The Versatility of Canvas Material in Custom Bag Manufacturing

Canvas has been a foundational fabric in the world of textiles for centuries. Originally used in sails, tents, and utility covers, it has now evolved into a preferred material in fashion, lifestyle, and utility products—especially custom-made bags. Its popularity stems from more than just its strength; canvas is known for its adaptability, cost-effectiveness, and compatibility with a wide range of design treatments. Today, brands looking to produce customized bags—from casual totes to tactical backpacks—are turning to canvas for its unmatched balance of rugged performance and creative flexibility.

Canvas fabric is considered one of the most versatile materials for custom bag manufacturing because of its durability, design adaptability, range of weights (GSM), and compatibility with various finishes, printing methods, and coatings.

But let’s bring this to life with a real-world case: A U.K.-based artisanal luggage brand struggled with high MOQ synthetic fabric suppliers that required expensive molds and restrictive minimums. They pivoted to 16oz cotton canvas with wax coating, custom-dyed to their signature green. Not only did they reduce upfront costs by 37%, but the tactile, natural look became a branding asset that resonated with eco-conscious consumers.

What makes canvas such a powerhouse in the world of custom bags? Let’s dive in from both technical and creative angles.

What Makes Canvas Material Ideal for Custom Bag Production?

Canvas fabric is ideal for custom bag production due to its structural strength, ease of shaping, high sewability, and support for branding elements like printing, embroidery, and dyeing. Its natural texture and rigidity allow it to hold bag shapes better than lightweight or overly stretchable materials.

Technical and Creative Advantages of Canvas

▸ Structural Integrity

Canvas, especially in medium-to-heavy weights (12oz–24oz), offers excellent shape retention. This is critical for:

- Structured totes

- Box-style backpacks

- Messenger bags that need to sit upright

| Weight (oz) | Ideal Bag Use |

|---|---|

| 10–12oz | Foldable totes, casual handbags |

| 14–16oz | Book bags, shopping totes, gear bags |

| 18–24oz | Tactical backpacks, camera bags, tool rolls |

▸ Sewability and Handling

Canvas cuts cleanly and resists fraying when handled properly. It also allows for:

- Easy topstitching (for visible seam details)

- Strong bartacking at stress points

- Consistent needle penetration during mass production

This makes it ideal for factories using both industrial and semi-industrial machines.

▸ Dyeing and Printing Adaptability

Canvas has high absorbency, making it great for:

- Pigment dyeing (vintage feel)

- Reactive dyeing (deep color and wash-fastness)

- Discharge printing

- Screen and digital pigment printing

Brand Example: A South Korean canvas bag label launched a limited-edition line with botanical-themed digital prints on 14oz enzyme-washed canvas. The result? Over 1,000 preorders in just 3 weeks—without any plastic-based materials.

▸ Tactile and Aesthetic Appeal

Canvas has a raw, earthy feel that synthetic fabrics often lack. It visually communicates durability, minimalism, and craftsmanship—key messages for lifestyle and eco-friendly brands.

How Does Canvas Compare to Other Materials Used in Bag Manufacturing?

Canvas stands out from other bag materials due to its breathability, customizability, environmental friendliness, and tactile value. Compared to synthetics like polyester and nylon, it offers a more natural look and feel, is easier to personalize, and performs well in both aesthetic and functional applications.

Canvas vs Synthetic and Natural Alternatives

▸ Canvas vs Polyester

| Feature | Canvas | Polyester |

|---|---|---|

| Texture | Natural, rugged | Smooth, often shiny |

| Print Compatibility | Excellent for pigments & dye | Limited (sublimation only) |

