How to Tell If Denim Is High-Quality?

Denim may be a universal wardrobe staple, but not all denim is created equal — and for B2B fabric buyers, the difference between high-quality and subpar denim can make or break a product line. Whether you’re developing a raw selvedge collection or mass-market stretch jeans, quality assurance starts at the fabric level.

So, how can you tell if denim is high-quality? High-quality denim typically features a tightly woven twill structure, consistent yarn tension, durable natural or blended fibers, strong colorfastness, balanced GSM, and reliable stretch recovery (if applicable). It should also pass basic physical tests like tensile strength, pilling resistance, and shrinkage control. The best denim isn’t just heavy — it’s engineered to age gracefully, resist breakdown, and deliver long-term customer satisfaction.

In 2022, a mid-sized U.S. brand switched from a budget denim mill to a premium OEKO-TEX®-certified Chinese supplier. The result? Return rates dropped by 37%, and repeat purchase frequency rose by 21% within one season.

If you’re evaluating fabric options and want to avoid sourcing pitfalls, this guide will give you the tools to assess denim quality confidently — with insights tailored to professional buyers and technical teams.

1. What Are the Key Characteristics of High-Quality Denim Fabric?

High-quality denim is defined by strong, uniform yarns; a consistent twill weave; stable dye application; and physical performance under abrasion, stretching, and repeated washing.

Understanding Core Quality Attributes

● Yarn Quality and Uniformity

- High-grade denim uses long-staple cotton or premium blends

- Look for:

- Ring-spun yarns (stronger than open-end)

- Minimal neps, slubs, or weak spots

- Even yarn twist = better durability

| Yarn Type | Description | Quality Indicator |

|---|---|---|

| Ring-Spun | Long-staple cotton, tightly twisted | ✅ Preferred for longevity |

| Open-End | Cheaper, shorter fibers | ❌ More prone to pilling |

| Dual-Core (blends) | Core of elastane/polyester for stretch | ✅ For performance denim |

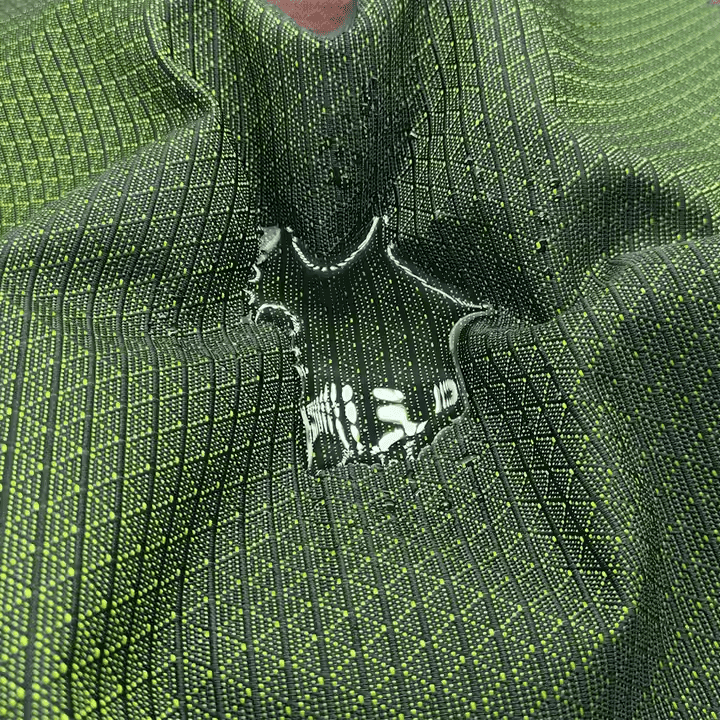

● Weave Consistency

- Classic denim = 3×1 right-hand twill

- Check for:

- Consistent twill angle

- No skipped weaves or broken threads

- Minimal fraying at raw edges

● Finishing Control

- High-end denim undergoes:

- Sanforization (pre-shrinkage)

- Enzyme or ozone washing (for softness)

- Laser or hand-distressing (premium fade aesthetics)

Request a finished fabric spec sheet, including: GSM, shrinkage %, width tolerance, stretch %, and finish type.

2. How Does the Weave Structure Affect Denim Quality?

Denim’s weave structure — especially the twill direction, density, and yarn count — plays a critical role in strength, drape, resistance to deformation, and visual character.

Twill Engineering in Denim Construction

● Twill Type and Direction

| Twill Style | Description | Use Case |

|---|---|---|

| 3×1 Right-Hand Twill | Warp over 3 wefts, angled from lower left to upper right | Classic jeans and raw denim |

| 2×1 Twill | Lighter weight, softer finish | Shirts, women’s jeans |

| Broken Twill | Alternating twill direction to reduce twisting | High-mobility, anti-leg-twist jeans |

Wrangler pioneered broken twill in the 1960s to reduce the “leg twist” that plagued earlier jeans during wear.

