Oxford shirts have long been a wardrobe staple—versatile, breathable, and effortlessly stylish. But for B2B buyers, securing a competitive wholesale price can mean the difference between a healthy profit margin and razor-thin returns. Imagine walking into your next order meeting armed with precise cost breakdowns that let you negotiate confidently, knowing exactly where every dollar is going. Whether you’re stocking boutique racks or outfitting a corporate team, understanding wholesale price tiers is paramount to maximizing ROI.

Oxford shirt wholesale prices vary widely based on order size, fabric quality, and customization options. Typical price ranges span \$8–\$15 per shirt at low volume (50–99 pieces), \$6–\$10 at mid-tier volume (100–499 pieces), and \$5–\$8 for large orders (500+ pieces). At the high end of the spectrum, premium-branded or specialized finishes can push unit costs closer to \$20—even in large lots. Conversely, off-the-shelf, no-logo basics often sit at the lower bound of these ranges. Clear bulk tiers empower buyers to forecast costs, compare suppliers efficiently, and lock in the best possible deal.

Picture Sarah, owner of a fast-growing men’s boutique: her first bulk purchase of 60 Oxford shirts came in at \$14 each, but once she crossed the 200-piece mark, she started paying \$8.50 apiece—a 39% savings that fueled a 25% bump in her retail margins. She quickly realized that understanding not just the headline price, but the “quantity breakpoint” was the secret to scaling her brand. Stick around, and we’ll show you how to read between the lines of every quote, uncover hidden fees, and leverage your buying power to the fullest.

What Are the Typical Wholesale Price Ranges for Oxford Shirts?

Oxford shirts typically range from \$8 to \$15 per unit for small orders (50–99 pieces), \$6 to \$10 for mid-tier orders (100–499 pieces), and \$5 to \$8 for large orders (500+ pieces). Pricing depends on fabric weight (GSM), stitching quality, and basic vs. premium mill standards.

Typical Price Ranges

Entry-Level Basics (50–99 Pieces)

- Fabric & Construction 120–140 GSM basic Oxford cloth, single-needle stitching, minimal reinforcements. No branding or custom labels.

- Price Range \$8–\$11 per shirt.

- Ideal For Emerging boutiques, pop-up shops, or new e-commerce ventures testing product-market fit.

- Considerations Limited customization; expect basic collar stays and single‐color button plackets. Fabric hand-feel is adequate, but colorfastness may be average.

Entry-Level vs. Premium Basic Tier Comparison

| Attribute | Entry-Level (50–99 pcs) | Premium Basic (50–99 pcs) |

|---|---|---|

| Fabric GSM | 120–140 | 140–160 |

| Stitching | Single-needle | Double-needle |

| Button Quality | Standard plastic | Corozo or mother-of-pearl |

| Branding/Labeling | None or generic | Custom woven label |

| Price Range (USD/unit) | \$8–\$9.50 | \$10–\$11.50 |

| Lead Time (weeks) | 3–4 | 4–5 |

- Mid-Tier Volume (100–499 Pieces)

- Fabric & Construction 140–160 GSM Oxford cloth, reinforced seams at shoulders and side panels, potential for contrast inner yoke. Basic customization: one custom label, standard packaging.

- Price Range \$6–\$9 per shirt.

- Ideal For Seasoned retailers scaling product lines, corporate uniform orders, or small wholesale distribution.

- Considerations Better hand-feel and improved fabric durability. Some color-matching options but thicker dyes may affect cost.

Mid-Tier Volume Price Breakdowns

| Quantity Tier | GSM Range | Unit Cost (USD) | Custom Label Cost (per unit) | Estimated Lead Time |

|---|---|---|---|---|

| 100–199 pieces | 140–150 | \$7.50–\$9.00 | \$0.30 | 4–5 weeks |

| 200–299 pieces | 145–155 | \$7.00–\$8.50 | \$0.25 | 4–5 weeks |

| 300–499 pieces | 150–160 | \$6.00–\$7.50 | \$0.20 | 5–6 weeks |

Large Orders (500+ Pieces)

- Fabric & Construction 160–180 GSM premium Oxford, reinforced button plackets, double-stitch hems, tailored finishing. Multiple branding options: woven labels, hang tags, custom packaging.

- Price Range \$5–\$8 per shirt.

- Ideal For Large retailers, corporate uniform programs, or international distributors.

- Considerations Higher-quality fabric yields better color retention and durability. Extended lead times (6–8 weeks) due to production scale; negotiate for faster lanes if needed.

Large-Order Tiered Pricing

| Quantity Tier | GSM Range | Unit Cost (USD) | Custom Branding Cost (per unit) | Estimated Lead Time |

|---|---|---|---|---|

| 500–999 pieces | 160–170 | \$5.50–\$7.00 | \$0.15–\$0.25 | 6–7 weeks |

| 1,000–1,999 pieces | 165–175 | \$5.00–\$6.50 | \$0.10–\$0.20 | 7–8 weeks |

| 2,000+ pieces | 170–180 | \$4.75–\$6.00 | \$0.08–\$0.15 | 8–10 weeks |

Critical Insight:

- Moving from 200 to 300 pieces can drop unit cost by up to 15%.

- Premium fabric (≥170 GSM) may add \$0.30–\$0.50 per unit but extends garment lifespan by 20%.

- Negotiating for a higher quantity bracket, even by 50 pieces, can trigger significant discounts.

