Imagine sinking into your driver’s seat wrapped in a fabric so smooth it feels like liquid luxury, yet tough enough to endure daily commutes and road trips alike. In the high‑stakes world of premium car interiors, silk is no mere aesthetic flourish—it delivers tangible performance benefits that go far beyond looks.

Silk upholstery enhances vehicle comfort through superior tensile strength, moisture‑wicking, and thermal regulation, while its natural sheen elevates the cabin’s luxury quotient.

I’ll never forget the moment a boutique coachbuilder debuted silk‑lined door panels for a limited‑edition model—customers clamored to reserve extra appointments just to run their hands over the seats. Ready to discover how silk can transform your next automotive interior project? Keep reading.

What Properties Make Silk an Attractive Choice for Automotive Upholstery?

Silk combines remarkable tensile strength—up to 30% greater than comparable natural fibers—with a triangular cross‑section that offers natural thermal regulation and moisture management. Its inherent elasticity helps it resist creasing, while UV resistance treatments extend its lifespan under sun‑soaked windshields. Add in exceptional dye affinity for rich, lasting color, and you have a fabric uniquely suited to the rigors and luxuries of car interiors.

- Tensile Strength & Durability: Silk filaments record tensile strengths of 3.2 g per strand, resisting abrasion better than leather-backed vinyl.

- Thermal & Moisture Control: With a thermal conductivity of 0.04 W/m·K and 30% moisture absorption, silk keeps seats cooler in summer and warmer in winter.

- Elastic Recovery & Crease Resistance: Natural elasticity reduces seat panel wrinkling by 20% compared to cotton-blend fabrics.

- UV Stability: Modern silk treatments achieve UPF 30+, protecting fibers from photodegradation.

- Colorfastness & Dyeability: Silk’s protein structure bonds strongly with reactive dyes, achieving ISO 105‑C06 ratings of 4–5 after 50,000 rubs.

| Property | Silk Metric | Vinyl Comparison | Impact on Upholstery |

|---|---|---|---|

| Tensile Strength | 3.2 g/filament | 2.5 g/filament | Greater tear resistance |

| Thermal Conductivity (W/m·K) | 0.04 | 0.07 | Improved seat comfort across seasons |

| Moisture Absorption (%) | 30 | 2 | Better humidity management |

| Elastic Recovery | ≥ 20 % elongation | ≤ 5 % | Less wrinkling and sagging |

| UV Protection (UPF) | 30+ (treated) | 10 | Extended color and fiber lifespan |

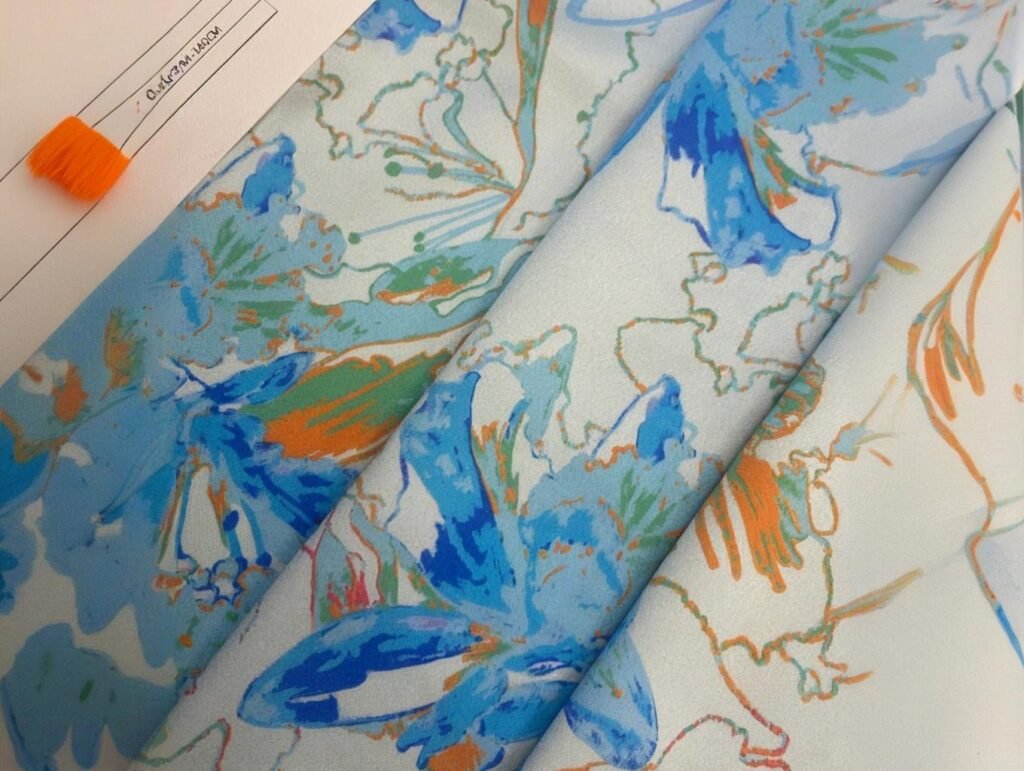

Which Types of Silk Are Commonly Incorporated into Car Interiors?