● Weave Density and Strength

| Metric | High-Quality Indicator |

|---|---|

| Ends Per Inch (EPI) | Higher EPI = Tighter construction |

| Picks Per Inch (PPI) | Balanced with EPI to avoid puckering |

| GSM | Should match target usage (e.g., 12–16oz for rigid jeans) |

● How to Inspect Twill Quality

- Hold fabric under light: diagonal lines should be clear and uninterrupted

- Check for skipped yarns, loose floats, or weft misalignment

- Feel the back side: weft should feel even, not fuzzy or irregular

A Turkish mill supplied two similar 11oz denims. One had a consistent 3×1 weave with ring-spun yarns, while the other showed skipped threads and uneven twill — resulting in a 20% higher complaint rate for finished garments.

Twill structure isn’t just visual — it defines how well the fabric wears, ages, and holds shape. Use a loupe or magnifying app to inspect at the yarn level.

3. Which Fiber Types and Blends Indicate Superior Denim?

High-quality denim is most often made from long-staple cotton or premium cotton blends that enhance stretch, durability, and hand feel. The right fiber mix depends on intended use — but natural, certified, or performance-engineered yarns usually outperform budget alternatives.

Evaluating Fiber Content for Quality and Longevity

● 100% Cotton vs Cotton Blends

| Fiber Composition | Pros | Ideal For |

|---|---|---|

| 100% Cotton (Ring-Spun) | Durable, authentic aging, recyclable | Heritage jeans, raw denim |

| Cotton + Elastane (1–3%) | Comfort, fit retention | Skinny jeans, women’s wear |

| Cotton + Poly (20–30%) | Lower cost, added strength | Workwear, fast fashion jeans |

| Cotton + TENCEL™ | Softness, drape, sustainability | Premium fashion denim |

Look for suppliers offering BCI cotton, GOTS organic cotton, or Lenzing™-certified cellulose fibers to ensure long-term fabric value and brand credibility.

● Stretch Denim Considerations

If you’re sourcing for stretch denim:

- Choose dual-core yarns (e.g., Lycra T400®) for better shape memory

- Avoid high elastane content (>4%) — can lead to bagging and poor longevity

| Stretch Recovery Test | Quality Threshold |

|---|---|

| <10% residual stretch | Excellent |

| 10–15% | Acceptable |

| >15% | Poor (may bag out) |

● Certifications to Prioritize

| Label | Meaning |

|---|---|

| OEKO-TEX® Standard 100 | Free from harmful substances |

| GOTS | Organic cotton, strict environmental control |

| GRS/RCS | Recycled polyester or cotton content |

A European denim label switched from 98/2 cotton-poly to organic cotton + TENCEL™ blend, achieving 30% fewer product returns due to improved softness, shrinkage control, and tear resistance.

4. Is Fabric Weight (GSM) a Reliable Indicator of Denim Quality?

Fabric weight (GSM or ounces per square yard) offers useful context, but isn’t a standalone measure of denim quality. A well-constructed 11oz fabric can outperform a poorly woven 14oz one — especially when weight is inflated by coating or filler yarns.

Understanding GSM and Functional Fabric Density

● Common Weight Ranges for Denim

| Category | Weight (oz) | GSM Range | Typical Use |

|---|---|---|---|

| Lightweight Denim | 6–9 oz | 170–260 gsm | Shirts, dresses, summer jeans |

| Midweight Denim | 10–12 oz | 270–340 gsm | All-purpose jeans, casual wear |

| Heavyweight Denim | 13–16 oz | 370–450 gsm | Raw denim, workwear, premium jeans |

| Ultra-Heavy Denim | 17–32 oz | 460+ gsm | Niche selvedge, biker or archival |

High GSM doesn’t always mean better quality. Some mills artificially boost fabric weight using thicker weft yarns or finishing resins, which don’t translate to performance or comfort.

● Key Performance Metrics Beyond GSM

| Metric | What to Check |

|---|---|

| Tear/Tensile Strength | ≥ 350 N (warp), ≥ 250 N (weft) |

| Dimensional Stability | <3% shrinkage on warp and weft after wash |

| Abrasion Resistance | ≥ 20,000 cycles (Martindale) |

● Visual & Physical Inspection Tips

- Heft test: Drape and fold fabric — high-quality denim should “stand” rather than collapse completely

- Snap test: Tug gently — cheap fillers will feel bouncy or spongey, premium denim feels dense but breathable

- Backlight test: Hold fabric against light — even thickness = better yarn consistency

Two 12oz denims from different suppliers:

- Supplier A: Ring-spun, 3×1 twill, 100% cotton, 3% shrinkage

- Supplier B: Open-end yarn, 2×1 twill, heavier starch finish, 7% shrinkage Although both were 12oz, Supplier A’s fabric outperformed in abrasion, fade retention, and customer returns — proving GSM alone isn’t enough.

