Which Is Better, 420D or 600D Oxford Fabric?

In the world of textiles, especially for B2B buyers sourcing outdoor gear, bags, or covers, choosing the right Oxford fabric can feel like a gamble—especially when trying to decide between 420D and 600D. These two denier ratings are often lumped together, but they serve very different purposes. A lighter 420D Oxford might be perfect for mobility and cost-saving, while 600D offers strength and structure that withstands harsh conditions. If you’re managing product development, procurement, or quality control, understanding this comparison isn’t just helpful—it’s critical.

420D Oxford is lighter, softer, and more flexible, making it ideal for lightweight bags or rain covers, while 600D Oxford is more rugged and abrasion-resistant, better suited for backpacks, tactical gear, and heavy-duty covers. Which one is better depends entirely on your use case, durability expectations, and cost-performance ratio.

In this article, we’re not just comparing specs—we’re walking through real applications, performance tests, sourcing challenges, and business implications to help you make the right decision for your supply chain. Let’s start with the fundamentals: what “D” actually means.

1. What Does Denier (D) Mean in Oxford Fabric and Why Does It Matter?

Denier refers to the thickness and weight of the individual threads used in the fabric weave. In Oxford fabric, it plays a huge role in determining strength, abrasion resistance, flexibility, and total weight.

Denier (D) in Oxford fabric indicates the thickness of the yarn—higher denier means heavier, more durable fabric. 420D is lighter and more pliable, while 600D is thicker, tougher, and more resistant to wear and tear.

Understanding Denier in Context

a. Definition & Technical Explanation

- 1 denier = the mass in grams of 9,000 meters of the yarn

- 420D = 420 grams per 9,000 meters

- 600D = 600 grams per 9,000 meters

b. Performance Comparison Table

| Feature | 420D Oxford | 600D Oxford |

|---|---|---|

| Yarn Thickness | Medium-light | Medium-heavy |

| Fabric Weight (GSM) | 140–180 gsm | 180–220 gsm |

| Durability | Moderate | High |

| Flexibility | High | Moderate |

| Abrasion Resistance | 3,000–8,000 cycles | 10,000–15,000 cycles |

| Coating Compatibility | PU, TPU | PU, PVC, TPU |

c. Why This Matters for Buyers

- If you’re sourcing for lightweight drawstring bags, 420D is often sufficient and more affordable.

- If you need military pouches, tool bags, or luggage, 600D provides the extra strength your customer demands.

d. Case Insight: Choosing Denier for a European Gym Brand

A European gym equipment startup tested both 420D and 600D Oxford for their duffel bag collection. Lab tests showed:

- 420D failed after 6,200 Martindale abrasion cycles

- 600D endured over 12,000 cycles before thread weakening The final choice? 600D Oxford with a PU backing for long-term durability in locker rooms and outdoor use.

2. How Are 420D and 600D Oxford Fabrics Made Differently?

Both 420D and 600D Oxford fabrics are typically woven in a basket weave style but use different yarn thicknesses and often go through different coating and finishing processes to match their use-case performance.

The core difference in manufacturing lies in the denier of the yarn used and the type and number of coating layers applied—600D requires thicker yarn and often has stronger coatings like PVC for added durability.

Comparing Manufacturing Process

a. Raw Material Differences

- Both 420D and 600D are usually made from polyester filament yarns

- 600D yarns are heavier and more resistant to stretch or fray

- 420D is often produced with finer yarn, allowing for tighter weave density and smoother texture

b. Weaving and Finishing Workflow

| Process Stage | 420D Oxford Fabric | 600D Oxford Fabric |

|---|---|---|

| Yarn Sourcing | 420D polyester filament | 600D polyester filament |

| Weaving | 2×2 or 2×1 basket weave | 2×2 basket weave (denser) |

| Dyeing | Jet dyeing or piece dyeing | Jet dyeing or pigment printing |

| Coating | Single-layer PU/TPU | Double-layer PU or PVC |

| Finishing | Calendaring, anti-fray | Waterproofing, anti-UV, IR resistance |

c. Case Study: SzoneierFabrics 600D Production

At SzoneierFabrics, our 600D Oxford is:

- Woven with UV-resistant 600D filament polyester

- Coated with double PU (≥1,000mm water column)

- Inspected using ISO 105-B02 for colorfastness and SGS abrasion tests

- MOQ: 100 meters | Lead Time: 5–7 days for custom shades

d. Why This Matters in Real-World Production

If your product will face frequent friction (like in travel luggage or toolkits), 600D’s tougher weave and thicker coating reduce the risk of tearing and coating flake-off. On the other hand, if flexibility and lighter shipping weight matter, 420D is faster and cheaper to manufacture with excellent drape.

3. Which Is Stronger: 420D or 600D Oxford Fabric?

When it comes to strength, 600D Oxford fabric clearly outperforms 420D due to its thicker yarn structure, denser weave, and enhanced coating potential. While 420D is still strong enough for many consumer goods, it doesn’t match the durability required for heavy-duty applications.

600D Oxford fabric is stronger than 420D in tensile strength, tear resistance, and abrasion endurance—making it the better choice for demanding use in backpacks, luggage, and tactical gear.

Evaluating Fabric Strength in Detail

a. Test Benchmarks: 420D vs. 600D

| Strength Metric | 420D Oxford Fabric | 600D Oxford Fabric |

|---|---|---|

| Tensile Strength | 800–1000 N (warp) | 1200–1600 N (warp) |

| Tear Resistance | 10–18 N | 18–25 N |

| Abrasion Resistance | 6,000–8,000 Martindale | 12,000–15,000 Martindale |

| Puncture Resistance | Moderate | High |

Values based on SGS test data (PU-coated samples)

b. Stress Test Example: Outdoor Tent Base Material

A U.S.-based outdoor gear supplier ran a side-by-side test:

- 420D sample failed after 4 months of UV exposure and ground abrasion

- 600D retained its coating and structure for 8+ months under same conditions

Result: 600D was used for base panels, while 420D was retained for sidewalls to save weight.

c. When Is 420D “Strong Enough”?

While 600D excels in strength, 420D is often “strong enough” for:

- Laptop sleeves

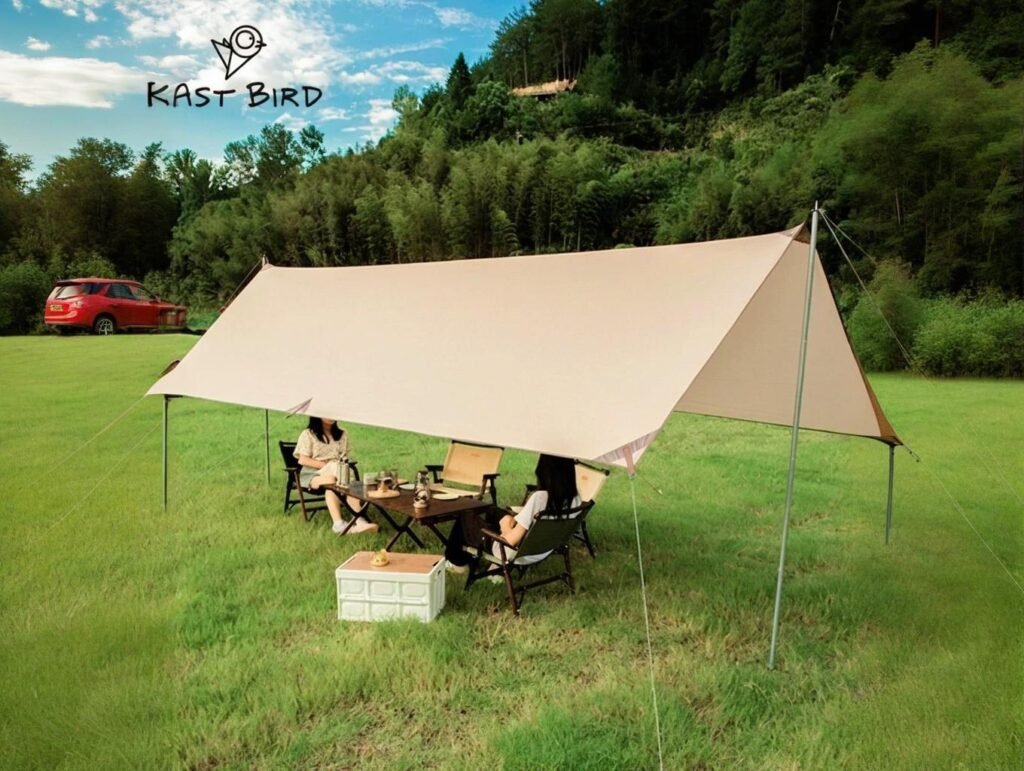

- Packable duffel bags

- Rainfly and canopies In these cases, the reduced material weight improves foldability and user comfort.

d. Tactical vs Lightweight Strategy

For military-grade or tactical bags, durability takes priority → 600D wins. For fashion or urban gear where design and portability matter more → 420D is often preferable.

4. Is 420D or 600D More Waterproof and Weather-Resistant?

Waterproofing in Oxford fabric is not solely dependent on the denier—it’s a result of the coating applied. However, 600D typically receives thicker PU or PVC coatings, making it more water-resistant and resilient against prolonged exposure.

600D Oxford fabric is generally more waterproof and weather-resistant due to thicker yarn, higher-density weave, and enhanced coating adhesion. It holds up better in wet, cold, or abrasive environments.

Coating Types and Environmental Resistance

a. Coating Methods Commonly Used

| Coating Type | Features | Compatibility |

|---|---|---|

| PU (Polyurethane) | Lightweight, flexible, cost-effective | Both 420D and 600D |

| PVC (Polyvinyl Chloride) | Thick, tough, excellent waterproofing | Mostly for 600D |

| TPU (Thermoplastic Polyurethane) | Eco-friendly, highly waterproof | Premium 600D use |

| Silicone | Extremely water-repellent, rare use | Custom 420D |

b. Waterproofing Performance Chart

| Fabric Type | Coating Type | Hydrostatic Pressure Rating (mm) | Durability |

|---|---|---|---|

| 420D PU | Single-layer PU | 800–1200 mm | Medium |

| 600D PU | Double-layer PU | 1000–1500 mm | High |

| 600D PVC | PVC | 1500–3000 mm | Very High |

Source: Szoneier internal lab testing, 2024

c. Real-World Test: Sourcing for Marine Covers

A South African boat accessory brand sourced both 420D and 600D for marine engine covers:

- 420D lasted 9–10 months before hydrolysis caused peeling

- 600D with double PU coating lasted 2 years and passed a 5,000-hour salt spray exposure test

The final order? 600D with UV + anti-mildew treatment, custom coated by SzoneierFabrics.

d. Climate-Specific Selection

- For humid, rainy environments: 600D is better due to greater waterproof layer thickness

- For dry, indoor environments: 420D can be sufficient if coated properly

5. What Are the Main Use Cases for 420D vs 600D in Bags, Tents, and Covers?

420D and 600D Oxford fabrics serve distinct purposes based on their durability, weight, and coating properties. Selecting the right one depends on the specific functional demands of your end product.

420D Oxford is commonly used for lightweight products like travel accessories, canopies, and rain covers, while 600D is the industry standard for backpacks, tactical gear, luggage, and outdoor furniture covers due to its superior durability.

