Polyester fabric is no longer just a cheap alternative—it’s a powerhouse of performance, versatility, and durability. Whether you’re sourcing for fashion, upholstery, or outdoor gear, understanding polyester is essential for today’s textile buyers. As sustainability demands and performance requirements continue to rise, polyester has evolved with technical innovations such as recycled PET and blended yarns.

Polyester fabric is a synthetic textile made from petrochemical-derived polymers and is known for its strength, wrinkle resistance, and moisture-wicking properties.

But what makes it so dominant in the textile market? Why do global manufacturers from Vietnam to Turkey rely on polyester as a key staple? In this guide, we’ll take a deep dive into the essential characteristics of polyester, its real-world applications, and how you can make smarter buying decisions—especially when dealing with MOQs, blends, and sustainability criteria.

Let’s begin with how this fiber is made and what differentiates it from its natural cousins.

What Is Polyester Fabric Made Of and How Is It Manufactured?

Polyester fabric is made from petroleum-based polymers through a chemical reaction involving ethylene glycol and dimethyl terephthalate (DMT), which are polymerized into polyethylene terephthalate (PET).

This polymer is then extruded, cooled, and spun into filaments that are either woven or knitted into fabrics. Depending on the end-use, these filaments can be textured, dyed, or blended with other fibers like cotton or spandex.

- Raw Materials Sourcing:

- Ethylene glycol: Derived from crude oil or natural gas.

- DMT or PTA (purified terephthalic acid): A primary acid component in the polymerization process.

- Production Stages: Stage Description Polymerization Chemical reaction of DMT and ethylene glycol Spinning Melt spinning into continuous filaments Drawing Aligning molecules for strength Texturing Crimping for elasticity or loft, depending on use Finishing Includes dyeing, brushing, or coating for water resistance

- Case Study: A Bangladeshi mill reduced water usage by 35% by switching to dry-dyeing polyester yarns.

- Tech Insight: Recycled polyester (rPET) is gaining traction. Brands like Patagonia and Adidas use bottles as feedstock.

How Does Polyester Compare to Natural Fabrics Like Cotton or Silk?

Polyester offers superior durability, wrinkle resistance, and moisture-wicking compared to cotton and silk, but lacks natural breathability and softness unless blended.

When compared head-to-head, polyester outperforms in specific technical aspects, especially in applications demanding high performance (like sportswear or technical uniforms). However, it doesn’t match the comfort or biodegradability of natural fibers.

- Performance Comparison Table: Property Polyester Cotton Silk Strength High Medium Low Breathability Low High Medium Moisture Wicking High Low Medium Wrinkle Resistance Excellent Poor Moderate Sustainability Low (PET) Medium Medium

- Use Case Example: A sportswear brand blended 85% polyester with 15% cotton to combine quick-drying function with comfort for marathon runners in Southeast Asia.

- Critical Viewpoint: Polyester’s dependence on fossil fuels raises environmental concerns, but modern recycling and circular economy initiatives are mitigating these issues.

- Consumer Trends: Younger buyers increasingly demand recycled polyester in apparel, especially in eco-labeled collections.

What Are the Technical Properties of Polyester Fabric?

Polyester fabric is defined by properties such as high tensile strength, low moisture absorption, wrinkle resistance, dimensional stability, and resistance to UV and abrasion. These qualities make it ideal for both apparel and industrial use.

For textile engineers and sourcing professionals, understanding the technical specs of polyester is key to choosing the right variant for each application—whether you’re designing swimwear, uniforms, or tents.

- Key Technical Specifications: Property Standard Value Range Tensile Strength 2.6 to 7.0 g/denier Elongation at Break 15% to 25% Moisture Regain 0.4% (very low, helps wick moisture) Melting Point 255–265°C Specific Gravity 1.38 g/cm³ UV Resistance High (especially for outdoor applications)

- Thermal Behavior:

- Softening at \~230°C, melting at \~255°C.

- Maintains dimensional stability even after repeated washing and drying.

- Strength & Durability:

- Outlasts natural fibers under stress.

- Common in workwear, outdoor jackets, and high-tension webbing.

- Case Insight: A UAE-based military textile supplier chose 1000D polyester with a PU backing for tactical gear due to its tear resistance and colorfastness.

- Tip for Buyers: Always request data sheets from suppliers before confirming large-scale orders, especially if your product involves safety, outdoor, or performance standards.