| Durability | High (esp. 14oz+) | Moderate to high |

| Sustainability | High (cotton-based) | Low (petroleum-based) |

| Cost | Medium | Low to medium |

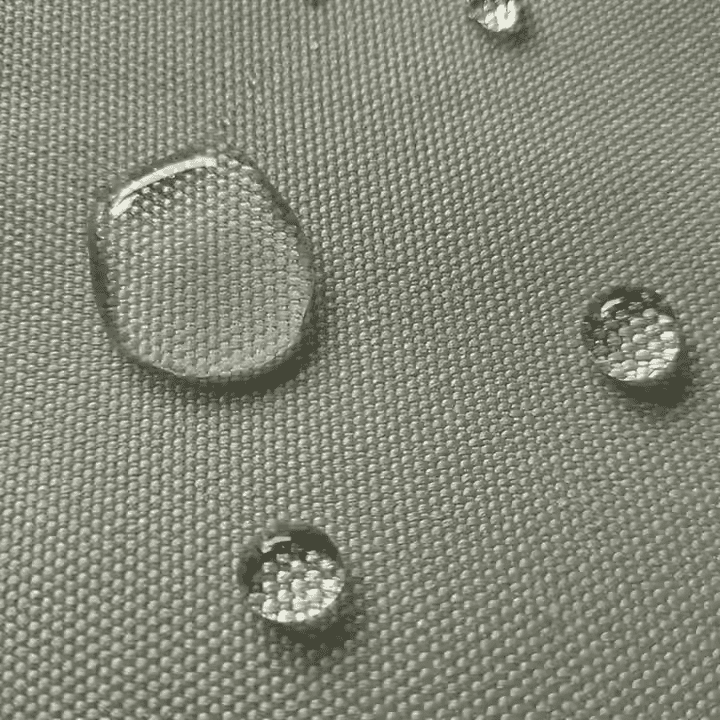

Polyester may be preferable for water-repellent gear but requires more coating. Canvas can be waxed or PU-coated while maintaining its character.

▸ Canvas vs Nylon

| Feature | Canvas | Nylon |

|---|---|---|

| Abrasion Resistance | Very high (esp. 18–24oz) | Very high |

| Branding Appeal | High (natural, warm) | Moderate (tech-oriented) |

| Sewability | Excellent | Requires sharper needles |

| Perceived Value | High | Medium |

Canvas is often chosen for lifestyle goods, while nylon dominates in technical gear like hiking or rescue backpacks.

▸ Canvas vs Leather

| Feature | Canvas | Leather |

|---|---|---|

| Cost | Low to moderate | High |

| Animal-Free | Yes (cotton-based) | No |

| Printing Flexibility | High | Low |

| Weight | Light to medium | Heavy |

Canvas wins in versatility and eco-friendliness. Many vegan brands combine canvas with faux leather trim for a hybrid look.

Product Insight: A Canadian women’s fashion brand launched a convertible crossbody-backpack using 16oz dyed canvas with vegan leather accents. The collection sold out in two months and was praised for being “urban, clean, and conscious.”

Which Types of Bags Are Commonly Made from Canvas Fabric?

Canvas fabric is used to make a wide variety of bags, ranging from simple totes to rugged tactical gear. Thanks to its wide GSM range and compatibility with coatings, linings, and embellishments, canvas can be adapted for lifestyle, professional, or industrial uses with ease.

Common types of bags made from canvas include tote bags, backpacks, messenger bags, duffels, drawstring bags, utility pouches, and camera bags. Canvas adapts to both structured and soft bag designs depending on the GSM and finish.

A Closer Look at Bag Types and Fabric Requirements

▸ Everyday and Lifestyle Bags

- Tote Bags: One of the most popular uses of canvas. Typically 10–14oz fabric, either natural or pigment dyed.

- Crossbody & Sling Bags: Often use 14–16oz for structure. Zippers, leather accents, or metal hardware may be added.

- Bucket Bags: 14oz enzyme-washed canvas allows a soft but durable structure.

- Mini Shoulder Bags: 12oz canvas paired with lining and embroidery creates a fashion-forward piece.

Market Data: A 2024 trend report from Etsy shows that “canvas tote bags” were among the top 10 searched handmade fashion items globally, with over 500,000 listings.

▸ Travel and Utility Bags

- Backpacks: 16–20oz canvas with PU or wax coating for outdoor performance.

- Duffels: Reinforced 18–22oz canvas with riveted handles or leather bottoms.

- Weekenders: Blended 14oz canvas with water-repellent lining and inner pockets.

▸ Professional and Tactical Bags

- Messenger Bags: 16oz waxed canvas for urban commuter styles; can be lined with polyester for laptop compartments.

- Camera Bags: High-density canvas (20oz+) with foam lining or EVA inserts.

- Tool Bags & Utility Pouches: Often 18–24oz canvas with heavy zippers, double stitching, and reinforcement bartacks.

| Bag Type | Suggested GSM | Surface Finish | Notes |

|---|---|---|---|

| Tote Bag | 10–14oz | Pigment dyed / printed | Flat seams, open top or zipper |

| Backpack | 16–20oz | PU coated or waxed | Structured base, heavy straps |

| Messenger Bag | 14–18oz | Waxed, pigment dyed | Lined interior, snap or buckle closure |

| Tool Bag | 18–24oz | PVC coated | High-strength handles, boxy structure |

Brand Case: A U.S. outdoor company used 22oz canvas with a waxed finish to manufacture duffel-style carry bags for field gear. The bags passed internal abrasion tests over 2,000 rub cycles and saw a 92% customer satisfaction rate within the first 6 months of launch.

