Denim looks familiar. Almost everyone feels they already “know” it. Yet in real sourcing and production, denim is one of the fabrics that causes the most misunderstandings, reworks, and unexpected costs. Two denims can look nearly identical on a hanger, share the same weight, and even come from the same region—yet behave very differently once cut, washed, worn, and scaled into repeat production.

The reason is simple: denim is not one fabric. It is a family of constructions, fibers, weaves, and finishing systems. Choosing “denim” without understanding which type you are selecting is like choosing “leather” without asking full-grain or split. The surface story is easy. The performance story is where most decisions succeed—or fail. Denim fabric types differ by weave structure, fiber composition, weight, and finishing method. These differences directly affect durability, stretch, shrinkage, handfeel, appearance, and long-term consistency. Buyers who understand how denim types are constructed—and how they behave after washing and wear—can select fabrics that match their product goals, control risk, and achieve repeatable results across production runs.

A sourcing manager once said, “We didn’t choose the wrong supplier—we chose the wrong denim type.” That distinction matters more than many realize.

What Are the Main Denim Fabric Types Used in Modern Apparel and Textile Products?

Denim is often spoken about as if it were a single material, but in modern apparel and textile production, denim is a family of fabrics, not a monolith. Two garments can both be called “denim” and yet behave entirely differently in wear, washing, aging, and manufacturing. These differences are not cosmetic; they are engineered through weave structure, fiber composition, loom type, and finishing state.

Understanding denim fabric types is therefore not about memorizing labels. It is about understanding what problem each denim type is designed to solve. Some prioritize durability and authenticity, others prioritize comfort and fit control, and still others exist to support specific aesthetic or branding goals.

Denim types exist to solve different problems—not to follow trends.

Understanding Denim Beyond the Label

In sourcing and product development, denim fabric types are often discussed using shorthand terms such as “rigid,” “stretch,” or “selvedge.” While these labels are useful, they can also be misleading if taken at face value. Each term actually represents a combination of construction choices that affect how the fabric behaves from yarn stage through consumer wear.

The most reliable way to understand denim types is to look at them through three lenses:

- Construction: weave structure, loom type, fabric density

- Fiber content: cotton-only or blended

- Finishing state: raw, washed, or treated

When these factors are considered together, the logic behind each denim category becomes clear.

Core Denim Fabric Categories by Construction

| Denim Type | Core Characteristics | Typical Uses |

|---|---|---|

| Rigid denim | 100% cotton, no stretch | Classic jeans, jackets |

| Stretch denim | Cotton blended with elastane | Fitted jeans, comfort wear |

| Selvedge denim | Narrow loom, finished edges | Premium and heritage styles |

| Raw denim | Unwashed, untreated | Fade-focused products |

| Washed denim | Pre-washed and finished | Ready-to-wear garments |

| Colored denim | Dyed warp or weft | Fashion and seasonal items |

These categories are not indicators of quality or price on their own. They represent functional and aesthetic choices made at the fabric level.

Rigid Denim: Structure and Authenticity

Rigid denim is typically made from 100% cotton yarns and contains no elastic fibers. Its defining characteristic is reliance on fabric structure rather than elasticity to hold shape.

Rigid denim offers:

- Strong vertical stability

- High abrasion resistance

- Pronounced aging and fade character

- A firm initial handfeel that softens over time

Because rigid denim does not recover well after stretch, it performs best in silhouettes with built-in ease, such as straight-leg jeans, relaxed fits, and structured jackets. Comfort develops gradually as the fabric breaks in.

In modern production, rigid denim remains important for:

- Heritage-inspired products

- Workwear aesthetics

- Consumers who value long-term wear character

However, rigid denim also brings challenges: higher shrinkage, narrower fit tolerance, and greater risk of fit complaints if patterns are too aggressive.

Stretch Denim: Control Through Elasticity

Stretch denim introduces elastane or similar elastic fibers—usually in the weft direction—to provide controlled stretch and recovery. This fundamentally changes how the fabric behaves.

Stretch denim offers:

- Improved comfort during movement

- Better fit tolerance across body variation

- Reduced risk of bagging and sagging when engineered well

| Attribute | Rigid Denim | Stretch Denim |

|---|---|---|

| Initial feel | Firm | Softer |

| Fit recovery | Low | High |

| Aging behavior | Gradual break-in | More controlled |

| Pattern tolerance | Narrow | Wider |

Stretch denim is widely used in fitted silhouettes, particularly in women’s and unisex apparel. Designers often choose it to reduce size complaints and improve immediate wear comfort.

The trade-off is that stretch denim typically ages more quietly. High-contrast fades are muted, and surface texture can flatten if elastane content is too high. For this reason, stretch levels are carefully calibrated rather than maximized.

Selvedge Denim: Construction as Identity

Selvedge denim is defined not by fiber content but by loom type. It is woven on narrow shuttle looms that produce a clean, self-finished edge (the selvedge). This edge prevents fraying and serves as a visible marker of traditional manufacturing.

Selvedge denim is associated with:

- Narrow loom widths

- Lower production speed

- Higher labor and setup costs

- Strong heritage and craftsmanship narratives

Functionally, selvedge denim behaves similarly to other rigid or low-stretch denims of comparable weight and yarn quality. Its value lies less in performance and more in brand positioning and storytelling.

For premium brands, selvedge denim supports authenticity claims and appeals to consumers who value process as much as product.

Raw Denim: Fabric as a Blank Canvas

Raw denim refers to denim that has not been washed, distressed, or softened after weaving. It is typically stiff, deeply indigo-dyed, and visually uniform at the time of purchase.

Raw denim offers:

- Maximum fade potential

- Strong contrast development over time

- A highly personalized wear pattern

Because it is untreated, raw denim shrinks and softens significantly with wear and washing. This makes fit selection critical. Raw denim is often favored by enthusiasts who are willing to invest time in breaking in a garment.

From a manufacturing standpoint, raw denim simplifies finishing but increases responsibility on pattern accuracy and shrinkage prediction.

Washed Denim: Ready-to-Wear Reliability

Washed denim has undergone one or more finishing processes—such as enzyme washing, stone washing, or softening—to achieve a desired look and feel before sale.

Washed denim provides:

- Predictable handfeel

- Reduced shrinkage risk

- Consistent appearance at point of purchase

Most commercial denim products fall into this category because it reduces consumer uncertainty. Buyers know what the garment will feel like and how it will fit immediately.

The trade-off is reduced personalization. Much of the aging narrative is predetermined by the wash process rather than created through wear.

Colored Denim: Expanding Beyond Indigo

Colored denim refers to fabrics where the warp, weft, or both are dyed in colors other than traditional indigo. This category includes black denim, garment-dyed denim, and seasonal color programs.

Colored denim is used to:

- Expand fashion versatility

- Support seasonal palettes

- Differentiate collections visually

Technically, colored denim may behave differently than indigo denim, particularly in fading and color retention. Some colors show wear more quickly, while others mask abrasion.

For sourcing teams, colored denim requires careful testing to ensure colorfastness and consistency across batches.

Specialty Denim Types That Matter in Sourcing

Beyond mainstream categories, many projects rely on specialty denim constructions that address specific issues.

Broken twill denim alters the weave direction to reduce leg twisting, improving visual stability. Slub denim uses intentionally uneven yarns to create texture and visual depth. Eco denim incorporates recycled fibers or low-impact dyeing methods to support sustainability goals.

Each of these types introduces trade-offs. Slub denim increases texture but can complicate consistency. Eco denim supports sustainability narratives but may require tighter quality control due to fiber variability.

Denim Type Is a Performance Decision

One of the most common sourcing mistakes is choosing denim types based on name recognition rather than behavior. A project may specify “selvedge” for prestige without considering fit tolerance, or “stretch denim” without defining recovery requirements.

In practice, denim type selection should start with questions such as:

- How should the garment feel on first wear?

- How much fit variation must the fabric absorb?

- How should the garment age over time?

- What level of manufacturing consistency is required?

Labels alone do not answer these questions.

Interaction Between Denim Type and End Use

Different end uses place different demands on fabric behavior.

