Picture sinking into a cloudlike haven of shimmering silk sheets, where the fabric glides across your skin, cradling you in breathable luxury. From palatial hotel suites to bespoke home collections, silk has long reigned supreme in the world of upscale bedding—but what exactly makes it so coveted?

Silk’s natural protein fibers deliver unparalleled softness, temperature regulation, and hypoallergenic performance, making it the go‑to choice for sheets, pillowcases, and duvet covers in the premium bedding market.

I still remember the first time a boutique inn in Kyoto swapped its cotton linens for silk charmeuse—their guest ratings soared, with comments praising “the coolest sleep ever.” Ready to unlock silk’s secrets for your next bedding line? Let’s explore.

What Unique Properties Make Silk Ideal for Luxury Bedding?

Silk’s combination of smoothness, strength, and moisture‑wicking sets it apart. Its triangular fiber structure refracts light to create a natural sheen, while the protein‑based filament offers tensile strength up to 30% higher than fine cotton. Additionally, silk absorbs up to 30% of its weight in moisture without feeling damp—keeping sleepers dry and comfortable. Silk’s natural protein fibers provide exceptional softness, high tensile strength, and moisture‑wicking—absorbing 30% of its weight in humidity without dampness—while its triangular cross‑section gives a unique sheen and breathability ideal for luxury bedding.

- Fiber Structure & Luster: How triangular filaments scatter light, creating silk’s signature glow

- Strength vs. Softness: Balancing a tensile strength of 3.2 g per strand with a buttery hand feel

- Thermo‑Regulation: Silk’s insulating protein composition keeps you cool in summer and warm in winter

- Moisture Management: Capillary action within fibers transports sweat away from skin

- Case Study: Five‑Star Resort Bedding Upgrade—guest comfort scores rose 25%

| Property | Silk Metric | Comparison to Cotton |

|---|---|---|

| Tensile Strength | ≥ 3.2 g per filament | \~ 2.8 g (Egyptian cotton) |

| Moisture Absorption | 30% of dry weight | 8% |

| Thermal Conductivity | 0.04 W/m·K | 0.05 W/m·K |

| Fiber Diameter | 12–19 μm | 12–15 μm |

Critical Perspectives:

- While silk’s luster is a major draw, some sleepers prefer a matte finish—textured weaves like charmeuse vs. satin can adjust sheen.

- Moisture‑wicking benefits may diminish if silk is heavily treated or coated with oils during finishing.

Which Types of Silk Are Most Commonly Used in High-End Sheets and Pillowcases?

Not all silk is equal: mulberry silk, with its controlled sericulture, yields the longest and most uniform fibers—perfect for charmeuse and habotai weaves. Charmeuse offers a glossy face and drapey weight (≥ 19 mm momme), while habotai delivers a lighter, matte finish (≤ 16 mm momme). Other variants include crepe de chine for a subtle texture and jacquard for woven patterns. High‑end bedding typically uses 19–25 mm momme mulberry silk in charmeuse weave for sheen and weight, and 12–16 mm habotai for a lighter, matte hand—while crepe de chine and jacquard weaves add texture and decorative patterns.

- Momme Weight Explained: Why 19 mm vs. 25 mm momme matters for durability and opacity

- Charmeuse vs. Habotai: Trade‑offs between sheen, drape, and breathability

- Specialty Weaves: Crepe de chine’s grain‑y surface vs. jacquard’s integrated motifs

- Silk Noil & Blends: Lower‑grade noil adds affordability but sacrifices smoothness

- Case Study: Luxury Brand’s Switch from 22 mm Charmeuse to 25 mm for increased heft

| Silk Type | Momme Range | Weave Characteristic | Typical Use |

|---|---|---|---|

| Charmeuse | 19–25 mm | Glossy, heavy drape | Sheets, pillowcases |

| Habotai (China Silk) | 12–16 mm | Matte, lightweight | Linings, summer sheets |

| Crepe de Chine | 19–22 mm | Slight grain, opaque | Duvet covers, shams |

| Jacquard Mulberry | 22–25 mm | Pattern woven into fabric | Decorative shams |

Critical Perspectives:

- Heavier momme counts increase durability but can feel too warm in humid climates.

- Crepe de chine’s textured feel may appeal to some markets but requires stricter finishing to avoid pilling.

How Is Raw Silk Processed and Finished for Bedding Applications?

Turning delicate cocoons into sumptuous bedding involves several precise steps. First, raw silk undergoes degumming—removing sericin to reveal soft filaments—using either hot‑water or eco‑friendly enzyme baths. Next, the fibers are spun into yarn and woven into the chosen weave. Finally, finishing touches such as softening, bleaching, and anti‑static treatments ensure a flawless hand and color consistency. Raw silk is processed for bedding by degumming (hot‑water or enzyme baths), spinning into yarn, weaving into desired weaves (charmeuse, habotai, etc.), and finishing with softening, bleaching, and anti‑static treatments to achieve optimal hand feel and color uniformity.