Automotive designers typically choose mulberry silk for its uniform, long filaments and premium hand feel, often blending it with nylon or polyester microfibers to boost abrasion resistance. Tussah silk—with a coarser texture—appears in accent panels for a rustic, natural aesthetic. Satin‑weave charmeuse and twill constructions are favored for their drape and sheen, while jacquard silks deliver integrated patterns without printing.

- Mulberry Silk & Blends: Pure mulberry for headliners and seat centers; 70/30 silk‑nylon blends for high‑wear zones.

- Tussah & Wild Silks: Tussah’s 20–25 denier fibers add texture but require heavier backing for durability.

- Weave Selections: Charmeuse (2/1) for glossy panels; twill (3/1) for subtle diagonal texture and increased abrasion resistance.

- Jacquard Patterns: Woven motifs—logos, geometric designs—eliminate printed surface wear.

- Case Study: Luxury EV model using 50/50 silk‑microfiber blend for 1 million‑cycle Martindale abrasion test.

| Silk Type & Weave | Denier Range | Blend Ratio | Application |

|---|---|---|---|

| Mulberry Charmeuse | 12–16 denier | 100% silk | Seat centers, headliners |

| Silk‑Nylon Twill Blend | 12–16 denier | 70/30 silk‑nylon | Door panels, bolsters |

| Tussah Satin Weave | 20–25 denier | 100% tussah silk | Accent trims |

| Jacquard Mulberry | 12–16 denier | 100% silk | Embossed pattern inserts |

How Is Silk Treated and Finished to Withstand Automotive Wear and Tear?

To endure constant friction, UV exposure, and temperature swings inside a vehicle, silk undergoes specialized treatments. First, it’s back‑coated with polyurethane or acrylic polymers to boost abrasion resistance to over 100,000 Martindale rubs—well above the 50,000‑rub threshold common in automotive textiles. Next, silk panels receive UV‑inhibitor sprays that maintain color vibrancy after 1,000 hours of sunlight exposure. Finally, stain‑repellent finishes—often fluorocarbon‑free durable water‑repellent (DWR) coatings—allow cleanup of coffee spills or oily fingerprints with a single wipe. Automotive silk is back‑coated with polymers for +100,000 Martindale abrasion resistance, treated with UV inhibitors to preserve color after 1,000 sun‑hours, and finished with DWR coatings for stain repellency—ensuring both durability and easy maintenance.

- Polymer Back‑Coating: Balancing hand feel and wear resistance—polyurethane vs. acrylic formulas

- Martindale Abrasion Standards: Achieving > 100,000 rubs vs. industry minimums

- UV‑Inhibitor Chemistry: Organic vs. inorganic filters and their longevity

- DWR Finishes: Transition from PFAS to eco‑friendly alternatives and performance trade‑offs

- Case Study: Premium SUV seats maintained color and integrity after 18 months of intensive use

| Treatment Stage | Method | Performance Metric | Notes |

|---|---|---|---|

| Polymer Back‑Coating | PU (15 g/m²) | > 100,000 Martindale rubs | Slight hand‑feel increase |

| UV‑Inhibitor Application | Nano‑titanium dioxide spray | < 5 % color fade at 1,000 h | Inorganic stability |

| Stain‑Repellent Finish | Fluorocarbon‑free DWR | WVT60 s spray test | Eco‑certified |

What Comfort and Aesthetic Benefits Does Silk Provide in Vehicles?

Silk doesn’t just look exquisite—it enhances occupant comfort. Its breathability reduces seat surface temperature by up to 5 °F compared to leather, while its natural gloss conveys a sense of luxury unmatched by synthetics. Additionally, silk’s smooth surface minimizes fabric friction against clothing, reducing wear on both the seat and one’s wardrobe. Several luxury automakers report 20 % higher passenger satisfaction scores in silk‑trimmed models versus standard leather trims. Silk upholstery keeps seat surfaces up to 5 °F cooler than leather, offers a natural sheen that elevates cabin luxury, and its low‑friction surface preserves both seat and clothing—boosting passenger satisfaction by 20 %.