5. How Do Stretch and Recovery Rates Impact Long-Term Wear?

High-quality stretch denim maintains its shape after repeated wear thanks to strong recovery properties, while poor-quality blends tend to bag out, sag, or deform after just a few washes.

The Mechanics of Stretch and Fabric Resilience

● What Is Fabric Recovery?

Recovery is how well a stretch fabric returns to its original shape after being extended. It’s measured as the percentage of deformation that doesn’t return after stress is removed.

| Fabric Composition | Stretch Recovery Rating |

|---|---|

| 98% Cotton / 2% Lycra® | Good (8–12% residual stretch) |

| 92% Cotton / 6% Poly / 2% Elastane | Excellent (≤8%) |

| 70% Cotton / 30% Poly | Poor (≥15%, prone to bagging) |

● Dual-Core Stretch Yarns

High-end stretch denim often uses dual-core yarns:

- A central elastane core wrapped with polyester or cotton

- Provides snap-back memory

- Lasts longer under mechanical stress

● Testing Stretch and Recovery

| Test Type | How to Perform | What to Look For |

|---|---|---|

| Stretch % | Pull fabric to 120% and release | Should stretch easily but rebound |

| Residual Elongation | Measure length post-release | <10% change = good performance |

| Multiple Wash Recovery | Re-test after 5–10 wash cycles | Shape should stay intact |

A fashion label used a budget 97/3 cotton-spandex blend for women’s jeans. Within 3 wears, knees sagged noticeably. After switching to a Lycra® dual-core version, customer complaints dropped by 41%, and reorders increased significantly.

● What Buyers Should Ask

- Is stretch uni-directional or bi-stretch?

- What’s the residual stretch % after 5 washes?

- Is it core-spun, covered yarn, or generic spandex?

In high-fit categories (skinny jeans, maternity denim, plus-size lines), strong recovery is non-negotiable. Don’t rely on fabric weight alone — test elasticity and memory performance.

6. What Tests Can You Perform to Verify Denim Durability?

To verify denim durability, buyers should run standardized lab tests like Martindale abrasion, tear and tensile strength, pilling resistance, and shrinkage simulation. These tests reveal how well the fabric withstands real-world usage.

Physical Testing for Fabric Reliability

● Key Lab Tests for Denim Quality

| Test Type | Standard Used | High-Quality Benchmark |

|---|---|---|

| Abrasion Resistance | Martindale ISO 12947 | ≥ 20,000 cycles (for daily use) |

| Tear Strength | ISO 13937 | ≥ 350 N warp, ≥ 250 N weft |

| Tensile Strength | ISO 13934 | ≥ 400 N warp direction |

| Dimensional Stability | AATCC 135 | < 3% shrinkage (after 3 washes) |

| Pilling Resistance | ISO 12945 | ≥ Grade 4 after 500 cycles |

● How to Perform Basic Buyer-Side Checks

If lab testing isn’t feasible early on, try these:

- Rub Test: Use thumb pressure to rub one area vigorously — does color transfer?

- Snap Test: Tug diagonally to feel weave tension

- Wash Simulation: Machine-wash swatch 3x at 40°C and observe changes in size, color, or shape

- Friction Check: Rub against another fabric to test pilling tendency

● Additional Colorfastness Tests

- Dry Crocking: Rub white cotton against dry denim — high-quality should transfer minimal dye

- Wet Crocking: Repeat test with damp swatch — bleeding = poor dye fixation

- Light Fastness: Expose fabric to sunlight for 72 hours — high-end denim holds color longer

| Test Condition | Good Result |

|---|---|

| Dry Crocking | Grade ≥ 4 |

| Wet Crocking | Grade ≥ 3 |

| Light Fastness | Grade ≥ 5 |

A North American retailer ordered denim that passed visual inspection but failed Martindale and colorfastness tests. The garments faded in retail display lighting within weeks. A shift to a Higg Index-certified supplier fixed this with minimal cost increase.

7. Do Dyeing Techniques and Color Fastness Affect Denim Value?

Yes — dyeing methods like rope dyeing, slasher dyeing, and sulfur/reactive techniques have a direct impact on denim’s visual appeal, fade behavior, and resistance to washing, rubbing, and light exposure. High-quality denim typically uses rope dyeing for deep, uniform, and long-lasting color.