What Are the Customization Options for Canvas Bags in Terms of Design and Functionality?

Canvas is one of the most customizable materials available for bag manufacturing. It supports nearly every type of finish, print, hardware, and construction method—making it a favorite for both new designers and established product lines.

Customization options for canvas bags include GSM selection, shape and size, closure type, strap and handle variations, pockets and compartments, lining materials, printing techniques, and branding treatments such as embossing, labels, and embroidery.

Design Variables that Define Canvas Bag Projects

▸ Weight (GSM) and Fabric Color

- 10oz–12oz for soft, foldable bags or budget giveaways

- 14oz–16oz for casual fashion, school, and urban commuter bags

- 18oz–24oz for tactical, utility, or structured bags

Color options range from undyed natural to full Pantone-matched pigment dye. Enzyme washing adds softness and a broken-in look.

Szoneier Tip: We offer over 30 standard GSM/color combinations and can develop custom dye lots for 100+ meter orders.

▸ Closures and Openings

- Zippers (nylon, metal, waterproof)

- Magnetic buttons

- Snap closures

- Velcro flaps

- Drawstrings with metal grommets

These affect not only aesthetics but also production cost and functionality.

▸ Lining and Pocket Design

Canvas can be:

- Unlined (for low-cost, simple totes)

- Lined with polyester or cotton blends (adds structure and color contrast)

- Foam or EVA-lined (for tech protection or shape retention)

Internal pockets (zippered, sleeve, mesh) and external compartments can be added for functionality.

▸ Handles and Straps

- Cotton webbing straps (adjustable or fixed)

- Riveted leather handles (premium look and feel)

- Canvas rolled handles

- Crossbody straps with sliders

Product Inspiration: A Danish accessories brand created a multiway canvas bag that converts from a tote to a backpack using two detachable straps. This required precise strap anchor positioning and dual closure points.

▸ Branding and Visual Elements

- Screen printing or heat transfer logos

- Embossed or stitched leather patches

- Embroidered motifs

- Woven labels, sewn-in tags, or interior QR codes

- Contrast binding, piping, or thread color for visual depth

Customization Table:

| Feature | Custom Option Examples |

|---|---|

| Fabric Weight | 10oz / 12oz / 14oz / 16oz / 20oz |

| Closure Type | Zipper / Snap / Drawstring / Velcro |

| Handle Style | Webbing / Leather / Rolled Canvas |

| Lining Material | Polyester / Cotton / Foam-padded |

| Branding Style | Printed / Embroidered / Patch / Heat Transfer |

How Does GSM and Coating Impact the Performance of Canvas Bags?

GSM (grams per square meter) and surface coating significantly influence the durability, weight, water resistance, and intended use of canvas bags. Choosing the correct GSM and finish ensures the bag functions as intended—whether for fashion, travel, workwear, or industrial use.

Higher GSM canvas offers better structure, load capacity, and abrasion resistance, while coatings like wax, PU, or PVC enhance water repellency, weather protection, and visual texture. Together, these factors define performance and product longevity.

Understanding GSM and Coating Interactions

▸ GSM Breakdown by Usage

| GSM Range | Typical Weight (oz) | Best Use Cases |

|---|---|---|

| 200–300 | 6–10oz | Lightweight totes, giveaways, inner pouches |

| 340–450 | 10–14oz | Fashion bags, everyday backpacks |

| 500–650 | 16–20oz | Outdoor, duffel, camera, and tool bags |

| 700–900+ | 22oz+ | Industrial covers, tactical or military bags |

Tip: For fashion-forward bags, 14oz enzyme-washed canvas gives the ideal balance between structure and soft drape. For gear or tactical use, 18oz waxed canvas provides needed rigidity and weather protection.

