, and daily commuting. Additionally, the fabric’s waterproof coatings, such as PU or PVC, ensure that personal belongings remain dry even during unexpected weather conditions. The combination of strength, waterproofing, and lightweight feel makes Oxford fabric a top choice for crafting tactical backpacks, duffel bags, and travel luggage.

Outdoor and Camping Gear

For outdoor enthusiasts, Oxford fabric is an indispensable material for making tents, awnings, tarps, and camping gear. Its rugged nature, combined with waterproof coatings, ensures that the fabric can endure harsh environmental conditions. Whether it’s rain, wind, or UV exposure, heavy-duty Oxford fabric offers reliable protection and longevity. Additionally, it is lightweight and easy to fold, making it convenient to transport and set up. Many outdoor products are also treated with UV-resistant and mildew-resistant coatings, enhancing their performance and extending their lifespan, making Oxford fabric a reliable choice for outdoor adventures.

Home Textiles and Decor

Oxford fabric is increasingly used in home textiles and decorative items due to its soft texture and stylish appearance. It’s commonly found in bed linens, pillowcases, cushion covers, and tablecloths. The fabric’s ability to retain vibrant colors and its resistance to wrinkling make it practical for home use. Additionally, its breathability and comfort make it a popular choice for bedroom and living room decor. Whether creating a cozy atmosphere or adding a touch of elegance, Oxford fabric enhances the aesthetic appeal of any living space.

Why Partner With Your Trusted Nylon Fabric Manufacturer For Your Bespoke Products Needs?

When it comes to creating durable, versatile, and stylish products, nylon fabric remains a top choice. As a manufacturer with years of expertise in nylon fabric production, we offer both wholesale options and fully customizable solutions tailored to meet your unique requirements. Szoneier factory is equipped with state of the art machinery, allowing us to produce nylon fabrics in a wide range of textures, weights, and colors to suit various applications,from apparel to accessories and home textiles.

Partnering with us ensures that you benefit from high-quality materials, competitive pricing, and flexible production capabilities. We pride ourselves on strict quality control measures, ensuring each batch meets industry standards and your expectations. Whether you’re looking for eco-friendly recycled nylon or specialized finishes such as water resistance or UV protection, we’ve got you covered. Let us bring your vision to life, offering custom dyeing, printing, and finishing options to create the perfect fabric for your products.

Choose us as your trusted nylon fabric manufacturer and enjoy a seamless, reliable partnership for all your bespoke fabric needs!

Fabric Structure Types

If you need help choosing the right fabric structure for your project, feel free to reach out to our expert team for guidance!

Plain weave is the most straightforward and widely used weaving method. It involves interlacing the warp and weft threads in an alternating manner, resulting in a flat, uniform surface. This simple construction provides strength and durability, making it ideal for various fabrics. Common applications include shirts, bed linens, and light curtains, as plain weave fabrics can be produced in a range of fibers such as cotton, linen, and silk. The texture is generally smooth, providing a versatile base for various finishes and treatments.

1. Plain Weave

Jacquard weaving is a sophisticated technique that allows for intricate patterns and designs by controlling individual warp threads. This method creates stunning motifs and textures, making it ideal for decorative fabrics. Jacquard fabrics can feature complex designs like florals, damasks, and other elaborate patterns, adding a touch of luxury to any product. Common uses include upholstery, drapery, and high-end garments, where aesthetics play a crucial role. The ability to create detailed designs without additional printing or dyeing makes jacquard a popular choice for premium textiles.

2. Jacquard Weave

Twill weave is characterized by a distinct diagonal pattern, resulting from the way warp and weft threads are interlaced. This unique structure not only adds visual interest but also enhances the fabric's durability. Twill fabrics are known for their strength, resilience, and resistance to wrinkles and creases, making them suitable for various applications, particularly in workwear and casual attire. Denim and gabardine are prime examples of twill fabrics, often used for jeans, trousers, and jackets. The diagonal ribbing effect adds depth and texture, setting twill apart from other weave types.

3. Twill Weave

Color weaving incorporates multiple colored yarns during the weaving process, allowing for vibrant patterns and designs to emerge directly in the fabric. Unlike dyeing or printing, which adds color post-production, color weaving integrates hues into the structure itself, resulting in designs that are not only visually striking but also durable. This method is ideal for creating fabrics with intricate patterns, such as plaids and checkered designs, without compromising the integrity of the material. Color woven fabrics are commonly used in apparel, accessories, and decorative textiles.

4. Color Weaving

In satin weave, warp (vertical) yarns dominate the fabric surface. Each weft (horizontal) thread passes under multiple warps (e.g., 4-8) in a staggered pattern, creating long "floats" where yarns lie uninterrupted. Minimal interlacing points reduce friction, yielding a smooth, glossy finish. The weave repeats over ≥5 yarns to avoid visible diagonal lines (unlike twill). Warp-faced satin emphasizes shine, while weft-faced sateen prioritizes softness. The loose floats enhance drape and luster but increase snagging risk. This method balances aesthetic appeal with structural simplicity, ideal for luxurious, lightweight fabrics.

