In medical environments, fabric is not just about comfort or appearance—it is part of the safety system. A gown that degrades after sterilization, a curtain that harbors moisture, or a bandage backing that loses strength can all introduce real risks. This is why medical textiles are judged by stricter standards than almost any other fabric category. Polyester fabric is a top choice for medical textiles because it offers consistent strength, excellent chemical and heat resistance, low moisture absorption, and reliable performance under repeated sterilization and laundering. These properties make polyester safer, more durable, and easier to control than many natural fibers in medical settings.

At SzoneierFabrics, many medical-related projects begin with cotton or blended fabrics but eventually shift toward polyester after testing reveals issues with shrinkage, microbial retention, or lifespan. Polyester’s dominance in medical textiles is not accidental—it is the result of decades of performance validation under real hospital conditions.

To understand why polyester has become so essential, we need to start with what medical textiles actually demand from a fabric.

What makes polyester fabric suitable for medical textile applications compared to other fibers?

Polyester is suitable for medical textiles because it combines mechanical strength, dimensional stability, chemical resistance, and process consistency—qualities that many natural fibers struggle to maintain under medical use conditions.

Medical textiles prioritize predictability, not just comfort.

Medical requirements vs fiber reality

Core demands of medical textiles

Medical fabrics are expected to withstand:

- Frequent washing at high temperatures

- Chemical exposure (detergents, disinfectants)

- Mechanical stress from repeated use

- Long service life without degradation

| Requirement | Why It Matters |

|---|---|

| Dimensional stability | Fit & coverage reliability |

| Strength retention | Tear & seam safety |

| Chemical resistance | Infection control |

| Controlled absorbency | Hygiene management |

Polyester meets these requirements more consistently than most natural fibers.

Polyester vs cotton: a practical comparison

| Property | Polyester | Cotton |

|---|---|---|

| Shrinkage after washing | Very low | High |

| Chemical resistance | Excellent | Moderate |

| Strength retention (wet) | High | Reduced |

| Microbial growth risk | Low | Higher |

| Lifespan | Long | Shorter |

Cotton offers comfort, but its hydrophilic nature becomes a liability in many medical environments.

Why consistency matters more than softness

In healthcare settings, fabric failure is not cosmetic—it’s functional.

Polyester’s synthetic origin allows:

- Tight control of yarn diameter

- Uniform fabric density

- Predictable performance across batches

At SzoneierFabrics, polyester medical fabrics show significantly lower variation in testing compared to natural alternatives, which is critical when scaling production.

Which properties of polyester are most critical for hygiene and infection control?

Polyester’s low moisture absorption, smooth fiber surface, and resistance to microbial growth make it especially effective for hygiene control and infection prevention in medical textiles.

Hygiene is not just about killing bacteria—it’s about preventing conditions where they thrive.

How polyester supports infection control

Low moisture absorption: the hidden advantage

Polyester absorbs less than 1% of its weight in moisture, compared to cotton’s 20%+.

| Fiber | Moisture Absorption |

|---|---|

| Polyester | <1% |

| Nylon | ~4% |

| Cotton | 20–25% |

Less moisture means fewer opportunities for bacteria to multiply.

Smooth fiber surface

Polyester fibers have smoother surfaces than natural fibers.

| Fiber Surface | Microbial Attachment |

|---|---|

| Smooth (polyester) | Lower |

| Irregular (cotton) | Higher |

This reduces bacterial adhesion and makes cleaning more effective.

Compatibility with hygiene protocols

Polyester tolerates:

- Chlorine-based disinfectants

- Alcohol exposure

- High-temperature washing

These are routine in medical facilities and often degrade natural fibers over time.

Real-world example: hospital curtains

In one hospital privacy-curtain project, polyester fabrics maintained acceptable hygiene levels after repeated wash cycles, while cotton blends showed increased microbial retention and visible degradation within months.

This is why polyester dominates in curtains, bedding, gowns, and protective covers.

How does polyester perform in sterilization and repeated laundering cycles?