- Daily-wear jeans benefit from stretch or washed finishes

- Heritage products favor rigid or raw denim

- Unisex collections often prefer balanced constructions

- Fashion capsules may prioritize color or texture

No single denim type is universally superior. Each is optimized for a specific combination of performance, aesthetics, and consumer expectation.

A Practical Sourcing Insight

Problems often arise when denim types are chosen for their perceived status rather than their functional suitability. A premium-sounding fabric may fail in real wear if its behavior contradicts the garment’s intent.

At SzoneierFabrics, denim selection discussions typically begin with end use, silhouette, and wash plan, not with trend labels. Once behavior requirements are clear, appropriate denim types can be identified or engineered to match those needs.

Manufacturing and Cost Considerations

Different denim types also carry different production implications.

- Selvedge denim limits yield due to narrow loom width

- Stretch denim requires careful elastane handling

- Raw denim shifts responsibility for shrinkage to the pattern stage

- Washed denim increases finishing cost but reduces consumer risk

Understanding these implications helps buyers evaluate true cost beyond fabric price per yard.

Denim Types as Strategic Tools

In modern apparel, denim fabric types are strategic tools. They shape not only how garments perform, but how brands are perceived.

Rigid and raw denims communicate authenticity and durability. Stretch and washed denims communicate comfort and accessibility. Specialty denims communicate innovation or craftsmanship.

The key is intentionality.

The main denim fabric types used in modern apparel—rigid, stretch, selvedge, raw, washed, colored, and specialty constructions—exist to solve different functional and aesthetic problems. They are not hierarchical, and none is inherently “better” than another.

Successful denim development starts by understanding how the fabric must behave, not what it is called. When denim types are selected based on behavior, end use, and manufacturing reality, products perform as expected and age with purpose.

In denim, the right fabric type is not the trendiest one. It is the one that quietly does its job—day after day, wear after wear.

Which Denim Weaves and Constructions Affect Durability, Stretch, and Appearance?

When denim performance is discussed, attention often goes to fiber content, fabric weight, or stretch percentage. Yet in real-world wear, weave structure and construction choices often matter more than any single spec on a data sheet. Two denims with identical fiber composition and weight can behave very differently depending on how yarns are interlaced, how densely they are packed, and how stretch is integrated.

Weave structure governs how stress travels through the fabric, how abrasion is resisted, how creases form, and how denim visually ages. It quietly determines whether a garment feels rugged or refined, whether it twists after washing, and whether it develops dramatic fades or smooth patina over time.

Weave choice quietly controls how denim lives over time.

Why Weave Structure Matters More Than Most Specs

Weave is the architecture of denim. It defines how warp and weft yarns interact under tension, friction, and repeated movement. While fiber quality determines what yarns can do, weave structure determines what the fabric actually does in daily use.

From a performance standpoint, weave affects:

- How abrasion is distributed across the surface

- How easily the fabric bends and recovers

- Where stress concentrates during movement

- How light reflects, influencing visual texture and fading

Because these effects compound over time, weave decisions often explain why two denims age very differently despite looking similar at first.

Common Denim Weave Types Explained

| Weave Type | Structure | Performance Impact |

|---|---|---|

| Right-hand twill | Diagonal rising to the right | High durability, classic fades |

| Left-hand twill | Diagonal rising to the left | Softer feel, smoother wear |

| Broken twill | Alternating diagonal direction | Reduces leg twist |

| Plain weave denim | Simple over-under | Lower durability, flatter look |

Among these, right-hand twill remains the dominant choice in traditional denim because it delivers a reliable balance of strength, abrasion resistance, and fade potential.

Right-Hand Twill: The Industry Standard

Right-hand twill is the most widely used denim weave. In this structure, warp yarns cross over weft yarns in a repeating diagonal pattern that rises from the lower left to the upper right.

This construction provides several advantages:

- Strong warp dominance, improving abrasion resistance

- Clear diagonal texture that supports high-contrast fading

- Structural stability under repeated wear

Right-hand twill tends to feel stiff initially, especially in rigid denim, but softens gradually as the fabric breaks in. This slow evolution is often seen as desirable, particularly in men’s and heritage-oriented products.

From a durability standpoint, right-hand twill distributes stress efficiently along the diagonal ribs, reducing localized wear. This makes it suitable for garments expected to endure long-term use.

Left-Hand Twill: Softer and Faster to Break In

Left-hand twill reverses the diagonal direction, rising from the lower right to the upper left. This subtle change has noticeable effects on fabric behavior.

Left-hand twill typically offers:

- A smoother surface feel

- Faster softening after wear and washing

- Less pronounced, more even fading

| Attribute | Right-Hand Twill | Left-Hand Twill |

|---|---|---|

| Initial stiffness | Higher | Lower |

| Fade pattern | High contrast | Softer, blended |

| Comfort over time | Gradual break-in | Faster softening |

Because left-hand twill abrades slightly differently, it often produces a flatter, less textured surface over time. Some vintage-inspired jeans favor this weave because it delivers comfort earlier in the garment’s life cycle.

The trade-off is reduced abrasion resistance compared to right-hand twill, which is why left-hand twill is less common in heavy-duty or workwear-oriented denim.

Broken Twill: Engineering Out Leg Twist

Broken twill was developed to solve a specific problem: leg twisting after washing. Traditional twill weaves can cause garments to rotate slightly along the leg as tension is released, particularly in rigid denim.

Broken twill alternates the twill direction at regular intervals, disrupting the continuous diagonal line.

This construction:

- Reduces torque and leg twist

- Creates a more balanced stress distribution

- Produces a subtler surface texture

Broken twill is frequently used in unisex and relaxed silhouettes where visual stability matters more than dramatic fading. While its fade character is typically less bold, its consistency makes it attractive for garments that must maintain alignment across sizes and body types.

Plain Weave Denim: Rare but Purposeful

Plain weave denim uses a simple over-under yarn interlacing rather than a twill diagonal. This structure is inherently less durable because stress is concentrated at frequent crossover points.

Plain weave denim typically offers:

- A flatter, more uniform appearance

- Lower abrasion resistance

- Limited fade expression

For this reason, it is rarely used in traditional jeans. However, it can appear in lightweight denim shirting, fashion applications, or hybrid fabrics where crispness matters more than longevity.

Weave Direction and Garment Behavior

Beyond durability, weave direction influences how garments behave after washing and during wear.

Weave affects:

- Surface smoothness and friction

- How creases set at knees and hips

- Whether garments twist or skew

Right-hand twill often shows sharper creases and higher-contrast whiskering. Left-hand twill tends to blur creases and soften lines. Broken twill minimizes distortion but also reduces dramatic visual effects.

These differences matter when aligning fabric choice with silhouette intent. A tailored garment benefits from sharper crease definition, while a relaxed silhouette may benefit from smoother, quieter aging.

Construction Density and Its Role in Durability

Weave structure alone does not determine durability. Construction density, often measured in picks per inch (PPI), plays a critical role.

Two fabrics can share the same weight and weave but perform very differently depending on how tightly yarns are packed.

| Construction Density | Typical Result |

|---|---|

| Low density | Softer handfeel, faster wear |

| Medium density | Balanced durability and drape |

| High density | Stronger, stiffer fabric |

Higher density increases abrasion resistance and tear strength by limiting yarn movement. However, it also reduces drape, increases stiffness, and can complicate sewing.

For this reason, density must be matched to end use. Heavy-duty garments may justify higher density, while comfort-driven styles may benefit from moderation.

Density Versus Weight: A Common Misunderstanding

Fabric weight is often used as a proxy for durability, but weight alone is misleading. A lighter fabric with high density can outperform a heavier fabric with loose construction.

Density determines how stress is shared across yarns. Loose constructions allow yarns to move excessively, accelerating wear even at higher weights.

This is why experienced sourcing teams evaluate weight and density together rather than in isolation.

