Stretch fabrics have already changed how clothing feels on the body, but a new generation of textiles is starting to change how clothing responds to the body. Instead of simply stretching and recovering, fabrics are now being designed to sense temperature, track movement, react to moisture, and even communicate data. This shift marks the emergence of smart spandex—a category that blends elasticity with intelligence.

smart spandex refers to spandex-based textiles that integrate temperature-regulating functions and/or embedded sensor systems while maintaining stretch, comfort, and durability. These fabrics don’t just move with the wearer; they adapt to physiological and environmental changes in real time.

What makes smart spandex compelling is that it doesn’t replace conventional stretch fabrics—it upgrades them. The familiar comfort of elastane becomes the foundation for responsive behavior, opening new possibilities in sportswear, medical textiles, rehabilitation garments, and wearable technology. As this technology matures, the line between fabric and device is becoming thinner, and understanding how smart spandex works is key to knowing where stretch textiles are headed next.

What Is “Smart Spandex” and How Does It Differ from Conventional Spandex Fabric?

Smart spandex is a stretch textile that retains the elastic performance of elastane while integrating additional functional systems such as temperature regulation, electrical conductivity, sensing capability, or responsive behavior. Conventional spandex focuses purely on stretch and recovery. Smart spandex is designed to interact with the body or environment, not just move with it.

This difference is not cosmetic. It changes how the fabric is engineered, tested, manufactured, and ultimately used in real products.

Conventional spandex is passive. Smart spandex is responsive.

Conventional spandex vs smart spandex at a glance

| Feature | Conventional Spandex | Smart Spandex |

|---|---|---|

| Stretch & recovery | Yes | Yes |

| Temperature response | No | Yes |

| Biometric sensing | No | Optional |

| Data interaction | No | Possible |

| Functional layers | Single | Multi-layer or hybrid |

The elastane fiber at the core is often similar in chemical composition. What fundamentally changes is what is built around that core and how the fabric system is designed to behave during wear, motion, washing, and long-term use.

How conventional spandex functions in practice

Traditional spandex fabrics are engineered to solve one problem: controlled elasticity. Elastane fibers can stretch 400–700% and recover repeatedly without permanent deformation. In apparel and performance textiles, this allows garments to:

- Fit tightly without restricting movement

- Maintain shape after repeated wear

- Improve comfort during dynamic motion

From a manufacturing standpoint, conventional spandex is relatively predictable. Key performance parameters include:

- Stretch percentage and recovery rate

- Fatigue resistance over repeated cycles

- Compatibility with dyeing and finishing processes

Once these parameters are met, the fabric’s role is essentially complete. It does not sense, regulate, or communicate. Any functionality must come from garment construction, not the material itself.

What makes spandex “smart”

Smart spandex is not defined by a single technology. Instead, it is defined by system integration. The fabric becomes a platform that supports additional functions while preserving elasticity.

Smart behavior is typically achieved by one or more of the following approaches:

- Integrating functional yarns alongside elastane

- Applying responsive surface or embedded coatings

- Embedding micro-scale sensors within the fabric structure

- Combining spandex with conductive, thermal, or phase-change materials

These elements are engineered so that stretch, recovery, and comfort are not compromised, which is one of the most difficult challenges in smart textile development.

In most commercial smart spandex fabrics, elastane remains the mechanical backbone. Functional components are distributed in a way that allows them to deform and recover in sync with the base fabric rather than resisting movement.

Structural differences between conventional and smart spandex fabrics

From a textile engineering perspective, the biggest difference lies in layering and architecture.

Conventional spandex fabrics are usually single-system structures: a knitted or woven construction where elastane is wrapped, plated, or core-spun with standard yarns such as nylon or polyester.

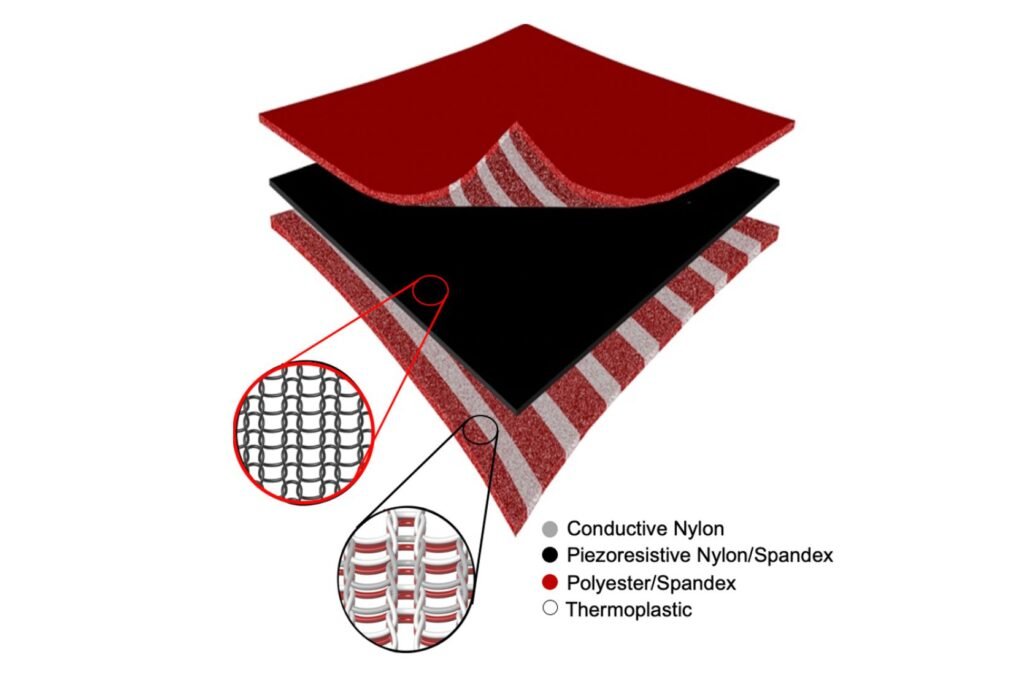

Smart spandex fabrics are often multi-system structures, which may include:

- A mechanical layer responsible for stretch and recovery

- A functional layer responsible for sensing, heating, cooling, or signal transmission

- A protective or insulation layer that shields functional elements from abrasion, sweat, or washing damage

This layered or hybrid approach allows the fabric to perform multiple roles simultaneously, but it also introduces new variables in production, testing, and quality control.

Why spandex is well suited for smart textile integration

Spandex is not used in smart textiles by accident. Its mechanical behavior solves several fundamental problems that rigid or low-stretch fabrics cannot.

| Requirement for Smart Textiles | Why Spandex Helps |

|---|---|

| Stable skin contact | High elasticity |

| Signal consistency | Strong shape recovery |

| Comfort during movement | Soft hand feel |

| Long-term wearability | Lightweight and flexible |

Accurate sensing and responsive behavior require consistent contact with the body. Fabrics that shift, wrinkle, or gap introduce noise into sensor readings and reduce reliability. Spandex-based fabrics conform closely to the skin, which improves measurement accuracy and user comfort at the same time.

Repeated deformation is another critical factor. Smart garments are expected to stretch thousands of times during their lifespan. Elastane tolerates this mechanical stress far better than rigid conductive films or brittle components, making it an ideal host material when smart elements are properly integrated.

Functional capabilities commonly added to smart spandex

Smart spandex does not imply a single function. Different applications prioritize different capabilities:

- Thermal regulation: Integration of phase-change materials or heat-responsive coatings that absorb or release heat as body temperature changes

- Conductivity: Use of conductive yarns or coatings to transmit electrical signals without limiting stretch

- Biometric sensing: Embedded strain, pressure, or bio-signal sensors that monitor movement, posture, or physiological data

- Adaptive compression: Variable support zones that respond to motion or load

Each function adds complexity. As functionality increases, so do the demands on material stability, wash durability, and long-term reliability.

Manufacturing and durability considerations

From a production standpoint, smart spandex introduces challenges that do not exist in conventional stretch fabrics.

Key manufacturing concerns include:

- Elastic compatibility: Functional components must stretch at similar rates to elastane to avoid delamination or breakage

- Wash resistance: Smart elements must survive repeated laundering, sweat exposure, and mechanical agitation

- Yield control: Multi-layer or hybrid fabrics typically have tighter tolerances and higher rejection risk

For example, conductive pathways must maintain electrical continuity even after hundreds of stretch-and-recovery cycles. Phase-change materials must remain encapsulated and evenly distributed. Sensors must stay accurately positioned despite fabric deformation.

These requirements often lead to lower production speeds and higher unit costs compared to conventional spandex fabrics.

Human-centered perspective on smart spandex

From the wearer’s point of view, smart spandex should not feel like a technical device. The success of smart spandex products depends largely on whether the technology remains invisible in daily use.

