In a market flooded with textile options, Oxford fabric has become the backbone of durable everyday essentials—from waterproof backpacks to industrial workwear and rugged tents. But what exactly makes Oxford fabric stand out in B2B applications? Why do brands and wholesalers consistently choose this material for function-driven products?

Oxford fabric is a woven textile known for its strength, versatility, and adaptability to coatings like PU, PVC, or TPU. It strikes a balance between cost-effectiveness and performance, making it ideal for industrial, fashion, and outdoor markets.

Whether you’re sourcing for custom tote bags or military-grade equipment covers, understanding Oxford fabric means making smarter decisions on durability, waterproofing, and cost per yard. In this guide, we break down everything you need to know: how it’s made, types available, performance specs, certifications, and how to pick the best type for your specific industry.

Let’s start with a fascinating origin story—from Oxford University students’ shirts to today’s heavy-duty luggage. Oxford fabric’s journey is anything but boring.

What Is Oxford Fabric and Why Is It So Popular in B2B Applications?

Oxford fabric is a durable woven material characterized by a basket-weave structure that can be crafted from polyester, nylon, or cotton blends. Originally designed for dress shirts, modern Oxford fabric has evolved into a go-to material for B2B buyers due to its cost-efficiency, customizability, and exceptional strength-to-weight ratio.

In short: Oxford fabric is popular in B2B because it offers the perfect mix of affordability, strength, and ease of coating or printing, which meets the needs of both functional and aesthetic product demands.

What Makes Oxford Fabric B2B-Friendly?

1. Structure & Strength

The basket weave (often 2×1 or 2×2) gives Oxford fabric its signature strength. For example, 600D polyester Oxford is commonly used in luggage because it resists tears and abrasions while staying relatively lightweight (around 230–280 GSM).

2. Custom Coating Capabilities

Oxford fabric supports multiple coatings:

| Coating Type | Properties | Common Applications |

|---|---|---|

| PU Coating | Water-resistant, breathable | Backpacks, fashion bags |

| PVC Coating | 100% waterproof, heavier | Tents, industrial covers |

| TPU Coating | Eco-friendly, flexible | Medical and sports gear |

3. Versatile Applications

Oxford fabric is used in:

- Promotional bags and totes for marketing campaigns

- Uniforms and workwear due to its abrasion resistance

- Outdoor furniture covers with UV-blocking layers

4. Cost Efficiency

Prices vary by denier and coating:

- 210D PU Oxford: \$0.65–\$0.90/meter (ideal for lightweight products)

- 600D PVC Oxford: \$1.10–\$1.50/meter (heavy-duty usage)

This price-performance balance makes it a preferred material for SMEs, wholesalers, and large-scale manufacturers alike.

