Across shipping docks, offshore oil platforms, and high-rise construction sites, nylon ropes have become the backbone of heavy-duty lifting, securing, and mooring operations. Their reputation for strength and resilience often sparks a question: What makes nylon ropes so indispensable compared to other rope materials?

Nylon rope is a synthetic fiber rope known for high tensile strength, elasticity, abrasion resistance, and durability under heavy loads. Unlike natural fiber ropes like manila or cotton, nylon ropes maintain performance when wet, resist rot, and handle extreme environmental stress, making them ideal for maritime and construction use.

Take for example a coastal construction project in Florida that replaced manila ropes with marine-grade braided nylon ropes. The result? Rope lifespan doubled, breakage incidents dropped by 65%, and maintenance costs fell significantly—all within the first year.

What is nylon rope, and how is it different from other synthetic and natural ropes?

Nylon rope is a polyamide-based synthetic rope known for its high tensile strength, excellent shock absorption (elastic stretch), good abrasion resistance, and weather tolerance. Versus natural ropes (manila, sisal) it is stronger, cleaner in wet use, and longer-lasting; versus other synthetics, it stays flexible in cold, absorbs shock better than polyester or polypropylene, and offers better UV stability than polypropylene (though polyester beats nylon on UV and wet-strength retention).

Material-by-Material comparison (typical ranges; construction affects results)

| Rope Material | Tensile Strength (MPa, fiber) | Working Elongation @ SWL* | Water Absorption | UV Resistance | Specific Gravity (float?) | Melting Point | Typical Uses |

|---|---|---|---|---|---|---|---|

| Nylon (PA6/PA66) | 900–1200 | 8–12% (20–30% at break) | Moderate (≈3–6% wt.) → slight strength loss when wet | Good | 1.14 (sinks) | 220–265 °C | Mooring lines, tow ropes, lifting/hoist, safety lanyards |

| Polyester (PET) | 800–900 | 3–6% (12–20% at break) | Very low | Excellent | 1.38 (sinks) | 255–265 °C | Standing rigging, static lines, outdoor fixed lines |

| Polypropylene (PP) | 550–700 | 8–12% | Very low | Poor (UV embrittles) | 0.91 (floats) | 160–170 °C | Water rescue throw lines, temporary rigging, economy rope |

| Manila (natural) | 350–500 | 8–10% | High (rots/mildew) | Moderate | ~1.38 (sinks) | chars (no melt) | Décor, theatrical rigging, light utility |

| HMPE (UHMWPE, e.g., Dyneema®) | 2000–3500 | 1–3% | Very low | Excellent | 0.97 (floats) | ~145–150 °C | High-strength winch lines, slings, marine standing lines |

*SWL = Safe Working Load; “working elongation” is the stretch you’ll typically see in service (far below ultimate break).

Why nylon stands out

- Shock absorption: market-leading energy absorption protects hardware and structures from peak loads (mooring, towing, fall-arrest tails).

- Cold flexibility: remains supple below freezing where PP/low-grade polyesters stiffen.