Stretch Integration and Weave Interaction

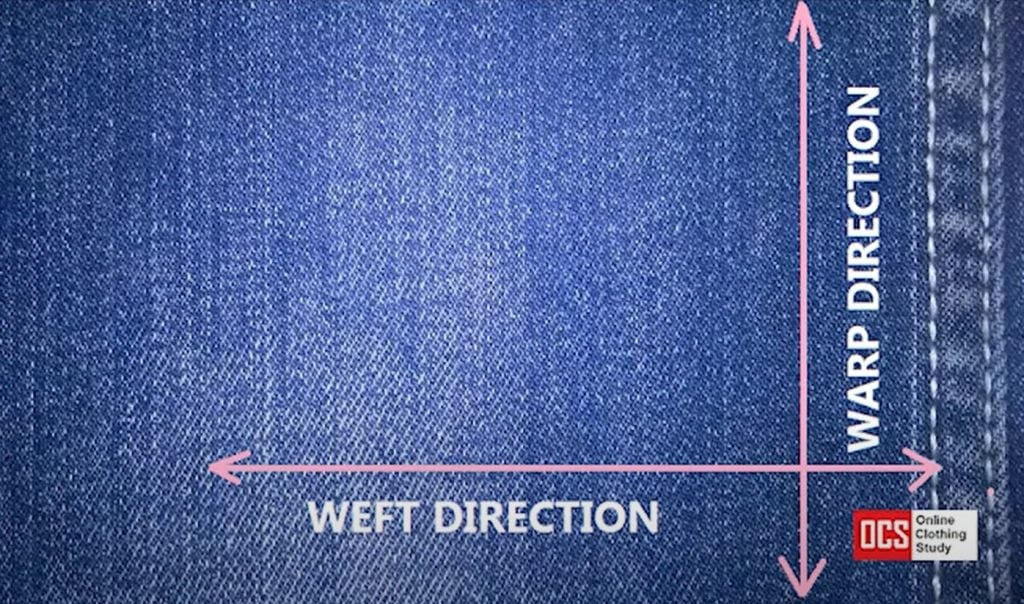

In stretch denim, weave structure influences how elastane behaves under stress. Most stretch denim places elastane in the weft direction, allowing horizontal stretch while preserving vertical stability.

Proper stretch integration depends on:

- Weave structure that controls yarn movement

- Density that supports recovery

- Balanced interaction between elastic and non-elastic yarns

When stretch is poorly integrated—through inappropriate weave or excessive elastane—problems emerge.

Common issues include:

- Knee bagging from uncontrolled weft stretch

- Growth after wear due to poor recovery

- Loss of silhouette in stress areas

Weave structures with better stability, such as right-hand or broken twill, often manage stretch more predictably than softer, looser constructions.

Appearance: How Weave Shapes Visual Aging

Denim appearance over time is not dictated by dye alone. Weave determines how indigo abrades and how underlying yarns are revealed.

- Right-hand twill emphasizes contrast and texture

- Left-hand twill produces smoother, more uniform fades

- Broken twill ages quietly with less directional character

These visual outcomes should align with brand intent. Dramatic fades suit heritage narratives. Controlled aging suits modern or minimalist designs.

Choosing Weave Based on End Use

Different products place different demands on weave performance.

- Workwear and classic jeans benefit from right-hand twill

- Comfort-driven or vintage-inspired styles may favor left-hand twill

- Unisex and alignment-sensitive garments often use broken twill

- Lightweight fashion items may experiment with plain weave

No weave is universally superior. Each solves a specific set of problems.

A Sourcing Reality Check

Buyers often ask, “Is this durable denim?” That question is too broad to be useful.

A more effective question is: Which weave, density, and construction choices created this durability?

Durability is not an inherent property. It is the result of deliberate decisions about how yarns are interlaced, how tightly they are packed, and how elasticity is controlled.

Weave as a Strategic Decision

In modern denim development, weave selection is a strategic decision, not a technical footnote. It affects cost, manufacturability, wear life, and brand perception.

Changing weave structure can sometimes solve problems that fiber changes cannot. For example, reducing leg twist through broken twill may be more effective than adjusting pattern or washing techniques.

Manufacturing and Cost Implications

Different weaves carry different production implications.

- Higher density weaves increase loom time and cost

- Broken twill requires more complex setup

- Softer weaves may reduce sewing efficiency

Understanding these trade-offs helps buyers evaluate true value rather than focusing solely on fabric price.

Denim durability, stretch behavior, and appearance are shaped as much by weave and construction as by fiber content or weight. Right-hand twill, left-hand twill, broken twill, and plain weave each create distinct performance profiles that influence how denim feels, wears, and ages.

Successful denim selection starts by understanding how weave distributes stress, controls movement, and shapes visual evolution. When weave choices align with end use and design intent, denim performs predictably and ages with purpose.

In denim, what you see on the surface is only part of the story. The real behavior is woven in.

How Do Raw, Selvedge, and Washed Denim Fabrics Differ in Performance and Use?

Raw denim, selvedge denim, and washed denim are often treated as style labels—shortcuts to signal quality, authenticity, or craftsmanship. In reality, they describe very different stages and methods of fabric preparation, each with concrete consequences for shrinkage, comfort, aging, production risk, and commercial viability.

The most expensive mistakes in denim sourcing often happen when these fabrics are chosen for their image rather than their behavior. Raw denim is assumed to be “premium.” Selvedge denim is assumed to be “better made.” Washed denim is assumed to be “ordinary.” None of these assumptions hold up once garments are worn, washed, graded, and sold at scale.

None is better by default. Each suits a different product goal.

The mistake is choosing by image instead of behavior.

Understanding What “State of Finish” Really Changes

Before comparing raw, selvedge, and washed denim, it is important to separate construction method from finishing state. These concepts are often mixed together in marketing language but represent different technical realities.

- Raw vs washed describes how much finishing the fabric or garment receives before sale.

- Selvedge vs non-selvedge describes how the fabric is woven, not how it is finished.

A denim can be raw and selvedge, washed and selvedge, raw and non-selvedge, or washed and non-selvedge. Performance depends on which variables are combined—not on the label alone.

Raw Denim: Untreated and Unforgiving

Raw denim, sometimes called dry denim, is denim fabric that has been woven and dyed but not washed, softened, or stabilized after weaving. It arrives stiff, dark, and structurally tense.

| Attribute | Raw Denim Behavior |

|---|---|

| Shrinkage | High on first wash |

| Handfeel | Very stiff initially |

| Fade potential | Extremely high |

| Fit predictability | Low without planning |

Raw denim offers maximum potential for personal fade patterns. Because indigo has not been redistributed or abraded through washing, wear marks develop sharply and with high contrast over time. This makes raw denim attractive to enthusiasts who value individualized aging.

However, raw denim places heavy demands on development discipline.

Shrinkage and Fit Risk in Raw Denim

The most significant technical challenge with raw denim is uncontrolled shrinkage. Without fabric-stage washing or sanforization, raw denim can shrink noticeably in length, width, or both—often unevenly.

This creates several risks:

- Inaccurate final garment measurements

- Inconsistent sizing between production batches

- High return rates when consumers wash garments for the first time

A common failure occurs when raw denim is graded and cut using assumptions appropriate for washed denim. The result is garments that fit acceptably before washing and poorly afterward.

Successful raw denim programs require:

- Accurate shrinkage testing at fabric stage

- Pattern compensation for expected dimensional change

- Clear consumer care instructions

Without these controls, raw denim becomes unpredictable at scale.

Comfort and Wear Experience

Raw denim prioritizes long-term character over immediate comfort. The initial handfeel is rigid, sometimes abrasive, and requires a break-in period. Some consumers enjoy this progression. Many do not.

For this reason, raw denim performs best in:

- Niche or enthusiast markets

- Heritage-focused products

- Straight or relaxed silhouettes

It is rarely appropriate for fitted garments, high-movement apparel, or collections where comfort complaints carry high commercial risk.

Selvedge Denim: Construction, Not Finish

Selvedge denim is defined by how it is woven, not by how it is finished. It is produced on narrow shuttle looms that create a clean, self-finished edge—known as the selvedge—along the fabric width.

| Attribute | Selvedge Denim Impact |

|---|---|

| Edge quality | Clean, self-finished |

| Loom speed | Slower |

| Consistency | High within narrow widths |

| Yield | Lower due to narrow loom width |

The selvedge edge prevents fraying and has become a visual marker of traditional craftsmanship. In many products, it is intentionally exposed at cuffs or seams to signal authenticity.