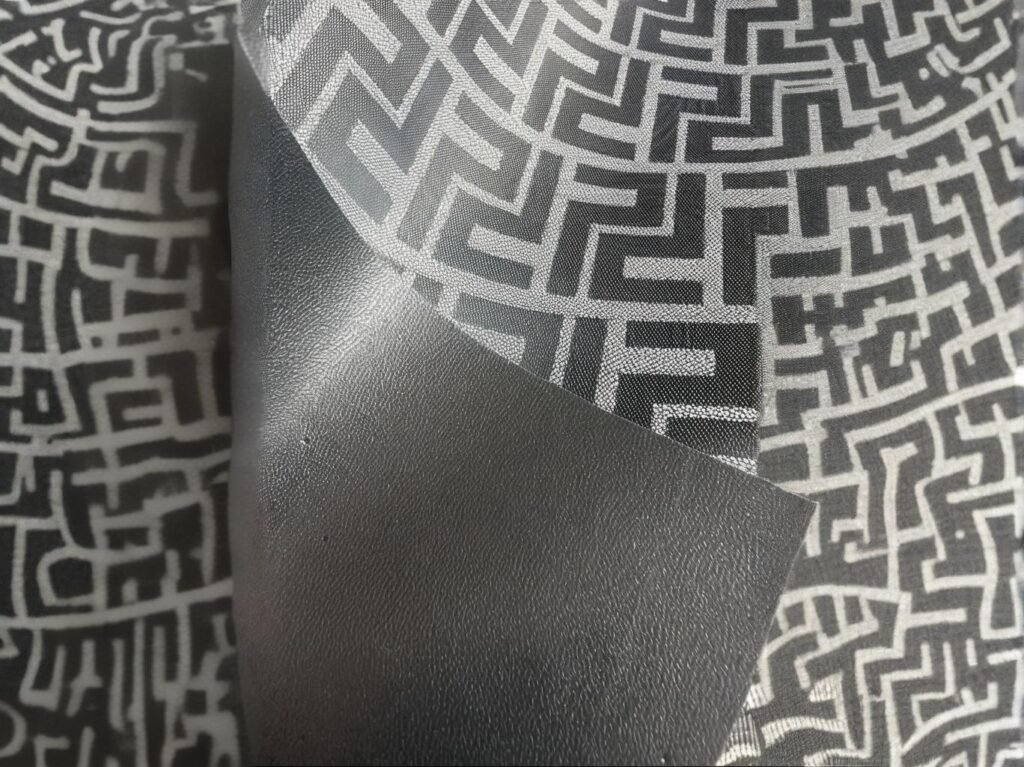

5. Printing & Branding Compatibility

Sublimation, heat transfer, and silk screen printing all work well on Oxford fabric, making it easy for B2B clients to customize private-label bags and promotional goods.

How Is Oxford Fabric Made? A Step-by-Step Manufacturing Overview

Oxford fabric is manufactured using a basket-weaving technique, typically involving synthetic yarns like polyester or nylon. The process includes yarn selection, weaving, dyeing, coating, and finishing—each step impacting the final fabric’s function.

Oxford fabric is created through a multi-stage process that includes weaving high-denier yarns into a basket weave, followed by dyeing and coating to enhance waterproofing, UV resistance, or flame retardancy.

Manufacturing Breakdown

Step 1: Yarn Selection

The process starts with choosing yarn:

- Polyester yarns (210D to 1680D): Common in waterproof gear.

- Nylon yarns: Known for tensile strength and softness.

| Denier | Description | Typical Use |

|---|---|---|

| 210D | Lightweight, soft | Cosmetic bags |

| 600D | Medium weight | School bags, tote bags |

| 1000D+ | Heavy duty | Military bags, outdoor covers |

Step 2: Weaving

A basket weave is used—usually a 2-over-2-under pattern—which increases the fabric’s structural integrity. This weave distinguishes Oxford from plain weaves like canvas or twill.