If the fabric feels stiff, heavy, or restrictive, users quickly abandon it regardless of functionality. This is why most successful smart spandex designs prioritize:

- Familiar stretch and softness

- Breathability comparable to standard activewear

- Minimal awareness of embedded technology

When done correctly, the wearer perceives the garment as normal stretchwear that simply performs better or provides useful feedback without drawing attention to itself.

Cost and application implications

Smart spandex fabrics typically cost more than conventional spandex due to:

- Additional raw materials

- More complex manufacturing processes

- Higher testing and quality control requirements

As a result, smart spandex is most commonly used in applications where added functionality delivers measurable value, such as performance sportswear, medical compression garments, rehabilitation apparel, and emerging wearable systems.

In contrast, conventional spandex remains the most cost-effective choice for everyday stretch garments where elasticity alone is sufficient.

Smart spandex is not about turning clothing into gadgets. It is about adding awareness and responsiveness to materials people already trust and wear every day.

The elastane fiber itself has not radically changed. What has changed is the way designers and engineers build systems around it—systems that allow fabric to sense, respond, and adapt while still behaving like stretchwear should.

Understanding this distinction is essential for anyone evaluating smart textiles, because the real difference lies not in the name, but in how the fabric is engineered, produced, and expected to perform over time.

How Do Temperature-Regulating Technologies Work in Smart Spandex Textiles?

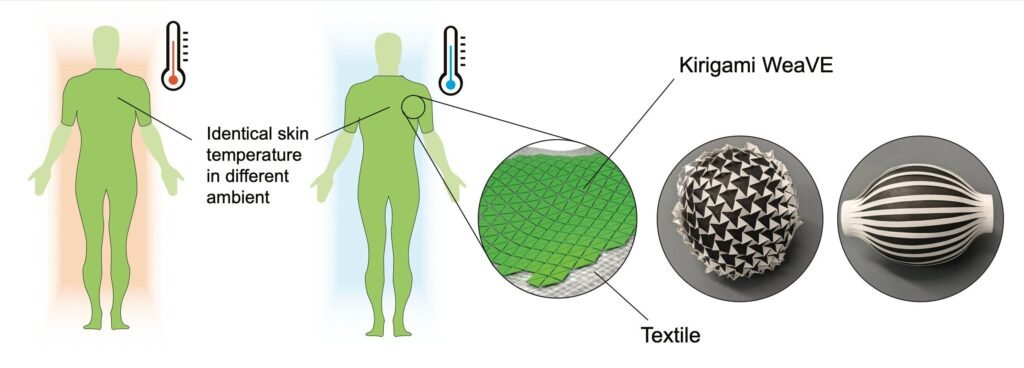

Temperature-regulating smart spandex textiles are designed to moderate heat exchange between the human body and the surrounding environment. Rather than actively heating or cooling like electronic wearables, these fabrics rely on passive material science and structural engineering to stabilize comfort across changing conditions.

In practical terms, the fabric behaves like a thermal buffer. When the body produces excess heat, the textile absorbs or dissipates it. When body temperature drops, the same system slows heat loss or releases stored warmth. The goal is not to make the wearer feel cold or hot, but to reduce temperature swings, which are a primary cause of discomfort and fatigue during long periods of wear.

This approach is especially effective in spandex-based textiles because elasticity keeps functional materials in close, uniform contact with the skin, allowing thermal regulation systems to work consistently even during movement.

The fundamental principle: passive thermal balance

Human thermal discomfort is rarely caused by absolute temperature alone. It is more often triggered by rapid temperature changes, such as overheating during activity followed by chilling during rest. Smart spandex textiles target this problem by smoothing out these fluctuations.

Key characteristics of passive temperature-regulating fabrics include:

- No external power source

- No electronics or wiring

- No user intervention

- Continuous, automatic response

Because these systems rely on physics rather than electronics, they remain lightweight, breathable, washable, and suitable for daily wear, sports, medical compression, and professional uniforms.

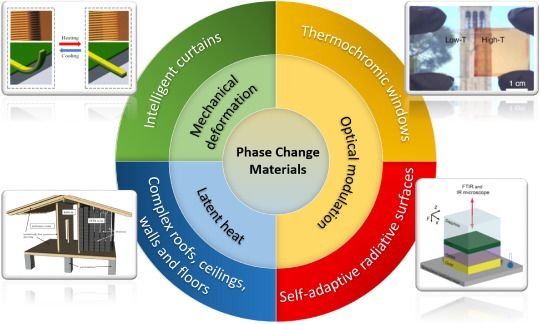

The main temperature-regulation approaches in smart spandex

Several material strategies are used to achieve thermal regulation. Each addresses heat management from a different angle, and many high-performance fabrics combine multiple approaches.

| Technology | How It Works |

|---|---|

| Phase-change materials (PCMs) | Absorb and release heat at defined temperatures |

| Thermo-responsive polymers | Alter structure or permeability with temperature |

| Moisture-heat coupling | Enhance evaporative cooling through sweat control |

| Layered thermal design | Control heat flow using fabric architecture |

Among these, phase-change materials (PCMs) are the most widely adopted in commercial smart spandex textiles due to their reliability and predictable performance.

Phase-change materials (PCMs): the thermal core

PCMs are substances that absorb or release latent heat when transitioning between solid and liquid states. This transition occurs within a narrow temperature window, typically aligned with the human skin comfort range (around 28–33°C).

When integrated into spandex textiles, PCMs function as microscopic heat reservoirs.

Key PCM behaviors include:

- Absorbing excess heat when body temperature rises

- Storing that heat without increasing fabric temperature

- Releasing stored heat when body temperature drops

| PCM Behavior | Wearer Effect |

|---|---|

| Heat absorption | Cooling sensation |

| Heat release | Warmth retention |

| Stable cycling | Consistent comfort |

To make PCMs usable in fabrics, they are typically micro-encapsulated. Each microcapsule contains a tiny amount of PCM enclosed in a durable polymer shell. These capsules are then bonded to fibers, embedded in coatings, or incorporated into yarn structures so they remain stable through repeated stretching and laundering.

Why PCMs work especially well with spandex

Spandex does not regulate temperature on its own, but it enables other technologies to perform more effectively.

Spandex improves PCM performance in several ways:

- Maintains close contact between PCM-treated fibers and skin

- Reduces air gaps that cause uneven heat transfer

- Keeps microcapsules evenly distributed during movement

- Prevents localized overheating or cooling

Because spandex stretches and recovers with the body, the PCM layer remains where it is most effective: at the skin–fabric interface, where heat exchange actually occurs.

Thermo-responsive polymers: adaptive permeability

Another approach involves polymers that change their molecular structure in response to temperature. As heat increases, these polymers may expand, increasing fabric porosity and allowing more heat and moisture to escape. As temperature drops, they contract, reducing airflow and conserving warmth.

In smart spandex fabrics, thermo-responsive polymers are often applied as:

- Thin surface coatings

- Fiber finishes

- Intermediate layers within laminated structures

Their main advantage is dynamic breathability. Instead of a fixed ventilation rate, the fabric adjusts automatically based on thermal conditions.

However, these systems typically offer gradual modulation rather than the immediate heat absorption provided by PCMs. For this reason, they are often used as complementary technologies rather than standalone solutions.

Moisture-heat coupling: sweat as a cooling tool

Human bodies rely heavily on evaporative cooling. Smart spandex textiles leverage this natural mechanism by managing how sweat is absorbed, transported, and evaporated.

Moisture-heat coupling works through:

- Rapid wicking of sweat away from the skin

- Spreading moisture across a larger surface area

- Accelerating evaporation to remove heat

Spandex plays a critical role here by ensuring consistent fabric-skin contact, which improves moisture pickup and transport. Without elasticity, fabrics may hang loosely, creating zones where sweat accumulates instead of evaporating efficiently.

This approach is especially effective during high-intensity activity, where metabolic heat production is high and evaporative cooling becomes the dominant thermal pathway.

Layered thermal design: structure matters

Beyond materials, fabric architecture strongly influences temperature regulation. Layered smart spandex textiles are engineered to control the direction and rate of heat flow.

Typical layered designs include:

- An inner layer optimized for moisture transfer

- A functional middle layer containing PCMs or adaptive polymers

- An outer layer designed for controlled heat release

This structure allows heat to be absorbed, delayed, or redirected depending on conditions. Spandex ensures these layers remain aligned and functional during stretching, compression, and repeated movement.

Thermal consistency: why stretch changes everything

Temperature regulation is not only about heat absorption or release—it is also about consistency.

| Fabric Type | Thermal Consistency |

|---|---|

| Rigid fabric | Variable |

| Loose knit | Inconsistent |

| Spandex-based | Stable |

Rigid fabrics shift position during movement, creating hot and cold spots. Loose knits allow air gaps to form and collapse unpredictably. Spandex-based fabrics maintain uniform contact, which leads to more predictable thermal behavior.