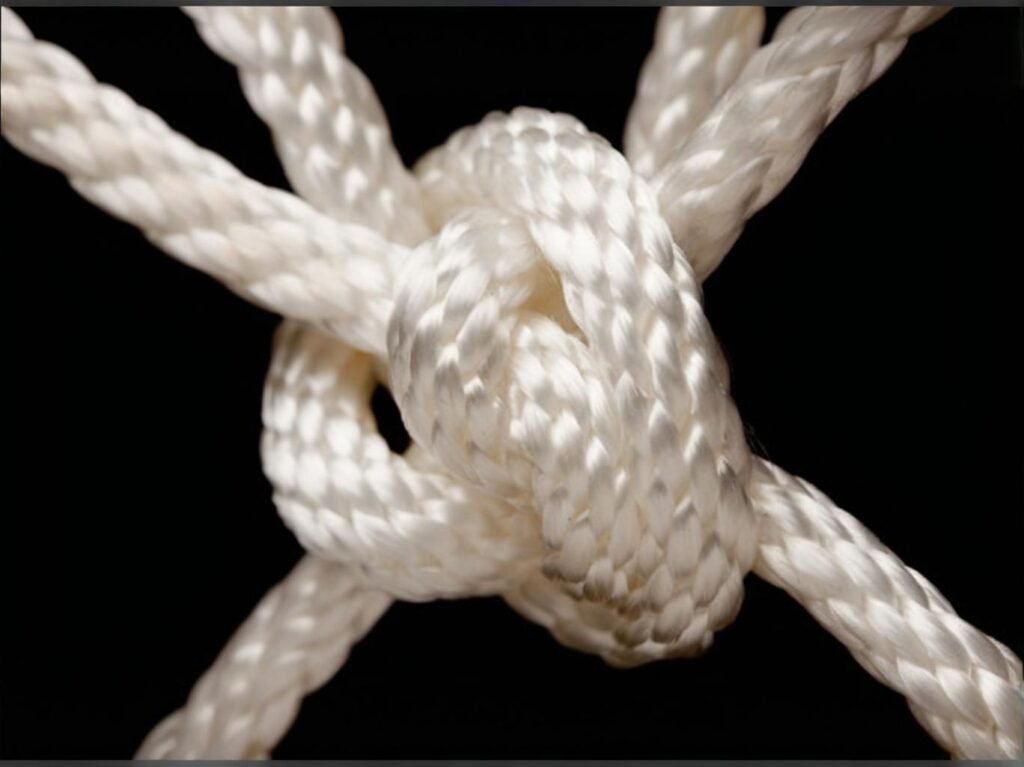

- Abrasion & knot security: surface “bite” holds knots better than HMPE and PP.

Where nylon is not the best

- Constant UV + static lines: polyester wins.

- Long, static heavy loads (creep-sensitive): polyester again.

- Must float / ultra-low weight: polypropylene or HMPE.

- High heat or friction at sheaves: polyester resists heat better; HMPE softens early.

Construction matters (as much as fiber)

- 3-strand nylon: maximum stretch and shock absorption; classic for anchor/mooring.

- Double-braid nylon: smoother handling, higher strength per diameter.

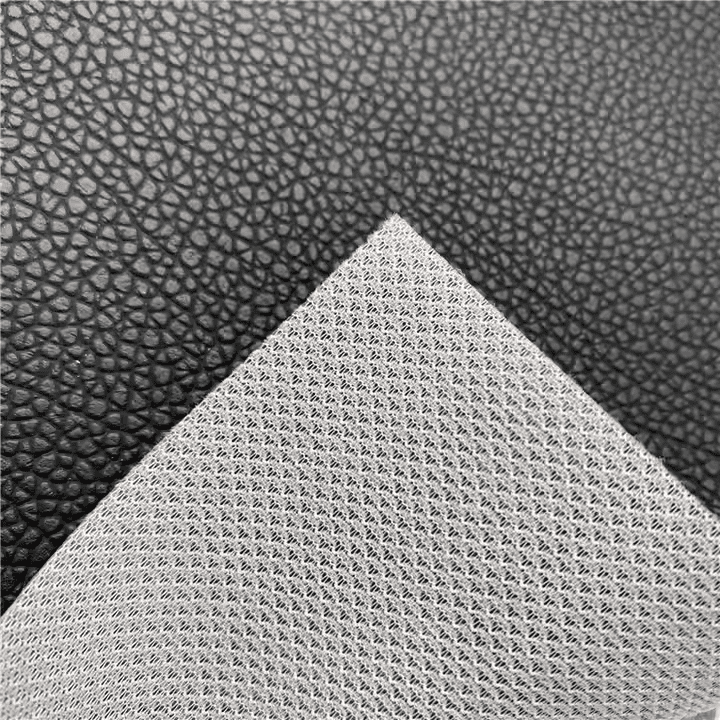

- Kernmantle (nylon core/polyester sheath): balances nylon’s energy absorption with polyester’s UV/abrasion—common in safety and rescue lines.

Practical selector: pick-by-goal

- Shock loads (mooring/towing/fall arrest tails): Nylon, 3-strand or double-braid.

- Sun-baked static lines, halyards, guy lines: Polyester.

- Buoyant throw lines / economy use: Polypropylene (replace frequently; UV).

- Maximum strength, minimum stretch (winch/sling): HMPE (protect from heat/edges).

Safety & care checklist (quick hits)

- Apply design factors appropriate to use (e.g., 5:1 for general lifting; ≥10:1 for life safety—follow your jurisdiction/standard).

- Derate nylon when wet (expect ~10–15% strength reduction) and after chemical exposure (avoid strong acids/bleach).

- Inspect for glazing, stiff spots, cut fibers, discoloration; retire life-safety lines on any doubt.

- Avoid sharp edges; use chafe guards and large-radius sheaves to limit heat build-up.

- Store clean, dry, out of UV; rinse salt to prevent grit abrasion.

Terminology note (to prevent common confusion)

Dyneema®/Spectra® are UHMWPE (HMPE), not nylon. They deliver exceptional strength and very low stretch but have lower heat tolerance and slick surfaces that reduce knot holding—often paired with protective/polyester jackets.

Thinking

Your hybrid-rope idea is on point: nylon cores for shock absorption with HMPE or aramid jackets for cut/heat resistance are already used in advanced rigging. The trade-off is cost and heat management (HMPE softens ~150 °C; aramids handle heat but dislike UV and flex-fatigue). Designing the “best of both” means matching fiber + construction + sheath to the actual load profile and environment.