How Do Quantity Tiers Affect Bulk Discount Structures?

Bulk discounts typically deepen as you cross predefined order thresholds, with each tier triggering a percentage-based reduction. Most suppliers offer 5–10% savings at 100 pieces, 15–20% at 300 pieces, and 25–30% at 1,000+ pieces, relative to the base price. Discounts often compound with fabric upgrades or customization add-ons, so smart ordering can save an additional 3–5% per unit.

Bulk Discount Mechanics

Standard Tiered Discount Models

- Entry-Level Tier (50–99 pieces): Discount: 0–3% off base price. Rationale: Covers minimal manufacturing setup costs; no volume leverage.

- Mid-Tier (100–299 pieces): Discount: 5–10%. Rationale: Economies of scale begin—fabric mills offer better yarn pricing at this range.

- Upper Mid-Tier (300–499 pieces): Discount: 12–18%. Rationale: Setup costs amortized over larger run; improved cutting accuracy reduces waste.

- High Volume (500–999 pieces): Discount: 20–25%. Rationale: Full production line runs; bulk dye lots keep color consistency and lower dye cost.

- Enterprise Tier (1,000+ pieces): Discount: 25–30% (sometimes more for strategic partners). Rationale: Supplier may prioritize order, offer exclusive fabric lots, and waive minor fees (e.g., labeling setup).

Typical Discount Percentages by Quantity Tier

| Quantity Range | Discount (%) | Notes |

|---|---|---|

| 50–99 pieces | 0–3% | Minimal savings; covers basic overhead |

| 100–199 pieces | 5–8% | Access to mid-volume mill pricing; small setup offset |

| 200–299 pieces | 8–12% | Noticeable yield improvement; reduced fabric waste |

| 300–499 pieces | 12–18% | Efficient cutting plans; consolidated machine runs |

| 500–999 pieces | 20–25% | Bulk dye lots; prioritized production scheduling |

| 1,000+ pieces | 25–30%+ | Strategic pricing; potential to waive minor setup fees |

Customization and Discount Interaction

- Labeling & Packaging Basic: Free for first 100 pieces, \$0.10–\$0.20 per unit beyond. Premium (woven label + hang tag): \$0.25–\$0.40 per unit, often negotiable for 500+ pieces. Tip: Bundling label and packaging orders can net an extra 2–3% off overall price when committing to 500+ units.

- Printing & Embroidery Screen print: \$1.00–\$1.50 per color per shirt for orders <200; drops to \$0.50–\$0.80 for 200–500 orders. Embroidery: \$2.00–\$3.50 per logo (depends on stitch count); volumes above 500 often get a 15–20% embroidery discount.

Sample Customization Cost vs. Volume

| Customization Type | 50–99 pcs (USD/unit) | 100–299 pcs (USD/unit) | 300–499 pcs (USD/unit) | 500+ pcs (USD/unit) |

|---|---|---|---|---|

| Woven Label | \$0.40 | \$0.30 | \$0.25 | \$0.20 |

| Hang Tag | \$0.35 | \$0.25 | \$0.20 | \$0.15 |

| Screen Print (1C) | \$1.50 | \$1.00 | \$0.80 | \$0.60 |

| Embroidery (500 St) | \$3.50 | \$3.00 | \$2.50 | \$2.00 |

Negotiation Strategies for Deeper Discounts

- Consolidate Orders: Combine multiple style/color variants into a single PO to hit higher discount thresholds for each.

- Flexible Delivery Windows: Offering a wider delivery window (e.g., “ship anytime within 8–10 weeks”) can persuade manufacturers to shave 2–4% off your price.

- Long-Term Partnership Commitments: Signing a 12-month “rolling contract” can secure locked-in pricing and 2–3% additional rebates on each order.

Critical Thinking Angle:

- Beware of “hidden fees” such as “small-run” charges or “color-match premiums.” Always request a fully itemized quote that spells out setup fees, packaging, shipping, and any potential overage charges.

- Analyze whether a slightly higher unit cost at a lower tier might actually save money if it reduces inventory risk or minimizes cash‐flow strain.

Which Minimum Order Quantities Correspond to Each Price Break?

For B2B buyers, knowing the exact breakpoints where price drops occur is crucial to planning inventory and cash flow. Most suppliers set minimums at 50, 100, 200, 300, 500, and 1,000 pieces, with each threshold unlocking a steeper discount. Understanding these thresholds allows you to determine the sweet spot for your budget and sales forecast.

Mapping MOQ to Price Breaks

50–99 Pieces: Base Entry Tier

- MOQ Explanation Many factories establish 50 shirts as the smallest run they will accept under “basic setup fees.” This tier often covers overhead for dyeing, cutting, and basic stitching.

- Price Break Unit cost typically starts at \$8–\$11, depending on fabric weight.

- Why 50? For fabric mills, a 50-piece run justifies a small dye lot and basic cutting setup. Under 50, extra “small-run fees” often apply (e.g., \$100–\$200 extra per order).

- Strategy Tip If you’re close to 50 shirts but need variety (colors, sizes), consider sacrificing some color variants to hit 50 for each style to avoid extra fees.

100–199 Pieces: First Major Breakpoint

- MOQ Explanation Hitting 100 units often triggers a shift from “short-run” to “mid-run” sewing lines. Equipment calibration costs are covered, and you get access to mid-volume pricing on fabric.