This is particularly important in compression garments, base layers, and fitted sportswear, where uneven temperature distribution can cause discomfort even if average temperature remains acceptable.

Passive vs active temperature control

Most commercially viable smart spandex textiles use passive temperature regulation.

Passive systems:

- Require no batteries

- Add minimal weight

- Remain fully washable

- Do not interfere with garment flexibility

Active systems—those using sensors, heating elements, or powered cooling—exist primarily in niche or experimental applications. While they offer greater temperature control, they introduce complexity, stiffness, maintenance issues, and limited lifespan.

For everyday apparel, medical wear, and performance textiles, passive systems offer the best balance between effectiveness and practicality.

Durability and wash performance

One of the biggest challenges in smart textile design is maintaining performance over time. Temperature-regulating features must survive:

- Repeated stretching and recovery

- Dozens or hundreds of wash cycles

- Mechanical abrasion during wear

In spandex textiles, PCMs and adaptive finishes are engineered to withstand these stresses. High-quality systems retain a significant portion of their thermal capacity even after extensive laundering, although gradual performance reduction is expected over long service life.

This durability is a key reason why PCMs dominate commercial applications—they are chemically stable and mechanically resilient when properly encapsulated.

Practical performance in real wear

In controlled wear trials and field use, temperature-regulating spandex garments typically demonstrate:

- Reduced peak skin temperatures during exertion

- Slower onset of overheating

- Less rapid cooling during rest periods

- Improved comfort in transitional environments

The effect is subtle rather than dramatic. Wearers often report feeling “more stable” or “less distracted by temperature” rather than noticeably cooler or warmer.

This subtlety is a strength. Overcorrection—making the wearer feel cold or hot—would be counterproductive. The objective is comfort continuity, not temperature extremes.

Application-specific benefits

Temperature-regulating spandex textiles are particularly valuable in:

- Sports and training apparel with variable intensity

- Compression garments worn for long durations

- Medical and recovery wear where comfort affects compliance

- Workwear used across indoor and outdoor environments

In each case, the benefit comes from reducing thermal stress, which supports endurance, focus, and overall wear satisfaction.

Design trade-offs and limitations

Despite their advantages, smart spandex textiles have limits.

Key considerations include:

- Added material cost compared to standard spandex

- Finite heat storage capacity of PCMs

- Gradual performance decline over time

- Need for careful process control during manufacturing

These systems do not replace insulation in cold environments or active cooling in extreme heat. They operate within a comfort-management range, not as standalone climate control solutions.

Why smart spandex remains commercially viable

The success of temperature-regulating spandex textiles lies in their integration into familiar garment systems. They do not require behavioral change from the wearer, special charging routines, or complex care instructions.

From a manufacturing perspective, they:

- Fit into existing knitting and finishing processes

- Scale well for mass production

- Offer measurable performance differentiation

From a user perspective, they simply feel more comfortable over time.

Temperature-regulating smart spandex textiles work by absorbing, storing, releasing, and redistributing heat through passive material systems such as phase-change materials, adaptive polymers, moisture management, and layered design.

Spandex itself does not regulate temperature, but it enables these technologies to function consistently and predictably by maintaining close, uniform contact with the body during movement.

The result is not dramatic heating or cooling, but reduced thermal fluctuation, smoother comfort transitions, and improved wear experience over long periods. In smart textiles, stability—not intensity—is what defines real performance.

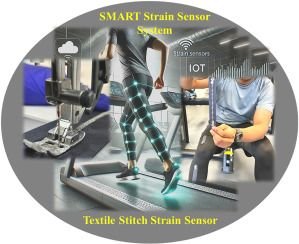

Which Sensor Systems Are Commonly Embedded in Smart Spandex for Biomonitoring?

Smart spandex has become one of the most important material platforms for wearable biomonitoring, not because it is electronic, but because it is mechanically intelligent. Its ability to stretch, recover, conform to the body, and remain comfortable over long wear cycles makes it uniquely suited to host sensors that must function reliably under constant deformation.

In biomonitoring garments, the technical challenge is rarely whether a parameter can be measured. Heart rate, muscle activity, temperature, or movement are all well-understood signals. The real challenge is maintaining stable, repeatable sensing while the fabric stretches, bends, twists, and relaxes thousands of times during real use.

Smart spandex solves this by acting as the mechanical backbone that keeps sensors aligned with the body, maintains contact pressure, and distributes strain evenly across sensing elements. As a result, certain sensor systems have emerged as industry standards due to their compatibility with spandex’s elastic behavior.

Smart spandex textiles most commonly embed strain sensors, temperature sensors, moisture sensors, and bioelectrical sensors, using conductive yarns, printed electronics, or flexible micro-sensor modules. These systems are engineered to deform synchronously with the fabric, preserving signal integrity during stretch, recovery, and repeated laundering.

The success of smart spandex is not about adding electronics—it is about integrating sensing into a dynamic textile system.

The Main Sensor Categories Used in Smart Spandex

Each sensor type addresses a different physiological or biomechanical signal. Their selection depends on the application: sports performance, medical monitoring, rehabilitation, or consumer wellness.

| Sensor Type | What It Measures |

|---|---|

| Strain sensors | Movement, stretch, posture, joint angle |

| Temperature sensors | Skin temperature, thermal trends |

| Moisture sensors | Sweat rate, humidity, hydration indicators |

| Bioelectrical sensors | Muscle activation (EMG), heart signals (ECG) |

Spandex plays a central role by maintaining consistent sensor-to-skin contact, which is critical for data accuracy.

Strain Sensors: The Foundation of Smart Spandex

Strain sensors are the most widely used sensing elements in smart spandex garments. They translate fabric deformation into electrical signals, enabling detailed motion and posture analysis.

When spandex stretches over a joint or muscle group, embedded strain sensors elongate proportionally. This deformation changes the sensor’s electrical resistance or capacitance, producing a measurable signal.

Common applications include:

- Gait and posture monitoring

- Joint angle tracking

- Respiratory rate measurement (chest expansion)

- Sports movement analysis

Because spandex stretches predictably and recovers reliably, strain sensors embedded in it can achieve high signal repeatability over thousands of cycles.

From an engineering perspective, strain sensors benefit from spandex’s ability to distribute stress evenly. This reduces localized strain concentration, which is one of the primary causes of sensor fatigue and drift.

Temperature Sensors: Subtle Signals, Stable Contact

Temperature sensors in smart spandex are typically used to monitor skin temperature trends, not absolute core body temperature. Their value lies in detecting changes over time rather than single-point measurements.

Spandex improves temperature sensing in two key ways:

- It maintains close, uniform contact with the skin

- It minimizes air gaps that cause thermal noise

These sensors are often thin-film resistive elements or printed thermistors integrated into the fabric surface or inner layer. Because spandex conforms tightly to the body, temperature sensors remain in a stable thermal environment even during movement.

Typical use cases include:

- Exercise load monitoring

- Recovery and fatigue analysis

- Early detection of inflammation or fever trends

Temperature sensors are less mechanically stressed than strain sensors, but they still benefit from spandex’s elasticity, which prevents sensor detachment or folding during wear.

Moisture Sensors: Reading the Body’s Output

Moisture sensors in smart spandex measure sweat presence, accumulation, or humidity, providing insight into hydration levels and thermoregulation.

These sensors often rely on changes in electrical conductivity or capacitance as moisture content increases. Conductive pathways embedded in spandex fabrics allow sweat to interact directly with the sensing surface.

Spandex is particularly well-suited for moisture sensing because:

- It maintains continuous skin contact during sweating

- It stretches without breaking conductive pathways

- It supports zoned sensor placement (e.g., underarms, back, chest)

In performance apparel, moisture sensors are used to correlate sweat patterns with exertion levels. In medical or occupational settings, they can help monitor dehydration risk or heat stress.

Bioelectrical Sensors: EMG and ECG in Stretchable Form

Bioelectrical sensors measure electrical signals generated by the body, such as muscle activation (EMG) or heart activity (ECG). These sensors are among the most sensitive to movement artifacts, making spandex integration especially valuable.

Traditional rigid electrodes struggle in dynamic environments because they lose contact or shift position. Spandex-based garments solve this by applying gentle, consistent compression, which stabilizes electrode placement.

Key advantages include:

- Reduced motion-induced signal noise

- Improved long-term comfort compared to adhesive electrodes

- Better alignment with muscle groups or cardiac zones

Bioelectrical sensors in spandex garments are commonly used in:

- Rehabilitation monitoring

- Sports science and muscle efficiency analysis

- Long-term cardiac screening

The elastic recovery of spandex ensures that electrodes return to their designed position after each movement, preserving data consistency.