The Science Behind Denim Dyeing

● Common Dyeing Methods

| Method | Description | Quality Level |

|---|---|---|

| Rope Dyeing | Yarns twisted into ropes, dipped in indigo repeatedly | ✅ Premium, even fading |

| Slasher Dyeing | Warp yarns dyed flat on sheet format | ⚠️ Fast, cost-effective |

| Sulfur Dyeing | Used for black, brown, or color denim | ⚠️ Moderate fastness |

| Pigment Dyeing | Sits on surface, not absorbed | ❌ Low fastness |

Rope dyeing allows “ring-dyeing” — only the outer yarn absorbs indigo. This creates authentic fades over time and prevents uneven discoloration.

● How to Identify Good Color Fastness

| Test | Evaluation Standard | Target for High-Quality Denim |

|---|---|---|

| Wash Fastness | ISO 105-C06 | Grade ≥ 4 |

| Light Fastness | ISO 105-B02 | Grade ≥ 5 |

| Rubbing Fastness | ISO 105-X12 | Dry ≥ 4, Wet ≥ 3 |

● Dye Depth and Aesthetic Impact

- Higher-quality denim often features multi-dip indigo (6–8 dips)

- Even color saturation across warp = better fade control

- Cheap dyeing leaves visible inconsistencies or patchy fades

Always ask your mill:

- How many indigo dips are used?

- Is the yarn dyed via rope or slasher?

- What’s the crocking grade?

● Case Example:

A Japanese premium denim brand sourced 14oz selvedge from a Chinese mill using 8-dip rope dyeing. They achieved signature fade aesthetics after 6–12 months of wear — a core selling point that justified a \$200+ price tag.

8. How Should B2B Buyers Evaluate Denim Suppliers for Quality Assurance?

B2B buyers should evaluate denim suppliers based on their weaving and dyeing infrastructure, testing certifications, sampling process, communication transparency, and post-sale quality monitoring. A high-quality supplier combines strong technical capabilities with dependable service.

A Practical Sourcing Framework

● Evaluation Checklist for Denim Suppliers

| Criterion | What to Look For |

|---|---|

| Technical Specs | Twill type, GSM, shrinkage %, stretch %, etc. |

| Certifications | OEKO-TEX®, GOTS, GRS, ISO 9001/14001 |

| Dyeing Technology | Rope dyeing or premium slasher with QC control |

| In-House Testing Lab | Offers pre-shipment inspection reports |

| MOQ & Sampling Policy | Low MOQ, fast sample turnaround (7–10 days) |

| Responsive Communication | Timely, professional, and tech-literate |

● Sample Approval Process

- Always request yardage samples (not just hand swatches)

- Run internal tests: shrinkage, GSM check, stretch test

- Request production-grade pre-shipment samples for consistency

● Supplier Red Flags

- Reluctance to provide lab data

- Inconsistent pricing without spec explanation

- Changing specs between sampling and production

- Lack of documentation or certification transparency

A French label partnered with a China-based mill offering 3×1 twill, 12oz OEKO-TEX®-certified denim with 8-day sample lead times and inline QA reports. After 18 months, return rates for denim fell below 3%, and lead times remained consistent within ±2 days across five production runs.

Build long-term partnerships with mills that support technical dialogue. This creates space for collaborative development, custom finishes, and co-branding (e.g., using Lycra®, TENCEL™, etc.).

How to Spot High-Quality Denim Before You Buy

Knowing how to identify high-quality denim can protect your brand from quality failures, returns, and inconsistent sourcing outcomes. Here’s a quick recap:

- Check the yarn: ring-spun, long-staple, uniform

- Inspect the weave: 3×1 twill, tight construction, clean edges

- Measure GSM accurately — not just what’s on paper

- Assess stretch and recovery if applicable

- Run durability and fastness tests or request lab data

- Verify dyeing methods and fading behavior

- Evaluate supplier reliability and responsiveness

Work with SzoneierFabrics — Your Partner in Premium Denim Sourcing

At SzoneierFabrics, we help B2B buyers source:

- Rigid and stretch denim (8–16oz)

- Certified organic or recycled denim (GOTS, OEKO-TEX®, GRS)

- Custom-woven fabrics with proprietary yarn or finish

- Fast sampling, low MOQ (starting at 100m), 100% QC-inspected production

Ready to upgrade your denim collection? Contact SzoneierFabrics today for expert support, free samples, and a sourcing experience built on transparency and long-term value.

Can't find the answers?

No worries, please contact us and we will answer all the questions you have during the whole process of bag customization.

Make A Sample First?

If you have your own artwork, logo design files, or just an idea,please provide details about your project requirements, including preferred fabric, color, and customization options,we’re excited to assist you in bringing your bespoke bag designs to life through our sample production process.