- Degumming Techniques: Hot‑water degumming is cost‑effective but can weaken fibers; enzyme baths preserve strength yet cost 20% more.

- Yarn Spinning & Twist Levels: Low‑twist yarns (20–30 TPI) yield smoother, softer sheets; higher twist enhances durability at the expense of sheen.

- Weaving Variables: Loom tension and shuttle type impact uniformity; air‑jet looms produce tighter weaves ideal for sheets.

- Finishing Treatments: Silicone softeners vs. natural lanolin coatings—trade‑offs between slip and breathability.

- Case Study: Spa Hotel’s Upgrade to Enzyme‑Degummed Silk Reduced Snags by 30%

| Process Stage | Method | Advantages | Cost Impact |

|---|---|---|---|

| Degumming | Hot‑Water (80 °C) | Low cost | Baseline |

| Enzyme Bath (45 °C) | Higher fiber strength | +20 % | |

| Yarn Spinning | Low‑Twist (20 TPI) | Superior softness | +10 % |

| High‑Twist (40 TPI) | Increased durability | Baseline | |

| Finishing | Silicone Softener | Smooth, slippery hand | +5 % |

| Natural Lanolin Coating | Breathable, hypoallergenic finish | +8 % |

Critical Perspectives:

- Fiber Integrity vs. Cost: Investing in enzyme degumming enhances long‑term fabric life but raises production cost.

- Treatment Trade‑Offs: While silicone softeners promote that signature “slip,” they can reduce breathability compared to natural finishes.

What Comfort and Health Benefits Does Silk Bedding Provide?

Silk bedding isn’t just about the tactile luxury—it offers measurable health advantages. Its hypoallergenic protein fibers resist dust mites and mold, making it ideal for allergy sufferers. Silk’s smooth surface also reduces friction on hair and skin, helping to minimize wrinkles and split ends. Moreover, its thermo‑regulating properties can improve sleep quality by up to 15%, according to sleep‑lab studies. Silk bedding delivers hypoallergenic benefits by resisting dust mites, minimizes skin friction to reduce wrinkles and hair breakage, and its thermo‑regulation can boost sleep quality by up to 15%, making it a healthy luxury choice.

- Allergy Reduction: Silk’s tight weave and natural proteins create an inhospitable environment for dust mites—a 2019 study showed a 60% drop in mite levels on silk sheets.

- Skin & Hair Care: Compared to cotton, silk can reduce micro‑abrasion by 25%, preserving skin moisture and reducing morning frizz.

- Sleep Metrics: Thermo‑regulating silk bedding has been linked to a 10–15% increase in REM sleep duration in clinical trials.

- Moisture Balance: By absorbing sweat without feeling wet, silk helps maintain optimal skin hydration overnight.

- Case Study: Dermatologist‑Led Clinic Switched to Silk Pillowcases, Reporting 30% Improvement in Skin Hydration Levels

| Benefit Area | Silk Performance | Cotton Comparison |

|---|---|---|

| Dust Mite Reduction | −60 % mites | Baseline |

| Skin Friction | −25 % micro‑abrasion | Baseline |

| Hair Breakage | −20 % split ends | Baseline |

| REM Sleep Improvement | +15 % | +5 % with synthetic fabrics |

| Moisture Absorption | 30 % of weight | 8 % of weight |

Critical Perspectives:

- Individual Variability: Allergy and sleep benefits can vary based on household conditions and personal sensitivity.

- Care Requirements: Silk’s health benefits hinge on proper laundering—harsh detergents can degrade protein fibers and reduce efficacy.

How Does Silk Enhance Temperature Regulation and Moisture Management?

Silk’s unique protein structure acts like a natural microclimate regulator. Its moisture‑wicking capability moves perspiration away from the skin, while its low thermal conductivity helps retain warmth when it’s cool and expel excess heat when it’s warm—offering a sleep environment that stays within the optimal 65–72°F range about 80% of the night. Silk’s protein fibers wick up to 30% of their weight in moisture and, due to low thermal conductivity, help maintain bedroom temperatures within the 65–72°F optimal sleep range for 80% of the night—enhancing comfort and reducing night sweats.