How Sensors Are Integrated into Spandex Fabrics

Sensor performance depends not only on the sensor itself, but on how it is integrated into the textile. Three dominant integration approaches are used today.

| Method | Description | Flexibility |

|---|---|---|

| Conductive yarns | Knitted or woven into fabric | Excellent |

| Printed sensors | Screen- or inkjet-printed circuits | Good |

| Flexible modules | Thin embedded sensor patches | Moderate |

Each method represents a trade-off between durability, signal quality, and manufacturing complexity.

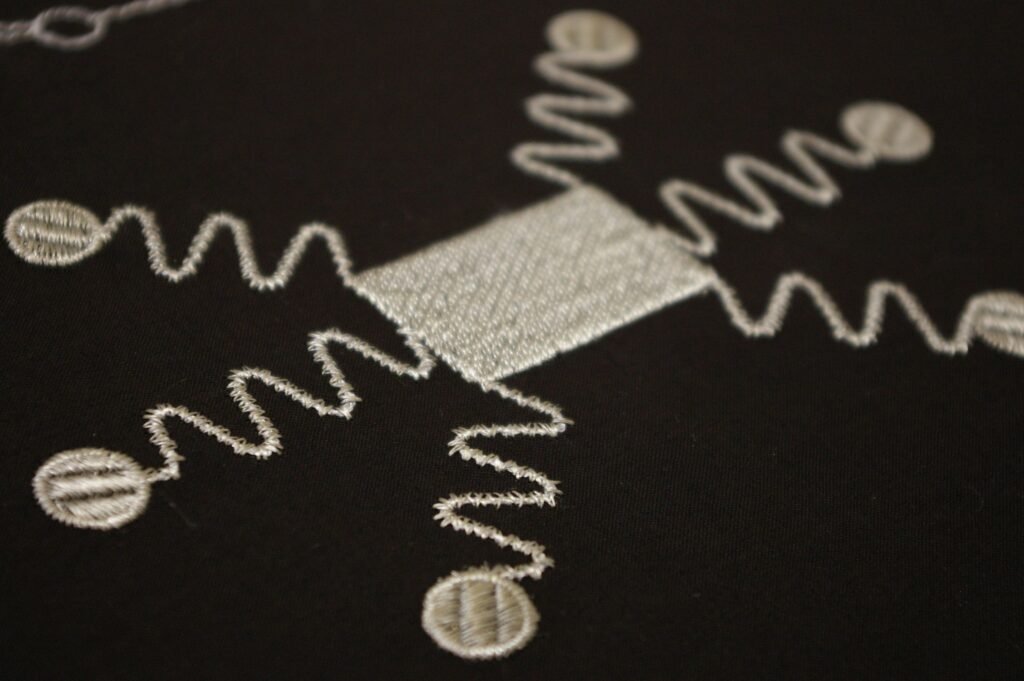

Conductive Yarns: The Dominant Integration Method

Conductive yarns are currently the most compatible solution for high-stretch spandex fabrics. These yarns may be silver-coated, carbon-based, or polymer-conductive, and are engineered to stretch alongside elastane fibers.

Their dominance is driven by mechanical compatibility rather than electrical superiority.

| Advantage | Why It Matters |

|---|---|

| Elastic continuity | Signal remains stable during stretch |

| Wash durability | Survives repeated laundering |

| Soft hand feel | No discomfort or pressure points |

| Seamless integration | Sensors remain invisible |

Because conductive yarns are part of the textile structure itself, they experience the same deformation profile as the surrounding spandex. This minimizes stress concentration and extends sensor lifespan.

Printed Sensors: Precision with Limits

Printed electronics allow precise sensor geometries and are well-suited for temperature or moisture sensing. However, printed traces must be carefully engineered to tolerate elongation.

In spandex fabrics, printed sensors are often placed in low-strain zones or designed with serpentine patterns that accommodate stretch.

While printed sensors offer good signal consistency, their long-term durability under extreme stretch is generally lower than conductive yarn systems.

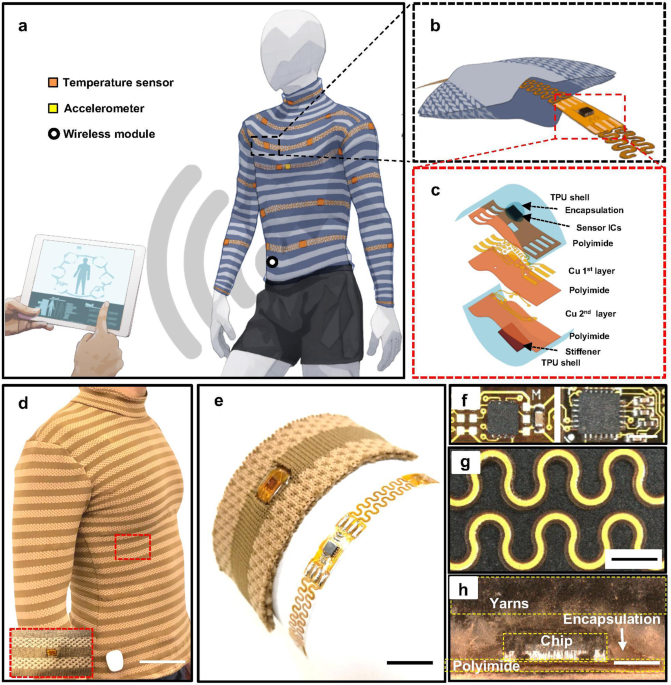

Flexible Modules: Hybrid Solutions

Flexible sensor modules are thin, encapsulated components bonded or laminated into spandex garments. They often house multiple sensing functions in a single patch.

These systems offer high signal fidelity but introduce mechanical discontinuities. To compensate, designers place them in areas with limited stretch or combine them with surrounding elastic zones that absorb strain.

Hybrid designs are common in medical-grade garments where signal accuracy outweighs maximum flexibility.

Data Accuracy and the Role of Spandex Stretch

Contrary to intuition, stretch does not always reduce accuracy. In some cases, it improves it.

| Fabric Behavior | Sensor Effect |

|---|---|

| Stable recovery | Reliable, repeatable data |

| Excess slippage | Signal noise and drift |

| Uneven stretch | Measurement inconsistency |

Spandex excels when elasticity is controlled, not excessive. Well-engineered smart spandex fabrics balance compression and stretch to maintain sensor alignment without restricting movement.

For strain sensors in particular, controlled stretch amplifies sensitivity, enabling detection of subtle movements that would be lost in looser garments.

Durability Under Repeated Use

Biomonitoring garments are expected to withstand:

- Thousands of stretch–recovery cycles

- Repeated washing and drying

- Daily wear over extended periods

Spandex’s fatigue resistance is critical here. High-quality elastane maintains recovery above 90–95% after thousands of cycles, which directly correlates with sensor signal stability.

When recovery degrades, sensors may still function electrically, but mechanical drift introduces noise. This is why fabric quality is as important as sensor technology in smart garments.

Manufacturing and Scalability Considerations

From a production standpoint, conductive yarn-based smart spandex fabrics integrate more smoothly into existing knitting processes. This allows:

- Scalable manufacturing

- Consistent sensor placement

- Lower assembly labor

Printed and module-based systems often require secondary processes, increasing cost and limiting throughput.

For large-scale applications such as sportswear or occupational monitoring, conductive yarn integration remains the most commercially viable approach.

Human-Centered Design Perspective

One of the most telling indicators of successful smart spandex design is invisibility to the wearer. Users should not feel sensors, wires, or rigid components. They should experience only the garment’s function: feedback, insight, or monitoring.

Spandex enables this by:

- Distributing pressure evenly

- Eliminating hard edges

- Allowing garments to move naturally with the body

When users forget they are wearing a monitoring system, compliance increases, and data quality improves.

The sensor systems most commonly embedded in smart spandex—strain, temperature, moisture, and bioelectrical sensors—are not chosen arbitrarily. They are selected because they align with spandex’s unique mechanical properties.

Smart spandex succeeds where rigid systems fail because it treats sensing as a mechanical problem first and an electronic problem second. By ensuring that sensors stretch, recover, and align with the body as naturally as the fabric itself, smart spandex enables biomonitoring that is accurate, durable, and genuinely wearable.

In the evolution of wearable technology, spandex is not just a fabric. It is the structural interface between the human body and digital data.

Which Sensor Systems Are Commonly Embedded in Smart Spandex for Biomonitoring?

Smart spandex has become one of the most important material platforms for wearable biomonitoring, not because it is electronic, but because it is mechanically intelligent. Its ability to stretch, recover, conform to the body, and remain comfortable over long wear cycles makes it uniquely suited to host sensors that must function reliably under constant deformation.