5. Satin Weave

Fabric Dyeing And Finishing Process

The fabric dyeing and finishing process is a crucial phase in textile manufacturing, transforming raw materials into vibrant, functional textiles. This process not only enhances the aesthetic appeal of the fabric but also improves its durability and usability

Dyeing

Dyeing is the process of adding color to fabric. Different dyeing techniques can be used depending on the type of fabric and the desired outcome: Fiber Dyeing: Color is applied directly to the fibers before they are spun into yarn. This method is often used for wool and silk and allows for rich, deep colors. Yarn Dyeing: The yarn is dyed before weaving into fabric. This technique is ideal for patterns like stripes or plaids and is commonly used for cotton fabrics. Piece Dyeing: In this method, the fabric is dyed after it has been woven. It is the most common method used for bulk production of colored fabrics. Batch Dyeing: Fabric is dyed in large batches, ensuring consistency in color across large quantities.

Printing

Printing adds intricate designs to fabric using various methods. The most common printing techniques include: Screen Printing: A stencil is created for each color, and dye is pushed through a mesh screen onto the fabric. This method is ideal for bold, vivid designs and is widely used for T-shirts and home textiles. Digital Printing: This modern technique uses inkjet technology to print designs directly onto fabric. It allows for high detail and quick turnaround times, making it perfect for custom designs. Rotary Screen Printing: Similar to screen printing but uses a cylindrical screen for continuous printing, making it efficient for large runs.

Coating

Coating involves applying a layer of material to the fabric to enhance its properties. This can include: Waterproofing: Fabrics are coated with a water-repellent finish to protect against moisture. This is commonly used for outdoor gear and clothing. Flame Resistance: Fabrics can be coated with fire-retardant chemicals to meet safety standards for specific applications, such as upholstery and workwear. Stain Resistance: A coating can be applied to fabrics to prevent stains from setting in, making them easier to clean and maintain.

Color Weaving

Color weaving involves incorporating colored yarns into the fabric during the weaving process. This method allows for intricate patterns and designs, such as:Jacquard Weaving: Developed in the 19th century, this advanced technique employs computerized looms to independently control thousands of warp threads, enabling photorealistic imagery and elaborate motifs. Modern applications range from luxury tapestries to technical textiles with embedded smart patterns, particularly valued in high-end upholstery and narrative-driven fabric art. Twill Weave: Characterized by its signature diagonal ribbing, this method interlaces colored weft threads in staggered sequences that enhance structural integrity. The angled texture not only camouflages stains but also improves abrasion resistance, making it ideal for durable workwear, designer denim, and performance-oriented home textiles like decorative pillow covers.

Fabric Structure Types

If you need help choosing the right fabric structure for your project, feel free to reach out to our expert team for guidance!

Plain weave is the most straightforward and widely used weaving method. It involves interlacing the warp and weft threads in an alternating manner, resulting in a flat, uniform surface. This simple construction provides strength and durability, making it ideal for various fabrics. Common applications include shirts, bed linens, and light curtains, as plain weave fabrics can be produced in a range of fibers such as cotton, linen, and silk. The texture is generally smooth, providing a versatile base for various finishes and treatments.

1. Plain Weave

Jacquard weaving is a sophisticated technique that allows for intricate patterns and designs by controlling individual warp threads. This method creates stunning motifs and textures, making it ideal for decorative fabrics. Jacquard fabrics can feature complex designs like florals, damasks, and other elaborate patterns, adding a touch of luxury to any product. Common uses include upholstery, drapery, and high-end garments, where aesthetics play a crucial role. The ability to create detailed designs without additional printing or dyeing makes jacquard a popular choice for premium textiles.

2. Jacquard Weave

Twill weave is characterized by a distinct diagonal pattern, resulting from the way warp and weft threads are interlaced. This unique structure not only adds visual interest but also enhances the fabric's durability. Twill fabrics are known for their strength, resilience, and resistance to wrinkles and creases, making them suitable for various applications, particularly in workwear and casual attire. Denim and gabardine are prime examples of twill fabrics, often used for jeans, trousers, and jackets. The diagonal ribbing effect adds depth and texture, setting twill apart from other weave types.

3. Twill Weave

Color weaving incorporates multiple colored yarns during the weaving process, allowing for vibrant patterns and designs to emerge directly in the fabric. Unlike dyeing or printing, which adds color post-production, color weaving integrates hues into the structure itself, resulting in designs that are not only visually striking but also durable. This method is ideal for creating fabrics with intricate patterns, such as plaids and checkered designs, without compromising the integrity of the material. Color woven fabrics are commonly used in apparel, accessories, and decorative textiles.

4. Color Weaving

In satin weave, warp (vertical) yarns dominate the fabric surface. Each weft (horizontal) thread passes under multiple warps (e.g., 4-8) in a staggered pattern, creating long "floats" where yarns lie uninterrupted. Minimal interlacing points reduce friction, yielding a smooth, glossy finish. The weave repeats over ≥5 yarns to avoid visible diagonal lines (unlike twill). Warp-faced satin emphasizes shine, while weft-faced sateen prioritizes softness. The loose floats enhance drape and luster but increase snagging risk. This method balances aesthetic appeal with structural simplicity, ideal for luxurious, lightweight fabrics.

5. Satin Weave

Fabric Structure Types

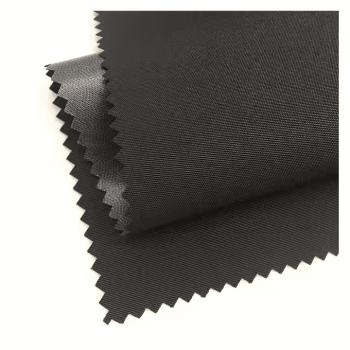

Oxford fabric comes in various types, each designed for specific uses and requirements. Cotton Oxford offers softness and breathability, making it ideal for casual shirts and bed linens.