Polyester maintains its strength, shape, and surface integrity through repeated high-temperature laundering and common sterilization methods, making it far more reliable than many natural fibers in medical-use cycles.

In healthcare settings, a fabric’s first wash means very little. What matters is how it performs after the 50th, 100th, or 200th cycle.

Why sterilization resistance matters so much

Common sterilization and cleaning conditions

Medical textiles are exposed to harsher treatments than everyday fabrics.

| Process | Typical Conditions |

|---|---|

| Industrial laundering | 60–90°C washing |

| Chemical disinfection | Chlorine, peroxide, alcohol |

| Thermal disinfection | Sustained high heat |

| Drying | High mechanical stress |

Each cycle compounds stress on the fiber.

Polyester vs natural fibers under stress

| Property After Repeated Washing | Polyester | Cotton |

|---|---|---|

| Dimensional stability | Excellent | Poor–moderate |

| Tensile strength retention | High | Decreases |

| Surface degradation | Minimal | Noticeable |

| Pilling / lint | Low | Higher |

Polyester’s molecular structure resists swelling and fiber breakage, which is why it holds up better over time.

Sterilization compatibility

Polyester tolerates:

- Steam exposure (within controlled limits)

- Chemical disinfectants

- Repeated heat drying

Cotton and some blends often show:

- Shrinkage

- Fiber weakening

- Increased lint formation

Lint is not just cosmetic—it can carry contaminants in medical spaces.

Real-world insight: reusable medical gowns

In reusable gown programs, polyester fabrics consistently outlast cotton alternatives by 2–3× the service life, reducing replacement frequency and operational risk.

At SzoneierFabrics, polyester medical fabrics are typically tested through accelerated wash simulations before approval.

Do different polyester constructions affect performance in medical contexts?

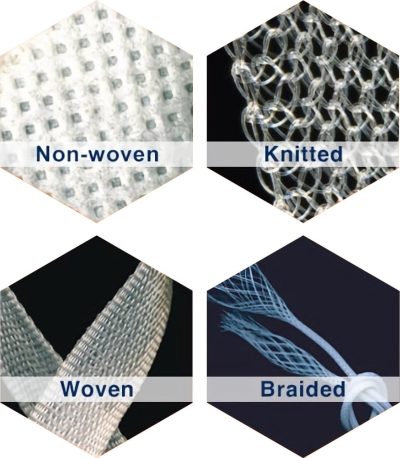

Yes. Woven, knitted, and nonwoven polyester fabrics serve different medical functions. Construction choice directly affects breathability, barrier protection, flexibility, and durability.

Polyester is not one fabric—it’s a platform.

Matching construction to medical function

Woven polyester fabrics

Woven polyester is tightly controlled and highly stable.

| Feature | Medical Benefit |

|---|---|

| High dimensional stability | Consistent fit |

| Low linting | Cleaner environments |

| Strong seam performance | Safer garments |

Typical uses:

- Hospital curtains

- Bedding

- Reusable gowns

- Mattress covers

Twill and plain weaves are commonly engineered for balance between strength and comfort.

Knitted polyester fabrics

Knits introduce elasticity and softness.

| Feature | Medical Benefit |

|---|---|

| Stretch & recovery | Better mobility |

| Improved drape | Patient comfort |

| Air permeability | Thermal comfort |

Typical uses:

- Patient apparel

- Bandage backings

- Support textiles

However, knit density must be carefully controlled to avoid snagging or barrier failure.

Nonwoven polyester fabrics

Nonwovens are engineered for single-use or controlled-lifespan applications.

| Feature | Medical Benefit |

|---|---|

| Controlled porosity | Fluid resistance |

| Cost efficiency | Disposable use |

| Consistency | Reliable barrier |

Typical uses:

- Surgical drapes

- Masks & covers

- Disposable gowns

Polyester nonwovens allow precise control of filtration and barrier properties.

Construction comparison at a glance

| Construction | Durability | Comfort | Barrier Control |

|---|---|---|---|

| Woven | Very high | Medium | Medium |

| Knit | Medium | High | Low–medium |

| Nonwoven | Low–medium | Low | High |

At SzoneierFabrics, construction is selected after defining risk level and use duration, not before.