In biomonitoring garments, the technical challenge is rarely whether a parameter can be measured. Heart rate, muscle activity, temperature, or movement are all well-understood signals. The real challenge is maintaining stable, repeatable sensing while the fabric stretches, bends, twists, and relaxes thousands of times during real use.

Smart spandex solves this by acting as the mechanical backbone that keeps sensors aligned with the body, maintains contact pressure, and distributes strain evenly across sensing elements. As a result, certain sensor systems have emerged as industry standards due to their compatibility with spandex’s elastic behavior.

Smart spandex textiles most commonly embed strain sensors, temperature sensors, moisture sensors, and bioelectrical sensors, using conductive yarns, printed electronics, or flexible micro-sensor modules. These systems are engineered to deform synchronously with the fabric, preserving signal integrity during stretch, recovery, and repeated laundering.

The success of smart spandex is not about adding electronics—it is about integrating sensing into a dynamic textile system.

The Main Sensor Categories Used in Smart Spandex

Each sensor type addresses a different physiological or biomechanical signal. Their selection depends on the application: sports performance, medical monitoring, rehabilitation, or consumer wellness.

| Sensor Type | What It Measures |

|---|---|

| Strain sensors | Movement, stretch, posture, joint angle |

| Temperature sensors | Skin temperature, thermal trends |

| Moisture sensors | Sweat rate, humidity, hydration indicators |

| Bioelectrical sensors | Muscle activation (EMG), heart signals (ECG) |

Spandex plays a central role by maintaining consistent sensor-to-skin contact, which is critical for data accuracy.

Strain Sensors: The Foundation of Smart Spandex

Strain sensors are the most widely used sensing elements in smart spandex garments. They translate fabric deformation into electrical signals, enabling detailed motion and posture analysis.

When spandex stretches over a joint or muscle group, embedded strain sensors elongate proportionally. This deformation changes the sensor’s electrical resistance or capacitance, producing a measurable signal.

Common applications include:

- Gait and posture monitoring

- Joint angle tracking

- Respiratory rate measurement (chest expansion)

- Sports movement analysis

Because spandex stretches predictably and recovers reliably, strain sensors embedded in it can achieve high signal repeatability over thousands of cycles.

From an engineering perspective, strain sensors benefit from spandex’s ability to distribute stress evenly. This reduces localized strain concentration, which is one of the primary causes of sensor fatigue and drift.

Temperature Sensors: Subtle Signals, Stable Contact

Temperature sensors in smart spandex are typically used to monitor skin temperature trends, not absolute core body temperature. Their value lies in detecting changes over time rather than single-point measurements.

Spandex improves temperature sensing in two key ways:

- It maintains close, uniform contact with the skin

- It minimizes air gaps that cause thermal noise

These sensors are often thin-film resistive elements or printed thermistors integrated into the fabric surface or inner layer. Because spandex conforms tightly to the body, temperature sensors remain in a stable thermal environment even during movement.

Typical use cases include:

- Exercise load monitoring

- Recovery and fatigue analysis

- Early detection of inflammation or fever trends

Temperature sensors are less mechanically stressed than strain sensors, but they still benefit from spandex’s elasticity, which prevents sensor detachment or folding during wear.

Moisture Sensors: Reading the Body’s Output

Moisture sensors in smart spandex measure sweat presence, accumulation, or humidity, providing insight into hydration levels and thermoregulation.

These sensors often rely on changes in electrical conductivity or capacitance as moisture content increases. Conductive pathways embedded in spandex fabrics allow sweat to interact directly with the sensing surface.

Spandex is particularly well-suited for moisture sensing because:

- It maintains continuous skin contact during sweating

- It stretches without breaking conductive pathways

- It supports zoned sensor placement (e.g., underarms, back, chest)

In performance apparel, moisture sensors are used to correlate sweat patterns with exertion levels. In medical or occupational settings, they can help monitor dehydration risk or heat stress.

Bioelectrical Sensors: EMG and ECG in Stretchable Form

Bioelectrical sensors measure electrical signals generated by the body, such as muscle activation (EMG) or heart activity (ECG). These sensors are among the most sensitive to movement artifacts, making spandex integration especially valuable.

Traditional rigid electrodes struggle in dynamic environments because they lose contact or shift position. Spandex-based garments solve this by applying gentle, consistent compression, which stabilizes electrode placement.

Key advantages include:

- Reduced motion-induced signal noise

- Improved long-term comfort compared to adhesive electrodes

- Better alignment with muscle groups or cardiac zones

Bioelectrical sensors in spandex garments are commonly used in:

- Rehabilitation monitoring

- Sports science and muscle efficiency analysis

- Long-term cardiac screening

The elastic recovery of spandex ensures that electrodes return to their designed position after each movement, preserving data consistency.

How Sensors Are Integrated into Spandex Fabrics

Sensor performance depends not only on the sensor itself, but on how it is integrated into the textile. Three dominant integration approaches are used today.

| Method | Description | Flexibility |

|---|---|---|

| Conductive yarns | Knitted or woven into fabric | Excellent |

| Printed sensors | Screen- or inkjet-printed circuits | Good |

| Flexible modules | Thin embedded sensor patches | Moderate |

Each method represents a trade-off between durability, signal quality, and manufacturing complexity.

Conductive Yarns: The Dominant Integration Method

Conductive yarns are currently the most compatible solution for high-stretch spandex fabrics. These yarns may be silver-coated, carbon-based, or polymer-conductive, and are engineered to stretch alongside elastane fibers.

Their dominance is driven by mechanical compatibility rather than electrical superiority.

| Advantage | Why It Matters |

|---|---|

| Elastic continuity | Signal remains stable during stretch |

| Wash durability | Survives repeated laundering |

| Soft hand feel | No discomfort or pressure points |

| Seamless integration | Sensors remain invisible |

Because conductive yarns are part of the textile structure itself, they experience the same deformation profile as the surrounding spandex. This minimizes stress concentration and extends sensor lifespan.

Printed Sensors: Precision with Limits

Printed electronics allow precise sensor geometries and are well-suited for temperature or moisture sensing. However, printed traces must be carefully engineered to tolerate elongation.

In spandex fabrics, printed sensors are often placed in low-strain zones or designed with serpentine patterns that accommodate stretch.

While printed sensors offer good signal consistency, their long-term durability under extreme stretch is generally lower than conductive yarn systems.

Flexible Modules: Hybrid Solutions

Flexible sensor modules are thin, encapsulated components bonded or laminated into spandex garments. They often house multiple sensing functions in a single patch.

These systems offer high signal fidelity but introduce mechanical discontinuities. To compensate, designers place them in areas with limited stretch or combine them with surrounding elastic zones that absorb strain.

Hybrid designs are common in medical-grade garments where signal accuracy outweighs maximum flexibility.

Data Accuracy and the Role of Spandex Stretch

Contrary to intuition, stretch does not always reduce accuracy. In some cases, it improves it.

| Fabric Behavior | Sensor Effect |

|---|---|

| Stable recovery | Reliable, repeatable data |

| Excess slippage | Signal noise and drift |

| Uneven stretch | Measurement inconsistency |

Spandex excels when elasticity is controlled, not excessive. Well-engineered smart spandex fabrics balance compression and stretch to maintain sensor alignment without restricting movement.

For strain sensors in particular, controlled stretch amplifies sensitivity, enabling detection of subtle movements that would be lost in looser garments.

Durability Under Repeated Use

Biomonitoring garments are expected to withstand:

- Thousands of stretch–recovery cycles

- Repeated washing and drying

- Daily wear over extended periods

Spandex’s fatigue resistance is critical here. High-quality elastane maintains recovery above 90–95% after thousands of cycles, which directly correlates with sensor signal stability.

When recovery degrades, sensors may still function electrically, but mechanical drift introduces noise. This is why fabric quality is as important as sensor technology in smart garments.

Manufacturing and Scalability Considerations

From a production standpoint, conductive yarn-based smart spandex fabrics integrate more smoothly into existing knitting processes. This allows:

- Scalable manufacturing

- Consistent sensor placement

- Lower assembly labor

Printed and module-based systems often require secondary processes, increasing cost and limiting throughput.

For large-scale applications such as sportswear or occupational monitoring, conductive yarn integration remains the most commercially viable approach.

Human-Centered Design Perspective

One of the most telling indicators of successful smart spandex design is invisibility to the wearer. Users should not feel sensors, wires, or rigid components. They should experience only the garment’s function: feedback, insight, or monitoring.

Spandex enables this by:

- Distributing pressure evenly

- Eliminating hard edges

- Allowing garments to move naturally with the body

When users forget they are wearing a monitoring system, compliance increases, and data quality improves.