Made from 100% cotton, this variant is soft, breathable, and highly comfortable. It is commonly used for shirts, casual wear, and bedding.

1. Cotton Oxford Fabric

Composed of synthetic polyester fibers, this type is more durable and resistant to shrinking and wrinkles.

2. Polyester Oxford Fabric

Made from nylon fibers, this variation is lightweight yet exceptionally strong and resistant to wear.

3. Nylon Oxford Fabric

A mix of cotton and synthetic fibers like polyester or nylon. It combines the softness of cotton with the durability of synthetics.

4. Blended Oxford Fabric

This is an Oxford fabric treated with a wax coating for enhanced water resistance and weatherproofing.

5. Waxed Oxford Fabric

Made from two twisted yarns, this version of Oxford fabric is known for its superior strength and durability.

6. 2-Ply Oxford Fabric

Typically woven with a higher thread count and thicker yarns, this Oxford variant is heavier and more robust.

7. Heavyweight Oxford Fabric

This is made with a finer weave and lighter thread count, offering a more breathable option.

8. Light-Weight Oxford Fabric

Fabric Weaving Process

01

Single-Sided Fabrics

Single-sided fabrics are produced using a straight forward weaving technique where the design and texture are visible on only one side of the fabric. The reverse side often has a plain, untextured appearance. This type of fabric is commonly used in garments, linings, and home textiles, where only one side is intended to be seen. The benefits of single-sided fabrics include simplicity in design and cost-effectiveness in production. Examples include satin, which features a glossy surface on one side, and muslin, known for its lightweight and breathable qualities.

02

Knitted Fabrics

Knitted fabrics are created by interlocking loops of yarn, resulting in a flexible and stretchy material. This process allows for a variety of textures and patterns, making knitted fabrics popular in apparel, activewear, and home textiles. Knitting can be performed using different techniques, such as warp knitting and weft knitting. Warp knitting involves yarns running parallel to the fabric’s length, providing greater stability, while weft knitting has yarns woven horizontally, offering more stretch. The unique properties of knitted fabrics, such as breathability and comfort, make them ideal for casual wear and sportswear.

03

Double-Sided Fabrics

Double-sided fabrics, also known as reversible fabrics, are woven to have distinct designs or textures on both sides. This type of fabric is produced by interlacing two layers of yarn, creating a thicker and more substantial textile. Double-sided fabrics are highly versatile and can be used in a variety of applications, from fashion to upholstery. The ability to use either side of the fabric adds value and functionality, allowing designers to create reversible garments and accessories. Common examples include double-faced wool, often used in coats, and plush velvet, popular in home furnishings.

04

Weft Knitting

Weft knitting is a specific type of knitting technique where the yarn is fed horizontally across the fabric. This process creates a series of interlocking loops, resulting in a stretchy and comfortable fabric. Weft knitted fabrics are widely used in garments such as T-shirts, sweaters, and leggings due to their excellent elasticity and ability to conform to the body. Additionally, weft knitting allows for a wide range of stitch patterns, offering designers creative flexibility in their projects. The softness and drape of weft knitted fabrics make them a favorite choice in casual and activewear.

Fabric Yarn Count

The denier (D) of Oxford fabric refers to the thickness of the fibers, which affects its strength and durability. Lower D numbers like 150D and 300D are lightweight, breathable, and ideal for everyday bags or clothing. As the D number increases, so does the fabric’s toughness. 600D and 900D provide better durability for outdoor gear and backpacks, while 1000D and 1200D are heavy-duty fabrics designed for demanding applications like military equipment or industrial use. Choosing the right denier ensures the perfect balance of strength, weight, and performance for your needs.

70D Oxford cloth

- very light, soft and breathable.

150D Oxford cloth

- light and breathable, suitable for daily light products, with low durability.

300D Oxford cloth

- moderate thickness, more durable than 150D, with certain wear resistance and water resistance.

420D Oxford cloth

- thicker and tougher, better water resistance, suitable for medium load applications.

600D Oxford cloth

- very common medium weight fabric, moderate thickness, durable and with good tear resistance.

800D Oxford cloth

- slightly thicker than 600D, with stronger wear resistance and tear resistance.

900D Oxford cloth

- stronger and more durable than 600D, with higher fabric density, stronger water resistance and tear resistance.

1000D Oxford

- Very thick, strong fabric, extremely wear-resistant, and excellent waterproof performance.

1200D Oxford

- The strongest type of Oxford cloth, the fabric is very thick, and the tear resistance and friction resistance are extremely outstanding.

1500D Oxford

- At the top of Oxford cloth in terms of extreme strength and durability, extremely strong and thick.

Fabric Printing Styles

Fabric printing is an essential aspect of textile design, allowing for the creation of unique patterns and vibrant colors that enhance the aesthetic appeal of fabrics. Various printing styles cater to different tastes and applications, providing endless possibilities for customization. Let’s explore some of the most popular fabric printing styles:

1. Intricate Printing

2. Black and White Printing

3. Botanical Prints

4. Geometric Prints

5. Knitted Jacquard

6. Abstract Prints

Fabric Densit

Oxford fabric is a durable, versatile material commonly used in apparel, bags, and outdoor gear. Its fabric density refers to the number of threads per square inch (or per 10 cm²) in the weave, which affects its strength, weight, and texture.