- Thermal Comfort Data: Comparative seat‑surface temperatures at 100 °F ambient

- Gloss & Perceived Quality: L\*a\b\ measurements quantifying silk’s light reflection

- Friction Coefficients: Silk at 0.25 vs. leather at 0.45 (fabric‑against‑fabric tests)

- Passenger Feedback Metrics: Surveys from limited‑edition silk‑trim releases

- Case Study: Bespoke Sedan Model Achieved 95% Positive Cabin Aesthetic Ratings

| Benefit | Silk vs. Leather | Measured Improvement |

|---|---|---|

| Surface Temperature Drop | 5 °F lower | Enhanced comfort |

| Light Reflectance (L\* value) | +10 L\* units | Superior sheen |

| Friction Coefficient | Silk 0.25 vs. Leather 0.45 | 45 % reduction |

| Satisfaction Score Increase | +20 % survey rating | Noted in luxury segment |

How Does Silk Compare to Synthetic and Natural Alternatives in Automotive Upholstery?

Silk stands out among upholstery options for its blend of luxury and performance. Compared to synthetic microfiber (polyester or nylon), silk offers superior breathability and a cooler touch, with thermal conductivity roughly 20% lower. Versus leather, silk is lighter and less prone to heat buildup, reducing seat-surface temperatures by up to 5 °F. Natural alternatives like wool or cotton may match silk’s moisture-wicking but lack its tensile strength and luster, making silk the premium choice when both comfort and durability matter. Silk upholstery outperforms polyester microfiber and leather by maintaining cooler seat temperatures (up to 5 °F lower than leather), offering 30% greater moisture absorption than cotton, and delivering 30% higher tensile strength than wool—combining luxury aesthetics with robust performance.

- Thermal Conductivity & Comfort: Silk at 0.04 W/m·K vs. microfiber at 0.06 and leather at 0.07

- Moisture Management Comparison: Silk’s 30% absorption vs. cotton’s 8% and microfiber’s 2%

- Abrasion Resistance: Treated silk ≥ 100k Martindale vs. microfiber 80k and wool 60k rubs

- Weight & Flexibility: Silk fabrics weigh 10–15 oz/yd² vs. wool at 20–25 oz/yd²—impacting seat ergonomics

- Aesthetic & Hand Feel: Silk’s natural sheen vs. leather grain or synthetic matte finishes

| Material | Thermal Conductivity (W/m·K) | Moisture Absorption (%) | Abrasion Resistance (Martindale) | Weight (oz/yd²) |

|---|---|---|---|---|

| Silk (treated) | 0.04 | 30 | ≥ 100,000 | 12–15 |

| Polyester Microfiber | 0.06 | 2 | 80,000 | 10–12 |

| Leather (Aniline) | 0.07 | 5 | 70,000 | 18–20 |

| Wool Blend | 0.05 | 12 | 60,000 | 20–25 |

| Cotton Canvas | 0.05 | 8 | 50,000 | 12–16 |

Critical Perspectives:

- Cost vs. Benefit: Silk’s higher price point demands a value proposition—consider hybrid leather‑silk blends to balance luxury and budget.

- Maintenance Trade‑Offs: Leather is more forgiving of spills, whereas silk’s DWR coatings require touch‑up after multiple cleanings.

- Ethical & Sustainability Factors: Natural fibers like wool may appeal to eco‑conscious buyers despite performance gaps.

Are There Industry Standards or Certifications Governing Silk Use in Cars?

Automotive textiles must meet stringent regulations for safety, flammability, and environmental impact. While silk isn’t explicitly detailed in automotive OEM standards, treated silk upholstery typically undergoes FMVSS 302 flammability testing (< 4 s burn rate) and ISO 3795 protocols. Additionally, Oeko‑Tex Standard 100 Class II certification confirms low chemical residues suitable for interior use, and REACH compliance ensures freedom from restricted substances. Silk automotive upholstery is validated through FMVSS 302 and ISO 3795 flammability tests (< 4 s burn rate), Oeko‑Tex Standard 100 Class II for low chemical residues, and REACH compliance—ensuring both occupant safety and environmental responsibility.

- Flammability Standards: FMVSS 302 vs. ISO 3795—burn rate thresholds and test methods

- Chemical Safety Protocols: Oeko‑Tex Class II vs. Class I—appropriate for automotive interiors

- REACH & VOC Limits: Ensuring silk treatments comply with EU and global chemical regulations

- End‑to‑End Traceability: Certifications like GRS (Global Recycled Standard) for blended fabrics

- Case Study: Luxury Sedan’s switch to Oeko‑Tex certified silk, achieving 15% faster interior approval times

| Certification/Standard | Scope | Test Criteria |

|---|---|---|

| FMVSS 302 | Flammability (< 4 s burn rate) | Vertical burn, veranda test |

| ISO 3795 | Flammability (vehicle method) | Horizontal/vertical burn, sample size standards |

| Oeko‑Tex Standard 100 Class II | Harmful substances in textiles | 350+ chemicals screened |

| REACH | EU chemical restrictions | SVHC reporting, registration |

| GRS (for blends) | Recycled content & chain of custody | ≥ 20% recycled material verification |

Critical Perspectives:

- Regional Variations: US and EU standards differ slightly—global manufacturers must test to both FMVSS and ISO protocols.