The sensor systems most commonly embedded in smart spandex—strain, temperature, moisture, and bioelectrical sensors—are not chosen arbitrarily. They are selected because they align with spandex’s unique mechanical properties.

Smart spandex succeeds where rigid systems fail because it treats sensing as a mechanical problem first and an electronic problem second. By ensuring that sensors stretch, recover, and align with the body as naturally as the fabric itself, smart spandex enables biomonitoring that is accurate, durable, and genuinely wearable.

In the evolution of wearable technology, spandex is not just a fabric. It is the structural interface between the human body and digital data.

4. How Do Thermal and Moisture Sensors Integrated in Spandex Garments Benefit Wearer Performance and Comfort?

Thermal and moisture sensors integrated into spandex garments improve wearer performance and comfort by detecting early heat buildup and sweat accumulation, then enabling timely responses—either through fabric behavior, garment design, or connected systems—before discomfort, fatigue, or performance decline occurs. The result is more stable body conditions during activity and prolonged wear.

Comfort is not about being perfectly cool or completely dry. In real use, comfort is about avoiding extremes—overheating, sudden chill, localized dampness, or prolonged humidity against the skin. Sensor-enabled spandex garments address these problems at their earliest stage, when small adjustments have the largest impact.

Why spandex is the preferred base for smart sensing garments

Spandex (also known as elastane) plays a structural role that goes far beyond stretch and fit. In sensor-integrated garments, spandex is the mechanical interface between the human body and the sensing system.

Because spandex maintains continuous, gentle contact with the skin:

- Sensors remain in consistent contact zones

- Micro-movements are tracked accurately

- Signal noise caused by fabric shifting is reduced

Loose fabrics allow sensors to lift away from the skin, creating delayed or inaccurate readings. Rigid fabrics maintain contact but compromise comfort and mobility. Spandex provides a balance: stable contact without restricting movement.

This close coupling between body and textile is what allows thermal and moisture sensors to detect trends, not just conditions.

How moisture sensing improves comfort and physiological stability

Moisture sensors embedded in spandex garments do not simply measure “wet or dry.” They track onset, location, and progression of perspiration.

Early detection matters. Once sweat saturates fabric, evaporation slows, skin temperature rises, and discomfort escalates rapidly. Moisture sensing allows systems to respond before saturation occurs.

Moisture sensors can:

- Detect the first appearance of sweat

- Track how moisture spreads across zones

- Identify areas where evaporation is insufficient

| Moisture Insight | Fabric or System Response |

|---|---|

| Early sweat detection | Enhanced evaporation pathways |

| Localized buildup | Zoned ventilation or mesh activation |

| Excess humidity | Cooling response or airflow increase |

In advanced garments, this data may also be transmitted externally—to a smartwatch, phone, or training system—allowing the wearer or coach to adjust intensity, posture, or rest timing.

From a comfort perspective, the key benefit is prevention. The wearer avoids the heavy, clammy phase where fabric sticks to skin and thermal stress accumulates.

Temperature sensing beyond “hot” or “cold”

Thermal sensors in spandex garments do not simply report absolute temperature. Their value lies in tracking change over time.

Key parameters include:

- Skin temperature trend (rising or falling)

- Rate of temperature increase

- Recovery speed after exertion

These measurements are more informative than a single temperature reading. A stable temperature trend often indicates efficient heat dissipation, while a rapid rise signals thermal overload.

| Thermal Pattern | Wearer Benefit |

|---|---|

| Stable temperature | Sustained comfort and endurance |

| Rapid rise detected | Early overheating prevention |

| Gradual cooling | Recovery support and reduced fatigue |

This is especially relevant in intermittent activity—sports, industrial work, or daily commuting—where the body repeatedly transitions between exertion and rest. Traditional fabrics respond slowly to these changes; sensor-enabled spandex responds in real time.

The role of zoned sensing and fabric response

Human bodies do not sweat or heat evenly. High-output zones such as the back, chest, underarms, and lower spine behave very differently from arms or legs.

Spandex garments allow sensors to be placed strategically in these zones without compromising fit. Zoned sensing enables localized responses rather than global adjustments.

For example:

- Increased ventilation in the upper back while maintaining insulation elsewhere

- Moisture management focused on high-sweat regions

- Thermal regulation that adapts to posture and movement

This targeted approach reduces unnecessary cooling, which can otherwise lead to chill and discomfort after activity stops.

Why sensor placement accuracy depends on stretch behavior

Sensor accuracy is not determined only by electronics. It is equally dependent on fabric mechanics.

Because spandex stretches and recovers with the body:

- Sensors stay aligned with anatomical landmarks

- Contact pressure remains consistent

- Signal delay is minimized

| Fabric Fit | Sensor Accuracy |

|---|---|

| Loose | Inconsistent, delayed |

| Rigid | Stable but uncomfortable |

| Spandex-based | Optimal balance |

Stretch is therefore not just about comfort. It is about signal fidelity—the accuracy and reliability of the data collected.

Poor fit leads to false positives, delayed detection, or missed events. Spandex minimizes these risks.

Performance benefits in athletic and professional use

In performance environments, thermal and moisture sensors support decision-making under stress.

For athletes, benefits include:

- Avoiding overheating before performance drops

- Managing hydration and pacing

- Optimizing recovery between intervals

For industrial or field workers, benefits include:

- Identifying heat stress risk early

- Reducing fatigue during long shifts

- Supporting compliance with safety thresholds

In both cases, the garment acts as a passive monitoring layer, requiring no conscious input from the wearer. Comfort and performance improve not because the wearer thinks about the data, but because the system responds early.

Everyday comfort: long-duration, low-intensity scenarios

Sensor-enabled spandex garments are not limited to sports or extreme environments. Their impact is often more subtle—but equally valuable—in everyday wear.

Common scenarios include:

- Long commutes with changing temperatures

- Office environments with uneven air conditioning

- Travel involving extended sitting and movement

In these cases, discomfort builds slowly. Traditional fabrics respond only after the wearer feels hot, cold, or damp. Sensor-integrated garments detect micro-changes early and help maintain equilibrium.

The result is reduced thermal fatigue—an often overlooked contributor to discomfort, irritability, and reduced concentration.

Comfort as stability, not sensation

A critical shift enabled by smart textiles is redefining comfort. Comfort is no longer a static sensation (“this feels cool”) but a dynamic stability state.

Thermal and moisture sensors help maintain this stability by:

- Preventing spikes rather than correcting extremes

- Supporting smooth transitions between states

- Reducing the frequency of discomfort events

This is why many users describe sensor-enabled garments as feeling “effortless” rather than noticeably different. The system works in the background.

Data use without intrusion

One concern with smart garments is the risk of over-engineering or intrusive feedback. Effective systems avoid this.

Well-designed spandex-based sensing garments:

- Do not require user interaction during wear

- Do not distract with constant alerts

- Provide value through passive regulation

When external data access is enabled, it is typically optional and post-use, supporting analysis rather than real-time interruption.

This balance is essential. The goal is to augment awareness, not replace natural bodily signals.

Durability and wash performance considerations

From a practical standpoint, sensor-integrated spandex garments must withstand repeated stretching, laundering, and drying.

Spandex supports this by:

- Distributing mechanical stress across the fabric

- Reducing point loading on sensor elements

- Maintaining dimensional stability after wash cycles

Moisture and thermal sensors designed for textile integration are typically encapsulated or printed in flexible formats, allowing them to bend and stretch with the garment rather than resisting movement.

This mechanical compatibility directly affects long-term comfort. Sensors that stiffen or degrade quickly create pressure points and reduce wearability.

Limitations and realistic expectations

Thermal and moisture sensors do not override physiology. They cannot stop sweating or eliminate heat generation. Their role is anticipation and moderation.

Key limitations include:

- Dependence on proper garment fit

- Reduced effectiveness if airflow is restricted externally

- Requirement for well-designed integration, not add-on components

Poorly designed smart garments can feel heavy, rigid, or distracting. Effective ones feel almost invisible.

Critical perspective: support, not substitution

Smart sensing garments work best when they support the body’s natural regulation, not attempt to control it completely.

The most successful designs:

- Enhance natural cooling mechanisms

- Reduce delay between physiological change and response

- Maintain comfort without demanding attention

In this sense, thermal and moisture sensors in spandex garments function like a skilled assistant—quiet, responsive, and largely unnoticed.

Strategic takeaway

Thermal and moisture sensors integrated into spandex garments improve wearer performance and comfort by stabilizing body conditions rather than reacting to discomfort after it occurs. Spandex enables accurate sensing through consistent skin contact, while sensor data supports early, localized responses to heat and moisture buildup.

The real value is not novelty, but reliability over time—sustained comfort, reduced fatigue, and better performance across both high-intensity and everyday use. When designed correctly, these garments do not feel “smart.” They simply feel right.