150T Oxford

190T Oxford

- Lightweight and soft, suitable for general light applications.

210T Oxford

- Slightly thicker than 190T, providing stronger wear resistance.

300T Oxford

- Higher wear resistance and strength, suitable for medium-strength applications.

400T Oxford

- Medium density, providing better strength and tear resistance.

500T Oxford

- Very strong, suitable for medium-to-high-strength applications.

600T Oxford

- Very strong, high fabric density, excellent waterproof and tear resistance.

800T Oxford

- Very strong, high fabric density, excellent waterproof and tear resistance.

1000T Oxford

- Ultra-high density, extremely strong, suitable for maximum pressure.

1200T Oxford

- Extremely strong and durable, the fabric is almost impossible to tear and has excellent waterproof properties.

1500T Oxford

- 1500T Oxford: Maximum density, almost unmatched strength.

Fabric GSM

Oxford fabric comes in a range of weights, each suited for different applications. Lightweight Oxford (150-200 GSM) is breathable and soft, perfect for shirts, casual wear, and light bags. Medium-weight Oxford (250-300 GSM) offers a good balance of durability and comfort, ideal for backpacks, jackets, and casual wear. Heavyweight Oxford (400 GSM and above) is thicker and more robust, designed for outdoor gear, luggage, and workwear. For industrial uses, extra-heavy Oxford (500+ GSM) offers unmatched durability and strength. Whether you need comfort or maximum durability, Oxford fabric’s weight options cater to all your needs.

- Lightweight Oxford Fabric (150-200 GSM): This is a breathable and soft variant, ideal for shirts, blouses, casual clothing, and light bags. It offers comfort and flexibility, making it suitable for warmer climates.

- Medium-Weight Oxford Fabric (250-300 GSM): This is the most commonly used range, offering a good balance between durability and comfort. It’s perfect for casual wear, backpacks, jackets, and medium-duty bags, providing sturdiness without sacrificing softness.

- Heavyweight Oxford Fabric (400+ GSM): This variant is thicker and more robust, making it perfect for heavy-duty applications like outdoor gear, luggage, tents, and workwear. It can withstand more stress and rough environments, offering superior durability and wear resistance.

- Extra Heavy Oxford Fabric (500+ GSM): This extremely durable fabric is designed for industrial or military-grade applications, offering high abrasion resistance and exceptional strength.

Factory Direct Wholesale Stock Cotton Fabric Styles

High-quality source manufacturers, providing bulk orders, spot and customized solutions for global retailers. Guaranteed fast delivery.

86T PU Coated Oxford Fabric

210d Oxford Fabric

300D Oxford fabric

300d Ripstop Oxford Fabric

420d Oxford Fabric

600d Polyester Oxford Fabric

900D Oxford Fabric

1680D PVC Coated Oxford Fabric

Jacquard Waterproof Oxford

Polyester Oxford Fabric

Pu Coated Polyester Oxford Fabric

PVC Coated Oxford Fabric

Textile Oxford Fabrics

TPU Laminated Waterproof Oxford Fabric

Waterproof Raincoat Fabric Oxford

Fabric Post Treatment Processes

Fabric finishing processes play a vital role in enhancing the quality and performance of our polyester fabrics. At the Szoneier mill, we use advanced technologies to ensure that each fabric meets the highest standards of durability, softness and functionality. Our finishing processes include dyeing, finishing and coating methods that not only enhance color vividness and fade resistance, but also enhance properties such as water and stain resistance. Through the careful application of these processes, we ensure that our polyester fabrics are not only beautiful, but also meet the needs of a variety of applications. We have listed 50 processes to make them the perfect choice for your needs.

What is Pre-shrinking ?

Pre-shrinking is a process that uses physical methods to reduce the shrinkage of fabric after water immersion, thereby lowering the shrinkage rate. Mechanical pre-shrinking involves wetting the fabric with steam or mist, followed by mechanical squeezing in the warp direction, which increases the amplitude of buckling waves, and then subjecting it to relaxed drying.

What is Stretching ?

Stretching is a finishing process that utilizes the plasticity of fibers like cellulose, silk, and wool in humid conditions. By gradually expanding the fabric to a specified width, this method stabilizes its shape during drying. Known as dimensional finishing, it helps the fabric maintain its intended dimensions and improves its overall structure, reducing distortion during use.

What is Sizing ?

Sizing is a technique that involves applying a sizing solution to the fabric and subsequently drying it to enhance its stiffness and body. This process improves the fabric’s strength, making it easier to handle during manufacturing and providing a more substantial feel. Sizing also helps reduce fraying and ensures better dye absorption, resulting in improved color depth and uniformity.

What is Heat Setting ?

Heat setting is a finishing process that stabilizes thermoplastic fibers in synthetic materials like nylon and polyester, preventing shrinkage or deformation. By applying controlled heat and pressure, it maintains the fabric’s dimensions and enhances stability, improving durability and providing a firmer hand feel for better quality and performance in various applications.

What is Whitening ?