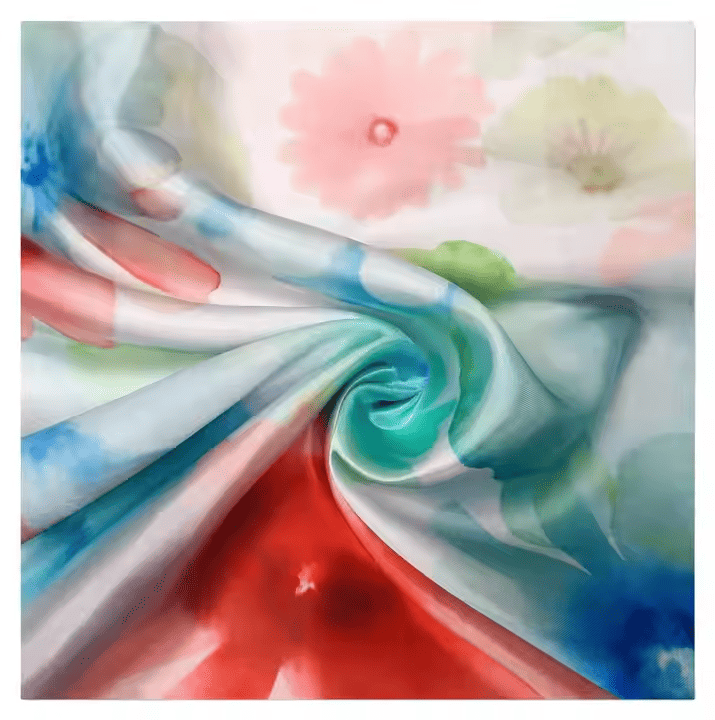

How Does Polyester React to Dyeing and Printing Techniques?

Polyester fabric responds best to disperse dyes through high-temperature dyeing processes such as HT dyeing or sublimation printing. The fiber’s low moisture content and crystalline structure require special treatment for effective color uptake.

Getting vivid, long-lasting colors on polyester isn’t as straightforward as dyeing cotton or rayon. However, when done correctly, polyester fabrics can exhibit excellent wash fastness, light fastness, and durability even in harsh environments.

- Common Dyeing Techniques: Method Suitable For Temperature Color Depth Disperse Dyeing Woven/knitted polyester \~130°C High Sublimation Printing Polyester blends (min 60%) 180–200°C (heat) Very High Dope Dyeing (solution) Technical fabrics During extrusion Permanent

- Use Case: A U.S. outdoor apparel brand used sublimation printing on recycled polyester to reduce water usage by 80% per production run.

- Challenges in Dyeing Polyester:

- Requires precise heat and pressure control.

- May exhibit dye migration if improperly cured.

- Tips for Buyers:

- Always confirm if suppliers can handle high-temp dyeing.

- For eco-conscious projects, ask about dope-dyed or cationic polyester.

- Tech Insight: Newer polyester fibers with modified cross-sections (e.g., trilobal, hollow) offer better dye affinity and softer hand-feel.

What Are the Common Applications of Polyester Fabric in 2024?

In 2024, polyester fabric is used extensively across fashion, home textiles, automotive, industrial, and medical sectors due to its versatility, cost-effectiveness, and performance characteristics.

From high-end sportswear to seatbelts, polyester plays a critical role in modern product development. Its durability and customization options make it indispensable in both fast fashion and technical textile segments.

- Apparel & Fashion:

- Sportswear: moisture-wicking polyester mesh and interlock knits.

- Fast fashion: cost-effective polyester/cotton blends with wrinkle resistance.

- Recycled polyester (rPET) increasingly replacing virgin fiber in global brands.

- Home & Hospitality Textiles:

- Polyester microfiber used for bed linens and sofa covers.

- Blackout curtains and upholstery fabric with flame-retardant coatings.

- Automotive & Transportation:

- Seat covers, headliners, and door trim often made from textured polyester fabrics.

- Webbing and strapping for safety harnesses and cargo control systems.

- Medical Textiles:

- Used in PPE gowns, wound care fabrics, and antimicrobial bedding solutions.

- Industrial Uses:

- Tarpaulins, tents, conveyor belts, and geotextiles made with woven polyester.

- Coated polyester for banners and advertising signage due to UV resistance.

| Application Sector | Polyester Variant Used | Performance Requirement |

|---|---|---|

| Sportswear | Polyester Spandex Blends | Stretch, breathability |

| Furniture Textiles | Textured Polyester Yarn | Stain-resistance, durability |

| Safety Equipment | High-Tenacity Polyester Webbing | Tear strength, UV resistance |

| Packaging & Branding | Coated Polyester Fabric | Weatherproof, print-friendly |

How Does Polyester Compare to Natural Fibers Like Cotton or Wool?

Compared to natural fibers, polyester is more durable, less absorbent, and more wrinkle-resistant, but less breathable and biodegradable. The choice depends on the application and desired performance.