What Selvedge Denim Does—and Does Not—Guarantee

Selvedge denim is often assumed to be superior in all respects. Technically, this is not true.

Selvedge denim does not automatically mean:

- Better fiber quality

- Greater durability

- Better comfort

- Superior fit behavior

What it does mean is:

- Narrower fabric widths

- Slower, more controlled weaving

- Higher production cost per yard

Performance depends on yarn quality, weave density, fiber composition, and finishing—just as it does with non-selvedge denim.

Yield and Cost Implications

One of the most overlooked aspects of selvedge denim is yield. Narrow loom widths reduce cutting efficiency, especially in garments with complex pattern shapes or multiple size ranges.

This can lead to:

- Higher fabric consumption per garment

- Increased waste

- Elevated unit cost

For straight-leg jeans with simple panels, this may be manageable. For fitted women’s styles or multi-gender collections, yield loss can become significant.

Selvedge denim therefore makes the most sense when its construction story adds real value to the product narrative.

Selvedge and Finish: Independent Choices

Selvedge denim can be raw or washed. Many premium products combine selvedge construction with raw finishing to maximize heritage appeal. Others wash selvedge denim to improve comfort while retaining the construction story.

These combinations should be chosen intentionally. Selvedge does not require raw finishing, and raw denim does not require selvedge construction.

Washed Denim: Production-Friendly and Predictable

Washed denim undergoes fabric-stage or garment-stage washing before final sale. Processes may include enzyme washing, stone washing, softening, or stabilization treatments.

| Attribute | Washed Denim Behavior |

|---|---|

| Shrinkage | Mostly removed |

| Handfeel | Softer and more flexible |

| Fit stability | High |

| Production risk | Lower |

Washed denim sacrifices some of the dramatic aging potential of raw denim, but it delivers predictability—a critical factor in commercial apparel.

Why Washed Denim Dominates Commercial Production

Most modern denim products use washed denim because it reduces uncertainty at nearly every stage:

- Fit is more predictable across sizes

- Consumer experience matches point-of-sale expectations

- Returns related to shrinkage are minimized

- Production tolerances are easier to manage

Washed denim allows designers to control appearance and feel upfront, rather than leaving those outcomes to chance.

This makes it particularly suitable for:

- Ready-to-wear collections

- Fitted silhouettes

- Women’s and unisex lines

- Large-scale production runs

Aging Behavior and Visual Trade-Offs

Washed denim ages more quietly than raw denim. Because some indigo has already been redistributed during washing, future fades are less dramatic.

For many brands, this is not a disadvantage. Controlled aging supports visual consistency across wearers and aligns with modern expectations of durability and appearance retention.

The key is alignment between brand promise and fabric behavior.

Comparing Performance Across the Three Types

When raw, selvedge, and washed denim are compared side by side, the differences become clear.

- Raw denim maximizes individuality but increases risk

- Selvedge denim emphasizes construction heritage but affects yield

- Washed denim prioritizes stability and scalability

None of these outcomes is inherently superior. They simply serve different objectives.

Choosing by Use, Not Reputation

One of the most common sourcing mistakes is choosing denim based on perceived prestige rather than functional suitability.

A real-world example illustrates this clearly. A lifestyle brand insisted on using selvedge denim for a fitted women’s line, believing it would elevate brand image. In practice, narrow loom widths reduced cutting efficiency, increased fabric waste, and inflated costs. Fit issues compounded the problem, as the rigid selvedge fabric offered little tolerance.

Switching to a wide-width washed denim preserved the visual look, improved comfort, stabilized sizing, and significantly improved margins. The product succeeded—not because it was less “authentic,” but because it was better aligned with its use case.

Decision Framework for Designers and Buyers

When choosing between raw, selvedge, and washed denim, the most useful questions are not aesthetic but practical:

- How much shrinkage risk can this product tolerate?

- How important is immediate comfort versus long-term aging?

- Does the construction story justify yield and cost impact?

- How predictable must sizing be across consumers?

Clear answers to these questions point naturally toward the appropriate denim type.

Interaction With Other Variables

It is also important to remember that finish state interacts with:

- Fiber composition

- Weave structure

- Fabric density

- Garment silhouette

A raw denim with elastane behaves very differently from a raw 100% cotton denim. A washed selvedge denim behaves differently from a washed wide-width denim. Labels alone do not capture these interactions.

Manufacturing and Planning Implications

From a production perspective, each denim type demands different planning discipline.

- Raw denim requires shrinkage modeling and consumer education

- Selvedge denim requires yield planning and cost control

- Washed denim requires wash consistency and finish control

Understanding these requirements early prevents costly surprises later.

Raw, selvedge, and washed denim differ not in prestige, but in risk profile and performance behavior.

Raw denim offers expressive aging at the cost of predictability. Selvedge denim offers construction heritage at the cost of yield and flexibility. Washed denim offers stability and scalability at the cost of fade drama.

The right choice depends on product intent, target consumer, and operational reality. When designers and buyers choose based on behavior rather than image, denim performs as expected—on the body, in production, and in the market.

In denim sourcing, the smartest decision is rarely the loudest one.

What Role Does Fiber Composition Play in Choosing the Right Denim Fabric Type?

When denim sourcing decisions fail, the root cause is often not the wash, the weight, or even the weave—it is the fiber composition. Fiber choice quietly governs how denim stretches, recovers, breathes, shrinks, and ages. It determines whether a garment feels authentic or artificial, forgiving or restrictive, stable or unpredictable. Long before a pattern is tested or a wash recipe is finalized, fiber composition has already set the boundaries of what the denim can and cannot do.

In modern apparel, denim fabric types are rarely chosen by construction alone. A rigid denim, a stretch denim, or a washed denim may share similar surface appearance, yet behave entirely differently because of what fibers sit inside the yarn. Cotton defines the soul of denim. Synthetic and elastic fibers define how controllable that soul becomes.

Fiber choice is function disguised as material.

How Fiber Blends Reshape Denim Behavior

Fiber composition affects denim across five critical dimensions:

- Stretch: how easily the fabric yields under movement

- Recovery: whether it returns to shape after stress

- Breathability: how it manages heat and moisture

- Aging: how fades, creases, and texture develop over time

- Dimensional stability: how predictable sizing remains after washing

Every denim fabric type—rigid, stretch, raw, washed, selvedge, or specialty—behaves differently depending on how these dimensions are balanced. Fiber blends are the tuning mechanism used to manage that balance.

Designers often focus on silhouette and wash. Buyers focus on price and availability. Fiber composition sits between them, translating design intent into real-world performance.

Common Denim Fiber Compositions

| Fiber Composition | Key Benefits | Trade-Offs |

|---|---|---|

| 100% Cotton | Authentic look, strong fades | Shrinkage, low recovery |

| Cotton + Elastane (1–3%) | Comfort, fit recovery | Muted aging |

| Cotton + Polyester | Stability, durability | Reduced breathability |

| Recycled blends | Sustainability appeal | Fiber variability |

Each blend solves a different problem. None is universally correct.

100% Cotton: Authenticity and Character

Pure cotton denim remains the reference point against which all other denim types are measured. Cotton’s natural properties—breathability, moisture absorption, and indigo affinity—create the sensory and visual cues most people associate with “real denim.”

Cotton delivers:

- Natural handfeel against the skin

- Deep, high-contrast fading over time

- A break-in process that reflects wear habits

- Strong cultural association with heritage denim

However, cotton also brings constraints. It stretches mechanically but recovers poorly. It swells when wet, leading to shrinkage. It relies heavily on construction and pattern ease to manage comfort.

For this reason, 100% cotton denim performs best in fabric types where structure and looseness are acceptable, such as rigid denim, raw denim, workwear styles, and heritage products. When used in fitted garments without adjustment, it often leads to fit complaints.

Cotton and Denim Fabric Types

Fiber composition determines how a denim fabric type behaves in use. For example:

- Rigid denim relies on cotton structure rather than elasticity

- Raw denim amplifies cotton’s aging and shrinkage behavior

- Selvedge denim often uses cotton-dominant yarns to reinforce authenticity

In these contexts, cotton’s limitations are not flaws—they are part of the intended experience.