Whitening enhances the brightness and whiteness of textiles using complementary colors. Techniques include blue tinting, which adds a subtle blue hue to reduce yellowing, and fluorescent whitening, which uses optical brighteners to reflect more light. These methods improve the fabric’s appearance, making it look cleaner and more vibrant.

What is Calendering, Electric Calendering, and Embossing ?

Calendering is a process that flattens fabric surfaces and creates patterns using heat and humidity to enhance luster. Flat calendering employs hard and soft rollers for a smooth finish, while soft calendering uses two soft rollers for a gentler gloss. Electric calendering utilizes heated rollers, and embossing adds patterns with engraved steel rollers, resulting in a lustrous look.

What is Napping ?

Napping is a finishing process that employs abrasive rollers or belts to raise a layer of short, dense fibers on the fabric’s surface. This brushing technique produces a plush nap, enhancing both the warp and weft yarns. The result is a soft, textured fabric that feels warm and inviting, making it ideal for clothing, blankets, and upholstery while improving its aesthetic appeal.

What is Raising ?

Raising is the process of lifting fibers from the surface of the fabric using dense needles or pricking, creating a layer of pile, also known as pile raising. This technique is primarily applied to coarse wool fabrics, acrylic fabrics, and cotton fabrics. The resulting pile layer enhances the fabric’s warmth, improves appearance, and provides a soft hand feel.

What is Shearing ?

Shearing is a process that removes unwanted fuzz from the fabric surface using a shearing machine. Its purpose is to clarify the fabric weave, achieve a smooth surface, or ensure an even finish on raised or fuzzy fabrics. Common products requiring shearing include wool fabrics, velvet, faux fur, and carpets.

What is Softening ?

Softening can be achieved through mechanical or chemical means. Mechanical softening involves multiple rubbing and bending actions on the fabric, but the resulting softness may not be ideal. Chemical softening involves applying softening agents to the fabric, reducing the friction coefficient between fibers and yarns, resulting in a noticeably soft and smooth hand feel.

What is Stiffening ?

Stiffening is a process that involves coating the fabric with a sizing solution and drying it to achieve a thick and firm hand feel. This finishing method aims to improve the fabric’s hand feel by applying a solution made from natural or synthetic polymers with certain viscosity, forming a thin film on the fabric that imparts smoothness, firmness, thickness, and fullness, while also enhancing the fabric’s strength and abrasion resistance.

What is Liquid Ammonia Treatment ?

Liquid ammonia treatment involves processing cotton fabrics with liquid ammonia to eliminate internal stress within the fibers, improving their luster and wear performance, reducing shrinkage, and increasing resilience, tensile strength, and moisture absorption. The resulting hand feel is soft, elastic, and resistant to wrinkles, with stable dimensions.

What is Weighting ?

Weighting is a process primarily aimed at compensating for the weight loss of silk fabrics after degumming, using chemical methods to increase the weight of silk textiles. Common methods include tin weighting, tannin weighting (not suitable for white or light-colored silk fabrics), and resin weighting.

What is Lightening ?

Lightening is a finishing process that utilizes the hydrolysis of polyester in high-temperature and specific concentrations of sodium hydroxide solution to gradually dissolve the fibers, reducing the fabric’s weight (typically controlled at 20%-25%) and creating depressions on the surface that lead to diffuse light reflection, resulting in a soft sheen. At the same time, the gaps between fibers in the yarn are enlarged, creating a silk-like effect.

What is Boiling Wool ?

Boiling wool is a process that treats wool fabrics in a hot water bath under tension to flatten and stabilize them, reducing deformation during later wet processing. Primarily used for finishing worsted wool fabrics, it enhances dimensional stability and improves hand feel, preventing future wrinkling or deformation.

What is Steaming Wool ?

Steaming wool is a process that stabilizes wool fabrics through steaming under humid heat conditions, improving hand feel and luster. This technique is primarily used for wool fabrics and their blends, but can also be applied to silk and viscose fabrics. The resulting fabric is dimensionally stable, with a smooth surface and a natural sheen, as well as a soft and elastic hand feel.

What is Pressing Wool ?

Pressing wool uses mechanical pressure and humid heat to flatten the fabric, enhancing its luster and texture. Key techniques include rotary pressing, which employs steam and heated cylinders for a smooth finish (though the shine is temporary), and electric board pressing, which offers a soft sheen and crisp feel but requires bulky equipment, mainly for worsted wool fabrics.

What is Felted Wool ?

Felted wool is a process that uses the felting property of wool to create dense, thick wool fabrics and form a pile on the surface, also known as fulling. Felting improves the hand feel and appearance of the fabric while enhancing its thermal insulation. This process is especially suitable for coarse wool fabrics.

What is Anti-felting ?

Anti-felting is a finishing process aimed at preventing or reducing the shrinkage and deformation of wool fabrics during washing and wear, thereby ensuring dimensional stability in garments. This principle involves chemically treating the scales to alter their surface state or covering the surface with a polymer layer to bond fiber interlace points, effectively removing the basis for felting.

What is Wrinkle Resistance ?

Wrinkle resistance is a finishing process that modifies the original composition and structure of fibers, enhancing their resilience and making the fabric less prone to wrinkling during wear. This method is primarily used for pure or blended cellulose fibers and can also be applied to silk fabrics.

What is Crinkle Finish ?