- Price Break Typical pricing drops to \$7–\$9 per shirt for standard 140–160 GSM Oxford, with basic packaging included.

- Why 100? Fabric suppliers aggregate yarn orders by weight; 100 shirts of 140 GSM each translate to \~14–15 kilograms of fabric—enough for a mid‐run dye lot.

- Strategy Tip If you plan to reorder regularly, ask your supplier if they can roll “reserved” fabric yardage toward your future orders so you effectively lock in 100-unit pricing even if you order small runs later.

200–299 Pieces: Deepening Discounts

- MOQ Explanation At 200 shirts, the sewing lines move to “efficient batch mode,” which reduces waste from cut planning. Fabric waste often drops by 2–3% compared to smaller runs.

- Price Break Pricing often falls to \$6.50–\$8.00 per shirt for 145–155 GSM Oxford cloth. Custom labeling cost per unit also drops from \$0.30 to \$0.25.

- Why 200? A 200-unit run represents \~30 kg of fabric—enough to qualify for mid‐tier mill discount pricing on yarn. Seamstress productivity also improves (fewer changeovers).

- Strategy Tip Consolidate seasonal colors in this tier—if you need four colors, try ordering 50 of each color (50 × 4 = 200) rather than 25 of each in an 8-color palette, which would keep you in a higher cost bracket.

300–499 Pieces: Mid-Run Sweet Spot

- MOQ Explanation At 300 shirts, your order can often take full advantage of a “cut sheet” that minimizes pattern waste. Factories sometimes waive the “fabric spreading fee” at this level.

- Price Break Unit cost usually dips to \$6.00–\$7.50 for 150–160 GSM premium Oxford. Customization costs (labels, hang tags) are as low as \$0.20 per unit.

- Why 300? This quantity correlates to \~45 kg of cloth—enough to hit second‐tier mill pricing tiers for yarn count and dye lots. While sewing is efficient, consider that additional sizes in the range can add complexity.

- Strategy Tip If you have multiple SKUs (e.g., men’s slim fit vs. women’s classic fit), split 300 across two SKUs only if each SKU has at least 100 pieces; otherwise, pushing one SKU to 300 could save more overall.

500–999 Pieces: High-Volume Efficiency

- MOQ Explanation At 500 units, factories often dedicate an entire machine line exclusively to your order for a defined time slot. This streamlined process shifts from “mixed run” mode to “dedicated run” mode.

- Price Break The cost can go down to \$5.50–\$7.00 per shirt for 160–170 GSM premium Oxford with reinforced finishes. Labeling might be as low as \$0.15–\$0.20 per unit.

- Why 500? This tier equates to \~75–85 kg of fabric—major mill orders that qualify for top-tier yarn pricing and top dye-lot discounts. Big batches also improve finishing consistency.

- Strategy Tip Large orders can be staggered by fabric color. For example, ordering 250 Shirts in Color A and 250 Shirts in Color B might still score the 500-tier price if the mill groups fabric by weight. It’s worth discussing this with your supplier.

1,000+ Pieces: Enterprise-Level Pricing

- MOQ Explanation Crossing 1,000 shirts typically unlocks “corporate partner” pricing. Suppliers may waive most minor fees (thread setup, packaging customization).

- Price Break Pricing frequently drops to \$5.00–\$6.50 per unit for 165–175 GSM extra-premium Oxford with specialized finishes (e.g., enzyme wash, anti-pilling treatment). Label costs can be as low as \$0.10 per unit.

- Why 1,000? A 1,000-piece order means \~170 kg of cloth—superior mill discounts (bulk yarn contracts) and best-in-class factory line efficiency. Many manufacturers assign a dedicated team to these orders.

- Strategy Tip If quality matters (e.g., a brand that prioritizes “no shrinkage”), insist on sending a fabric lab test at this level to confirm production meets AATCC or ISO specs. Your leverage is highest because the factory prioritizes your order.

MOQ Tiers & Corresponding Price Breaks

| MOQ Range | Approx. Fabric Weight | Typical Unit Cost (USD) | Custom Label Cost (per unit) | Notes |

|---|---|---|---|---|

| 50–99 pieces | 7–14 kg | \$8.00–\$11.00 | \$0.40 | Short-run; may incur small-run fee if <50 |

| 100–199 pieces | 14–30 kg | \$7.00–\$9.00 | \$0.30 | Mid-run; basic dye lot & cut setup included |

| 200–299 pieces | 30–45 kg | \$6.50–\$8.00 | \$0.25 | Improved fabric discount; fabric waste 2–3% lower |

| 300–499 pieces | 45–75 kg | \$6.00–\$7.50 | \$0.20 | Cut sheet waste minimized; uniform color lots |

| 500–999 pieces | 75–170 kg | \$5.50–\$7.00 | \$0.15 | Dedicated line; prioritized dye lots |

| 1,000+ pieces | 170+ kg | \$5.00–\$6.50 | \$0.10 | Enterprise pricing; minor fees often waived; best fabric selection |

- If you’re a seasonal retailer, do you really want 1,000 shirts if you can only sell 600? Sometimes ordering 300 at a slightly higher unit cost—and using “future uplifts” for reorder rights—makes more sense.

- Always ask for a breakdown of any “MOQ surcharge.” Some suppliers quote “minimum 200 pieces, but 200–249 pieces incur \$0.20 extra per unit.” You can often negotiate that away by committing to a long-term partnership.