What materials and conductive elements are used to enable sensing and regulation in smart spandex?

Smart spandex is a revolutionary fabric that combines the elasticity of traditional elastane with functional technologies like temperature regulation, biometric sensing, and data transmission. To enable these capabilities, smart spandex integrates a range of materials, each playing a crucial role in maintaining the fabric’s primary function as a flexible, comfortable textile while also introducing the technology required for active sensing or regulation.

In smart spandex, materials must behave like textiles first—and electronics second. This ensures that the fabric can still stretch, recover, and conform to the body like traditional spandex while supporting complex, integrated functions like sensing or thermal regulation.

Core Material Building Blocks in Smart Spandex

The key to smart spandex lies in the interaction between several material categories, each carefully chosen for its unique properties. These materials must not only work in harmony with elastane fibers to ensure comfort, but also incorporate conductive elements and functional coatings to enable smart features without compromising stretch or durability.

| Material Category | Function |

|---|---|

| Spandex (Elastane) | Provides stretch and recovery, forming the fabric’s core elastic properties |

| Base Fibers (Nylon/Polyester) | Add structure, durability, and improve the overall mechanical properties of the fabric |

| Conductive Yarns | Enable signal transmission and sensing capabilities within the fabric |

| Functional Coatings | Offer thermal regulation or moisture-wicking properties, allowing the fabric to respond to environmental conditions |

| Encapsulation Layers | Protect sensitive conductive and functional materials, ensuring durability and washability |

Each layer or component plays a distinct role in maintaining the overall functionality and wearability of the fabric. In the construction of smart spandex, the compatibility of these layers is essential—materials must be engineered to stretch and recover without compromising the embedded electronics or thermal functions.

Conductive Yarns: The Backbone of Textile Sensing

Conductive yarns are one of the most essential components of smart spandex, enabling the textile to perform functions such as biometric sensing, motion detection, or even electrical signal transmission.

Conductive yarns are integrated with traditional fibers (like spandex, nylon, or polyester) and provide the necessary electrical properties while maintaining the overall elasticity and flexibility of the fabric. There are several types of conductive yarns, each offering unique advantages depending on the intended application:

| Type | Characteristics |

|---|---|

| Silver-coated Yarns | Highly conductive, soft, and ideal for short-range applications like capacitive sensing or electrical signal transmission. |

| Carbon-based Yarns | Flexible and stable under repeated deformation, often used in applications that require consistent conductivity over time. |

| Conductive Polymers | Lightweight and tunable, these materials are ideal for integrating into textiles where weight and stretchability are critical. |

| Hybrid Yarns | A combination of two or more conductive materials, balancing cost, performance, and durability for practical use in large-scale production. |

Silver-coated yarns dominate the early stages of smart spandex production because of their excellent conductivity, but carbon-based yarns are becoming increasingly popular for their durability, cost efficiency, and stable long-term performance. Conductive polymers and hybrid yarns also offer opportunities for creating cost-effective, flexible smart fabrics that maintain electrical functionality while still being comfortable to wear.

Thermal-Regulating Materials

One of the key features of smart spandex is its ability to respond to environmental changes, particularly temperature. To enable this, phase-change materials (PCMs), thermo-responsive polymers, and moisture-activated coatings are integrated into the fabric. These materials allow smart spandex to regulate body temperature, enhance comfort, or improve performance under varying environmental conditions.

Thermal-regulating smart spandex often includes:

- Phase-change microcapsules (PCMs): These materials absorb, store, and release heat based on changes in temperature, keeping the wearer’s body temperature stable in fluctuating conditions.

- Thermo-responsive polymer finishes: These polymers change their structure or properties when exposed to heat, allowing the fabric to expand or contract to adjust to the wearer’s needs.

- Moisture-activated cooling finishes: These coatings enhance cooling through evaporation, particularly in high-sweat areas.

| Material | Response Mechanism |

|---|---|

| PCMs (Phase-change Materials) | Absorb heat when the fabric gets too warm, then release it when it cools down, maintaining a stable temperature for the wearer. |

| Smart Polymers | Change shape or structure in response to temperature shifts, allowing the fabric to adapt and provide enhanced comfort. |

| Cooling Finishes | Enhance evaporation, promoting cooling when the fabric is exposed to sweat or humidity. |

These materials must be engineered to survive stretching and mechanical deformation, which is a significant challenge. For example, phase-change materials must be encapsulated in a way that they do not crack or leak during wear, ensuring they continue to perform without sacrificing fabric flexibility.

Dive Deeper: Why Material Compatibility Is the Hardest Problem

Creating smart spandex requires balancing the inherent conflicts between the traditional textile properties and the need for embedded electronics or functional coatings. Material compatibility is the hardest challenge in designing smart textiles because these materials often have conflicting demands:

- Electrical conductivity vs. elasticity: Conductive materials, like silver-coated yarns or carbon-based fibers, can be rigid and may hinder the stretchability of the fabric. Therefore, conductive materials must be carefully integrated into the fabric to allow for both electrical functionality and sufficient flexibility.

- Coating adhesion vs. stretch: Functional coatings, such as thermal finishes or moisture-wicking layers, must adhere well to the fabric. However, excessive adhesion can limit the fabric’s ability to stretch or cause coatings to crack under repeated deformation.

- Wash durability vs. softness: Encapsulation layers protect sensitive conductive or functional elements from washing, but thicker encapsulations can make the fabric stiffer or less comfortable.

The smart textile designer’s challenge is to find the right balance, using design compromises that make the fabric functional without compromising comfort, flexibility, or wearability.

| Conflict | Design Compromise |

|---|---|

| Rigid Conductors | Reduced stretch zones in specific areas where electrical conductivity is needed, such as around sensors or conductive pathways. |

| Soft Coatings | Lower longevity in some cases, requiring more frequent replacement or care to maintain functionality. |

| Strong Encapsulation | Increased stiffness, which can affect the fabric’s overall feel and flexibility, particularly when large areas of functional material are encapsulated. |

Human-Centered Takeaway

The best smart spandex fabrics should feel seamless, not “engineered.” While the presence of technology in the fabric is essential for functionality, the wearer should not notice the difference between wearing regular stretchwear and smart fabric.

Smart spandex must remain soft, flexible, and comfortable. If the fabric feels stiff, scratchy, or heavy, the material system has failed, regardless of how advanced the sensing or temperature-regulation technologies are. Therefore, achieving invisibility in performance—making the technology feel natural—is a hallmark of a successful smart textile.

The Future of Smart Spandex

As manufacturers continue to develop new methods for integrating conductive elements, thermal regulation, and sensing technologies into smart spandex, we can expect more innovative applications in sportswear, medical garments, wearables, and beyond. The key to success in this emerging field will be finding the right materials and ensuring their compatibility with the core properties of spandex, ensuring both comfort and functionality are delivered without compromise.

How are smart spandex textiles manufactured and what challenges arise during production?

The production of smart spandex textiles integrates traditional fabric manufacturing with advanced textile technology. These textiles contain embedded conductive yarns or temperature-regulating materials, and their manufacturing processes must accommodate both elasticity and electrical functionality. As a result, smart spandex production presents a set of unique challenges—particularly around sensor durability, elasticity maintenance, and achieving consistency at scale.

Smart spandex is not a simple extension of conventional spandex production. It is a hybrid process combining textile engineering with electronics, requiring precise control at each stage to ensure both fabric comfort and reliable performance.

Key Manufacturing Stages

The production of smart spandex involves a series of steps, each with its own technical requirements:

| Stage | Smart-Specific Requirement |

|---|---|

| Yarn preparation | Tension matching to prevent damage to conductive yarns |

| Knitting/weaving | Accurate placement of sensors or conductive threads |

| Dyeing/finishing | Protect conductivity during processing |

| Heat setting | Ensure elasticity is preserved after conductive integration |

| Testing | Combined electrical and textile performance checks |

At each step, manufacturers must consider how the fabric will behave under stretch and ensure that the added sensors or conductive elements do not interfere with the fabric’s inherent properties, such as elasticity or comfort.

Yarn Preparation and Conductive Yarns

Smart spandex textiles typically integrate conductive fibers or sensor threads into the yarn, a step that requires careful tension control. Conductive yarns behave differently from standard fibers:

- Lower elongation: Conductive fibers are generally less stretchable than spandex, so they must be carefully tensioned to prevent breakage.

- Higher friction: These fibers have more friction than traditional fibers, which makes it harder for them to glide smoothly during production.

- Sensitivity to tension: Too much tension can damage the conductive threads, while too little tension leads to poor integration with the stretch fabric.

| Issue | Result if Uncontrolled |

|---|---|

| Over-tension | Yarn breakage, leading to downtime and waste |

| Uneven feed | Signal inconsistencies or dropouts in data transmission |

| Misplacement | Distorted or inaccurate data collection |

Specialized machines and experienced operators are needed to manage the tension and placement of conductive yarns. If the sensors are improperly integrated, it can lead to signal loss or distorted data, which would render the fabric unusable for its intended purpose.