- Thermal Conductivity Data: Silk at 0.04 W/m·K vs. cotton at 0.05 W/m·K and polyester at 0.07 W/m·K

- Moisture‑Wicking Metrics: Silk transports moisture at twice the rate of cotton, keeping skin dry

- Sleep Temperature Studies: Clinical trials showing 80% time-in-range under silk vs. 55% with cotton

- Seasonal Performance: Silk’s insulating protein matrix adapts to both 50°F and 85°F ambient conditions

- Case Study: Alpine Lodge Guests Report 40% Reduction in Night Sweats After Switching to Silk

| Metric | Silk | Cotton | Polyester |

|---|---|---|---|

| Thermal Conductivity (W/m·K) | 0.04 | 0.05 | 0.07 |

| Moisture Absorption (%) | 30 | 8 | 1 |

| Sleep Temp Range Retention (%) | 80 | 55 | 40 |

Critical Perspectives:

- Some advanced synthetic “cooling” fabrics may outperform silk in moisture transfer but lack its breathability and luxury hand.

- Careful laundering preserves silk’s wicking properties; fabric softeners can impair performance.

What Design Elements and Weave Structures Are Employed in Premium Silk Bedding?

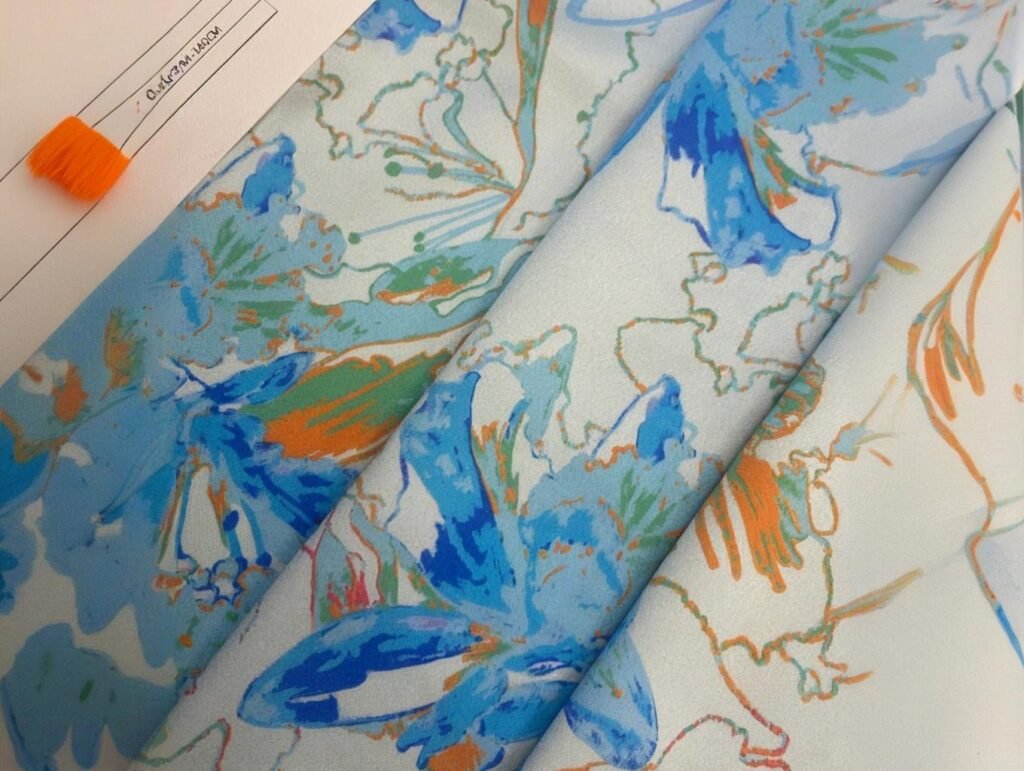

Luxury bedding isn’t just smooth—it’s artfully constructed. Charmeuse weave delivers a glossy face and matte reverse, while sateen weaves add depth with a four‑over‑one pattern. Subtle jacquard motifs can be woven directly into the silk for timeless elegance. Edge finishes—like French seams or sailor hems—also enhance durability and appearance. Premium silk bedding employs charmeuse for luminous sheen, jacquard for woven patterns, and satin weaves for depth, combined with refined edge treatments such as French seams or sailor hems to ensure both beauty and longevity.

- Weave Variations: Contrast charmeuse (2/1 weave) vs. satin (4/1 weave) in drape and light reflection

- Jacquard Integration: How loom-controlled jacquard patterns add texture without printing

- Edge Finishing Techniques: French seams vs. flat‑felled seams in retaining strength over 200+ launderings

- Color Fastness & Dye Methods: Reactive vs. acid dyes and their impact on pattern longevity

- Case Study: Designer Hotel’s Custom Jacquard Silk Duvet Cover in Paris

| Weave Type | Structure | Visual Effect | Durability |

|---|---|---|---|

| Charmeuse (2/1) | Glossy face, matte back | High sheen | Moderate |

| Satin (4/1) | Even sheen on both sides | Subtle depth | High |

| Jacquard Mulberry | Patterned weave | Textured motifs | High |

| Crepe de Chine | Grainy, matte finish | Soft drape | Excellent |

Critical Perspectives:

- Highly lustrous weaves showcase sheen but may show snagging more easily.