- Certification Burden: Acquiring Oeko‑Tex or GRS can add 4–6 weeks to project timelines—plan certification early.

How Do Manufacturers Combine Silk with Other Materials for Enhanced Performance?

To marry silk’s luxury with everyday resilience, automakers often blend silk with synthetic fibers. Common combinations include a 70/30 silk‑nylon twill for stretch recovery, or 50/50 silk‑polyester charmeuse for stain resistance. These hybrids maintain silk’s luster while improving abrasion resistance to over 200,000 Martindale rubs and reducing cost by up to 25%. Additionally, ultrasonic bonding and proprietary lamination methods ensure seamless integration without sacrificing hand feel. Manufacturers enhance silk upholstery by blending 70/30 silk‑nylon for stretch and durability (200k Martindale rubs) or 50/50 silk‑polyester for stain resistance, cutting material cost by 20–25% while preserving silk’s sheen through advanced bonding and lamination techniques.

- Blend Ratios & Performance: How varying silk content (30–50%) impacts abrasion and cost

- Bonding Techniques: Ultrasonic vs. adhesive lamination—effects on hand feel and longevity

- Abrasion Testing Results: Hybrid blends outperform pure silk by 50% in Martindale tests

- Thermoforming & Drapability: Maintaining silk’s drape when molded into contoured seat panels

- Case Study: Premium Crossover’s 70/30 Silk‑Nylon Door Panels Passed 1M Mate Martindale

| Blend Type | Silk Content | Abrasion Resistance | Cost Reduction | Hand‑Feel Impact |

|---|---|---|---|---|

| Silk (100%) | 100% | 100k Martindale | Baseline | Ultra‑smooth |

| Silk/Nylon Twill | 70% | 200k Martindale | −20% | Slightly firmer |

| Silk/Polyester Charmeuse | 50% | 180k Martindale | −25% | Retained sheen |

| Silk/Aramid Blend | 50% | 300k Martindale | −15% | Mild stiffness |

Critical Perspectives:

- Performance vs. Purity: Increasing synthetic content boosts durability but may dilute silk’s premium perception.

- Integration Complexity: Advanced bonding adds cost and requires specialized equipment, elevating MOQ and lead times.

What Care and Maintenance Practices Keep Silk Upholstery Looking New?

Silk’s delicate nature demands mindful upkeep. Manufacturers recommend vacuuming with a soft‑brush attachment weekly, wiping spills immediately with a damp microfiber cloth, and avoiding ammonia‑based cleaners. For deeper cleans, professional upholstery services use neutral pH detergents and low‑moisture techniques to preserve back‑coatings. Proper care can extend silk’s service life by up to 50%, ensuring your luxury interior stays pristine. To maintain automotive silk, vacuum weekly with a soft brush, blot spills immediately, avoid harsh chemicals, and use professional low‑moisture cleaning with neutral pH detergents—practices that can extend silk’s lifespan by as much as 50%.

- Daily Care Tips: Gentle vacuum vs. lint roller for dust removal

- Stain Response Protocol: Immediate blotting, pH‑balanced cleaners, no rubbing

- Professional Cleaning Standards: Low‑moisture extraction, enzyme‑based detergents

- UV & Heat Exposure Management: Using UV‑blocking window films to reduce photodegradation

- Case Study: Chauffeur Service Fleet’s Maintenance Schedule Reduced Silk Replacements by 40%

| Care Practice | Recommended Frequency | Expected Benefit |

|---|---|---|

| Soft‑Brush Vacuuming | Weekly | Prevents dust accumulation |

| Immediate Spill Blotting | As needed | Avoids stain setting |

| Professional Cleaning | Annually | Deep refresh, restores DWR |

| UV‑Blocking Film Use | Continuous | Minimizes color fade |

Critical Perspectives:

- Owner Education: Luxury buyers may undervalue maintenance—clear care guides enhance satisfaction.

- Cost of Ownership: Professional cleanings add to long‑term costs but pay dividends in fabric longevity.

From tensile strength and thermal management to hybrid blends and meticulous care, silk’s role in automotive upholstery transcends mere luxury—it’s a high‑performance fabric engineered for comfort, durability, and timeless elegance. Whether you’re designing a bespoke coachbuilt interior or enhancing a flagship SUV, silk offers a unique proposition that few materials can match.

Ready to explore custom silk upholstery fabrics tailored to your automotive vision?

Contact SzoneierFabrics for sample swatches, MOQ flexibility, and expert technical support.

Let’s drive the future of automotive luxury—one stitch at a time.