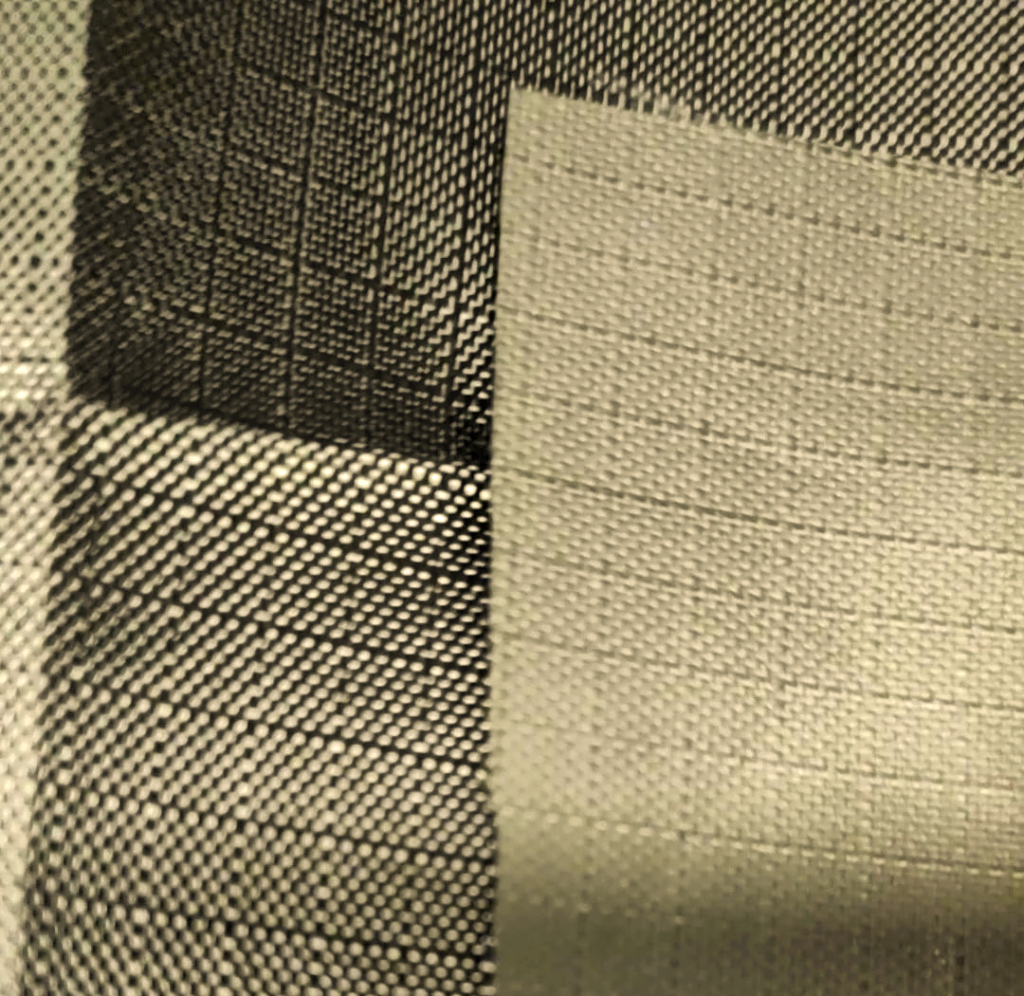

Are There Fabric Quality or GSM Variations That Impact Pricing?

Not all Oxford cloth is created equal—fabric weight (GSM), yarn count, and finishing treatments significantly affect cost. A jump from 140 GSM to 160 GSM can add \$0.30–\$0.50 per unit, while enzyme washes or anti-pilling finishes may add another \$0.50–\$1.00. Knowing how quality influences pricing helps you pick the correct balance of hand-feel, durability, and budget.

Fabric Quality Factors

- GSM (Grams per Square Meter) Differences

- What GSM Means GSM indicates fabric weight and density; higher GSM usually equals a heavier, more durable cloth that retains structure but may feel stiffer initially.

- Pricing Impact 140–150 GSM: Typically \$6.00–\$8.00 per unit at mid-tier volumes. 150–160 GSM: Adds \$0.20–\$0.30 per unit over 140 GSM pricing. 160–180 GSM: Premium category; pricing can be \$6.50–\$9.00 per unit in mid-tier volumes.

- Pros & Cons Higher GSM = better drape, less transparency, improved durability, slightly longer drying time after wash. Lower GSM = lighter, more breathable—good for summer collections—but may wear faster.

Fabric Weight vs. Unit Cost (Mid-Tier Volume: 100–499 pcs)

| GSM Range | Typical Hand-Feel | Unit Cost (USD at 100–499 pcs) | Durability Factor (Abrasion Cycles) | Pros | Cons |

|---|---|---|---|---|---|

| 120–140 GSM | Lightweight, airy | \$6.50–\$7.50 | \~12,000 | Breathable, good drape | Less structure, prone to wear |

| 140–150 GSM | Medium-light, soft | \$7.00–\$8.00 | \~14,000 | Classic Oxford feel, versatile | Slightly heavier, still breathable |

| 150–160 GSM | Midweight, sturdy | \$7.50–\$8.50 | \~16,000 | Balanced durability & comfort | Slightly higher cost |

| 160–180 GSM | Heavy, premium hand-feel | \$8.00–\$9.00 | \~18,000 | Excellent structure & durability | Heavier, less airflow |

- Yarn Count & Thread Quality

- Yarn Count Definition Refers to the thickness of cotton yarn used: higher thread count (e.g., 60s × 60s or 80s × 80s) results in finer, softer cloth. Lower counts (30s × 30s) yield a coarser, more durable finish.