Crinkle finish is a process that creates various irregular wrinkles on fabric. Techniques include mechanical pressing for an embossed appearance, such as hand crinkling and rope crinkling, as well as rubbing methods like liquid flow dyeing and tumbler drying. This finish is mainly applied to pure cotton, polyester/cotton blends, and polyester filament fabrics.

What is Water Repellent Finish ?

Water repellent finishing involves treating fibers with chemical water repellents to lower the surface tension, causing water droplets to not wet the surface. This process is also known as breathable waterproof finishing and is suitable for materials used in raincoats and travel bags. Based on the durability of the water repellent effect, it can be categorized as semi-durable or durable.

What is Oil Repellent Finish ?

Oil repellent finishing involves treating fabrics with oil-repellent agents to create a surface that repels oil. Fabrics that undergo oil repellent finishing are also water-repellent and possess good breathability. This technique is mainly applied to high-quality raincoats and specialized wear materials.

What is Antistatic Finish ?

Synthetic fiber fabrics can accumulate static electricity due to low moisture and high crystallinity. Antistatic finishing applies chemical agents to enhance hydrophilicity and reduce static by creating a conductive layer on hydrophobic surfaces for ionization. However, this method is generally less effective and durable than blending or interlacing conductive fibers during weaving.

What is Easy-Clean Finish ?

Easy-clean finishing simplifies dirt removal from fabric during standard washing while preventing re-accumulation. It enhances the fibers’ surface hydrophilicity, reducing surface tension between the fibers and water. When wet, the hydrophilic layer expands, creating mechanical forces that help detach dirt by applying a hydrophilic polymer layer to the fabric’s surface.

What is Mold and Mildew Resistant Finish ?

Mold and mildew resistant finishing typically involves applying chemical anti-mold agents to cellulose fiber fabrics to kill or inhibit microbial growth. To prevent textiles from molding during wet processing or in humid environments, common anti-mold agents include formaldehyde and 2-phenylphenol.

What is Flame Retardant Finish ?

Flame retardant finishing involves treating fabric surfaces with flame retardant agents to improve the fabric’s fire resistance. Common flame retardant agents include phosphoramide, ammonium phosphate, and polyvinyl chloride, all of which can reduce combustion rate and slow down flame spread.

What is Waterproof Finish ?

Waterproof finishing treats fabric surfaces with agents like fluorocarbon compounds, polyurethane, and silicone to block moisture while maintaining breathability. This finishing is applied to products such as rain gear, tents, and outdoor sportswear. Fluoropolymer coatings are commonly used, forming a barrier against water without compromising airflow.

What is Durable Press Finish ?

Durable press finishing involves applying resin finishing to cellulosic fiber fabrics to improve their crease resistance. The finishing is primarily applied to fabrics that require high durability, such as workwear and casual wear. The primary agent used in durable press finishing is DMDHEU (dimethylol

dihydroxyethyleneurea).

What is Stain-Resistant Finish ?

Stain-resistant finishing involves applying agents to the surface of fabrics to reduce dirt adhesion and enhance stain resistance. This can be achieved through methods such as chemical treatment or applying a special surface coating. Common stain-resistant agents include fluoropolymer-based finishes, which repel water and oil-based stains.

What is Antimicrobial Finish ?

Antimicrobial finishing involves applying antimicrobial agents to the surface of textiles to inhibit microbial growth, odors, and degradation caused by bacteria and fungi. Common antimicrobial agents include silver ions, quaternary ammonium compounds, and organic biocides. This finishing technique is widely used in medical textiles, activewear, and home textiles.

What is Coating ?

Coating is a finishing process where a layer of polymer material is applied to the surface of the fabric, forming a barrier against water and other external factors. This process can also provide additional properties such as breathability and UV protection. Coatings can be applied using methods such as knife-over-roll or rotary screen printing.

What is Gluing ?

Gluing is a finishing process that utilizes adhesive materials to bond fabric layers or attach various components, such as linings and interlinings. This technique is commonly used in the production of garments and upholstery, providing structural integrity and durability to the final product.

What is Laminating ?

Laminating involves bonding two or more layers of fabric together using heat, pressure, or adhesives to create a composite material with enhanced properties. This process can improve the fabric’s strength, durability, and weather resistance, making it suitable for a variety of applications such as outdoor gear, footwear, and protective clothing.

What is Compounding ?

Compounding is a finishing process that combines different materials, such as rubber, plastic, or textile fibers, to create a composite material with specific performance characteristics. This technique is often used in the production of high-performance textiles, such as those used in automotive or industrial applications.

What is Composite ?

Composite finishing involves combining different textile materials or layers to enhance the overall performance of the fabric. This technique is commonly used in technical textiles, where multiple layers are bonded to achieve specific properties such as strength, breathability, and insulation.

What is Sanding ?

Sanding is a finishing process that involves abrading the surface of the fabric to create a soft, velvety texture. This technique is often applied to cotton and polyester fabrics, resulting in a luxurious hand feel and enhancing the fabric’s aesthetic appeal.

What is Brushing ?

Brushing is a finishing process that lifts and opens the surface fibers of the fabric, creating a soft and fuzzy texture. This technique is commonly used on fabrics like fleece and flannel, providing a cozy hand feel and enhancing warmth.

What is Crimping ?

Crimping is a process that imparts a wave or crinkle effect to fibers or fabrics, enhancing their texture and appearance. This technique is often used in synthetic fibers to improve their elasticity and resilience.