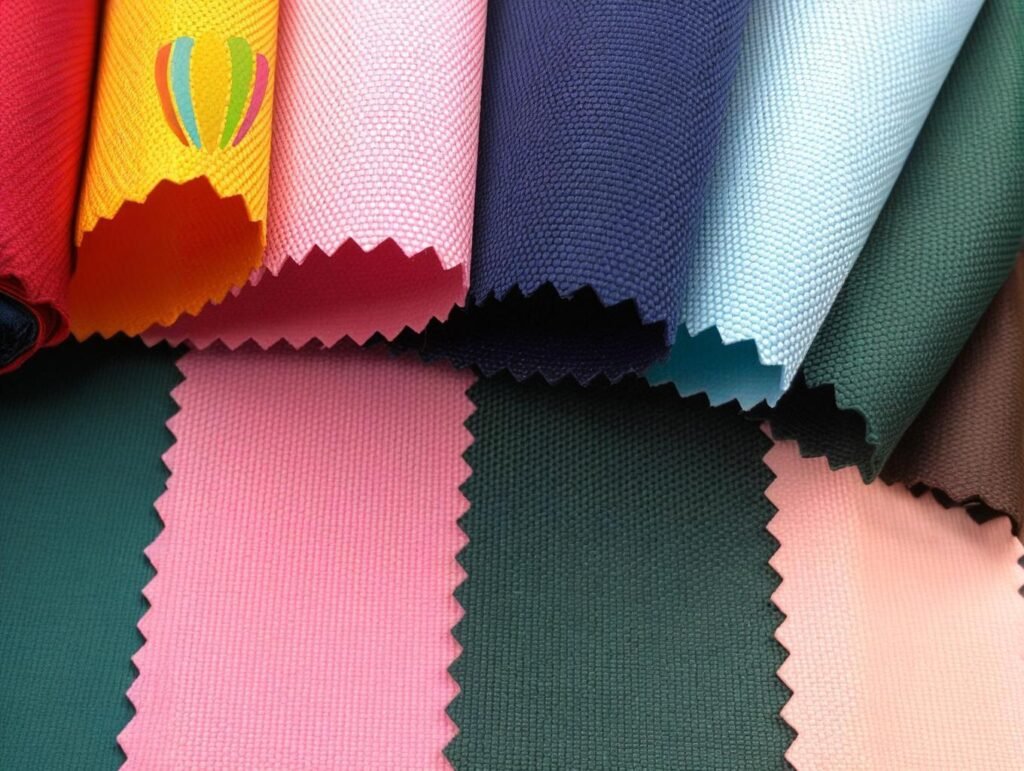

Step 3: Dyeing

Dyeing is done in batches using methods such as:

- Piece dyeing for consistency in mass production

- Dope dyeing (solution dyeing) for colorfastness in outdoor fabrics

Step 4: Coating

Post-dyeing, the fabric is treated with:

- PU for flexibility

- PVC for full waterproofing

- TPU for eco-conscious brands

Each coating adds different performance characteristics (breathability, UV resistance, or chemical resistance).

Step 5: Finishing

Finishing touches may include:

- Anti-fray treatments

- UV stabilizers

- Fire-retardant chemicals (meets CPAI-84 or ISO 6941)

A custom order for a Japanese camping brand may require 1000D Oxford with PU coating, UV resistance, and CPAI-84 certification, produced within 18 days at Szoneier’s factory.

What Are the Different Types of Oxford Fabric (PU, PVC, TPU, Nylon, Polyester)?

Oxford fabric comes in a wide variety of material bases and coatings, each with specific use-cases depending on durability, waterproofing, texture, and sustainability needs.

Oxford fabric types include PU-coated, PVC-coated, and TPU-coated options, made with polyester or nylon yarns. Each type offers unique benefits in terms of waterproofing, flexibility, environmental friendliness, and price.

Comparing Oxford Fabric Types

1. Based on Coating Type

| Type of Coating | Key Features | Pros | Cons | Common Uses |

|---|---|---|---|---|

| PU Coated Oxford | Polyurethane finish | Lightweight, breathable | Moderate water resistance | School bags, shopping totes |

| PVC Coated Oxford | Polyvinyl chloride coating | 100% waterproof, rugged | Heavier, less breathable | Tents, raincoats, truck covers |

| TPU Coated Oxford | Thermoplastic polyurethane | Eco-friendly, flexible | More expensive | Medical bags, sportswear |

Quick Tip: If your customer wants reusable waterproof grocery bags, 210D PU Oxford is lightweight, cost-effective, and customizable.

2. Based on Yarn Material

- Polyester Oxford: Affordable, colorfast, tear-resistant.

- Nylon Oxford: Softer, stronger, higher abrasion resistance, slightly pricier.

| Material | Durability | Feel | UV Resistance | Cost (USD/meter) |

|---|---|---|---|---|

| Polyester | Good | Medium stiffness | Medium | \$0.65–\$1.50 |

| Nylon | Excellent | Softer | Lower (unless treated) | \$1.00–\$2.20 |

3. Based on Denier (D) Strength

Denier reflects yarn thickness. Higher denier = stronger and heavier.

| Denier Rating | Description | Ideal For |

|---|---|---|

| 210D | Lightweight, foldable | Pouches, promotional bags |

| 420D | Mid-weight, flexible | Daypacks, covers |

| 600D | Durable & waterproof | Backpacks, cooler bags |

| 1680D | Ultra-strong ballistic | Luggage, tactical gear |

A U.S. outdoor brand chose 1680D nylon Oxford with TPU coating for its premium hiking backpacks to ensure both environmental friendliness and abrasion resistance.