Cotton + Elastane: Control Through Elasticity

Adding elastane transforms how denim behaves, even at very low percentages. A change from 0% to 1% elastane can dramatically alter comfort, recovery, and fit tolerance.

Cotton–elastane blends typically offer:

- Improved comfort during sitting and movement

- Better recovery after wear

- Reduced size complaints

- More forgiving fit across body variation

| Elastane Content | Typical Effect |

|---|---|

| 0–0.5% | Minimal stretch, structural assist |

| 1–1.5% | Subtle comfort and tolerance |

| 2–3% | High adaptability and contouring |

At SzoneierFabrics, elastane levels above 2% are carefully evaluated. While higher stretch improves immediate comfort, it often increases the risk of knee bagging, seat sagging, and long-term shape loss if not supported by construction and finishing.

How Elastane Changes Denim Fabric Types

Elastane reshapes traditional denim categories:

- Stretch denim is defined primarily by elastane content

- Washed denim with elastane prioritizes stability and comfort

- Unisex denim often uses low elastane to balance tolerance and structure

However, elastane also changes aging behavior. Creases soften, fades become more uniform, and texture flattens compared to pure cotton denim. Designers seeking dramatic wear patterns often accept less control in exchange for visual character.

Stretch Placement and Performance

Most modern stretch denim places elastane in the weft direction. This allows horizontal stretch for comfort while preserving vertical stability and length control.

Correct stretch placement:

- Supports sitting and bending

- Preserves inseam length

- Maintains silhouette geometry

Incorrect placement or overuse can cause:

- Length growth

- Sagging silhouettes

- Poor recovery at knees and seat

Stretch placement is therefore as important as stretch percentage. Two fabrics with identical elastane content can perform very differently depending on how that elastane is integrated.

Cotton + Polyester: Stability Over Sensation

Polyester is introduced into denim primarily for control, not comfort. It increases dimensional stability, reduces shrinkage, and improves abrasion resistance.

Cotton–polyester blends offer:

- Lower shrinkage after washing

- Improved tear and abrasion strength

- Better color retention

They are commonly used in:

- Utility and workwear denim

- High-rotation garments

- Unisex products requiring consistency

The trade-offs are real. Polyester reduces breathability and dampens natural fading. Denim becomes more predictable, but less expressive.

For brands prioritizing durability and consistency over heritage character, this compromise is acceptable. For brands built on authenticity narratives, it may not be.

Recycled and Sustainable Fiber Blends

Recycled cotton and recycled polyester are increasingly used to support sustainability goals. These fibers reduce environmental impact but introduce new technical considerations.

Advantages include:

- Lower raw material footprint

- Strong sustainability messaging

Challenges include:

- Shorter fiber lengths

- Greater variability in yarn strength

- Increased need for quality control

Recycled blends often perform best when combined with virgin fibers to stabilize performance. When used thoughtfully, they can support modern denim fabric types without undermining durability.

Fiber Blends and Washing Behavior

Fiber composition directly affects how denim responds to washing.

| Fiber Type | Shrinkage Impact | Aging Look |

|---|---|---|

| Cotton | Higher | Natural, high contrast |

| Polyester | Lower | Uniform, controlled |

| Elastane | Controlled | Softer creases |

Cotton-heavy fabrics shrink more but age more expressively. Synthetic-heavy fabrics shrink less but age quietly. Elastane moderates both stretch and visual evolution.

This interaction is especially important when choosing between raw and washed denim. Raw cotton denim magnifies shrinkage and aging. Washed blended denim minimizes surprises.

Fiber Composition as a Fit Strategy

One of the most underappreciated roles of fiber composition is its function as a fit management tool. Instead of forcing patterns to absorb all body variation, fiber blends can share the load.

- Pure cotton shifts fit responsibility to pattern and ease

- Elastane shares fit responsibility with the fabric

- Polyester stabilizes fit across sizes

Choosing the wrong blend can quietly undermine an otherwise sound design. A rigid cotton denim in a fitted silhouette will expose every grading flaw. A high-stretch denim in a loose silhouette may collapse visually.

A Real Sourcing Insight

A men’s denim program experienced high return rates due to discomfort and shrinkage complaints. The garments used a 100% cotton denim with traditional construction. Rather than changing silhouette or wash, the fabric was adjusted to a 98/2 cotton–elastane blend.

The result was immediate:

- Comfort improved without visible stretch

- Shrinkage complaints dropped sharply

- Fit tolerance increased across sizes

Weight, weave, and appearance remained unchanged. Fiber composition solved the problem quietly.

Matching Fiber Composition to Denim Fabric Type

Successful denim development aligns fiber composition with fabric type and end use:

- Rigid and raw denim benefit from high cotton content

- Stretch denim requires controlled elastane integration

- Washed denim favors blends that stabilize sizing

- Unisex denim benefits from balanced cotton–elastane ratios

Fiber composition should never be an afterthought. It defines how all other decisions behave in practice.

The Key Question to Ask

Instead of asking, “Is this stretch denim?”, a more useful question is:

“How does this fiber blend support fit, wear, aging, and consistency for this specific product?”

This shift in thinking moves denim selection away from labels and toward behavior.

Manufacturing and Cost Implications

Fiber composition also affects production:

- Elastane requires controlled heat and tension during sewing

- Polyester affects dye uptake and finishing recipes

- Recycled fibers demand tighter yarn quality control

Ignoring these implications often leads to hidden costs later in development.

Fiber composition is not about softness alone. It is about control—control over stretch, recovery, aging, and dimensional stability. Cotton defines denim’s identity. Elastane and synthetics define how manageable that identity becomes.

Choosing the right denim fabric type without understanding fiber composition is guesswork. Choosing the right fiber blend turns denim into a predictable, purposeful material rather than a risk.

In denim, what the garment does over time matters more than how it looks on day one. Fiber composition is where that story begins.

How Should Buyers Evaluate Denim Weight, Thickness, and Handfeel for Different Applications?

In denim sourcing, weight numbers are often treated as shortcuts to quality. A higher ounce figure is assumed to mean stronger, more premium fabric, while lighter denim is dismissed as less serious. In reality, many sourcing mistakes begin with this assumption. Denim performance is not defined by weight alone, and evaluating weight, thickness, and handfeel separately almost always leads to mismatches between fabric and end use.

Experienced buyers evaluate denim as a system. Weight defines structural potential, thickness affects construction and drape, and handfeel determines how the fabric is perceived and tolerated by the wearer. These elements interact. When they are aligned, denim feels intentional. When they are not, denim feels confused—either stiff without purpose or soft without control.

Good denim feels intentional, not accidental.

Reading Denim Beyond the Label

Fabric labels rarely tell the full story. Two denims both labeled “12 oz” can behave in completely different ways once cut, washed, and worn. One may hold a sharp silhouette, while the other collapses after finishing. One may sew cleanly, while the other resists needles and distorts seams.

To evaluate denim properly, buyers must move beyond single metrics and understand what each parameter actually represents—and what it does not.

Weight (oz) vs Thickness: Not the Same Thing

Weight and thickness are often confused, but they measure different realities.

| Attribute | What It Reflects | Why It Matters |

|---|---|---|

| Weight (oz/yd²) | Mass per unit area | Structure, durability, perceived substance |

| Thickness | Yarn bulk and fabric density | Drape, flexibility, sewing behavior |

| Handfeel | Surface feel and bending resistance | Comfort, perceived quality |

Weight measures how much material is present. Thickness measures how that material is distributed. A fabric can be heavy because it is dense, or thick because it is loosely packed. These two constructions behave very differently.

A dense denim with fine, tightly packed yarns may feel relatively thin in hand yet weigh more and resist abrasion well. A bulky denim with coarse yarns may feel thick and spongy but lack long-term durability.

This distinction is critical when matching fabric to application.

Why Weight Alone Is a Poor Decision Tool

Weight tells you how much material is there, not how that material works. Buyers who choose denim purely by ounce often encounter problems after washing or wear testing.