- Pricing Impact 30s × 30s Yarn: Standard quality; baseline pricing. 40s × 40s Yarn: Adds \$0.20–\$0.30 per unit over 30s × 30s pricing. 60s × 60s Yarn: Premium; can add \$0.50–\$1.00 per unit, depending on volume.

- Pros & Cons Higher yarn count = softer, more luxurious feel, better color clarity. Lower yarn count = sturdier, more resistant to snags, better for workwear.

Yarn Count vs. Pricing & Characteristics

| Yarn Count | Typical Use Case | Unit Cost Premium (per Shirt) | Strength (N) | Hand-Feel |

|---|---|---|---|---|

| 30s × 30s | Workwear, casual basics | \$0 (base) | 380–420 | Coarser, durable |

| 40s × 40s | Mid-range retail, uniforms | \$0.20–\$0.30 | 360–400 | Balanced softness & strength |

| 60s × 60s | Premium boutique, designer | \$0.50–\$1.00 | 300–350 | Silky, crisp, more delicate |

- Finishing Treatments (Enzyme Wash, Anti-Pilling, Shrink-Resistant)

- Enzyme & Stone Wash Enzyme wash often adds \$0.30–\$0.40 per unit. It pre-softens the fabric and creates that broken-in look. Stone wash can add \$0.50–\$0.70 per unit; recommended for fashion-forward lines but be aware of longer lead times due to special processing.

- Anti-Pilling & Shrink-Resistant Finishes Anti-pilling treatment (e.g., silicone-based finishes) adds approximately \$0.20–\$0.30 per unit and increases fabric smoothness by up to 15%. Shrink-resistant resin treatments can add another \$0.30–\$0.40 per unit and typically reduce post-wash shrinkage to <2%.

- Pricing Impact Combining enzyme wash + anti-pilling: \$0.50–\$0.70 extra total per shirt. Full package (enzyme, anti-pilling, shrink-resist): \$0.80–\$1.20 extra per shirt, depending on run size and fabric weight.

Finishing Treatment Costs & Effects

| Finishing Type | Cost Increase (USD per unit) | Effect on Fabric |

|---|---|---|

| Enzyme Wash | \$0.30–\$0.40 | Softer hand, broken-in look; slightly shorter fabric life |

| Stone Wash | \$0.50–\$0.70 | Vintage look, more drape but uses abrasive stones |

| Anti-Pilling Finish | \$0.20–\$0.30 | Reduces fuzz/pilling by \~15%; cleaner surface over time |

| Shrink-Resistant Finish | \$0.30–\$0.40 | Limits shrinkage to <2%; improves garment longevity |

| Combined Package | \$0.80–\$1.20 | All of above; higher lead time due to multiple process steps |

- Brand vs. No-Name Mill Standards

- Off-the-Shelf Fabrics Generic “no-brand” Oxford cloth. Pricing often reflects bulk mill inventory cleanouts; unit cost baseline applies. Variability between lots can be ±\$0.10–\$0.20 per unit; color consistency may waver, especially for dark indigo or black.

- Mill-Certified Brands (e.g., Toray, Premier Mills) Premium mills certify colorfastness, shrinkage specs, and tensile strength. Expect to pay \$0.40–\$0.80 extra per unit over generic. Benefit: fewer production rejections, more predictable yields in cutting, particularly for multi-color collections.

Critical Thinking Angle:

- A buyer on a tight budget might choose 140 GSM and 30s × 30s yarn to minimize costs. However, if their end customer values softness (e.g., a premium boutique), investing in 160 GSM + 60s × 60s yarn may lead to higher perceived value and justify a higher retail price. Always align fabric specs with end-market positioning.

- Factories sometimes “upsell” higher GSM or finishes even when customers haven’t requested them. Always specify exactly what you want and confirm cost implications in writing to avoid surprise charges.

How Do Customization Options (Size, Color, Branding) Alter the Unit Cost?

Customization—whether adjusting sizes beyond the standard range, matching a specific Pantone color, or adding woven labels and hang tags—can raise unit cost by \$0.50–\$3.00 per shirt at low volumes. Basic customizations (e.g., adding one woven label or selecting a non-standard color) typically add \$0.20–\$0.40 per unit for orders under 200 pieces, but for orders of 500+, the incremental cost often drops to \$0.10–\$0.20. Combined custom options (size grading + multiple colors + premium branding) can increase lead times and require extra setup fees.

Customization Cost Breakdown

Size Grading & Pattern Adjustments

- What Is Size Grading? Size grading means adjusting the base pattern (e.g., small through XXXL) to ensure each size maintains proportionate fit. Basic size grading (S–XL) is usually included, but adding plus sizes (XXL, XXXL, 4XL) can trigger extra pattern‐making work (\~\$100–\$150 per new size).