Which Industries Commonly Use Oxford Fabric and for What Products?

Oxford fabric’s flexibility makes it a go-to choice across diverse industries—from fashion and outdoor recreation to logistics and healthcare.

Industries like outdoor gear, fashion, logistics, hospitality, and promotional merchandising rely heavily on Oxford fabric for its cost-effective strength, customizable properties, and waterproofing options.

Industry Applications

1. Outdoor & Camping Gear

- Products: Tents, tarps, hiking backpacks, sleeping bag covers.

- Fabric Types: 420D PU or 600D PVC Oxford

- Features Needed: UV resistance, waterproofing, tear resistance

Brands like Decathlon often use 600D polyester Oxford for entry-level tents because it balances performance with price.

2. Fashion & Accessories

- Products: Tote bags, laptop sleeves, casual backpacks

- Fabric Types: 210D–420D PU Oxford

- Features Needed: Lightweight, printable, colorfast

| Application | Recommended Oxford Fabric | Reason |

|---|---|---|

| Cosmetic bags | 210D PU-coated | Easy to clean, vibrant colors |

| Urban backpacks | 600D PU-coated | Water-resistant, medium weight |

3. Medical & Healthcare

- Products: First aid kits, patient transport bags, PPE carrying cases

- Fabric Types: TPU-coated Oxford (420D–600D)

- Features Needed: Antimicrobial coating, waterproof, flexible

4. Industrial & Transport

- Products: Tool bags, equipment covers, warehouse divider curtains

- Fabric Types: 1000D or 1680D PVC-coated Oxford

- Features Needed: Flame retardancy, abrasion resistance, load capacity

Many logistics companies specify 1680D PVC Oxford fabric for cargo covers due to its long-term durability and cost-efficiency.

5. Hospitality & Home

- Products: Chair covers, laundry bags, storage organizers

- Fabric Types: 420D polyester PU-coated

- Features Needed: Easy wash, mold resistance, aesthetic printability

6. Promotional & Custom Branding

- Products: Logo tote bags, giveaways, trade show gear

- Fabric Types: 210D PU-coated Oxford

- Features Needed: Printable surface, low cost, light weight

A U.K.-based promotional agency ordered 5,000 units of 210D Oxford drawstring bags with silk-screen logos for a global fitness brand’s product launch.

How Do You Choose the Right Oxford Fabric for Your Product Needs?

Choosing the right Oxford fabric depends on product usage, required durability, environmental exposure, and design aesthetics. B2B buyers must consider denier strength, coating type, breathability, customization, and compliance requirements before committing to bulk orders.

To choose the right Oxford fabric, evaluate your product’s functional needs (e.g., water resistance, weight), expected user environment (indoor vs. outdoor), and compatibility with design features like colorfast printing or logo placement.

Your Buyer’s Checklist for Oxford Fabric Selection

1. Define the Product Function

| Product Type | Recommended Fabric | Features Needed |

|---|---|---|

| Backpack | 600D PU or PVC Oxford | Water resistance, tear strength |

| Tent or Rain Fly | 210D–420D PU Oxford | Waterproofing, UV protection |

| Luggage | 1000D–1680D PVC Oxford | Abrasion resistance, structure |

| Promotional Tote | 210D PU Oxford | Lightweight, printable surface |

| First Aid Bag | 600D TPU Oxford | Flexibility, antibacterial, cleanable |

A Korean OEM client for first responder kits prioritizes TPU over PVC for eco-compliance and flexibility in -20°C environments.