This comparison is critical for brands deciding between natural sustainability and synthetic performance. While cotton may feel softer and be more breathable, polyester wins in longevity, water resistance, and care convenience.

- Head-to-Head Comparison Table:

| Property | Polyester | Cotton | Wool |

|---|---|---|---|

| Moisture Absorption | Very Low (0.4%) | High (\~8%) | Very High (\~30%) |

| Wrinkle Resistance | Excellent | Poor | Moderate |

| Biodegradability | Low (synthetic) | High | High |

| Strength (Wet/Dry) | Stable | Weaker when wet | Sensitive to abrasion |

| Wash Durability | High | Moderate | Requires care |

| Cost Efficiency | High | Moderate | Low |

- Comfort vs Performance:

- Cotton is preferred for direct skin contact due to breathability.

- Polyester excels in performance gear, uniforms, and products requiring longevity.

- Sustainability Outlook:

- Polyester’s sustainability is improving with the rise of recycled polyester (rPET).

- Circular design and end-of-life recyclability are becoming more viable.

- Case Study: A European hotel chain switched from 100% cotton to a 60/40 polyester-cotton blend for bed linens, cutting replacement costs by 30% and improving laundry efficiency.

Are There Sustainable or Recycled Polyester Fabric Options?

Yes, recycled polyester (rPET) made from post-consumer PET bottles and industrial waste is a sustainable alternative that maintains the performance of virgin polyester while reducing environmental impact.

With the global push toward sustainability, recycled polyester is now a standard offering among certified suppliers. OEKO-TEX, GRS (Global Recycled Standard), and Bluesign certifications have become essential indicators of environmentally responsible production.

- What is rPET (Recycled Polyester)?

- Produced from used plastic bottles (PET) or pre-consumer polyester waste.

- Lower carbon footprint: rPET production emits 45–55% less CO₂ than virgin polyester.

- Comparable tensile strength and dyeability to virgin polyester.

- Certifications to Look For: Certification Purpose What It Ensures GRS Recycled content and traceability Verified recycled content, responsible processing OEKO-TEX Chemical safety No harmful substances Bluesign Resource efficiency and safety Controlled inputs, cleaner outputs

- Brand Commitments to Recycled Polyester:

- Adidas uses over 90% recycled polyester in its sportswear collections.

- H\&M and Zara plan to fully switch to recycled synthetics by 2030.

- Challenges and Limitations:

- rPET still relies on plastic waste, which itself is tied to fossil fuel use.

- Fiber degradation after multiple recycling loops.

- Dyeing of recycled polyester sometimes requires additional treatment steps.

How Can Buyers Choose the Right Polyester Fabric for Their Application?

Buyers should consider application-specific factors such as fabric weave, denier, GSM (grams per square meter), finish type, and certifications when selecting polyester fabrics.

Selecting the right polyester fabric is not just about price—it’s about functionality, performance, and long-term ROI. Whether it’s apparel, upholstery, or industrial webbing, understanding technical specs is key.

- Key Parameters to Consider:

| Factor | Typical Range | Impact on Performance |

|---|---|---|

| Denier (D) | 75D–1200D | Higher D = thicker and more durable |

| GSM (g/m²) | 90–400 | Heavier fabric = more opaque and strong |

| Weave Type | Plain, Twill, Satin, Ripstop | Affects stretch, strength, breathability |

| Finish Type | Water-repellent, Fire-retardant | Adds specific functionality |

| Stretch Composition | With spandex or 100% polyester | Stretch needed for leggings, activewear |

| Certifications | OEKO-TEX, GRS, REACH | Compliance and buyer confidence |

- Use-Based Recommendations:

- T-Shirts: 160–180 GSM interlock knit with OEKO-TEX certification.

- Activewear: 200–250 GSM polyester-spandex with 4-way stretch.

- Curtains: 300+ GSM heavy twill weave with flame-retardant coating.

- Webbing: 1000D+ polyester with high UV resistance and tensile strength.

- Tip for Buyers: Ask for lab test results (such as colorfastness, abrasion resistance, shrinkage rates) along with swatches before finalizing bulk orders. A sample MOQ batch test is often the best investment before scaling.

Ready to Source Custom Polyester Fabric?

SzoneierFabrics has been trusted by international buyers and premium brands for over a decade. Whether you’re sourcing moisture-wicking polyester for activewear, UV-resistant coated polyester for bags, or custom-printed polyester for interior décor, we’ve got you covered.

We offer:

- ✅ Free samples & fast prototyping

- ✅ Low MOQ & private label support

- ✅ 100% quality guarantee with global certifications

Contact SzoneierFabrics today to discuss your custom polyester fabric needs. Our textile experts are ready to support your development from design to delivery—seamlessly.