▸ Types of Coatings and Their Effects

| Coating Type | Benefits | Use Case |

|---|---|---|

| Wax Finish | Water-resistance, vintage patina | Messenger bags, artisanal backpacks |

| PU Coating | Lightweight water repellency | Urban commuter bags, laptop sleeves |

| PVC Coating | Full waterproof barrier, tear resistance | Industrial and tactical bags, tarps |

| Silicone Finish | Smooth texture, soft handfeel | Premium lifestyle accessories |

| Flame Retardant | Fire safety compliance | Military packs, event gear, exhibition kits |

Case Study: A logistics bag company in Germany sourced 20oz waxed canvas from Szoneier for courier bags. Post-deployment, field data showed a 40% longer lifecycle compared to nylon equivalents, with superior stitch retention in rain exposure.

▸ Coating vs Lining Strategy

For budget-conscious builds:

- Use PU coating on outer canvas

- Pair with unlined interiors

For premium builds:

- Use waxed or PVC-coated canvas

- Add branded polyester or cotton lining with label detailing

This approach allows flexibility in tiered product pricing.

Is Canvas a Sustainable and Eco-Friendly Option for Bag Brands?

Canvas, especially when made from 100% cotton or organic fibers, is widely recognized as an environmentally responsible choice. It is biodegradable, long-lasting, recyclable, and often processed with fewer synthetic chemicals than petroleum-based fabrics.

Canvas is considered a sustainable option because of its natural fiber base, reduced energy footprint during manufacturing, long product lifespan, and high reusability—especially when sourced from OEKO-TEX or GOTS-certified mills.

Sustainability Metrics for Canvas Material

▸ Environmental Impact Comparison

| Material Type | Biodegradable | Renewable | Recyclable | Manufacturing Emissions |

|---|---|---|---|---|

| Cotton Canvas | Yes | Yes | Yes | Low to Medium |

| Polyester | No | No | Limited | High |

| Nylon | No | No | Low | Very High |

| Organic Canvas | Yes | Yes | Yes | Low |

Certification Markers:

- OEKO-TEX® Standard 100 – ensures no harmful chemicals

- GOTS (Global Organic Textile Standard) – certifies organic origin and ethical production

- REACH compliance – required for EU import safety

Szoneier offers canvas that meets OEKO-TEX and REACH criteria, with documentation available for each production lot.

▸ Consumer Preference Shift Toward Natural Bags

According to Google Trends and Etsy 2024 Insights:

- Searches for “eco canvas bag” have increased by 34% year-over-year

- Brands using recycled or natural canvas in packaging and bags report higher retention among Gen Z and millennial buyers

Brand Highlight: A U.S. accessories company used GOTS-certified 12oz canvas for its Earth Day collection. It led to press features, influencer partnerships, and a 3x increase in monthly sales.

▸ Lifecycle and End-of-Life Advantages

Canvas:

- Can be upcycled into smaller goods (e.g. coin pouches, straps, patches)

- Biodegrades faster than synthetic counterparts in natural environments

- Can be paired with recycled linings or trims to further reduce footprint

What Printing and Branding Methods Work Best on Canvas Bags?

Canvas fabric is an excellent surface for branding because of its natural absorbency, flat weave, and durability. Whether you’re applying logos, graphics, or decorative art, canvas supports a wide range of printing, embroidery, and labeling techniques that remain vivid and durable even with daily use.

The best branding methods for canvas bags include screen printing, digital pigment printing, embroidery, heat transfer, woven labels, and stitched-on patches. Each method offers a unique aesthetic and performance profile depending on the design goal and product usage.

Branding Techniques for Canvas Bags

▸ Printing Options

| Method | Best For | Notes |

|---|---|---|

| Screen Printing | Bold logos, solid colors | Economical for large runs, highly durable |

| Digital Pigment Printing | Multicolor, detailed graphics | Best for low MOQ or complex designs |

| Discharge Printing | Vintage looks on dark fabric | Requires specific fabric treatments |

| Sublimation | Not suitable for 100% cotton canvas | Requires polyester content |

| Heat Transfer | Small logos, detailed graphics | Fast, good for small runs, but can peel under heat use |

Tip: For 100% cotton canvas, water-based screen printing is both eco-friendly and delivers excellent texture retention.

▸ Embellishment and Patch Branding

- Embroidery: Adds perceived value and long-lasting branding. Perfect for premium or minimalistic designs.

- Leather Patch (stitched or riveted): Ideal for vintage or rugged brands. PU leather alternatives available.

- Woven Labels: Great for small-scale brand identifiers, usually sewn onto side seams or interior.

- Debossed Metal Tags: Attached via rivet or loop, common in high-end urban styles.