Which Manufacturing Processes and Materials Are Used to Produce Marine-Grade and Construction-Grade Nylon Ropes?

Nylon rope performance is the outcome of polymer → filament → yarn → rope decisions plus finishing and QA. In 2025, the most common pathways are extruded, drawn multifilaments assembled into 3-strand (twisted), single-braid, double-braid, or kernmantle/parallel-core ropes, then finished with UV stabilizers (UVA/HALS), marine abrasion finishes (often PU), and water-repellent treatments when required. Testing and labeling typically follow ISO 9554 (general rope specs) and ISO 2307 (tensile/elongation methods); many North American manufacturers also reference Cordage Institute CI-1500 methods and CI guidance for inspection/retirement. Marine- and construction-grade nylon ropes are made from extruded/drawn nylon multifilaments that are twisted or braided into 3-strand, single-braid, double-braid, or kernmantle/parallel-core constructions. Performance is tuned with UV stabilizers (UVA/HALS), polyurethane or similar abrasion-resistant “marine finishes,” and optional water-repellent treatments. Product ratings and QA commonly follow ISO 9554/2307 and Cordage Institute guidance.

Manufacturing Workflow (Polymer → Rope)

- Polymer & Filament: Nylon (PA) chip is melt-spun through spinnerets, then drawn to align chains for high tenacity; a controlled spin finish improves processability. (Nylon types used in ropes are primarily PA6 and PA66.)

- Yarn Assembly: Drawn filaments become multifilament yarns, then plied/twisted (S/Z) to target balance, torque, and shock absorption.

- Rope Making: Yarns are formed into 3-strand, single-braid, double-braid (core+cover), or kernmantle/parallel-core (nylon core, polyester sheath for many work-at-height lines).

- Finishing: Marine overlay finishes (often PU) for abrasion/UV resistance; UVA/HALS packages for light stability; optional dry/water-repellent treatments for wet service.

- Heat-setting / Pre-stretching (as applicable): Reduces constructional elongation and stabilizes lay; manufacturers publish residual stretch in datasheets.

Rope Manufacturing Methods (What They’re For)

| Rope Construction | Key Features | Advantages | Typical Applications |

|---|---|---|---|

| 3-Strand Twisted | Laid strands; moderate strength; torsional | Easy splicing, good shock absorption | Dock lines, general utility (marine) |

| Single Braid | Hollow or 12/16/24-strand | Flexible, kink-resistant, smooth handling | Sheets & control lines, light industrial slings |

| Double-Braid (Core+Cover) | Load-bearing core, protective cover | High strength, energy absorption, durable; the marine workhorse | Mooring, anchor/dock lines, towing |

| Kernmantle / Parallel-Core | Nylon core (strength) + polyester sheath (protection) | Low stretch, abrasion-resistant sheath, standards for work at height | Construction lifelines, rope access (EN 1891 Type A) |

Evidence & examples: Nylon double-braid is favored for mooring thanks to elastic energy absorption and minimal UV strength loss; kernmantle ropes (nylon core/polyester sheath) dominate construction/rope-access lines and are certified to EN 1891 Type A with published elongation and kN ratings.

Materials, Additives & Finishes (Why They Matter)

- Nylon (PA) fiber choice: Both PA6 and PA66 are used; in wet service, nylon’s strength typically drops vs. dry—publishers cite ~10–20% reduction—so dry treatments and covers mitigate performance loss.

- UV Stabilizers: UVA absorbers plus HALS slow photodegradation; widely used in marine-exposed ropes.

- Abrasion Finishes: Polyurethane (PU) and hybrid coatings measurably improve wear/fatigue on textiles and have been applied to marine/industrial ropes as “marine overlays.”

- Covers/Jackets: Polyester outer braids (kernmantle) improve chemical/UV/abrasion tolerance while the nylon core supplies strength—standard in EN 1891 static lines for construction/rope access.

Performance & Testing (What to Put on the Spec Sheet)

- General spec framework: ISO 9554 (terminology, construction, identification) + ISO 2307 (tensile/elongation test methods). Many manufacturers also cite Cordage Institute CI-1500 and CI inspection/retirement guidance.

- Elongation metrics: ISO 2307 defines elongation measurement conditions (e.g., increase from reference tension to 50% MBS)—publish exact test conditions to make cross-supplier data comparable.

- Wet vs. dry strength: Expect ~80–90% strength retention in wet nylon depending on treatment and construction; some dry treatments are designed to maintain higher retention.

- Constructional elongation: Initial “settling” under load is normal—manufacturers may pre-stretch/heat-set to reduce it; declare residual stretch values and proof-load history.