Is polyester fabric compatible with antimicrobial finishes and protective coatings?

Yes. Polyester is one of the most compatible base fabrics for antimicrobial finishes and protective coatings because of its chemical stability, smooth surface, and strong adhesion with functional treatments.

In medical textiles, the fabric is only half the solution—the finish completes the system.

Why polyester accepts functional finishes so well

Surface chemistry and finish adhesion

Polyester’s uniform, non-porous surface allows controlled bonding of finishes.

| Finish Type | Compatibility with Polyester | Performance Stability |

|---|---|---|

| Silver-ion antimicrobial | Excellent | High |

| Quaternary ammonium | Good | Medium–high |

| Zinc-based treatments | Good | Medium |

| PU / TPU coatings | Excellent | Very high |

| Fluorine-free repellents | Excellent | High |

Natural fibers often absorb finishes unevenly, reducing effectiveness over time.

Antimicrobial durability under laundering

Medical textiles must retain antimicrobial function after repeated washing.

| Fabric Base | Finish Retention (After 50 Washes) |

|---|---|

| Polyester | High |

| Cotton | Medium |

| Cotton blends | Medium–low |

Polyester’s resistance to swelling and fiber damage helps finishes remain active longer.

Barrier and protective coatings

Polyester supports a wide range of coatings used in medical settings.

| Coating Type | Medical Purpose |

|---|---|

| PU coating | Fluid barrier |

| TPU membrane | Breathable protection |

| Acrylic | Surface durability |

| Silicone | Soft touch & sealing |

These coatings are commonly used in isolation gowns, mattress covers, and protective drapes.

Critical balance: protection vs comfort

Over-coating can reduce breathability.

| Risk | Outcome |

|---|---|

| Excess coating thickness | Heat buildup |

| Poor coating uniformity | Weak barrier zones |

| Incompatible finish | Cracking or peeling |

At SzoneierFabrics, coating weights and curing parameters are adjusted to maintain vapor transmission while achieving required protection levels.

What role does moisture management play in medical textiles, and how does polyester handle it?

Moisture management is critical in medical textiles because excess moisture encourages bacterial growth, skin irritation, and discomfort. Polyester’s low moisture absorption and fast-drying behavior make it easier to control moisture compared to natural fibers.

Dry fabrics are safer fabrics.

Moisture control from a clinical perspective

Why moisture is a medical risk

Excess moisture can lead to:

- Skin maceration

- Increased microbial growth

- Reduced barrier performance

- Patient discomfort

This is especially critical in bedding, wound-contact layers, and long-wear garments.

Polyester’s moisture behavior

Polyester does not hold moisture inside the fiber.

| Property | Polyester | Cotton |

|---|---|---|

| Moisture absorption | <1% | 20–25% |

| Drying speed | Fast | Slow |

| Wet weight gain | Minimal | High |

| Odor retention | Lower | Higher |

Instead of absorbing sweat, polyester moves moisture along the fabric surface, allowing faster evaporation.

Engineered moisture management

Medical polyester fabrics often include:

- Capillary yarn structures

- Hydrophilic surface finishes

- Zoned moisture control

| Technique | Benefit |

|---|---|

| Capillary channels | Rapid liquid spread |

| Directional finishes | One-way moisture movement |

| Dual-layer fabrics | Dry skin contact layer |

These designs help keep skin dry even during prolonged contact.

Comfort vs clinical control

Some applications prioritize moisture movement over softness.

| Application | Moisture Priority |

|---|---|

| Patient gowns | Balanced |

| Bedding | High |

| Wound dressings | Critical |

| Privacy curtains | Low |

Polyester allows moisture control to be engineered to the application, rather than relying on fiber behavior alone.

Are there sustainability concerns with polyester in medical textiles, and how are they being addressed?

Yes, conventional polyester raises sustainability concerns due to its fossil-based origin. However, in medical textiles, durability, reuse, and emerging recycled polyester (rPET) solutions significantly reduce environmental impact over a product’s full lifecycle.

