Which Is Better, Nylon or Oxford Fabric?

Nylon and Oxford fabric are two of the most widely used materials in the textile industry—particularly for backpacks, luggage, workwear, tents, and tactical gear. But when it comes to selecting the ideal fabric for your product, the choice isn’t as straightforward as it seems. Many buyers ask, “Which is stronger?” or “Which holds up better outdoors?” or “What’s more cost-effective for mass production?”—but the answer always depends on context, not just composition.

Nylon is a synthetic fiber known for its exceptional strength, abrasion resistance, and flexibility, while Oxford is a type of weave that can be made from nylon, polyester, or cotton. So, it’s not a matter of fiber vs fiber—but fiber vs fabric construction.

Understanding that distinction is the key to smart sourcing. In this article, we won’t just compare the specs—we’ll explore the manufacturing, real-world performance, use-case scenarios, and buyer-specific recommendations that influence your bottom line.

Let’s begin by decoding what exactly separates nylon from Oxford fabric—and why the difference matters so much in real-world applications.

1. What Is the Difference Between Nylon and Oxford Fabric in Terms of Composition and Weave?

Nylon is a synthetic polymer fiber, while Oxford is a fabric structure or weave type, not a fiber itself. In other words, Oxford fabric can be made from nylon, polyester, or cotton, depending on its intended use. The key distinction lies in the material (nylon vs polyester vs cotton) and how that material is woven.

Nylon is a raw fiber that offers high tensile strength and flexibility, whereas Oxford refers to a basket weave pattern often used to create versatile fabrics from different yarns like nylon or polyester.

Composition vs Construction

a. Definition Breakdown

| Term | Definition |

|---|---|

| Nylon | A synthetic fiber (polyamide) derived from petroleum |

| Oxford Fabric | A type of weave (basket weave), not a fiber |

b. Oxford Fabric Can Be Made From:

- Polyester (most common in 300D–600D versions for bags, covers)

- Nylon (1680D ballistic Oxford, tactical gear)

- Cotton or poly-cotton (for shirting and uniforms)

- Recycled PET (rPET) (for eco-conscious buyers)

c. Visual Comparison

| Feature | Nylon (Fiber) | Oxford Fabric (Weave) |

|---|---|---|

| Function | Base material | Structure of yarn interlacing |

| Appearance | Smooth, tight | Textured, visible basket weave |

| Flexibility | Very high | Depends on yarn type and weave tension |

| Common Uses | Ropes, jackets, gear webbing | Bags, tents, shirts, promotional products |

d. Case Example: Buyer Misconception

A U.S. startup ordered “nylon Oxford” assuming it meant 100% nylon. The supplier provided polyester Oxford (a common budget version). After testing, the fabric tore under stress. The takeaway: Always clarify if you mean nylon fiber or Oxford structure with nylon yarns.

2. Which Fabric Is More Durable and Abrasion-Resistant for Long-Term Use?

Nylon outperforms standard polyester Oxford in terms of abrasion resistance, tensile strength, and durability, especially under high-friction or heavy-load environments. However, Oxford fabrics made from nylon yarns—like 1680D ballistic Oxford—combine the strength of nylon with the versatility of the Oxford weave.

In most cases, nylon (especially in ballistic or ripstop form) is more durable than polyester-based Oxford fabric. But high-denier Oxford made from nylon yarns can match or exceed nylon’s ruggedness depending on coating and construction.

Fabric Strength and Longevity

a. Durability Comparison Table

| Property | Nylon 420D/840D | Oxford 600D Polyester | Oxford 1680D Nylon |

|---|---|---|---|

| Tensile Strength | Excellent (≥1200 N) | Moderate (900–1100 N) | Excellent (1400–1800 N) |

| Abrasion Resistance | Very high (≥20,000 cycles) | High (12,000–18,000 cycles) | Very high (25,000+ cycles) |

| Flex Retention | Excellent | Good | Excellent |

| UV Resistance (untreated) | Moderate | Higher than nylon | Moderate |

| Coating Compatibility | PU, TPU, silicone | PU, PVC | PU, TPU |

b. Which Holds Up in Harsh Use?