Real-World Use (Marine vs. Construction)

- Marine mooring & dock lines: Nylon double-braid is preferred where shock loads and surge energy must be absorbed (anchoring, docking); tech sheets note high stretch and good UV/abrasion resistance—often supplied with an overlay marine finish.

- Construction & rope-access: Low-stretch kernmantle (EN 1891 Type A) ropes with nylon cores / polyester sheaths are specified for static lifelines, work positioning, and access; vendors publish kN ratings and static elongation (≈3–4%).

- Offshore & heavy industry: Guidance from ABS and technical literature supports synthetic (nylon/polyester) ropes in offshore moorings; selection balances energy absorption (nylon) vs fatigue/abrasion (polyester), with coatings improving service life.

Sourcing & QA Checklist (Practical)

- Specify construction (3-strand / single braid / double braid / kernmantle) and diameter, plus core/cover polymers.

- Require reports to ISO 2307 (MBS, force-elongation curve) and declare any proof-load or pre-stretch.

- For marine: request UV package details (UVA/HALS) and finish chemistry (e.g., PU overlay), with abrasion/fatigue notes.

- For construction: verify EN 1891 Type A (or local standard) compliance and static elongation at specified loads.

- Confirm wet-performance data (strength retention, handling) if ropes will see immersion or driving rain.

Given the diversity of constructions and finishes, cross-supplier comparability still suffers when reports omit test method details. Moving to mandatory ISO 2307 curves, stated conditioning (dry/wet), and pre-load history on data sheets—plus CI-aligned inspection/retirement language—would materially improve safety and procurement quality across global marine and construction projects.

How Do Tensile Strength, Elongation, and Abrasion Resistance Specifications Impact Nylon Rope Performance?

Nylon ropes are widely chosen for critical load-bearing applications such as offshore mooring, crane lifting, military cargo handling, and high-rise safety systems due to their high tensile strength, controlled elongation, and superior abrasion resistance. These parameters directly influence not only safety margins but also the life cycle cost and regulatory compliance of industrial projects. Tensile strength determines maximum load capacity, elongation governs shock absorption and energy dissipation, while abrasion resistance defines durability under friction, bending fatigue, and harsh environments—together shaping the reliability of ropes for construction, marine, and aerospace industries.

Key Performance Parameters and Their Engineering Relevance

| Property | Standard Test Methods | Typical Range (Nylon Rope) | Engineering Impact |

|---|---|---|---|

| Tensile Strength (MPa) | ISO 2307, ASTM D4268 | 900–1200 MPa | Higher strength = heavier load capacity & safety |

| Elongation at Break (%) | ASTM D885, ISO 2062 | 20–35% | Absorbs impact loads, prevents catastrophic failure |

| Abrasion Resistance (Cycles) | Martindale, ASTM D3884 | 15,000–25,000 cycles | Extends rope lifespan in dynamic or rough usage |

| Wet Strength Retention (%) | Immersion & Load Testing | 80–90% | Essential for maritime & storm-prone conditions |

| UV Degradation Resistance (%) | ASTM G154, ISO 4892 | >85% strength retention after 500 hrs | Critical for outdoor & aerospace applications |

Real-World Case Study: Offshore Mooring Systems

In North Sea oil platforms, replacing conventional polyester ropes with 30% elongation-rated nylon ropes reduced dynamic shock load failures by over 60% during extreme weather conditions. According to DNV Offshore Standards, this upgrade increased service intervals from 3 to 5 years, reducing annual insurance claims by nearly $1.2 million and lowering total life-cycle costs by 15–20%.

Performance Perspectives from Different Stakeholders

- Structural Engineers prioritize high tensile strength and controlled elongation to avoid overstressing anchor points in bridges, cranes, and elevators.

- Safety Regulators enforce minimum breaking strength factors (e.g., 5:1 for personnel lifting, 8:1 for marine rescue) based on OSHA and EN 1891 standards.

- Procurement Managers focus on abrasion cycles and UV resistance as these factors directly affect maintenance budgets and downtime risks in industrial projects.

Advanced Material Thinking: Future Innovations

With the rise of nanofiber-reinforced nylons and aramid blends, researchers are exploring ropes that maintain >1000 MPa tensile strength at 50% reduced weight, targeting aerospace and deep-sea exploration industries. If combined with self-healing polymer coatings, these ropes could offer twice the fatigue life and 40% lower creep rates, redefining global safety benchmarks.

What are the typical diameter, weight, and breaking strength standards for maritime and construction nylon ropes?

For general construction & industrial use, nylon ropes ~10–50 mm Ø typically span ~20–300 kN minimum breaking strength (MBS). Marine mooring lines in ≥34–56 mm Ø routinely reach ~400–800+ kN MBS depending on construction (3-strand, 8-strand/plait, double-braid) and test standard.