Use Case Breakdown by Application

a. Oxford Fabric Use Case Matrix

| Application Type | Recommended Fabric | Reason |

|---|---|---|

| School Backpacks | 600D | High abrasion, daily use, load-bearing |

| Travel Duffel Bags | 600D | Requires structure, water-resistance |

| Rain Covers | 420D | Lightweight, foldable, water-shedding |

| Tent Rainfly | 420D | Light, flexible, easy to pitch |

| Tent Floor | 600D or 1680D | Needs high durability, puncture resistance |

| Camping Chairs | 600D | Structural stability and frequent friction |

| Luggage Linings | 420D | Flexibility and reduced bulk |

| Pet Carriers | 600D | Load-bearing and scratch resistance |

b. Buyer Insights: What Brands Choose

- Outdoor Brands (like Coleman or Quechua): 420D for rainfly, 600D for flooring

- Tactical Brands (like 5.11 Tactical): 600D with PU or PVC for load-bearing bags

- Corporate Gift Brands: 420D for lightweight promotional backpacks due to lower cost

c. Case Study: OEM Orders at SzoneierFabrics

In 2024, a German e-commerce bag brand ordered:

- 420D PU Oxford for foldable gym bags

- 600D PVC Oxford for rugged tactical sling bags Both lines were designed and manufactured by SzoneierFabrics, with logo printing and water-repellent treatments. Their reorder rate was 89% after launch due to positive customer reviews on fabric durability.

d. Product Fit Tips

- Want to reduce shipping cost? Go for 420D (less weight = less freight)

- Want to raise perceived product quality? Use 600D with branded PU or PVC coating

6. Do 420D and 600D Oxford Fabrics Differ in Cost, MOQ, and Lead Time?

Yes, 420D is generally cheaper to produce, lighter to ship, and often available with lower minimum order quantities. In contrast, 600D—being heavier and more industrial-grade—tends to have a slightly higher price point but also greater perceived value.

420D Oxford fabric is more cost-efficient and ideal for smaller MOQs or promotional runs, while 600D Oxford, though slightly more expensive, offers stronger durability for long-term or premium use.

Cost & Sourcing Comparison

a. Cost per Meter Comparison (2024 Factory Pricing)

| Fabric Type | Average Price (PU Coated) | MOQ at SzoneierFabrics | Lead Time |

|---|---|---|---|

| 420D Oxford | $0.65–$0.90/meter | 100 meters | 3–7 business days |

| 600D Oxford | $0.85–$1.15/meter | 100 meters | 5–10 business days |

Note: Prices vary depending on coating (PU/PVC/TPU), custom dyeing, and print.

b. How MOQ Affects Decision-Making

- 420D is often used in lower-MOQ promotional bags, where cost per unit is critical

- 600D, despite higher cost, allows for higher perceived product value, justifying a price markup for resale or retail

c. Logistics Cost Comparison

Heavier 600D means:

- Slightly higher freight cost per roll

- Requires more robust packaging (especially if PVC coated) But may save long-term by reducing returns from fabric failure

d. Buyer Profile Comparison

| Buyer Type | Recommended Fabric | Why |

|---|---|---|

| New E-commerce Brand | 420D | Lower risk, faster production |

| Government/Tactical Order | 600D | Performance + specs |

| Promotional Gifting Firm | 420D | Lightweight, cheap, fast |

| Mid-size Luggage OEM | 600D | Rugged build, durability focus |

7. Which One Offers Better Printability and Color Retention?

Both 420D and 600D Oxford fabrics can be printed using standard methods like screen printing, heat transfer, or sublimation. However, 420D tends to offer a smoother surface for finer prints due to its finer yarn and tighter weave, while 600D is better suited for bold logos and high-contrast graphics.

420D Oxford generally provides better printability and color precision, while 600D Oxford holds color longer under rugged use and repeated exposure. The best choice depends on the intended environment and design complexity.