What is Thickening ?

Thickening is a finishing process that involves adding a thickening agent to the fabric, enhancing its texture and weight. This technique is commonly used in heavy-duty textiles, such as canvas and denim, to improve durability and performance.

What is Pilling Resistance ?

Pilling resistance is a finishing process that enhances the fabric’s ability to resist the formation of pills or small balls of fibers on the surface. This technique is especially important for fabrics that are subject to frequent abrasion, such as knitwear and upholstery.

What is Color Fastness ?

Color fastness finishing involves treatments that enhance the fabric’s ability to retain its color and resist fading during washing and exposure to sunlight. This technique is essential for ensuring the longevity of dyed textiles and is commonly applied to garments and home textiles.

What is Lightfastness ?

Lightfastness finishing involves applying treatments that protect the fabric from fading or discoloration due to exposure to light. This process is particularly important for outdoor textiles and fabrics used in window treatments, ensuring that they maintain their original appearance over time.

What is Thermal Insulation ?

Thermal insulation finishing involves treatments that enhance the fabric’s ability to retain heat, providing warmth and comfort in cold conditions. This technique is commonly used in outerwear and bedding, utilizing materials such as down or synthetic insulation.

What is UV Protection ?

UV protection finishing involves treatments that enhance the fabric’s ability to block harmful ultraviolet (UV) radiation from the sun. This process is essential for outdoor textiles, such as swimwear and sun protective clothing, ensuring that they provide adequate protection against sun damage.

What is Antibacterial Finish ?

Antibacterial finishing involves applying treatments to the fabric that inhibit the growth of bacteria, preventing odors and degradation. This technique is commonly used in activewear and medical textiles, providing added hygiene and freshness.

What is Odor Control ?

Odor control finishing involves treatments that reduce or eliminate odors in fabrics, enhancing their freshness and wearability. This process is often applied to activewear and home textiles, utilizing antimicrobial agents and odor-absorbing materials.

What is Flame Resistant Finish ?

Flame resistant finishing involves applying treatments to fabrics that enhance their ability to resist ignition and slow down the spread of flames. This process is crucial for protective clothing and upholstery in environments where fire hazards are present.

What is Reinforcement ?

Reinforcement finishing involves adding extra layers or materials to enhance the strength and durability of fabrics. This technique is commonly used in workwear, outdoor gear, and upholstery, ensuring that textiles can withstand wear and tear.

What is Environmental Finishing ?

Environmental finishing involves applying treatments and processes that minimize the environmental impact of textiles, such as using eco-friendly dyes and finishes, reducing water and energy consumption, and implementing recycling practices.

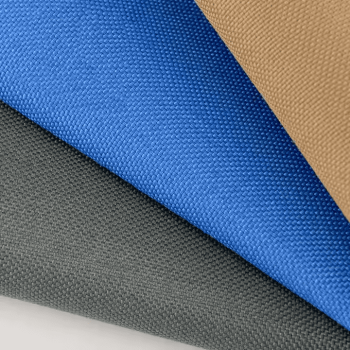

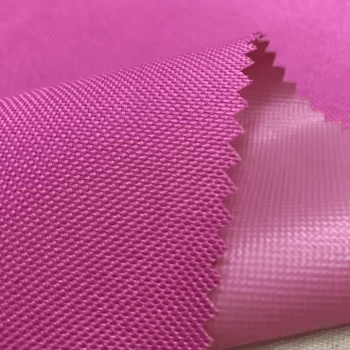

Free Pantone Color Choice

For all your polyester fabric customization needs, we offer a free Pantone color selection to ensure your products reflect your exact vision. Our extensive color chart includes a wide array of Pantone options, allowing you to select the perfect shade to match your project requirements—whether it’s for apparel, bags, outdoor gear, or home textiles. Each color category is carefully curated to include vibrant tones, soft neutrals, and everything in between, providing a diverse palette to inspire creativity.

Color Categories:Our fabric color chart is divided into clear categories, making it easy for you to navigate and find your desired hues. Whether you’re searching for bold colors that stand out or subtle tones for a minimalist design, our organized color chart ensures quick selection. These categories cover a full spectrum of options, from bright and eye-catching shades to more muted and elegant tones, perfect for any polyester fabric project.

Color Swatches and Codes:Each category contains multiple swatches that display the available shades within that color family. Next to each swatch, you’ll find the Pantone color code, which ensures consistency and accuracy when placing your order. These Pantone codes serve as an industry standard, guaranteeing that the color you see on our chart is exactly what will be delivered in the fabric. This attention to detail ensures that your products maintain their visual appeal and stay true to your original design.

Custom Color Options:If our extensive standard chart doesn’t perfectly match your needs, we also offer fully customizable fabric colors. Simply provide us with your desired Pantone code or specific color samples, and our team will work with you to develop a fabric color that fits your exact vision. This option is ideal for companies looking for exclusive branding opportunities or designers aiming to create a unique and personal touch.

Digital Rendering Services:To help you visualize how your chosen fabric color will appear on your finished product, we provide digital rendering services. This allows you to preview how the selected color looks in context, whether it’s on a garment, bag, or other textile product. With this tool, you can fine-tune the color choice or make adjustments to other design elements before production begins, ensuring that your custom polyester fabric meets your expectations.