Knitting and Weaving Challenges

The knitting or weaving stage is where conductive threads or sensors are integrated into the fabric. Precision is essential:

- The placement accuracy of these threads determines the functionality of the final product.

- Improper placement of conductive yarns can lead to signal interference or disconnections.

Because spandex is a stretch fabric, the integration of conductive elements without compromising the elasticity of the fabric is a delicate process. The stretching of the fabric can cause the conductive threads to stretch and break, or it can alter their placement, which negatively impacts the fabric’s electronic properties.

Dyeing and Finishing Limitations

Dyeing and finishing processes, commonly used to enhance the appearance and texture of fabrics, can pose significant risks when working with smart spandex textiles:

| Process | Risk |

|---|---|

| High-temperature dyeing | Can degrade the conductivity of embedded sensors or yarns |

| Aggressive chemicals | May damage the protective coatings of conductive threads |

| Over-relaxation | Can cause sensor drift, reducing the effectiveness of the smart fabric |

Unlike conventional fabrics, smart spandex textiles require a different approach to dyeing and finishing. High temperatures used during dyeing or finishing processes can damage the integrity of the conductive components. Some chemicals, like bleach or harsh solvents, can degrade or strip away the conductive properties of the fibers, leaving them ineffective for data transmission.

As a result, many manufacturers must redesign their dyeing and finishing processes, using lower-temperature dyeing methods, mild chemicals, or specially designed protective coatings to safeguard the conductive elements.

Scaling from Lab to Production

Many smart spandex concepts work well in prototype or lab conditions, but they fail during large-scale production. Some common challenges in scaling up include:

| Lab Success | Production Reality |

|---|---|

| Small batches | Continuous runs, requiring constant quality and process control |

| Manual control | Automated variability, which requires more precise monitoring |

| Gentle handling | Industrial-scale stresses from high-speed machinery |

In lab environments, production is typically slower and more controlled, with each step being fine-tuned to avoid errors. However, in industrial settings, smart spandex is processed at a much larger scale. This introduces challenges such as:

- Inconsistent feeding or tensioning of yarns during high-speed machine operations

- Variability in sensor placement, especially when production runs become larger

- Increased stress on the fabric, which can cause damage to the conductive components over time

To meet these challenges, manufacturers need to simplify the technology for mass production without sacrificing performance. Ensuring consistent electrical and textile performance at scale requires robust quality control systems, process automation, and real-time monitoring.

Quality Control (QC) in Smart Spandex Textiles

Quality control becomes far more complex when both mechanical and electrical properties are evaluated. Not only must the fabric perform like regular spandex (flexibility, stretch, comfort), but it must also retain its sensor functionality under everyday conditions. QC processes must test both stretch–recovery and electrical resistance to ensure reliable performance.

QC for smart spandex textiles includes:

- Stretch and recovery testing: Ensures the fabric maintains its elasticity without damaging embedded sensors or wires.

- Electrical resistance testing: Verifies that the conductive threads are still transmitting data effectively after fabrication and finishing.

- Wash durability cycles: Evaluates how well the smart spandex textile retains its properties after repeated washing.

- Sensor signal validation: Checks that the embedded sensors remain functional and accurate after processing.

| QC Area | Purpose |

|---|---|

| Mechanical | Ensures the fabric maintains comfort, stretch, and recovery |

| Electrical | Confirms the functionality of embedded sensors and wiring |

| Environmental | Assesses durability and long-term reliability under wash and wear conditions |

These tests require specialized equipment and skilled operators who can distinguish between functional wear and failure.

Challenges in Maintaining Elasticity

Maintaining elasticity in smart spandex textiles is a critical concern because conductive fibers and sensors generally have different stretch properties compared to traditional spandex fibers. If the conductive elements lose their elasticity, the fabric can lose its shape or break under stress.

To maintain elasticity, manufacturers may:

- Use blends of elastane with other materials to preserve flexibility

- Apply coatings that protect the sensors while allowing fabric stretch

- Test pre-stretching before integrating sensors to ensure the fabric’s recovery after stretching

Practical Insight: Balancing Technology and Comfort

Incorporating technology into spandex fabrics without compromising comfort is a delicate balance. Smart textiles need to be both functional and wearable, meaning that comfort should not be sacrificed for performance.

Manufacturers face the challenge of producing fabrics that not only work as electronic textiles but also meet consumer expectations for comfort, softness, and breathability.

Overcoming Production Challenges

The manufacturing of smart spandex textiles is a complex, multi-stage process that involves balancing electrical functionality with textile performance. Key challenges include maintaining elasticity and comfort, protecting sensors during dyeing and finishing, and ensuring consistent product quality across high-volume production runs.

To overcome these challenges:

- Manufacturers must adapt traditional spandex production methods to incorporate advanced textile technologies.

- Strict quality control protocols must be in place to monitor both mechanical and electrical properties.

- Innovations in material science—such as better conductive fibers or optimized finishing treatments—can help streamline production while maintaining fabric performance.

As technology improves, the production of smart spandex will become more efficient, scalable, and accessible for a variety of applications, from fitness wear to medical textiles and beyond. By addressing these challenges head-on, manufacturers can ensure that smart spandex textiles meet both functional and aesthetic expectations for consumers.

7. How do smart spandex applications differ across sportswear, medical textiles, and wearable tech?

Smart spandex is an incredibly versatile material, capable of supporting a wide range of functionalities depending on the application. Whether it’s used in sportswear, medical textiles, or wearable technology, the demands on the material and the sensors it carries vary significantly. Each sector has its own set of performance intensity, data accuracy needs, and user requirements, and as a result, the design, integration, and usage of smart spandex differ to meet those specific goals.

The same material platform—spandex—serves very different purposes depending on whether it’s intended to track a marathon runner’s movement, monitor a patient’s recovery, or serve as the interface for smart wearable devices. Below, we break down how smart spandex adapts for each use case.

Sportswear: Adaptive Comfort and Performance Feedback

In sportswear, smart spandex is designed to support athletic performance, comfort, and mobility. It’s essential that the fabric adapts to the body during movement, providing real-time feedback while also maintaining comfort over long periods of wear. Sensors in sportswear are typically focused on monitoring physical exertion and enhancing performance without disrupting the wearer’s movements.

Key Focus Areas for Sportswear Applications:

- Comfort: Given that athletes and fitness enthusiasts wear these garments for extended periods, comfort is paramount. Smart spandex needs to be lightweight, breathable, and non-restrictive.

- Data Accuracy: Data accuracy requirements in sportswear are moderate, as slight deviations from perfect precision are often tolerable for most fitness activities. However, motion, posture, or exertion must be reliably tracked.

- Wash Durability: High durability is critical. Sportswear undergoes frequent washing, so the sensors embedded within the spandex need to be resistant to wear and tear over time.

- Weight and Softness: As with all performance apparel, weight and softness are crucial. Smart spandex must remain comfortable and flexible, without feeling bulky or cumbersome.

| Priority | Sportswear Focus |

|---|---|

| Comfort | Very high |

| Data accuracy | Moderate |

| Wash durability | High |

| Weight & softness | Critical |

Smart spandex in this category is typically engineered to be as lightweight as possible while still embedding sensors that track things like movement, heart rate, and body temperature. Think of compression garments, running shorts, or sports bras designed with integrated sensors to monitor exertion levels or posture correction.

Medical Textiles: Precision and Consistency

In medical and therapeutic applications, precision and reliability are paramount. Smart spandex garments in this space are designed for long-term wear, usually for patients who require continuous monitoring for health conditions such as muscle rehabilitation, pressure monitoring in compression garments, or joint mobility tracking in recovery garments.

Key Focus Areas for Medical Applications:

- Measurement Accuracy: Extremely high. Data collected from medical textiles must be accurate for both diagnostics and therapeutic interventions. Medical professionals rely on precise feedback to adjust treatments or recovery plans.

- Stability Under Wear: These garments are meant for extended wear over long periods, so they must remain consistent and stable during prolonged use, even when exposed to physical strain.

- Repeatability: The ability to maintain consistent, reliable data over time is critical. Medical devices built into smart spandex must not experience drift or variability.

- Regulatory Compliance: Many medical textiles are subject to strict regulatory standards such as FDA approval for medical devices. This necessitates extra care in design, material selection, and compliance with clinical protocols.

| Priority | Medical Focus |

|---|---|

| Measurement accuracy | Very high |

| Stability under wear | Very high |

| Repeatability | Critical |

| Regulatory compliance | Essential |