In healthcare, sustainability must be measured by total use cycles, not just raw material origin.

Sustainability through a medical lens

Why longevity matters more than fiber origin

A medical fabric used and washed hundreds of times can outperform single-use alternatives environmentally.

| Factor | Short-Lived Fabric | Durable Polyester |

|---|---|---|

| Replacement frequency | High | Low |

| Waste generation | High | Lower |

| Total resource use | High | Lower |

Reusable polyester gowns, curtains, and bedding often result in lower lifecycle emissions than disposable options.

Recycled polyester (rPET) in medical textiles

Recycled polyester is increasingly used where certification and traceability allow.

| Aspect | rPET Polyester |

|---|---|

| Performance parity | High (when engineered) |

| Hygiene compatibility | Good |

| Durability | Slightly lower–equal |

| Availability | Growing |

For non-critical or medium-risk applications, rPET offers a balanced sustainability upgrade without sacrificing reliability.

Certification and compliance considerations

Medical textiles typically require:

- Consistent quality

- Traceable inputs

- Stable supply

Not all recycled polyester meets these criteria yet, but controlled programs are expanding rapidly.

Reducing waste through design

Polyester’s versatility allows:

- Modular designs

- Repairable components

- Longer service intervals

At SzoneierFabrics, sustainability discussions often focus on extending usable life, not just changing fiber labels.

Which medical applications benefit most from polyester fabrics, and how should buyers choose the right specification?

Polyester benefits medical applications that require hygiene control, durability, and consistent performance. Choosing the right specification depends on risk level, contact duration, comfort needs, and cleaning intensity.

There is no “one polyester fabric” for healthcare—only well-matched specifications.

Application-driven fabric selection

Common medical applications and requirements

| Application | Key Requirements | Polyester Advantage |

|---|---|---|

| Privacy curtains | Low lint, hygiene | Excellent |

| Reusable gowns | Durability, wash resistance | Excellent |

| Bedding & mattress covers | Moisture control, strength | Excellent |

| Bandage backings | Stability, cleanliness | Good |

| Disposable drapes | Barrier control | Via nonwovens |

Polyester adapts across all of these through construction and finishing choices.

Choosing the right construction

| Need | Recommended Construction |

|---|---|

| Long-term use | Woven polyester |

| Comfort & movement | Knitted polyester |

| Barrier & filtration | Nonwoven polyester |

| Fluid resistance | Coated woven polyester |

Selecting construction first avoids performance mismatches later.

Key specifications to define early

| Parameter | Why It Matters |

|---|---|

| Fabric weight (GSM) | Comfort vs durability |

| Weave/knit density | Airflow & barrier |

| Finish type | Hygiene & protection |

| Wash durability | Lifecycle cost |

| Compliance needs | Market acceptance |

Skipping this step often leads to redesigns and delays.

Real-world sourcing insight

Many medical projects fail not because polyester is unsuitable—but because specifications were copied from non-medical fabrics. Medical use requires purpose-built engineering.

Why polyester remains the backbone of medical textiles

Polyester is a top choice for medical textiles because it delivers predictable hygiene performance, long-term durability, sterilization resistance, and design flexibility. While sustainability challenges exist, they are increasingly addressed through reuse, recycled inputs, and smarter fabric engineering.

In medical environments, reliability saves time, cost, and risk—and polyester consistently delivers it.

Develop Medical-Grade Polyester Fabrics with SzoneierFabrics

SzoneierFabrics is a China-based fabric R&D and manufacturing factory with years of experience developing medical-grade polyester fabrics tailored to real clinical demands.

We provide:

- Free fabric design and technical consultation

- Low-MOQ customization and fast sampling

- Options for woven, knit, and nonwoven polyester

- Compatibility with antimicrobial finishes and coatings

- Short lead times and 100% quality assurance

If you are developing or upgrading medical textile products and need reliable, compliant, and application-specific polyester fabrics, contact SzoneierFabrics to request samples or start a custom development project today.