Common issues include:

- Fabric that feels premium in hand but collapses after finishing

- Heavy denim that is uncomfortable for daily wear

- Thick denim that is difficult to sew consistently

Weight must always be interpreted alongside thickness and handfeel to predict real performance.

Typical Denim Weight Ranges by Application

While no weight range is universal, industry practice provides useful reference points.

| Application | Common Weight Range |

|---|---|

| Shirts and light garments | 6–8 oz |

| Casual jeans and skirts | 9–11 oz |

| Classic jeans | 12–13 oz |

| Jackets and workwear | 14–16 oz |

These ranges reflect functional expectations, not quality levels. A 10 oz denim chosen correctly can outperform a poorly constructed 14 oz denim for its intended use.

At SzoneierFabrics, most buyers targeting everyday wear settle in the 10–13 oz range because it balances durability, comfort, and manufacturability across seasons.

Thickness: How Denim Moves and Sews

Thickness is influenced by yarn size, yarn twist, and construction density. It affects how the fabric bends, how seams stack, and how garments behave after washing.

Thicker-feeling denims tend to:

- Resist bending

- Feel more padded or bulky

- Create heavier seam stacks

Thinner-feeling denims tend to:

- Drape more easily

- Sew more cleanly

- Feel lighter in motion

Neither outcome is inherently better. The key is alignment with end use.

Thickness and Garment Type

Thickness matters differently depending on the product.

- Shirts and lightweight tops require low thickness for comfort and clean seams

- Fitted jeans need moderate thickness to avoid bulk at seams

- Jackets and overshirts can tolerate greater thickness for structure

A denim that feels excellent as yardage may become problematic once seams, hems, and facings are layered. This is why thickness must be evaluated with construction in mind, not just handfeel alone.

Handfeel: The Most Subjective—but Critical—Factor

Handfeel is how denim communicates quality to the wearer. It is shaped by surface texture, yarn flexibility, and finishing. While subjective, handfeel strongly influences purchasing decisions and wear satisfaction.

Handfeel is affected by:

- Yarn twist (tighter twist feels firmer)

- Surface hairiness or smoothness

- Washing and finishing treatments

A fabric can be technically durable but fail commercially if its handfeel feels harsh, lifeless, or overly stiff for its intended market.

Why Handfeel Must Be Tested Over Time

One of the most common evaluation mistakes is judging handfeel only in its unwashed state. Many denims change dramatically after finishing.

Buyers should always assess handfeel at multiple stages:

- Before washing

- After first wash

- After second wash

Some denims soften gradually and reach an ideal balance. Others soften too quickly and lose structure. Without multi-stage testing, these behaviors remain hidden until production.

How Washing Alters Perception

Enzyme washing, stone washing, and softening treatments can:

- Reduce surface friction

- Relax yarn tension

- Lower perceived stiffness

This can improve comfort—but it can also undermine silhouette support if the base construction is not strong enough. Fabrics that rely on stiffness rather than structure often fail after washing.

Practical Tactile Evaluation: What Experienced Buyers Do

Beyond lab data, experienced buyers rely heavily on hands-on evaluation. When handling denim samples, they often perform simple but revealing tests.

Common questions include:

- Does the fabric crease sharply or softly when folded?

- Does it spring back or stay wrinkled after release?

- Does it feel heavier or lighter after washing?

These observations reveal how the fabric manages stress and recovery—qualities that directly affect wear performance.

Creasing as a Diagnostic Tool

Sharp creases often indicate higher density and firmer yarn control. Soft creases suggest looser construction or softer yarn twist. Neither is right or wrong, but each suits different applications.

Tailored garments benefit from fabrics that crease cleanly and predictably. Relaxed garments benefit from fabrics that bend and recover gently.

Weight, Thickness, and Handfeel as a System

The most reliable denim selections emerge when buyers consider weight, thickness, and handfeel together.

For example:

- A midweight denim with high density may feel thin but perform structurally

- A thick-feeling denim with low density may feel soft but wear quickly

- A heavy denim with poor handfeel may alienate consumers despite durability

Understanding these interactions prevents overreliance on any single parameter.

Matching Denim Feel to End Use

Different applications demand different balances.

- Everyday jeans benefit from moderate weight, moderate thickness, and balanced handfeel

- Workwear prioritizes weight and density over softness

- Fashion garments may prioritize handfeel and drape over long-term durability

Buyers should evaluate denim through the lens of how the garment will be worn, not how the fabric feels in isolation.

A Real-World Evaluation Example

A buyer selected a 13 oz denim because it felt firm and premium in hand. On paper, it seemed ideal for tailored jeans. After enzyme washing, however, the fabric lost too much body. Seams softened, and the silhouette blurred.

The solution was not increasing weight. Instead, the buyer switched to a denim of the same weight but higher weave density. The fabric retained structure after washing, and the garment performed as intended.

The lesson was clear: weight alone did not determine outcome. Construction did.

Why Heavier Is Not Always Better

Chasing heavier denim often introduces unintended problems:

- Increased discomfort in warm climates

- Higher sewing difficulty and defect risk

- Reduced wear compliance for everyday consumers

Heavier denim only makes sense when its additional structure is actually needed. Otherwise, it becomes a liability rather than an asset.

Communicating Requirements to Suppliers

When discussing denim with suppliers, buyers should avoid vague requests such as “heavier” or “more premium.” Instead, they should communicate:

- Target weight range

- Desired thickness and drape

- Handfeel expectations before and after washing

Clear communication reduces trial-and-error sampling and speeds development.

Manufacturing and Cost Implications

Weight and thickness also influence cost beyond fabric price.

- Thicker fabrics slow sewing speed

- Heavier fabrics increase shipping weight

- Dense fabrics increase loom time

Evaluating denim holistically helps buyers understand total cost, not just cost per yard.

A Buyer’s Evaluation Checklist

Before approving denim for production, experienced buyers typically confirm:

- Weight aligns with application, not trend

- Thickness supports intended construction

- Handfeel remains appropriate after washing

- Fabric behavior matches silhouette logic

Skipping any of these checks increases risk later.

The Role of Experience and Testing

No chart replaces physical testing. The most accurate evaluations combine numeric data with tactile experience and wear trials. Denim that performs well in theory can still fail in practice if handfeel or behavior contradicts use case.

Denim weight, thickness, and handfeel are interdependent. Evaluating them in isolation leads to poor decisions. Weight defines potential, thickness shapes construction, and handfeel determines acceptance.

The best denim choices are not the heaviest or stiffest, but the most appropriate for the product’s purpose. When buyers evaluate denim as a system rather than a number, they reduce risk, improve performance, and deliver garments that feel deliberate rather than accidental.

In denim sourcing, intention shows through the hand.

Which Finishing and Treatment Options Define Denim Fabric Functionality and Style?

In denim manufacturing, fabric selection is only half the story. Finishing and treatment are where denim truly becomes a product—where stiffness turns into comfort, raw indigo becomes character, and unstable yardage becomes wearable apparel. The same base denim can feel rigid or fluid, predictable or risky, refined or aggressively distressed depending entirely on how it is finished.

This is why experienced buyers and manufacturers rarely evaluate denim based on greige fabric alone. They evaluate the finished behavior. Shrinkage, handfeel, strength retention, and visual consistency are all shaped at the finishing stage. When finishing decisions are made casually or too late, problems appear downstream: inconsistent sizing, weakened seams, collapsed silhouettes, or unexpected return rates.

Finishing is where denim becomes wearable—or problematic.

How Finishes Reshape Denim Behavior

Denim finishing modifies fabric behavior across four critical dimensions:

- Appearance: color depth, contrast, and surface texture

- Comfort: softness, flexibility, skin feel

- Dimensional stability: shrinkage and size retention

- Durability: fiber strength and abrasion resistance

Each finishing method shifts these dimensions in different directions. No finish improves everything at once. Every treatment involves trade-offs that must align with the product’s intended use.

Common Denim Finishing Methods and Effects

| Finish Type | Main Effect | Trade-Off |

|---|---|---|

| Rinse wash | Clean look, mild softening | Limited visual depth |

| Enzyme wash | Softer handfeel | Reduced fiber strength |

| Stone wash | Vintage, worn appearance | Fabric stress |

| Acid wash | High contrast patterns | Weakened fibers |

| Sanforization | Dimensional stability | Slight stiffness |

Understanding what each finish actually does—rather than what it symbolizes—is essential for functional denim sourcing.