- For military bags and motorcycle gear → Ballistic nylon (1680D Oxford or Cordura)

- For daypacks and midweight luggage → 600D polyester Oxford with PU coating

- For lightweight promotional items → 300D polyester Oxford is sufficient

c. Real-Life Example: Backpack Manufacturer Test

A Malaysian backpack brand tested:

- 600D polyester Oxford (PU double-coated)

- 840D nylon plain weave

- 1680D ballistic Oxford nylon

Only 1680D nylon Oxford survived 30 kg drop test from 2 meters + abrasion cycles beyond 25,000. Nylon plain weave frayed at the edges. Polyester failed first at the shoulder strap seam.

3. How Do Nylon and Oxford Fabric Compare in Water Resistance and Coating Compatibility?

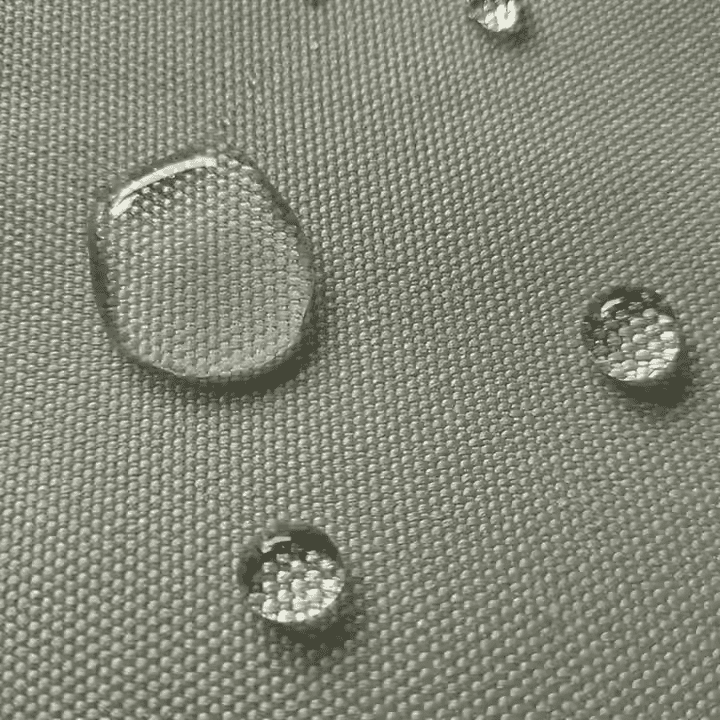

Both nylon and Oxford fabrics can be made highly water-resistant with proper coating, but polyester-based Oxford holds coatings like PU and PVC better over time, while nylon absorbs more moisture unless treated. Nylon, however, performs better in flexibility under cold or wet conditions, especially with TPU or silicone coatings.

Oxford fabric made from polyester yarn is typically more water-repellent after PU or PVC coating, while nylon performs better in flexible, cold-weather waterproofing with TPU or silicone coatings. Coating choice determines final resistance more than the base fabric.

Waterproofing & Coating Guide

a. Coating Compatibility Table

| Fabric Type | PU Coating | PVC Coating | TPU Coating | Silicone Coating |

|---|---|---|---|---|

| Nylon Plain Weave | ✅ | ⚠️ (less bond) | ✅✅ | ✅✅ |

| Polyester Oxford 600D | ✅✅ | ✅✅ | ✅ | ⚠️ |

| Nylon Oxford 1680D | ✅✅ | ⚠️ | ✅✅ | ✅ |

✅ = Compatible | ✅✅ = Ideal | ⚠️ = Less effective or heavy

b. Hydrostatic Head Test Benchmarks (Water Pressure Resistance)

| Fabric + Coating | Water Resistance (ISO 811) |

|---|---|

| 600D Polyester Oxford + PU | 1200–1800 mm |

| 840D Nylon + TPU | 1500–2000 mm |

| 1680D Nylon Oxford + TPU | 2000–3000 mm |

| Cotton Oxford (untreated) | 200–300 mm |

c. Coating Durability Over Time

- Polyester Oxford holds PU or PVC coatings longer with less yellowing

- Nylon can delaminate over time unless coated with TPU or silicone

d. SzoneierFabrics Case: Waterproof Duffel Bag Series

A U.K. outdoor brand tested 420D nylon Oxford with TPU coating vs 600D polyester Oxford with PU coating:

- Nylon passed -15°C cold bend test

- Polyester had better color retention after 30-day UV exposure Result: Nylon version was chosen for ski and winter sports market

4. Is Nylon or Oxford Fabric Better for Making Backpacks, Bags, and Outdoor Gear?

It depends on the bag’s function, environment, and brand positioning. Nylon is generally better for premium, performance-focused products (e.g., hiking packs, tactical gear), while polyester Oxford is more suited to cost-efficient everyday bags (e.g., school, promo, travel use).

For premium or performance bags, nylon—especially in 420D, 840D, or 1680D Oxford weave—is stronger and more reliable. For budget or mid-tier bags, PU-coated polyester Oxford (300D–600D) offers durability and value.

Use-Based Fabric Selection

a. Backpack & Bag Fabric Comparison Table

| Use Case | Recommended Fabric | Why |

|---|---|---|

| Tactical/Military Packs | 1000D Cordura nylon or 1680D Oxford nylon | Extreme abrasion & load |

| Outdoor Hiking Bags | 420D/840D nylon with TPU | Lightweight + weather resistance |

| School or Travel Backpacks | 600D PU-coated polyester Oxford | Cost-effective, tough enough |

| Promotional Tote Bags | 300D polyester Oxford | Lightweight, printable |

| Waterproof Duffel Bags | Nylon Oxford + TPU | Flexibility + water resistance |

| Tool Bags/Work Packs | 900D–1680D Oxford polyester or nylon | Structure + weight support |

b. Weight-to-Durability Ratio

| Fabric Type | GSM (Typical) | Strength-to-Weight Efficiency |

|---|---|---|

| 420D Nylon Oxford | 160–180 gsm | High |

| 600D Polyester Oxford | 180–220 gsm | Moderate |

| 1680D Nylon Oxford | 280–340 gsm | Very High |

c. Real-World B2B Insight

An Italian OEM luggage buyer working with SzoneierFabrics tested:

- 600D Polyester Oxford (PU coated) for roller bags

- 1680D Nylon Oxford for heavy-duty cargo packs

After multiple drop and abrasion tests, the 1680D nylon version received:

- 25% longer lifespan in field use

- Better shape retention after loading 30+ kg

The decision? Offer dual-tiered SKUs: polyester for retail price point, nylon for pro gear.

5. What Are the Weight and GSM Differences Between Nylon and Oxford Fabric?

GSM (grams per square meter) is a key measurement when comparing nylon and Oxford fabrics. While nylon yarns tend to be lighter and stronger per denier, Oxford fabrics vary in GSM based on their yarn type (polyester, nylon, cotton) and weave tightness. Nylon generally delivers better strength-to-weight performance.

Nylon offers better strength-to-weight ratio compared to polyester Oxford, which makes it ideal for lightweight gear. However, Oxford’s GSM varies widely depending on fiber type and intended function.