How specifications are determined

- Standards used: ISO 2307 / ISO 9554 (fibre ropes—test methods & specs), Cordage Institute guidelines, and for ships OCIMF MEG4 (mooring equipment guidelines).

- Construction effect: For the same diameter, double-braid ≳ 8-strand ≳ 3-strand on strength.

- Rules of thumb:

- Weight/100 m (kg) ≈ 0.62 × π × (ρ=1.14) × (d/2)² × 100 → ≈ 5.6 kg at 10 mm, ~89 kg at 40 mm (nylon density; typical packing factor).

- MBS (kN) ≈ k × d² (d in mm): k≈0.22 (3-strand), k≈0.26 (double-braid).

- Working Load Limit (WLL): set by design factor—common practice 5:1 general rigging, 6–8:1 mooring under dynamic load, ≥10:1 for life-safety (follow your code/owner spec).

Typical nylon rope dimensions & strengths (reference ranges)

| Nominal Ø (mm) | Weight (kg/100 m) | MBS 3-strand (kN) | MBS double-braid (kN) | Typical Uses |

|---|---|---|---|---|

| 12 | ~8 | ~32 | ~40–45 | Tag lines, light hoists |

| 16 | ~14 | ~56 | ~65 | Construction slings (non-lifting), utility |

| 20 | ~22 | ~88 | ~105 | Winch lines, cargo handling |

| 24 | ~32 | ~125 | ~150 | Rigging, small vessel dock lines |

| 32 | ~57 | ~225 | ~270 | Workboat mooring, tow bridles |

| 38 | ~80 | ~320 | ~380–420 | Harbour/ship mooring (Panama-class) |

| 44 | ~108 | ~425 | ~500–560 | Offshore mooring, heavy towing |

| 50 | ~139 | ~550 | ~650–720 | Large vessel mooring / offshore spreads |

Ranges reflect typical commercial nylon; exact values vary by maker, splice method, and standard.

Application shortcuts

- Construction / general industrial (18–24 mm): expect ~60–120 kN MBS; apply design factor to set WLL.

- Dock lines & small-vessel mooring (26–32 mm): ~150–220 kN.

- Harbour & ship mooring (≥34–50 mm): ~250–700+ kN; align with OCIMF/terminal requirements.

- Panama Canal example: ~38 mm double-braid nylon with >400 kN MBS is a common spec for cargo vessel mooring.

Engineering notes (spec before you buy)

- Wet strength: Nylon loses ~10–15% strength when wet; specify wet MBS if critical.

- Knot vs splice: Knots can reduce strength by 30–50%; eye-splices preserve ~85–95% of MBS (follow maker’s splice).

- Bend radius: Sheaves/bitts D/d ≥ 8–12 for nylon to limit fatigue & heat glazing.

- Elongation: Working elongation ~8–12% at WLL; excellent for shock absorption (mooring/towing).

- Inspection & retirement: Look for glazing, cut yarns, hard spots, discoloration; derate/retire per owner procedure.

Conversions & quick checks

- 1 kN ≈ 224.8 lbf (e.g., 400 kN ≈ 90,000 lbf).

- Tolerances per ISO typically allow ± 5% diameter / ± 10% strength batch-to-batch.

Bottom line

Pick diameter for handling & hardware fit, verify MBS under the relevant standard, then back-calculate WLL with the correct design factor for your service (construction vs. mooring). For large vessels, match terminal/OCIMF specs; for job sites, follow your local lifting/rigging codes and never rate a rope without the standard, construction, and splice method documented.

How Do Environmental Factors Like UV, Saltwater, and Chemical Exposure Affect Nylon Rope Durability?

Nylon ropes are valued for their tensile strength, elasticity, and cost-effectiveness, making them a preferred choice in maritime transport, offshore drilling, construction hoisting, and rescue operations. However, prolonged exposure to ultraviolet (UV) radiation, saltwater immersion, and chemical pollutants can significantly alter their mechanical properties and service life. For industries where human safety and equipment reliability are non-negotiable, understanding these degradation mechanisms is essential for predictive maintenance and cost optimization. UV radiation leads to photo-oxidative chain scission, saltwater accelerates hydrolysis and internal fiber abrasion, and chemical solvents can trigger polymer softening and micro-cracking—causing up to 40% strength loss over two years without protective treatments.

