At first glance, a wetsuit looks simple: soft, stretchy, warm. But behind that comfort is a surprisingly technical material decision that quietly determines how a wetsuit feels in the water, how long it lasts, and how well it performs in real conditions. That decision is neoprene shore hardness. Two wetsuits can use the same thickness, the same pattern, even the same outer fabric—and still feel completely different once worn. The difference often comes down to how hard or soft the neoprene foam actually is.

the neoprene shore hardness scale helps wetsuit manufacturers quantify how soft, compressible, and resilient a neoprene sheet is. It directly influences flexibility, thermal insulation, durability, and the overall “premium” feel of a wetsuit. Choosing the right hardness is not about picking the softest option available—it’s about matching material behavior to water temperature, activity type, and user expectations.

Many early-stage wetsuit designs struggle because hardness is treated as a background detail instead of a core performance parameter. Once you understand how shore hardness works—and how manufacturers use it intentionally—it becomes much easier to design wetsuits that move naturally, insulate reliably, and age gracefully instead of breaking down too soon.

What Is Neoprene Material and Why Is Shore Hardness Important for Wetsuit Manufacturers?

Neoprene is a closed-cell synthetic rubber foam, most commonly based on polychloroprene, and it has been the core material of wetsuit manufacturing for decades. Its primary role is to provide thermal insulation while allowing enough flexibility for swimming, paddling, and diving movements. However, neoprene is often misunderstood as a single, uniform rubber material. In reality, it is a highly engineered foam system, and one of the most critical parameters defining its behavior is Shore hardness.

For wetsuit manufacturers, Shore hardness is not an abstract lab value. It directly influences how a wetsuit stretches, how it compresses under water pressure, how warm it remains at depth, and how long it maintains its fit and performance over repeated use. Two wetsuits made from neoprene of the same thickness can feel and perform completely differently depending on hardness. This is why experienced wetsuit developers treat Shore hardness as a core design variable, not a secondary specification.

Neoprene is not just “rubber.” It is a carefully balanced foam architecture where hardness acts as a control dial for performance.

What Neoprene Really Is in a Wetsuit Context

Wetsuit neoprene is a laminated composite, not a single material layer. Each component plays a distinct role, but Shore hardness is primarily tied to the foam core.

Neoprene wetsuit material typically consists of:

- A closed-cell foam core for insulation and buoyancy

- An outer fabric lamination for abrasion resistance and shape stability

- An inner fabric lamination for comfort, skin feel, and moisture handling

- Trapped gas bubbles within the foam that slow heat transfer

| Component | Function |

|---|---|

| Foam cells | Thermal insulation and buoyancy |

| Rubber matrix | Elastic recovery and structural integrity |

| Fabric lamination | Tear resistance and surface durability |

The foam core contains thousands of microscopic closed cells filled with gas. These cells are what keep the body warm by reducing heat loss to surrounding water. Shore hardness measures how resistant this foam structure is to indentation and deformation, which directly reflects cell wall thickness, rubber stiffness, and overall foam resilience.