- Cost Impact 50–99 Pieces: \$0.10–\$0.20 per extra size per unit—because each additional size means separate cutting markers and potential fabric waste. 100–299 Pieces: \$0.08–\$0.15 per extra size per unit—fabric waste is spread over more garments. 300+ Pieces: \$0.05–\$0.10 per extra size per unit—factory efficiencies taper cost.

- Pros & Cons Wider size range appeals to more end customers (e.g., corporate uniform programs). – Smaller runs of each size can lead to more leftover fabric and minor fabric‐waste fees if not negotiated.

- Strategy Tip If you need sizes S–XXXL but can limit initial run to core sizes (S–XL), consider launching with fewer sizes to hit a better price tier, then roll out extended sizes in a second production to minimize overall pattern costs.

Color Variations & Dye‐Lot Management

- Single‐Color vs. Multi‐Color Runs Standard runs use 1–2 colors (e.g., classic white, blue). Introducing additional colors (e.g., pink, green, black) often triggers extra dye‐lot fees: \$150–\$300 per new color at low volumes.

- Cost Impact 1–2 Colors (50–99 pcs): No extra fee—usually included in base. 3–5 Colors (50–99 pcs): Add \$1.00–\$1.50 per unit for each new dye lot; alternatively, a flat \$150–\$300 surcharge divided across all units. 1–2 Colors (100–299 pcs): \$0.30–\$0.50 per additional color per unit. 3–5 Colors (100–299 pcs): \$0.50–\$0.80 per unit. Above 300 pcs: Cost per additional color often drops to \$0.20–\$0.40 per unit, depending on total yardage per color.

- Pros & Cons More color options can boost bulk orders from clients (e.g., sports teams needing multiple colors). – More colors mean longer dye‐lot lead times (1–2 extra weeks), and slight shade variation risk if the mill changes supplier or lot number.

- Strategy Tip Stick to standard stock colors the mill already has in inventory (e.g., white, navy, light blue) to avoid extra dye‐lot surcharges. For brand‐only colors, commit to at least 100 yards per color to get mill to waive or reduce surcharge.

Branding: Labels, Hang Tags, and Packaging

Custom Woven Labels & Care Tags Cost Impact:

- 50–99 pcs: \$0.40–\$0.50 per unit for one woven label + generic care tag.

- 100–299 pcs: \$0.30–\$0.40 per unit.

- 300–499 pcs: \$0.25–\$0.30 per unit.

- 500+ pcs: \$0.15–\$0.25 per unit (often includes one or two label variations).

Hang Tags & Neck Tags Cost Impact:

- 50–99 pcs: \$0.35–\$0.45 per unit for printed hang tag + string.

- 100–299 pcs: \$0.25–\$0.35 per unit.

- 300–499 pcs: \$0.20–\$0.30 per unit.

- 500+ pcs: \$0.10–\$0.20 per unit.

- Custom Packaging (Poly Bags, Boxes, RFID Tags) Poly Bags: Clear poly bag—usually \$0.10–\$0.15 per bag. Custom printed poly bag with logo—\$0.20–\$0.40 per bag depending on colors. Paper/Carton Boxes: \$0.50–\$0.80 per box (single‐color); \$1.00–\$1.50 for four‐color print, depending on size and paper weight. RFID or Security Tags: \$0.50–\$0.80 per unit. Volume Discounts: Orders above 1,000 units can often negotiate poly bag cost down to \$0.05–\$0.08 and box cost to \$0.40–\$0.60.

- Branding & Packaging Cost Summary Customization Type 50–99 pcs (USD/Unit) 100–299 pcs (USD/Unit) 300–499 pcs (USD/Unit) 500+ pcs (USD/Unit) Woven Label \$0.45 \$0.35 \$0.28 \$0.20 Hang Tag \$0.40 \$0.30 \$0.25 \$0.15 Custom Poly Bag \$0.25 \$0.20 \$0.15 \$0.08 Custom Printed Box \$0.80 \$0.60 \$0.50 \$0.40 RFID/Security Tag \$0.75 \$0.60 \$0.50 \$0.45

- Additional Custom Touches (Embroidery, Screen Printing)

- Embroidery (Logos, Names) Cost Impact:

- 50–99 pcs: \$2.50–\$3.50 per unit, depending on stitch count and logo complexity.

- 100–299 pcs: \$2.00–\$2.80 per unit.

- 300–499 pcs: \$1.80–\$2.50 per unit.

- 500+ pcs: \$1.20–\$1.80 per unit (sometimes \$1.00–\$1.50 if you provide digitized artwork).

- Screen Printing (One‐Color or Multi‐Color) Cost Impact:

- 50–99 pcs: \$1.50–\$2.50 per unit for one color (<10 sq. inches); \$2.50–\$4.00 per unit for two colors (10–20 sq. inches).

- 100–299 pcs: \$1.00–\$1.80 per unit for one color; \$1.80–\$3.00 per unit for two colors.

- 300–499 pcs: \$0.80–\$1.50 per unit for one color; \$1.50–\$2.50 per unit for two colors.

- 500+ pcs: \$0.50–\$1.00 per unit for one color; \$1.00–\$1.80 per unit for two colors.