Production Process Of Fabric

At Szoneier factory, the production process of polyester fabric is a blend of advanced technology and meticulous craftsmanship. We begin with the polymerization of raw materials to create polyester fibers, which are then spun into yarn. These yarns undergo weaving or knitting to form the base fabric. To ensure top-tier quality, each stage of production is carefully monitored, from dyeing and finishing to applying special treatments like water resistance or UV protection. Our cutting-edge machinery allows us to produce fabrics in a wide range of textures and finishes, customized to meet the specific needs of your project. With our commitment to precision and excellence, you can count on durable, vibrant, and versatile polyester fabrics ready for any application.

Testing Equipment Of Fabric Production

At Szoneier fabric production factory, we utilize state of the art testing equipment to ensure the highest standards of quality and durability. Our advanced machinery includes tensile strength testers, colorfastness testing equipment, abrasion resistance testers, and moisture control systems. Each piece of fabric undergoes rigorous testing for consistency, performance, and longevity, allowing us to guarantee top-quality products that meet both industry standards and customer expectations. This commitment to quality ensures fabric excellence from production to final delivery.

Make A Sample First?

Got a specific artwork, logo, or design concept in mind? We’re all ears! Share every detail—your preferred fabric type, Pantone colors, and any custom features you want. Our team will partner with you to nail your vision with precision. We’ll start by creating a fabric sample so you can touch, feel, and inspect the quality, texture, and color firsthand before committing to full production. This way, we tweak things until it’s exactly what you imagined. Let’s turn your ideas into a fabric that’s uniquely yours !

Video Of Product And Production

Get a behind the scenes look at our fabric production process with our exclusive factory video. where you can witness the fascinating journey of our polyester fabrics from raw materials to finished products. Our informative videos provide a behind-the-scenes look at the advanced techniques and skilled craftsmanship that define our manufacturing process. Whether you’re interested in the production methods or the innovative designs we offer, these videos reflect our dedication to quality and creativity in fabric development. Join us and explore the artistry of our fabric production!

Cooperating Brands Trusted

Your product is produced in reliable factory like our already cooperating international brand partners below:

International Certification

You can totally trust us with all certifications shown below.

Oxford fabric is a versatile textile traditionally made from cotton, but modern variations often include polyester, nylon, or a blend of both. The unique weave pattern, typically a basket weave or plain weave, gives the fabric its signature texture and durability. Cotton Oxford is breathable and soft, making it ideal for shirts and casual wear. On the other hand, polyester and nylon versions are more rugged, offering water resistance, strength, and abrasion resistance. Blended Oxford combines the comfort of natural fibers with the toughness of synthetics, making it suitable for a wide range of applications from clothing to heavy-duty outdoor gear.

Oxford fabric’s versatility makes it popular for various applications, including:

- Apparel: Cotton Oxford is commonly used in dress shirts, casual wear, and school uniforms due to its soft and breathable nature.

- Bags and Backpacks: Polyester and nylon Oxford fabrics are strong and durable, perfect for backpacks, duffel bags, and luggage.

- Outdoor Gear: Heavier grades of Oxford fabric are treated with PU or PVC coatings to become waterproof, making them ideal for tents, awnings, and camping gear.

- Home Textiles: Lightweight Oxford is used in bed linens, pillowcases, and curtains.

- Workwear and Uniforms: Blended or polyester Oxford is popular for uniforms due to its resistance to wrinkles and shrinking.

Proper care of Oxford fabric ensures its longevity and maintains its appearance. Follow these tips:

- Washing: Most Oxford fabrics can be machine washed, but it is recommended to use cold or lukewarm water to maintain the fabric’s texture and color.

- Drying: Air drying is preferable, as high heat can damage certain coatings or cause shrinkage. If using a dryer, set it to low heat.

- Ironing: Use a medium temperature for cotton Oxford and a low setting for polyester or nylon. Always check the care label.

- Waterproof Treatments: Reapply waterproof coatings as needed, especially after washing or prolonged exposure to water.

Not all Oxford fabrics are waterproof by default. Cotton Oxford is typically not waterproof and is more suited for apparel and light-duty uses. However, nylon and polyester Oxford fabrics can be treated with PU (Polyurethane) or PVC (Polyvinyl Chloride) coatings, making them water-resistant or even waterproof. These coated fabrics are commonly used in outdoor gear, tents, tarps, and luggage to protect against rain and moisture. The level of waterproofing can vary, so always check the product specifications for water resistance ratings.

Oxford fabric is distinct from other woven textiles because of its basket weave pattern, which combines two or more threads over and under to create a durable yet breathable texture. Unlike plain weaves or twill fabrics, Oxford fabric is softer and more comfortable while maintaining excellent durability. Additionally, it is more affordable than high-end natural fabrics, making it a popular choice for both casual wear and heavy-duty applications. The versatility in weight and finish makes it suitable for a broad range of products, from lightweight shirts to rugged outdoor gear.

Frequently Asked Questions

Welcome to our FAQ section on customized Oxford fabrics, where we answer your most common questions and provide insights into fabric types, customization options, features, and order-related details. Whether you’re looking to learn more about the various oxford fabric styles, specialized finishes, or the ordering process, we’re here to help. Our goal is to ensure that you have all the information needed to make informed decisions about selecting the perfect oxford fabric for your unique project.