2. Match Fabric Denier to Load and Use Frequency

- 210D–420D: Suitable for lightweight, daily-use items

- 600D: A good all-rounder for durability with flexibility

- 1000D–1680D: Ideal for heavy-load or high-wear products

3. Consider Coating for Performance Requirements

| Coating Type | Waterproof | Breathable | Eco-Friendly | Fire Retardant Option |

|---|---|---|---|---|

| PU | Yes | Moderate | Moderate | Yes (treated) |

| PVC | Yes | Low | No | Yes (built-in) |

| TPU | Yes | High | Yes | Optional |

Always request coating thickness in millimeters—e.g., “0.25mm PVC”—to ensure quality control in sourcing contracts.

4. Determine Color, Printing & Branding Needs

- Sublimation printing works best on white PU-coated polyester Oxford

- Silk-screen printing is ideal for bulk orders with bold logo designs

- Embroidery requires higher-denier Oxford (420D+)

5. Ask for Certifications & Test Results

- ISO 13934 (Tensile Strength)

- ISO 2286-2 (Coating Thickness)

- ASTM D6413 (Flame Resistance)

- OEKO-TEX or REACH (Chemical Safety)

Request a full COA (Certificate of Analysis) and a batch swatch for validation before finalizing a bulk order.

Is Oxford Fabric Waterproof, UV-Resistant, or Fire-Retardant?

Oxford fabric can be made waterproof, UV-resistant, and fire-retardant through chemical coatings and finish treatments. However, the level of protection depends on fabric weight, base yarn, and the specific coating or laminate applied during finishing.

Yes, Oxford fabric can be customized to be waterproof, UV-resistant, and fire-retardant, provided it undergoes the appropriate coating and testing protocols during production.

Understanding Performance Treatments

1. Waterproofing Levels

| Coating | Waterproof Rating | Common Testing Standard |

|---|---|---|

| PU | 800mm – 3,000mm | ISO 811:2018 |

| PVC | 3,000mm – 10,000mm+ | ISO 811:2018 |

| TPU | 5,000mm+ | ISO 811:2018 |

A client in Canada requested 1000D Oxford with 10,000mm waterproof rating and sealed seams for snowmobile covers.

2. UV Resistance

UV-blocking treatments help prevent color fading and fabric degradation under prolonged sun exposure.

| Feature | Description |

|---|---|

| UV Inhibitor Coating | Additives like HALS (Hindered Amine Light Stabilizers) |

| UPF Rating | Usually UPF 30–50+ for outdoor applications |

| Testing Standard | ASTM D4329 or ISO 4892-2 |

For tent applications, UV resistance over 300 hours is recommended.

3. Fire Retardant Options

Oxford fabric can meet flammability standards such as:

- CPAI-84 for camping tents

- NFPA 701 for industrial curtains

- ISO 6941 for international garment/fire-resistance compliance

| Fabric | Treatment | Compliance |

|---|---|---|

| 600D PVC Oxford | Built-in FR | CPAI-84, NFPA 701 |

| TPU Oxford | Optional coating | ISO 6941 |

A European OEM ordered TPU-coated Oxford for medical gear storage bags, requesting both antibacterial and fire-retardant certifications—delivered with ISO lab test reports for EU compliance.

4. Breathability vs Waterproofing Trade-off

Heavier coatings (like PVC) reduce breathability, while TPU offers a balance of airflow and protection—ideal for high-performance bags and outdoor gear.

What Are the MOQ, Lead Time, and Customization Options for Bulk Orders?

For B2B buyers, sourcing Oxford fabric involves navigating minimum order quantities (MOQ), production lead times, and design flexibility. These factors impact inventory planning, branding capability, and time-to-market—especially for private label or OEM clients.

Oxford fabric MOQs typically start from 500 to 1000 meters per color, with lead times ranging from 7 to 25 days depending on fabric type, finishing treatments, and order complexity. Most manufacturers, including SzoneierFabrics, offer flexible customization options for coating, printing, and branding.