GSM Comparison and Implications

a. Typical GSM Range by Fabric Type

| Fabric Type | Common GSM Range | Notes |

|---|---|---|

| 300D Polyester Oxford | 130–160 gsm | Lightweight, good for linings, promo bags |

| 420D Nylon Plain Weave | 160–180 gsm | Slightly heavier but stronger than 300D polyester |

| 600D Polyester Oxford | 180–220 gsm | Most common for backpacks and luggage |

| 840D Nylon (Plain) | 200–240 gsm | High tear resistance, more flexible than 600D polyester |

| 1680D Nylon Oxford | 280–340 gsm | Heaviest, best for ballistic applications |

b. Strength-to-Weight Ratio: Nylon vs Polyester Oxford

| Metric | Nylon (420D–1680D) | Polyester Oxford (300D–600D) |

|---|---|---|

| Weight | Lighter at equivalent strength | Heavier to match performance |

| Durability per gsm | Higher | Moderate |

| Flexibility | Higher | Stiffer at high denier |

c. When GSM Impacts Performance

- For airline luggage or military-grade packs, lower GSM with higher strength = shipping and tactical advantage

- For budget retail bags, GSM consistency supports structure and cost control

d. Case Example: E-commerce Seller A/B Test

A U.S. Amazon seller ordered two versions of a gym duffel:

- Version A: 600D polyester Oxford @ 210gsm

- Version B: 420D nylon Oxford @ 180gsm

Result:

- Nylon version weighed 18% less, held same load

- Conversion rate was higher for the lighter version with identical pricing

6. Do Nylon and Oxford Fabric Differ in Terms of Dyeing, Printing, and Appearance?

Yes. Polyester-based Oxford fabric accepts color and printing (e.g., screen, heat transfer, sublimation) more easily and is more UV stable. Nylon has lower colorfastness, but can be solution-dyed or pigment-dyed for deeper hues. For high-end visual appeal, nylon has a smoother surface, while Oxford has a textured, woven look.

Oxford fabric—especially polyester-based—is easier to dye and print, making it better for custom designs. Nylon has a sleeker look but can be more difficult to print unless specially treated.

Printability and Color Behavior

a. Dyeing & Printing Compatibility Table

| Fabric Type | Dye Method | Print Compatibility | UV Resistance |

|---|---|---|---|

| Polyester Oxford (300D–600D) | Disperse dyes, sublimation | Excellent (screen, heat transfer, sublimation) | High |

| Nylon Plain Weave | Acid dyes, pigment dyes | Good (requires pre-treatment) | Moderate |

| Nylon Oxford (420D–1680D) | Pigment or dope-dyed | Fair (not ideal for sublimation) | Moderate |

| Cotton Oxford | Reactive dyes | Excellent for water-based ink | Low |

b. Visual Appearance Differences

| Factor | Nylon | Oxford Fabric |

|---|---|---|

| Surface Texture | Smooth and glossy | Matte, woven texture |

| Dye Depth | Rich, clean finish | Slightly muted with texture |

| Branding Detail | Less absorbent for ink | Better for bold, colorful logos |

c. Real-Life Brand Example

A French outdoor accessory brand tested:

- 600D polyester Oxford → Heat transfer logo was crisp, edge-stable

- 840D nylon → Needed silicone pre-treatment for same print effect

They chose polyester Oxford for the lower cost and better print fidelity in colorful branded gear.

7. Are There Cost Differences Between Nylon and Oxford Fabric for Bulk Sourcing?

Yes. Nylon is generally more expensive than polyester Oxford fabric due to higher raw material costs and better performance properties. Oxford fabric, especially in 300D and 600D polyester variants, is more affordable and widely used for mid-tier products, promotions, and mass-market applications.

Nylon typically costs 20–40% more per meter than polyester Oxford fabric, depending on denier, weave, and coating. The price gap can be justified when long-term durability or high-end market perception is a priority.