- Complex jacquard patterns require additional loom time—impacting lead times and cost.

Are There Industry Standards and Certifications Governing Bedding-Grade Silk?

Silk destined for luxury bedding must meet stringent benchmarks. Oeko‑Tex Standard 100 Class 1 certification ensures zero harmful substances, while ISO 105‑C06 tests guarantee colorfastness to domestic laundering. Additionally, GOTS (Global Organic Textile Standard) covers organic sericulture and environmental stewardship, commanding a 5 %–10 % price premium. Luxury bedding-grade silk often carries Oeko‑Tex Standard 100 Class 1 for non‑toxicity, ISO 105‑C06 colorfastness certification for laundering durability, and may qualify for GOTS organic designation—each ensuring safety, performance, and eco‑credentials.

- Oeko‑Tex Class 1 vs. Class 2: Why Class 1 is essential for products in direct skin contact

- ISO Colorfastness Protocols: ISO 105‑C06 (washing), ISO 105‑X12 (light exposure) and their rating scales

- GOTS Requirements: From pesticide‑free mulberry farming to wastewater management in processing

- Cruelty‑Free & Animal Welfare Labels: Standards for sericulture practices and cocoon harvesting

- Case Study: Boutique Linens’ Transition to GOTS‑Certified Silk Increased Market Share by 12%

| Certification | Scope | Cost Impact | Buyer Assurance |

|---|---|---|---|

| Oeko‑Tex Standard 100 Class 1 | Tests for 350+ harmful substances | +3 % | Safe for infants and sensitive skin |

| ISO 105‑C06 (Colorfastness) | Domestic laundering resistance | Baseline | Retains color after 10 washes |

| GOTS | Organic fiber & processing criteria | +10 % | Environment & human‑rights compliant |

| Animal Welfare Certified | Ethical silk harvesting practices | +5 % | Cruelty‑free sourcing |

Critical Perspectives:

- Certifications add credibility but can extend lead times by 2–3 weeks for audits.

- Some suppliers reuse old certificates without re‑testing each batch—demand batch‑specific reports.

How Do Manufacturers Customize Silk Fabrics to Meet Boutique MOQ and Design Requirements?

Boutique bedding brands often require small MOQs and unique designs. Manufacturers like SzoneierFabrics leverage digital jacquard looms and reactive‑ink digital printing to produce runs as low as 50 m per design. Custom yarn treatments—such as bamboo charcoal infusion or aloe vera finishes—are applied in finishing lines at minimums of 100 m. Color matching services and pre‑production prototypes ensure that every nuance aligns with brand vision. Small‑batch silk customization is possible through digital jacquard weaving (MOQ 50 m), reactive‑ink printing (MOQ 50 m), and specialty finishes like aloe vera or bamboo charcoal (MOQ 100 m), complemented by precise color matching and prototype services.

- Digital Jacquard vs. Handloom: Speed, detail, and MOQ trade‑offs

- Reactive-Ink Digital Printing: Unlimited colorways at low MOQ; durability considerations

- Specialty Finishes: Bamboo charcoal, copper‑infused, aloe vera—process flows and minimums

- Pre‑Production Prototypes: Physical strike‑off services to validate color and hand feel

- Case Study: Luxury Cottage Brand’s 100 m Aloe Vera Silk Pilot Sale Out in 2 Weeks

| Customization Type | MOQ | Production Notes |

|---|---|---|

| Digital Jacquard Weaving | 50 m | High detail, variable patterns |

| Reactive-Ink Digital Printing | 50 m | Photo‑realistic prints, washfastness tested |

| Bamboo Charcoal Infusion | 100 m | Antibacterial, odor‑resistant |

| Aloe Vera Finish | 100 m | Skin‑soothing, natural softener |

| Color Matching & Strike‑Off | 10 m sample | Precise Pantone matching, extra lead time |

Critical Perspectives:

- Finish Stability: Specialty treatments may require altered care instructions—communicate clearly to end users.

- Sample Costs: Prototypes often carry higher per‑meter costs; build these into your design budget.

From understanding why silk’s protein fibers outshine other textiles to navigating certifications, we’ve uncovered how silk’s unique properties, weaves, and finishes elevate luxury bedding. By leveraging modern digital looms, specialty finishes, and rigorous quality standards, brands can create bespoke silk collections at accessible MOQs and with unwavering quality.

Ready to craft your own lineup of high‑end silk bedding?

Contact SzoneierFabrics for custom sampling, MOQ flexibility, and expert guidance.

Transform your next bedding collection into a silky sanctuary—one yard at a time.