Environmental Stress Factors and Their Measurable Impact

| Environmental Factor | Primary Degradation Mechanism | Typical Performance Loss (%) | Industry Standard Tests | Mitigation Strategies |

|---|---|---|---|---|

| UV Radiation (Sunlight) | Photo-oxidation, surface embrittlement | 20–30% tensile loss in 12 mo | ASTM G154, ISO 4892 UV Exposure | UV-absorbing coatings, dark pigments, stabilizers |

| Saltwater Immersion | Hydrolysis, chloride ion abrasion | 15–25% loss in 2 yrs | ASTM D1141 Salt Fog, DNV Offshore | Polyurethane coatings, freshwater rinse schedules |

| Chemical Exposure (Acids/Oil) | Polymer chain cleavage, swelling | 25–40% after prolonged contact | ISO 175 Chemical Immersion Tests | Fluoropolymer coatings, nylon 6/12 chemical blends |

| Extreme Temperatures | Low-temp brittleness, elasticity loss | 10–15% elongation drop < -20°C | ASTM D746 Brittleness Tests | Thermal-stabilized nylon copolymers |

Data compiled from DNV Offshore Standards, ASTM & ISO testing protocols

Real-World Case Study: Offshore Fishing Trawlers

In tropical fisheries, nylon ropes without UV treatment degraded up to 28% in tensile strength within the first year. A study by the Norwegian Marine Research Institute (2023) found that switching to UV-stabilized, double-braided nylon ropes with polyurethane coatings reduced annual rope replacement costs by 35–40% and extended service intervals from 18 to 36 months.

Perspectives from Different Stakeholders

- Maritime Engineers: Specify UV inhibitors and salt-resistant coatings as standard for mooring lines in offshore oil platforms.

- Construction Managers: In petrochemical zones, solvent- and acid-resistant nylon variants are mandatory per OSHA 1926.502 regulations to prevent sudden tensile failures.

- Safety Auditors: Implement ISO 2307 rope strength monitoring protocols, requiring quarterly inspections under high-UV or chemical-risk environments.

Smart Coatings & Self-Healing Polymers

With the rise of nanocoatings and self-healing polymers, researchers are developing nylon ropes capable of micro-crack repair when exposed to UV-induced oxidation or chemical erosion. Laboratory simulations by MIT Materials Science Department (2024) show prototype ropes maintaining >90% tensile strength after 10 years of accelerated aging, a potential game-changer for aerospace tethers and deep-sea exploration cables.

Are There International Certifications and Testing Methods for Industrial-Grade Nylon Ropes?

Yes. Industrial-grade nylon ropes must comply with ISO 2307 tensile testing, OCIMF Mooring Equipment Guidelines, and marine certifications like ABS and DNV-GL, alongside ASTM and Cordage Institute standards for abrasion, UV resistance, and environmental durability. These certifications ensure ropes meet breaking strength, elongation, and safety performance benchmarks for global construction, shipping, and offshore industries.

Rope Certification & Testing Standards

| Standard / Certification | Governing Body | Scope of Testing & Requirements | Key Application Sectors |

|---|---|---|---|

| ISO 2307:2019 | International Standards Org | Tensile strength, elongation, diameter, weight, shrinkage | Construction, Maritime, Industrial |

| OCIMF Mooring Equipment Guide (MEG4) | Oil Companies Intl. Marine Forum | Mooring line performance, safety factors, fatigue testing | Shipping, Offshore Tanker Mooring |

| ABS / DNV-GL Marine Approvals | American Bureau of Shipping, DNV | Rope design, load testing, environmental resistance | Commercial Shipping, Offshore Energy |

| Cordage Institute Standards | Cordage Institute, USA | Abrasion, UV, chemical exposure, cyclic loading tests | Industrial, Rescue, Military Applications |

| ASTM D4268, D885 | ASTM International | Fiber tensile, elongation, abrasion resistance | Construction Ropes, Safety Equipment |

| ISO 9554:2019 | International Standards Org | General specs for fiber ropes: labeling, diameter, construction | Cross-Industry Quality Compliance |

Real-World Example: Global Shipping Industry

- Singapore Port Authority enforces ISO 2307 + OCIMF MEG4 compliance for all tanker mooring ropes.

- Result: 22% reduction in mooring accidents over five years due to standardized rope strength ratings and fatigue testing protocols.

Industry Perspectives

- Shipowners & Operators: Rely on ABS/DNV-GL certifications to comply with marine insurance requirements and IMO safety codes.

- Construction Firms: Use ISO tensile and abrasion data to select ropes for tower cranes, elevators, and hoists.

- Military & Rescue Buyers: Specify Cordage Institute CI-1201 ropes for life-safety operations, ensuring documented UV and chemical resistance testing.