▸ Placement Considerations

- Front panel: Primary logo placement (screen print or embroidery)

- Side seam: Discreet branding with woven label

- Interior lining: Printed care label or brand story tag

- Bottom panel: Leather or embossed canvas patches for limited editions

Case Study: A Japanese fashion label collaborated with Szoneier to develop a series of pigment-dyed canvas pouches with custom “blind” debossed leather patches and tone-on-tone embroidery. The subtle branding helped the bags stand out in a saturated market and positioned the brand as elevated yet accessible.

How to Choose the Right Canvas Fabric Supplier for Custom Bag Projects?

Finding the right supplier for your canvas bag manufacturing isn’t just about price. It’s about reliable communication, consistent quality, sampling support, and proven experience in custom fabric processing and bag application. The wrong supplier can delay your launch, compromise quality, or inflate costs.

When choosing a canvas fabric supplier, prioritize their customization capabilities, fabric quality certifications, MOQ flexibility, sample policy, and communication responsiveness. Ask for swatches, technical sheets, and factory photos before placing bulk orders.

Evaluation Criteria for Canvas Suppliers

▸ Key Qualities to Look For

| Criteria | What to Check |

|---|---|

| GSM Customization | Can they weave or source exact GSM specs? |

| Color Matching | Pantone dyeing ability and dye lot control |

| Print & Coating Options | Screen, digital, wax, PU, FR, etc. |

| Certifications | OEKO-TEX, REACH, GOTS (if eco credentials are needed) |

| Sampling Policy | Free or low-cost swatch books, print tests, mockups |

| MOQ Flexibility | Ability to support 50–300m MOQ for trial or DTC runs |

Tip: Ask for customer references or previous work samples. Trustworthy suppliers will happily show off their portfolio.

▸ Questions to Ask Before Ordering

- Can you provide a GSM range and swatch book?

- How do you handle color matching and dye consistency across batches?

- What is your turnaround time for custom printing or coated canvas?

- Do you offer sewn prototypes or sample yardage for testing?

- Can you ship fabric rolls with custom width or edge treatment?

Sourcing Insight: Szoneier Fabrics offers 3–5 day swatch sampling, over 20 standard GSMs in stock, and OEM finishing for branding elements. They provide production photos, QC reporting, and shipping tracking—all in one communication thread for ease of project management.

Canvas Bags Built to Your Vision—Durability Meets Customization

Canvas is not just a material—it’s a message. It communicates function, craft, sustainability, and authenticity. For brands aiming to produce bags that last, feel premium, and support creative identity, canvas offers a perfect foundation. From GSM selection to branding treatment, every aspect of a canvas bag can be tailored without compromising its strength.

Whether you’re starting your first product line or scaling up your private label, working with a responsive, experienced fabric partner ensures your concept becomes a retail-ready product—without surprises.

Bring Your Canvas Bag Project to Life with Szoneier

At Szoneier Fabrics, we help brands and creators around the world design and manufacture canvas fabric tailored for custom bags. We offer:

- Over 30 GSM/color combinations

- Custom dyeing, coating, and printing services

- Low MOQs starting at 50 meters

- Free design consultation and swatch kits

- Fast sampling, reliable lead times, and global shipping

Contact us now for a tailored quote or to request your canvas fabric sample kit. Let’s build your next best-selling bag—together.

custom canvas bag fabric, canvas material for bags, canvas fabric for tote bags, printed canvas for bags, canvas GSM for bags, waxed canvas bag material, cotton canvas for bag making, canvas bag manufacturing, best canvas for backpacks, heavy-duty canvas for bags, canvas fabric for sewing bags, coated canvas fabric supplier, waterproof canvas for bags, eco canvas bag fabric, custom printed canvas fabric, canvas fabric wholesale for bags, canvas for tool bags, organic cotton canvas fabric, canvas bag OEM supplier, canvas fabric for fashion bags, low MOQ canvas bag fabric, custom canvas fabric for bags, types of canvas for bags, PU coated canvas for bags, canvas bag material supplier China, screen printed canvas fabric, dyed canvas fabric for bags, GSM canvas chart for bags, canvas vs polyester for bags, branded canvas bags material,

Can't find the answers?

No worries, please contact us and we will answer all the questions you have during the whole process of bag customization.

Make A Sample First?

If you have your own artwork, logo design files, or just an idea,please provide details about your project requirements, including preferred fabric, color, and customization options,we’re excited to assist you in bringing your bespoke bag designs to life through our sample production process.