Sourcing & Production Insights

1. MOQ Expectations for B2B Buyers

| Order Type | Typical MOQ | Notes |

|---|---|---|

| In-stock fabric | 50–100 meters | Available for fast sampling |

| Custom dyeing/coloring | 500–1000 meters | Per color |

| Custom coating or lamination | 1000+ meters | Requires setup |

| Full OEM with branding | 1000–3000 meters | Ideal for brands, varies by spec |

Szoneier offers low-MOQ options starting from 300 meters per design for selected denier & PU fabric—ideal for small brands testing new SKUs.

2. Standard Lead Times

| Process | Lead Time (Days) |

|---|---|

| Stock fabric dispatch | 2–5 |

| Custom color dyeing | 7–12 |

| Coating and finishing | 10–18 |

| Full OEM with printing | 15–25 |

3. Available Customization Options

- Denier selection: 210D, 420D, 600D, 1000D, 1680D

- Coating: PU, PVC, TPU (optional double-side)

- Color: Pantone matching or digital swatch match

- Logo Printing: Silk-screen, sublimation, reflective heat transfer

- Embossing/Lamination: Textured or matte finish available

- Functionality Add-ons:

- Flame retardant treatment

- UV blocking agents

- Antimicrobial finishes

A Dutch logistics firm customized 1680D PVC Oxford in a Pantone 295C navy blue with reflective screen printing and fire-retardant treatment, produced in 21 days at SzoneierFabrics.

How Does Oxford Fabric Compare to Other Fabrics Like Canvas, Polyester, and Nylon?

Choosing between Oxford and alternative fabrics depends on key performance parameters like water resistance, durability, weight, cost, and branding flexibility.

Compared to canvas, polyester, and nylon, Oxford fabric offers superior customization potential, balanced cost-performance ratio, and better waterproofing when coated. It’s a smart all-rounder for both soft and rugged product needs.

Comparison Chart

| Feature | Oxford Fabric | Canvas | Polyester Fabric | Nylon Fabric |

|---|---|---|---|---|

| Waterproof Capability | Excellent (coated) | Poor (unless waxed) | Moderate (treated) | Good (treated) |

| Abrasion Resistance | Medium–High | Medium | Low–Medium | High |

| Weight (GSM) | 100–450 | 300–600 | 80–250 | 100–400 |

| Flexibility | Medium | Low (stiff) | High | Very High |

| Eco-friendliness | Medium (TPU only) | High (natural) | Low (synthetic) | Low (synthetic) |

| Color Retention | Good | Moderate | Excellent | Good |

| Cost per Meter (USD) | \$0.65–\$2.20 | \$1.00–\$2.80 | \$0.50–\$1.50 | \$1.00–\$2.50 |

| Common Usage | Bags, tents, uniforms | Tote bags, workwear | Flags, indoor use | Sportswear, tactical gear |

Choosing Based on Application

| Use Case | Best Fabric Choice | Why |

|---|---|---|

| Promotional bags | Oxford or Polyester | Budget-friendly, printable |

| High-end tote bags | Canvas | Eco feel, premium texture |

| Hiking or military gear | Nylon Oxford (1680D) | Abrasion resistance, strength |

| Outdoor furniture covers | PVC-coated Oxford | UV/waterproof, durable |

| Fashion backpacks | PU-coated Oxford | Lightweight, customizable |

When price, performance, and versatility need to align—Oxford fabric is usually the best compromise.

Ready to Source High-Quality Oxford Fabric?

Whether you need 210D PU-coated Oxford for lightweight bags or heavy-duty 1680D PVC Oxford for industrial applications, SzoneierFabrics has you covered.

We provide:

- ✅ Free samples for quality testing

- ✅ Low MOQ customization starting from 300 meters

- ✅ Coating, lamination, and printing support

- ✅ Fast lead times from 7 to 25 days

- ✅ Full OEM/ODM services with 100% quality assurance

Reach out to us now to discuss your Oxford fabric needs, request a quote, or get your first prototype sample shipped this week.