Rinse Washing: Minimal Intervention, Maximum Control

Rinse washing is one of the lightest finishing methods. It removes surface starch and excess dye without aggressively altering fabric structure.

Rinse-washed denim typically offers:

- Cleaner, more uniform color

- Slightly softer handfeel than raw denim

- Minimal fiber damage

Because it preserves much of the original fabric strength, rinse washing is often used for:

- Entry-level washed denim

- Products that rely on structure rather than distress

- Collections where consistency matters more than dramatic aging

The limitation is visual depth. Rinse washing does little to create contrast or texture. It is a functional finish rather than a stylistic one.

Enzyme Washing: Softness Through Controlled Degradation

Enzyme washing uses biological enzymes to selectively break down surface fibers. This reduces stiffness and creates a smoother handfeel.

Key outcomes of enzyme washing include:

- Noticeably softer fabric

- Reduced surface fuzz

- More comfortable wear from day one

However, enzyme washing works by removing material. Overuse weakens yarns and reduces abrasion resistance. This is why enzyme parameters must be carefully calibrated.

Enzyme washing is widely used in:

- Everyday jeans

- Women’s and comfort-focused denim

- Lightweight and midweight fabrics

When balanced correctly, it improves wearability without compromising structure. When pushed too far, it shortens garment life.

Stone Washing: Visual Impact at a Cost

Stone washing introduces pumice stones into the wash cycle to physically abrade the fabric surface. This creates a worn, vintage look with softened edges and visible contrast.

Stone washing delivers:

- Strong visual character

- Broken-in appearance

- Softer handfeel

The cost is mechanical stress. Stones impact fabric unevenly, weakening fibers, seams, and edges. Over time, this can lead to premature wear, especially at stress points.

Because of this, stone washing is best reserved for:

- Fashion-driven products

- Styles where visual impact outweighs longevity

- Fabrics with sufficient base strength

Many modern programs reduce stone load or combine stones with enzymes to limit damage.

Acid Washing: High Contrast, High Risk

Acid washing creates dramatic, high-contrast patterns by partially removing dye through chemical processes. The result is visually striking but structurally aggressive.

Acid washing:

- Produces bold, irregular contrast

- Weakens fibers significantly

- Reduces overall fabric lifespan

For this reason, it is typically used sparingly in niche or seasonal collections. Acid-washed denim prioritizes appearance over durability and is rarely suitable for everyday wear products.

Sanforization: Stability Before Style

Sanforization is not a visual finish but a mechanical pre-shrinking process applied at the fabric stage. It compresses the fabric to reduce future shrinkage during washing.

Sanforized denim offers:

- Predictable post-wash dimensions

- Reduced size variation

- Greater confidence in pattern grading

The trade-off is a slightly firmer handfeel before washing. However, this stiffness is often mitigated through subsequent finishing.

For buyers who prioritize fit consistency and low return rates, sanforization is often the most important treatment of all—even though it is invisible to the consumer.

Fabric-Stage vs Garment-Stage Finishing

Where finishing occurs has major implications for consistency and risk.

| Stage | Result |

|---|---|

| Fabric-stage wash | Stable cutting, predictable sizing |

| Garment-stage wash | Visual control, higher size risk |

Fabric-stage finishing stabilizes yardage before cutting. This improves yield, grading accuracy, and production efficiency. It is especially valuable for large-scale or multi-size programs.

Garment-stage finishing allows precise visual control on finished pieces but introduces variability. Shrinkage and distortion occur after sewing, which can affect fit if not carefully managed.

For scalable production, many buyers prefer fabric-stage stabilization followed by controlled garment washing to balance consistency and appearance.

Why Finishing Order Matters

The sequence in which finishes are applied can dramatically change outcomes. For example:

- Softening before washing may lock in shrinkage

- Washing before softening may relax fabric more fully

- Enzyme treatment before stone washing reduces damage

Changing the order—even with the same treatments—can alter handfeel, shrinkage, and strength retention.

This is why finishing recipes must be treated as technical specifications, not interchangeable steps.

Finishing and Fiber Interaction

Finishing effects vary depending on fiber composition.

- 100% cotton denim responds strongly to washing and abrasion

- Cotton–elastane denim requires lower mechanical stress to protect recovery

- Polyester blends resist abrasion but show less visual change

A finish that works well on rigid cotton denim may damage stretch denim or produce flat results on synthetic-heavy fabrics. Finishing must be matched to fiber behavior.

Sustainability-Driven Finishing Methods

Environmental pressure has reshaped denim finishing over the last decade. Many traditional methods are being replaced or supplemented by lower-impact alternatives.

Common sustainability-focused finishes include:

- Low-water washing to reduce consumption

- Ozone fading to replace chemical bleaching

- Laser treatments to create wear patterns without abrasion

These methods reduce environmental footprint and often improve consistency. However, they require precise calibration. Poorly executed ozone or laser treatments can weaken fabric or create unnatural visuals.

Ozone and Laser: Precision Tools, Not Shortcuts

Ozone washing fades denim using oxidized oxygen, reducing water and chemical use. Laser finishing creates localized wear patterns without physical abrasion.

When used correctly, these methods:

- Reduce fabric damage

- Improve repeatability

- Lower environmental impact

When used carelessly, they can produce flat color, brittle fibers, or artificial-looking patterns. Technology does not replace judgment.

A Sourcing Insight from Practice

One brand sought a heavily worn look using aggressive stone washing. Quality issues followed: seam damage, inconsistent appearance, and shortened wear life. By switching to a combined enzyme + ozone process, the brand achieved a similar aesthetic with far less fabric stress.

Consistency improved, durability increased, and returns declined. The base fabric did not change. The finishing logic did.

Matching Finishes to Denim Fabric Types

Different denim fabric types respond best to different finishing strategies:

- Raw denim often uses minimal finishing to preserve aging potential

- Rigid denim benefits from light rinsing or sanforization

- Stretch denim requires gentle finishes to protect recovery

- Fashion denim may justify aggressive treatments for visual impact

There is no universal finishing recipe. Each product demands its own balance.

Evaluating Finishing During Development

Buyers should never approve denim based on untested finishes. At minimum, evaluation should include:

- Handfeel before and after finishing

- Shrinkage measurement

- Visual consistency across samples

- Strength retention at stress points

Skipping these checks often leads to costly corrections later.

Cost and Production Implications

Finishing choices affect cost beyond the wash itself.

- Aggressive finishes increase defect risk

- Complex recipes extend lead time

- Inconsistent finishes increase rejection rates

Understanding these implications helps buyers assess total cost, not just wash price.

Finishing as a Design Decision

Finishing is not a last step—it is a design decision. It shapes how denim looks, feels, and survives real use. Treating finishing as an afterthought often undermines otherwise sound fabric and pattern choices.

Finishing and treatment define denim fabric functionality as much as fiber, weave, or weight. Rinse washing, enzyme treatment, stone washing, acid washing, and sanforization each reshape denim behavior in specific ways, introducing both benefits and compromises.

The most successful denim programs choose finishes based on how the garment must perform, not just how it should look on launch day. When finishing logic aligns with fabric construction and end use, denim becomes predictable, wearable, and commercially viable.

In denim, the final feel is never accidental. It is finished that way.

What Common Sourcing Mistakes Do Buyers Make When Selecting Denim Fabric Types?

In denim sourcing, most quality problems do not originate on the production line. They are chosen much earlier—during fabric selection, approval, and specification. By the time garments show size drift, bagging, weak seams, or inconsistent appearance, the root cause is usually not poor sewing or careless washing. It is a sourcing decision made under incomplete evaluation or incorrect assumptions.

Denim is often treated as a familiar material. Because it is widely used and visually recognizable, buyers sometimes assume that different denim types are broadly interchangeable. This assumption is expensive. Denim is a system of fiber, weave, weight, density, and finishing, and changing one element without revalidating the whole system introduces risk.