Cost Breakdown and Budget Planning

a. Bulk Pricing Comparison (FOB China, 2025 estimates)

| Fabric Type | Price per meter (USD) | MOQ (typical) | Lead Time (days) |

|---|---|---|---|

| 300D Polyester Oxford (PU) | \$0.65 – \$0.85 | 100m | 5–7 |

| 600D Polyester Oxford (PU) | \$0.80 – \$1.10 | 100m | 5–10 |

| 420D Nylon (PU/TPU) | \$1.10 – \$1.50 | 300m | 7–12 |

| 840D Nylon (TPU) | \$1.60 – \$2.10 | 300m | 10–14 |

| 1680D Nylon Oxford (Ballistic) | \$2.00 – \$2.80 | 300–500m | 10–15 |

Prices based on SzoneierFabrics’ standard PU-coated and TPU-coated versions

b. Why Nylon Costs More

- Higher manufacturing and polymerization costs

- Often requires additional coating or pre-treatment

- Limited mill availability for high-denier weaves like 1680D

c. Cost-Effective Use of Nylon

- Use nylon only in load-bearing or abrasion-critical zones (bottom panel, straps)

- Combine with polyester Oxford in non-impact areas to reduce cost without sacrificing strength

d. SzoneierFabrics Hybrid Bag Program

One Korean buyer commissioned:

- 600D polyester Oxford body

- 840D nylon base and stress points Cost reduced by 22% compared to full-nylon build, with same durability ratings in lab tests.

8. How Should B2B Buyers Choose Between Nylon and Oxford Fabric Based on Product Needs?

There’s no universal “better” fabric. Nylon wins on performance and premium perception, while Oxford (especially polyester-based) excels in cost-efficiency, printability, and market scalability. The right choice depends on your product’s functional requirements, brand positioning, and buyer expectations.

B2B buyers should select nylon for high-performance applications (tactical gear, outdoor sports, military), and polyester Oxford for mass-market, promotional, or price-sensitive product lines like school bags or travel accessories.

Strategic Fabric Selection Framework

a. Buyer Persona & Application Matrix

| Buyer Type | Application | Best Fabric Type |

|---|---|---|

| Outdoor Gear Retailer | Waterproof hiking backpacks | 420D/840D nylon + TPU coating |

| Fashion Accessories Brand | Printed laptop sleeves | 600D polyester Oxford + PU |

| Military Contractor | Tactical vests and pouches | 1680D ballistic nylon Oxford |

| E-commerce Bag Seller | Lightweight travel bags | 300D–600D polyester Oxford |

| Government Tender Vendor | Utility packs + logo print | GRS 600D Oxford (polyester) |

b. Top Factors to Consider

| Factor | Choose Nylon If… | Choose Oxford If… |

|---|---|---|

| Weight vs Strength | You want the strongest fabric at low weight | You need structure and medium durability |

| Print or Branding Need | Branding is minimal or subtle | Bright prints or logos are key |

| Climate or Conditions | Cold, wet, rugged environments | Indoor, dry, or urban use |

| Budget Constraints | Cost is less of an issue | Price point must stay low to medium |

| MOQ / Sampling Flexibility | You accept higher MOQ and lead time | You need fast sampling and low entry barrier |

c. Sourcing Recommendations from SzoneierFabrics

- Offer dual-SKU strategy: Nylon for high-end/pro gear; Oxford for standard buyers

- Combine materials for function vs cost optimization

- Use certified materials (GRS, OEKO-TEX) to appeal to green buyers

- Request samples and lab tests before full production

Nylon or Oxford—Choose by Function, Not Hype

Nylon and Oxford aren’t enemies—they’re tools. When chosen correctly, each one helps optimize your product line across performance, price, brand, and buyer segment. As B2B buyers navigate the balance between function, cost, and design, understanding the fiber vs fabric difference is crucial.

SzoneierFabrics offers:

- Nylon and Oxford fabric options in all major deniers

- Custom coatings, colors, and finishes

- Low MOQs, fast sampling, and factory-direct pricing

- Certified solutions with GRS, OEKO-TEX, ISO compliance

Contact SzoneierFabrics now to request free swatches, view fabric performance data, or get a quote tailored to your next project.

Can't find the answers?

No worries, please contact us and we will answer all the questions you have during the whole process of bag customization.

Make A Sample First?

If you have your own artwork, logo design files, or just an idea,please provide details about your project requirements, including preferred fabric, color, and customization options,we’re excited to assist you in bringing your bespoke bag designs to life through our sample production process.