Testing Parameters Typically Required

| Test Parameter | Standard Reference | Performance Benchmarks |

|---|---|---|

| Minimum Breaking Strength | ISO 2307 / ASTM D885 | Varies by diameter & construction |

| Elongation at Break | ISO 2307 | 15–30% typical for nylon ropes |

| Abrasion Resistance | Cordage Institute CI-1503 | 10,000+ cycles no visible damage |

| UV Resistance | ASTM G154 / ISO 4892 | ≥80% strength retention after 500 hrs |

| Chemical Resistance | ASTM D543 | Pass/fail with acids, alkalis, oils |

| Cyclic Loading Fatigue | OCIMF MEG4 | 5000+ load cycles to 50% MBS |

Toward Digital Rope Traceability

Industry experts propose QR-code-enabled traceability tags embedded into rope terminations:

- Scan via smartphone → view certification history, test data, manufacture date, and next inspection due.

- Would streamline port safety inspections and construction site audits globally.

What Are the Key Differences Between Twisted, Braided, and Double-Braided Nylon Rope Structures?

Nylon ropes are engineered in different structural designs—from simple three-strand twisted ropes to advanced double-braided and parallel-core composites—each offering unique trade-offs in tensile strength, elongation properties, abrasion resistance, and handling characteristics. Selecting the right rope structure is critical for maritime, construction, rescue, and industrial applications where safety margins and operational efficiency are paramount. Twisted nylon ropes provide cost efficiency and splicing simplicity, braided ropes deliver superior flexibility and smooth handling, while double-braided and composite-core ropes offer maximum strength, durability, and shock absorption for high-demand marine and construction operations.

Rope Structure Performance Comparison

| Rope Structure | Design Characteristics | Tensile Strength (Typical Range) | Flexibility & Handling | Typical Applications | Standards & Testing Methods |

|---|---|---|---|---|---|

| 3-Strand Twisted | Helical fiber arrangement, open lay | 20–150 kN (ISO 2307) | Medium | Dock Lines, Utility Rigging, Temporary Construction | ASTM D4268, ISO 1141 |

| Single-Braided (Hollow) | Interwoven strands, no internal core | 50–250 kN | High | Sailing Sheets, Rescue Operations, Arborist Ropes | UIAA Safety Standards, NFPA 1983 |

| Double-Braided | Core rope enclosed in braided sheath | 150–500+ kN | Medium–High | Mooring Lines, Offshore Platforms, Crane Hoisting | DNV Offshore Standards, ABS Rules |

| Parallel-Core Composite | Multiple cores with load-sharing jacket | >500 kN | Moderate | Military Lifting, Industrial Hoists, Aerospace Systems | NATO AQAP, ISO 9554 |

Data based on ASTM, ISO, and DNV test protocols for rope tensile performance

Real-World Case Studies

- Offshore Oil Platforms: In North Sea drilling rigs, double-braided nylon ropes with polyurethane coatings replaced twisted ropes, increasing tensile strength reliability by 40% and reducing rope failures during winter storms by over 60% according to DNVGL-RP-E305 Offshore Mooring Reports (2023).

- Rescue Operations:Hollow-braided nylon ropes are preferred by mountain rescue teams for ease of splicing, low weight, and kink resistance, enabling rapid deployment in time-critical missions.

Stakeholder Perspectives

- Maritime Engineers: Require double-braided or composite-core ropes for mooring where shock absorption and strength retention under wet conditions are mandatory per OCIMF Mooring Equipment Guidelines.

- Construction Site Managers: Choose cost-effective twisted ropes for temporary scaffolding where reusability and low upfront cost outweigh long-term durability.

- Rescue & Safety Agencies: Favor hollow-braided structures for fast rigging, low weight, and high knot-holding capability, as per NFPA 1983 Life Safety Rope Standards.

Hybrid Rope Designs

With advances in robotic braiding technologies and AI-driven fiber placement, researchers are exploring zonal-strength ropes where the core handles tensile load while the sheath resists abrasion and UV degradation. This hybrid design could achieve up to 30% weight savings without sacrificing breaking strength or fatigue resistance, potentially transforming aerospace tethering and deep-sea lifting systems.

How do cost, maintenance, and lifespan considerations influence the choice of nylon ropes for heavy-duty applications?

For heavy-duty work (ports, towing, construction), buying on lifecycle beats buying on sticker price. Double-braided nylon costs more upfront than 3-strand, but its lower inspection frequency, better abrasion resistance, and longer service life (≈2–3×) usually deliver a lower total cost of ownership (TCO) and fewer operational disruptions.