Most denim problems are chosen early—long before production starts.

Where Denim Sourcing Often Goes Wrong

Sourcing mistakes tend to repeat across brands, seasons, and markets. They are rarely caused by lack of effort. More often, they result from shortcuts, overreliance on labels, or pressure to move quickly. Understanding these patterns helps buyers avoid issues that are otherwise predictable.

Mistake 1: Treating Weight as the Main Quality Indicator

One of the most persistent misconceptions in denim sourcing is equating fabric weight with quality. Heavier denim is often assumed to be stronger, more premium, or more durable.

| Assumption | Reality |

|---|---|

| Higher oz equals higher quality | Construction and density matter more |

| Lighter oz equals weak fabric | Density and yarn quality can compensate |

Weight measures mass per area, not how yarns are arranged or how stress is distributed. A 14 oz denim with loose construction can wear out faster than a 12 oz denim with high density and strong yarn control.

Buyers who select denim primarily by ounce often discover problems after washing or wear testing. The fabric may feel impressive in hand but lose structure, soften excessively, or distort once finished.

Quality comes from balance, not mass.

Why This Mistake Happens

Weight is easy to understand and easy to communicate. Density, yarn twist, and weave are harder to visualize and harder to compare across suppliers. As a result, weight becomes a proxy for quality—even when it should not.

Experienced sourcing teams use weight as a filter, not a decision point. It narrows options but never replaces construction evaluation.

Mistake 2: Ignoring Post-Wash Behavior

Approving denim based only on greige or unwashed samples is one of the most costly errors buyers make. Denim changes significantly after washing, and those changes are rarely linear or intuitive.

| Skipped Step | Result |

|---|---|

| No shrinkage testing | Size drift after sale |

| No wear simulation | Knee bagging, seat growth |

| No seam evaluation | Puckering, distortion |

Many denims soften, relax, or lose density after enzyme or rinse washing. Others shrink unevenly or reveal weak points only after stress is applied. Without wash-stage testing, these behaviors remain hidden until production—or worse, until consumers wear the garment.

Buyers who skip washing tests often face returns later, even when the fabric looked excellent at approval stage.

Why Wash Testing Is Non-Negotiable

Denim is designed to change. Indigo redistributes. Yarns relax. Finishes alter friction and recovery. Evaluating denim only before washing is like evaluating leather before tanning—it shows potential, not performance.

At minimum, buyers should evaluate:

- Dimensional change after washing

- Handfeel before and after wash

- Recovery after simulated wear

Skipping these steps transfers risk from development to the market.

Mistake 3: Confusing Denim Type With Finishing Result

Labels such as raw, selvedge, and washed are often misunderstood and overvalued. Buyers sometimes assume these terms describe performance, when they actually describe process or construction context.

| Misunderstanding | Consequence |

|---|---|

| Selvedge equals better quality | Yield loss and higher cost |

| Raw denim equals stability | High shrinkage and fit risk |

| Washed denim equals low quality | Missed consistency benefits |

Selvedge denim describes loom type, not durability or comfort. Raw denim describes finishing state, not predictability. Washed denim describes treatment, not inferiority.

When buyers choose denim based on reputation rather than behavior, they often introduce problems that conflict with the product’s actual use.

Reputation-Driven Decisions vs Functional Decisions

A fabric chosen to “signal premium” may undermine fit or comfort. A fabric dismissed as “basic” may actually deliver better consistency and lower returns. Denim sourcing fails when image overrides function.

Understanding what each denim type actually does prevents these reputation-driven mistakes.

Mistake 4: Changing Denim Without Re-Testing

Another common sourcing error occurs when buyers switch suppliers, mills, or production lots without full re-validation. Even when specifications appear identical on paper, denim behavior can shift.

Reasons include:

- Differences in yarn source or preparation

- Variations in loom setup or tension

- Subtle changes in finishing chemistry

Denim is sensitive to small changes. A 1% difference in elastane content or a slight density variation can alter recovery, shrinkage, or handfeel.

Switching denim without re-testing assumes equivalence where none is guaranteed.

Why “Same Spec” Is Not the Same Fabric

Specifications describe targets, not outcomes. Two mills may meet the same spec range but deliver different behavior due to process differences. This is especially true for stretch denim, washed denim, and blended fabrics.

Re-testing after any fabric change is not redundant—it is risk management.

Mistake 5: Underestimating Communication Gaps

Many denim problems originate not from the fabric itself, but from how requirements are communicated. Descriptions such as “soft but firm,” “premium handfeel,” or “comfortable stretch” invite interpretation.

Without numeric boundaries and reference samples, suppliers fill gaps with their own assumptions.

Clear specifications outperform assumptions every time.

Effective denim communication includes:

- Defined fiber composition with tolerances

- Target weight and acceptable range

- Shrinkage limits after washing

- Reference samples for handfeel and appearance

When expectations are vague, outcomes drift.

How Ambiguity Becomes Cost

Ambiguous specs lead to:

- Multiple sampling rounds

- Late-stage fabric changes

- Inconsistent bulk production

Each correction adds time and cost. Clear upfront communication reduces iteration and accelerates development.

Mistake 6: Evaluating Fabric in Isolation

Some buyers evaluate denim as yardage without considering the garment it will become. A fabric that feels excellent in hand may behave poorly once cut into a specific silhouette.

Common oversights include:

- Ignoring seam stacking in thick fabrics

- Overlooking stretch behavior in fitted designs

- Using rigid denim for high-movement garments

Denim performance emerges only when fabric, pattern, and finish interact. Evaluating one without the others creates blind spots.

Mistake 7: Over-Correcting After a Problem Appears

When issues arise—such as bagging or shrinkage—buyers sometimes respond by overcorrecting. For example, adding more elastane to solve comfort complaints or increasing weight to solve durability issues.

These reactions often introduce new problems:

- Excess elastane reduces aging character

- Excess weight reduces comfort and wear compliance

Most issues are better solved by rebalancing construction, not by pushing a single parameter to extremes.

A Pattern Behind Most Mistakes

Across these sourcing errors, a common pattern emerges: decisions are made using shortcuts rather than behavior-based evaluation.

- Labels replace testing

- Weight replaces construction analysis

- Assumptions replace documentation

Denim sourcing improves dramatically when buyers slow down at the evaluation stage rather than rushing to approval.

How Experienced Buyers Avoid These Traps

Buyers who consistently achieve stable denim programs tend to share similar habits:

- They test fabrics after washing, not before approval

- They document behavior, not just specs

- They revalidate after any change

- They choose denim types based on use, not image

These habits reduce surprises and protect margins.

The Cost of “Almost Right” Denim

Denim that is almost right often performs worse than denim that is clearly wrong. Small mismatches—slightly too soft, slightly too rigid, slightly too unstable—create ongoing friction with consumers.

Returns, complaints, and negative reviews rarely point directly to fabric choice. They surface as fit issues, comfort issues, or durability concerns. But the origin is usually denim selection.

Building a More Reliable Sourcing Process

Avoiding common denim sourcing mistakes does not require deeper technical complexity. It requires clearer process discipline:

- Evaluate denim after finishing

- Separate image from function

- Communicate specs numerically

- Re-test when anything changes

These steps are simple, but they are often skipped under time pressure.

Most denim sourcing mistakes are not technical failures—they are decision failures. Treating weight as quality, skipping wash validation, confusing denim labels with performance, and relying on vague descriptions all introduce avoidable risk.

Denim rewards clarity. When buyers evaluate behavior instead of reputation and process instead of assumptions, fabric choices become predictable rather than problematic.

In denim sourcing, problems rarely appear suddenly. They are usually approved quietly at the beginning.

How Can Buyers Choose the Right Denim Fabric Type and Supplier for Consistent Production?

In denim manufacturing, consistency is rarely an accident. Brands that deliver stable fit, repeatable quality, and predictable customer experience season after season usually follow a disciplined fabric-selection process—and work with suppliers who understand denim as a system, not a swatch. The biggest sourcing failures do not come from choosing a “bad” denim, but from choosing a denim that behaves differently in bulk than it did in development, or from working with suppliers who treat denim as a commodity rather than a performance material.