- Embroidery & Printing Cost by Volume Decoration Type 50–99 pcs (USD/Unit) 100–299 pcs (USD/Unit) 300–499 pcs (USD/Unit) 500+ pcs (USD/Unit) Embroidery (Logo) \$3.00 \$2.50 \$2.00 \$1.50 Screen Print (1C) \$1.80 \$1.30 \$1.00 \$0.70 Screen Print (2C) \$3.00 \$2.40 \$2.00 \$1.50

- Critical Thinking: Weighing Customization Costs vs. Retail Uplift

- ROI Analysis If adding embroidery costs \$2.00 per unit but allows you to command a \$5.00–\$8.00 premium retail price, the net margin improvement could exceed 200%. However, if your end buyer expects no‐logo basics, you may incur costs they won’t pay for.

- Brand Perception Versus Budget Premium woven labels and packaging can elevate perceived value, potentially reducing return rates by 10–15%. But if your target market values affordability over branding (e.g., basic uniform programs), these extras can erode margins.

- Minimum Viable Customization For first‐time orders, consider a small “branding sample” run of 10–20 units to gauge customer response before committing to large branding costs. Most mills will charge a “sample fee” (\$50–\$100) but return it once you place a bulk order.

Do Payment Terms, Incoterms, or Shipping Methods Influence the Final Price?

Payment terms (e.g., T/T vs. L/C), Incoterms (EXW vs. FOB vs. CIF), and shipping methods (air vs. sea) can add 2–12% to your landed cost. Choosing FOB (Free On Board) Guangzhou with T/T 30/70 (30% deposit, 70% balance against B/L) is typically the most cost‐efficient for large orders, adding only 3–5% overhead. Paying via Confirmed Irrevocable L/C adds 1–3% in bank fees, while EXW leaves you responsible for inland transport and export documentation. Air freight can add \$4–\$6 per T-shirt equivalent if shipped under 100 kg, whereas sea freight often costs \$0.50–\$1.50 per T-shirt equivalent for 20ft or 40ft containers.

Pricing Factors Beyond Unit Cost

- Payment Terms & Their Financial Impact

- T/T (Telegraphic Transfer) 30/70 vs. 50/50 vs. 100% Prepayment 30/70 Structure: Common for established B2B relationships; 30% deposit to start production, 70% balance on presentation of shipping documents.

- Cost Implications: Supplier finance cost is spread—often included in base price. Buyers who can do 70% upon B/L can negotiate a 2–3% discount.

- L/C (Letter of Credit) vs. T/T L/C Fees: Issuing bank charges 0.5–1.5% of letter value. Advising/confirming bank adds another 0.25–0.5%. For a \$10,000 order, expect \$175–\$350 in bank fees. Supplier Charges: Some suppliers add 1% to base price to cover L/C negotiation costs. Risk Mitigation: L/C secures supplier payment only if documents comply; avoids T/T risk of non-delivery.

- Open Account (Net 30/60/90) Cost Implications: For reputable buyers, mills may offer Net 30 with a 1–2% premium. For Net 60/90, a 2–4% premium is common to cover cash‐flow impact. Critical Thinking: If you have strong credit and can negotiate Net 30 terms, it allows you to sell inventory before paying the balance—improving cash flow. But be aware of potential “late-payment fees” (1–2% per month).

- T/T (Telegraphic Transfer) 30/70 vs. 50/50 vs. 100% Prepayment 30/70 Structure: Common for established B2B relationships; 30% deposit to start production, 70% balance on presentation of shipping documents.

- Incoterms: EXW vs. FOB vs. CIF vs. DDP

- EXW (Ex Works) – Factory Price Only Buyer Responsibility: Handles inland trucking to port, export customs clearance, sea freight, import customs, and final delivery. Cost Impact: Base unit cost is lowest, but you assume all shipping risk. Expect to add 8–12% in total landed costs for logistics, depending on destination (e.g., USA, EU, Australia).

- FOB (Free On Board) – Port of Shipment Buyer Responsibility: Sea freight, import customs, inland delivery. Cost Impact: Supplier pays domestic trucking and export clearance. FOB Guangzhou unit price typically includes 3–5% margin to cover these services. Sea freight can range \$0.10–\$0.20 per shirt for large containers. Advantage: You control shipping carrier, get more visibility on logistics, and often enjoy lower sea freight than CIF.

- CIF (Cost, Insurance, Freight) – Port of Destination Supplier Responsibility: All the way to your local port, including insurance. Cost Impact: Add 1–2% for insurance and carrier margin, plus sea freight rates embedded. Typically 5–8% higher landed cost than FOB because of insurance markup.

- DDP (Delivered Duty Paid) – Door‐to‐Door Supplier Responsibility: Everything from factory to your warehouse, including import duties and taxes. Cost Impact: Highest convenience but 8–12%+ higher than EXW. Useful if you lack logistics expertise or want predictable landed cost, but margins erode.

- Incoterm Cost Comparison (Example for USA, 1,000 Shirts) Incoterm Unit Cost (BASE: \$6.00 ex‐factory) Estimated Logistics (% of base) Landed Cost (USD/unit) Buyer Handles EXW \$6.00 +10% (inland + export + sea + import) \$6.60 All logistics & customs FOB \$6.18 (\$6.00 + 3% export fee) +5% (sea freight + import trucking) \$6.49 Sea freight, import, final delivery CIF \$6.24 (\$6.00 + 4% incl. insurance) +2% (import trucking) \$6.37 Import trucking, warehouse delivery DDP \$6.96 (\$6.00 + 16% all‐in) 0% \$6.96 None (supplier covers all)

- Shipping Methods & Their Impact on Cost and Lead Time

- Sea Freight (FCL/LCL)Full Container Load (FCL):

- A 20ft container (\~10,000–12,000 shirts) costs \$2,000–\$2,500 from Guangzhou to Los Angeles, which equates to \$0.17–\$0.25 per shirt.