Cost vs. Performance—what really moves TCO

A. Construction choices and what you pay for

| Rope Type | Typical Uses | Upfront Cost (USD/100 m) | Service Life* | Inspection Cadence | Operational Notes |

|---|---|---|---|---|---|

| 3-strand twisted nylon | General rigging, light mooring | 100–150 | 2–3 yrs | High (every 3–6 mo) | Cheapest; highest creep & chafe; knots reduce strength most |

| Single-braid (8/12-strand) nylon | Utility mooring, tug assist | 150–220 | 3–4 yrs | Medium (6–9 mo) | Good handling; easier splice/repair than DB |

| Double-braid nylon (DBN) | Terminal mooring, towing, heavy hoist | 250–400 | 5–7 yrs | Low (12–18 mo) | Best abrasion & fatigue life; stable elongation under load |

| Parallel-core / composite | Critical lifts, offshore spreads | 400–600+ | 7–10 yrs | Low (annual) | Highest stability & cut/heat resistance; premium price |

*Under comparable duty cycles and good maintenance; environment and handling can shorten or extend life significantly.

B. A simple lifecycle model you can reuse

Annualized TCO ≈ (Purchase ÷ Service Life) + Annual Maintenance + (Replacement/Downtime ÷ Service Life)

Illustration (one berth set, 8 lines × 110 m each):

- 3-strand nylon:

- Purchase: 1.1 × $150 × 8 = $1,320 → $528/yr (2.5-yr life)

- Maintenance: $600/yr (frequent inspections/repairs)

- Replacement events (labor, delay): $800 every 2.5 yrs → $320/yr

- Total ≈ $1,448/yr

- Double-braid nylon:

- Purchase: 1.1 × $320 × 8 = $2,816 → $469/yr (6-yr life)

- Maintenance: $320/yr

- Replacement events: $800 every 6 yrs → $133/yr

- Total ≈ $922/yr

Result: DBN saves ~$526/yr; payback ≈ 2.8 years despite higher capex. (Numbers are illustrative to show the math; plug in your own prices and duty cycles.)

C. Maintenance levers that extend life (and cut TCO)

- Chafe management: stitched/Velcro chafe guards, smooth bitts & fairleads; reduces external wear → +20–40% life.

- Right bend radius: keep D/d ≥ 8–12 (sheave/bit diameter to rope diameter) to limit heat/glazing.

- Splice > knots: eye-splices preserve ~85–95% MBS; knots can cut strength 30–50%.

- End-for-end & rotation: relocate wear zones quarterly in high-duty berths.

- Clean & dry: freshwater rinse after salt/silt exposure; dry, UV-shielded storage; avoid chemicals (acids/bleach).

- Golden-sample, then batch QC: verify diameter, MBS, elongation and splice efficiency before committing to bulk.

D. Environment & duty-cycle multipliers (adjust your expectations)

| Stressor | Effect on Nylon | What to Specify/Do |

|---|---|---|

| Wet service | −10–15% strength; higher elongation | Ask for wet MBS rating if critical; apply higher design factor |

| High UV / heat | Gradual embrittlement; glazing at tight bends | Prefer double-braid or jacketed lines; use UV covers; control D/d |

| Sand/silt abrasion | Accelerated sheath wear | Rinse after use; chafe sleeves where lines cross hardware |

| Dynamic shock loads | Peak-load spikes drive early retirement | Nylon is good here; ensure correct size and energy absorption margin |

E. Quick selector by economics

- Lowest capex, light duty, short cycles: 3-strand (plan for frequent swaps).

- Balanced cost & robustness: single-braid (8/12-strand).

- Heavy-duty, long life, fewer shutdowns: double-braid.

- Critical ops (offshore, engineered lifts): parallel-core/composite with validated splice terminations.

F. KPIs to track (and put in contracts)

- Annualized TCO/line (target down YoY).

- Average time-to-retirement (months) by position.

- Incident rate (snap-back, glazing events per 10,000 hours).

- MBS retention at inspection (proof-load/elongation profile vs. baseline).

- Out-of-service days due to rope work.

Add carbon per service year to your scorecard. Longer-life ropes (e.g., double-braid) often cut both costs and embodied carbon per year by reducing replacements, freight, and disposal—aligning procurement with financial and ESG targets in one move.

If you want, I can drop your current specs into a one-page TCO calculator (with sliders for price, service life, inspections, and downtime) so you can compare constructions on your real numbers.

Partner with Szoneier for Custom Nylon Rope Solutions

From tensile strength and abrasion resistance to UV protection and double-braided engineering, nylon ropes remain the gold standard for maritime and construction-grade applications worldwide. But choosing the right rope involves balancing technical specs, environmental durability, and cost efficiency for your project’s unique needs.

At Szoneier, we leverage 18+ years of manufacturing expertise to deliver:

- Custom nylon ropes engineered for specific load, environmental, and safety requirements

- Marine-grade & construction-grade specifications meeting ISO, ASTM, and OCIMF standards

- Low-MOQ production, rapid sampling, and global delivery for projects of all sizes

- Advanced coatings & hybrid rope structures for maximum lifespan and safety

Contact Szoneier today to explore custom nylon rope solutions designed for your toughest maritime or construction challenges.