Printing & Dye Performance Analysis

a. Print Compatibility by Fabric Type

| Method | 420D Oxford | 600D Oxford | Notes |

|---|---|---|---|

| Screen Printing | ✅ | ✅ | Works well on both, better detail on 420D |

| Sublimation | ✅ (with white base) | ❌ | 420D (polyester) can absorb dye via heat |

| Heat Transfer | ✅ | ✅ | 600D requires stronger pressure and temp |

| UV Digital Print | ✅ | ✅ | High-end custom options; surface prep needed |

b. Colorfastness Ratings (ISO 105 Tests)

| Fabric Type | Colorfastness to Washing | Colorfastness to Light | Notes |

|---|---|---|---|

| 420D Oxford PU | 4–5 | 3–4 | Slight fade in UV exposure |

| 600D Oxford PU | 4–5 | 4–5 | Holds up well outdoors |

Test results based on 2023 SGS reports (standard PU coating)

c. Design Use Case Comparison

- 420D: Great for custom branding, intricate patterns, color gradients

- 600D: More durable for bold logos on outdoor gear, backpacks, tactical wear

d. Case Study: B2B Promotional Goods Supplier

A Canadian promotional firm requested:

- 420D for event totes and printed gym sacks (logo clarity a priority)

- 600D for co-branded daypacks used outdoors (needed long-lasting branding)

420D samples showed better edge sharpness and lower bleed, but required careful coating to avoid sublimation interference. For 600D, PVC-backed fabric needed silicone pre-treatment before heat transfer.

8. How Do You Choose Between 420D and 600D Oxford Fabric for Your Specific Product?

The best choice between 420D and 600D Oxford depends on your product’s intended use, target price point, brand positioning, and customer expectations. There is no universally “better” option—only what’s more fit for purpose.

Choose 420D if your product needs to be lightweight, low-cost, or highly printable. Opt for 600D when your focus is rugged use, outdoor conditions, or high-performance durability.

The Final Decision Matrix

a. Decision-Making Table for Buyers

| Buyer Goal/Constraint | Recommended Option | Reason |

|---|---|---|

| Lightweight product | 420D | Easier to carry, lower freight |

| Outdoor durability | 600D | Abrasion- and weather-resistant |

| Detailed printing | 420D | Finer yarn accepts small print elements |

| High-end bag or tactical gear | 600D | Better structure, brand perception |

| Small promotional batch | 420D | Lower MOQ, faster printing |

| Long-term retail line | 600D | Long-lasting durability |

b. Questions B2B Buyers Should Ask

- What’s the expected life cycle of the product?

- Will the product face frequent outdoor or heavy-duty use?

- Is branding or appearance more important than rugged performance?

- How sensitive is my client/customer to unit cost vs quality?

- What certifications or compliance standards do I need?

c. SzoneierFabrics Buyer Tip

We recommend:

- 420D Oxford for custom promotional goods, light gym bags, and soft-sided pouches

- 600D Oxford for OEM backpacks, military-grade gear, tactical packs, and seat covers

If unsure, request dual sampling and conduct small test runs using both. SzoneierFabrics offers free samples, low MOQ (100m), and expert guidance to help you make the best long-term sourcing decision.

Make the Right Choice with SzoneierFabrics

420D and 600D Oxford fabrics both have unique strengths—lightweight flexibility vs rugged endurance. By understanding the core differences in weave, performance, printability, and cost structure, you can align your sourcing decisions with your brand goals and customer expectations.

With over 18 years in Oxford fabric R&D and manufacturing, SzoneierFabrics helps B2B clients—from startups to established brands—source high-quality custom Oxford fabrics with short lead times, free design support, and certified quality.

Ready to request samples or a custom quote?Contact SzoneierFabrics now to get expert guidance and pricing tailored to your project needs.

Can't find the answers?

No worries, please contact us and we will answer all the questions you have during the whole process of bag customization.

Make A Sample First?

If you have your own artwork, logo design files, or just an idea,please provide details about your project requirements, including preferred fabric, color, and customization options,we’re excited to assist you in bringing your bespoke bag designs to life through our sample production process.