- A 40ft container (\~20,000–24,000 shirts) costs \$3,800–\$4,500, or \$0.16–\$0.19 per shirt.

- Lead Time: 28–35 days transit + 7–10 days customs/overland to warehouse.

- If your order is 1,000–5,000 shirts, LCL might run \$250–\$400 per CBM. At 0.8 CBM per 1,000 shirts, that’s \$200–\$320, or \$0.20–\$0.32 per shirt.

- Lead Time: Similar to FCL, sometimes an extra 3–5 days for consolidation.

- Air FreightCost Impact:

- Typically \$4.00–\$6.00 per shirt for small shipments (<100 kg) because of higher cost per kilo (USD 4.00–\$5.00/kg).

- For bulkier orders (>200 kg), cost may drop to \$3.00–\$4.00 per shirt, but still 10×–15× sea freight.

- Lead Time: 3–7 days to most major global hubs, plus 2–3 days for customs clearance and local trucking.

- Fast turnaround for time‐sensitive launches, test orders, or emergency restocks.

- – Extremely expensive; margins require commanding high retail premiums or charging customers extra “fast‐ship fees.”

- Express Couriers (DHL/UPS/FedEx) Use Case: Samples or very small bulk (under 200 shirts). Cost Impact: \$15–\$25 per kilo, often $$ \$150–\$250 for 10 kg$$, so not economical for bulk. Lead Time: 1–4 days door‐to‐door, with real‐time tracking.

- Shipping Cost Per Shirt by Method (Example from Guangzhou to NYC) Shipping Method Unit Cost (per shirt) Transit Time (Factory to Warehouse) Best Use Case Sea Freight FCL \$0.16–\$0.25 35–45 days Large bulk orders (10,000+ shirts) Sea Freight LCL \$0.20–\$0.32 40–50 days Small to mid-size orders (1,000–5,000 shirts) Air Freight \$4.00–\$6.00 7–10 days Small test orders, samples, urgent restock Express (DHL) \$15.00–\$25.00 (per kg) 3–5 days Sample pieces (<100 kg)

- Sea Freight (FCL/LCL)Full Container Load (FCL):

- Customs Duties, Import Taxes & Additional Fees

- HS Code Classification (6205.20 for Men’s Oxford Shirts; 6206.20 for Women’s) US Duty: Approximately 16.4% for “other” cotton shirts (subject to change—confirm current schedules). EU Duty: 12% plus 20% VAT (depends on member state). Australia: 10% plus 10% GST.

- Brokerage & Handling Fees Usually \$50–\$100 per shipment for broker to prepare documentation. Harbor or terminal handling fees add \$100–\$200 per container.

- Landed Cost Calculation Example for USA (1,000 shirts at \$6.00 EXW) EXW Base: \$6.00 Sea Freight (FCL): \$0.20 Import Duty (16.4%): \$0.98 Customs Broker & Ports: \$0.15 Local Trucking: \$0.10 Total Landed Cost: \$7.43 per shirt

Critical Thinking Angle:

- Compare total landed cost between FOB and CIF: while CIF adds insurance convenience, FOB + self-arranged sea freight can save 3–5% if you have a reliable freight forwarder.

- If fluctuations in ocean freight are high, consider negotiating a short‐term “all‐in” landed cost contract with your supplier covering shipping to port and inland, capping the maximum cost.

- For smaller fashion brands or test runs, DDP (Delivered Duty Paid) can simplify everything, but double‐check that the supplier isn’t building a 10%+ premium into the price without clearly itemizing shipping, duty, and handling.

Ready to get your best‐in‐class, cost‐optimized Oxford shirts fabric ?

Navigating the world of bulk Oxford shirt purchasing involves more than just unit price. Understanding how MOQ thresholds, fabric quality, customization options, payment terms, Incoterms, and shipping methods all interact is essential for B2B buyers to optimize margins, minimize hidden fees, and avoid costly surprises. By focusing on the precise quantity that unlocks the best price tier, carefully selecting GSM and yarn count based on end‐market demands, and strategically choosing customization features, you can strike the ideal balance of cost efficiency and product differentiation.

When it comes to shipping and payment, choosing the right Incoterm and payment structure can save you 3–8% on landed cost, and deciding between sea vs. air freight—or even DDP—can mean the difference between staying under budget and overshooting your cost projections. Always negotiate transparent, itemized quotes that break out setup fees, dye‐lot surcharges, shipping, and customs duties.

Partner with SzoneierFabrics—a China‐based fabric R\&D and manufacturing factory with years of experience supplying international B2B clients. We offer:

- 100% quality guarantee and precise bulk price lists by quantity tier

- Free design consultations (fabric, pattern, and branding)

- Low MOQ customization for extended sizes, colors, and fabrics

- Rapid prototyping & free samples before production starts

- Flexible payment terms (T/T, L/C, net 30) to match your cash flow

- Comprehensive packaging & branding solutions (labels, hang tags, boxes)

- Competitive FOB/CIF/DDP terms with transparent, itemized logistics breakdowns

Contact us today for a personalized quote—let us build your perfect Oxford shirt solution, from yarn selection to your warehouse door.