Understanding Shore Hardness in Neoprene

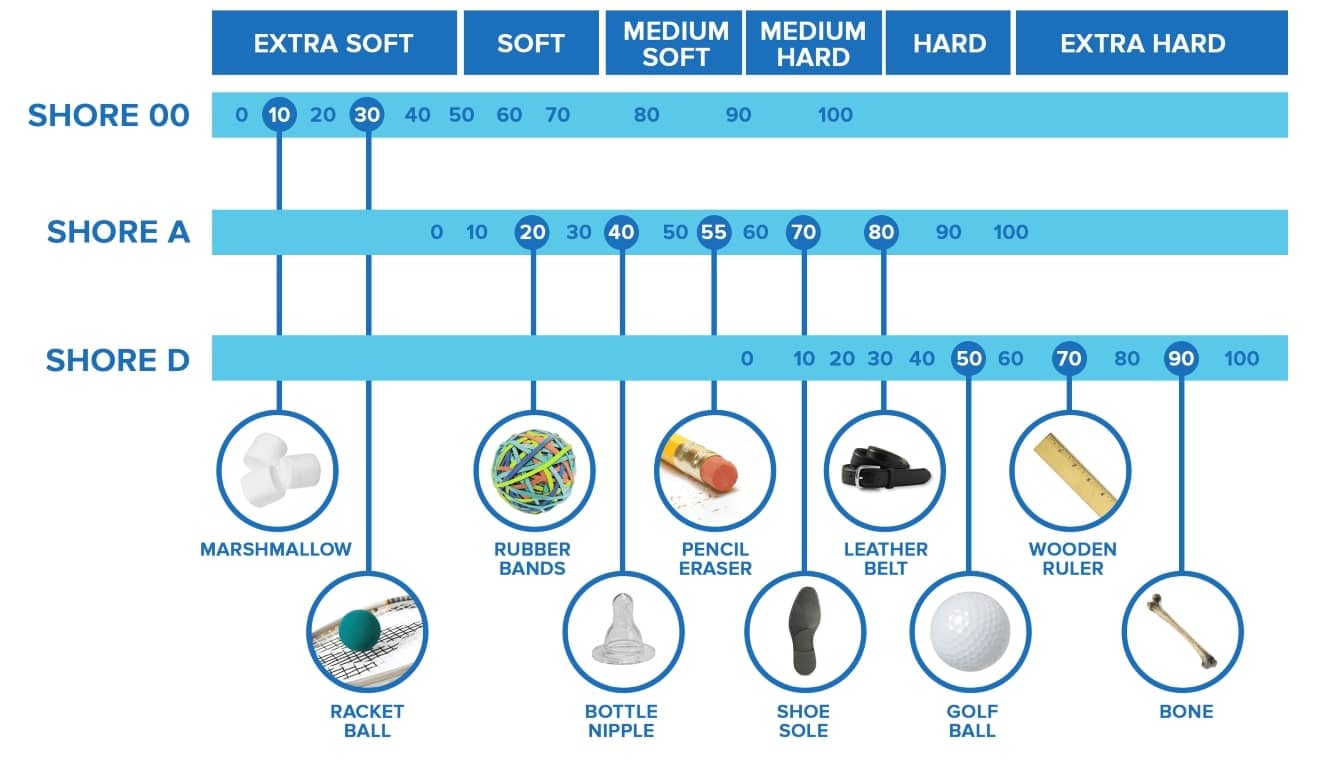

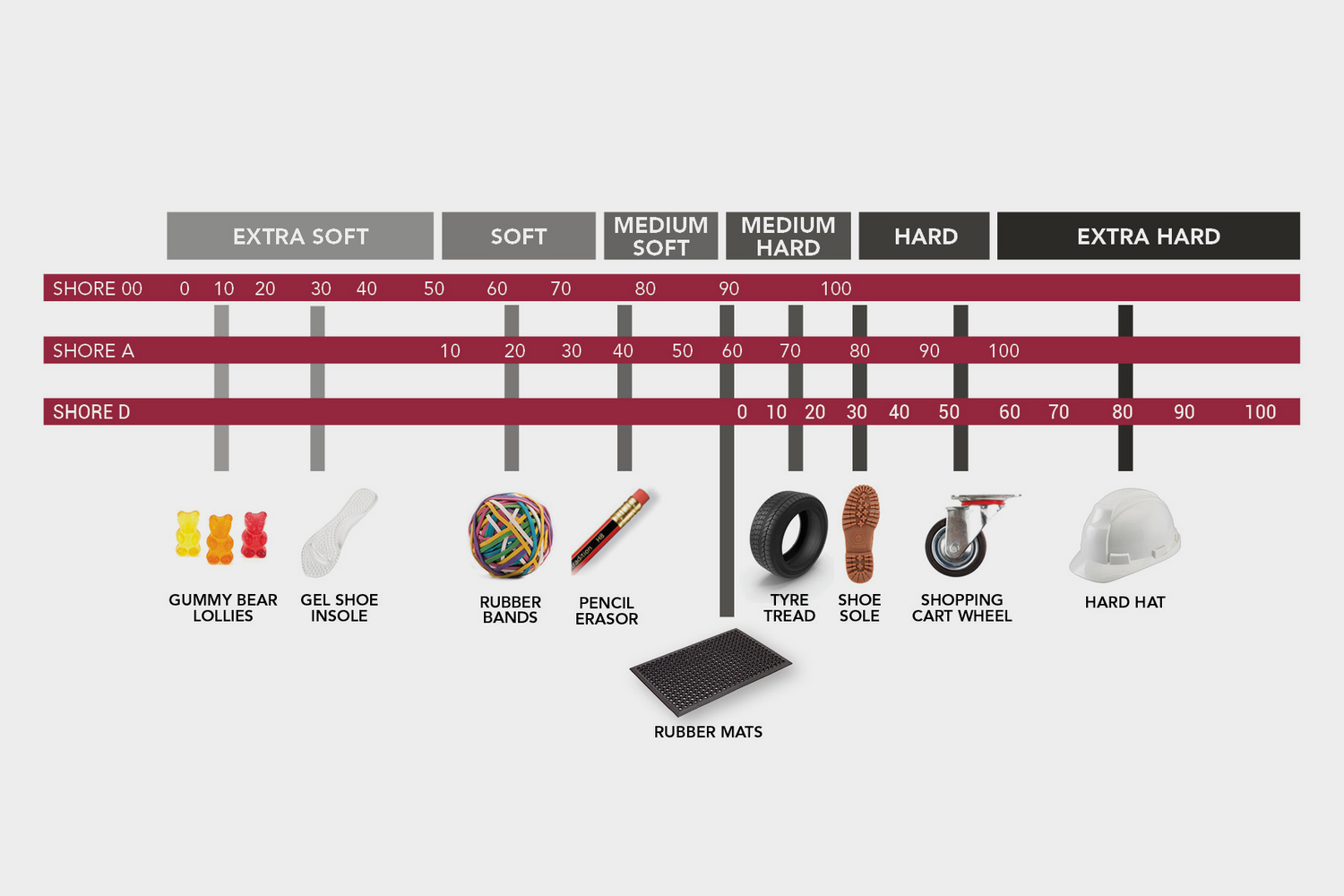

Shore hardness is measured using a durometer, most commonly on the Shore A scale for neoprene foams. The test applies a standardized indenter to the material surface and measures resistance. Lower numbers indicate softer foam; higher numbers indicate firmer foam.

In wetsuit terms, Shore hardness is not about “hard” or “soft” in a casual sense. It defines how the foam behaves under real-world conditions such as stretching during paddling, compression at depth, and repeated cycles of use and recovery.

A difference of just 3–5 Shore A points can noticeably change how a wetsuit feels on the body and how it performs in water.

Why Hardness Matters More Than Thickness Alone

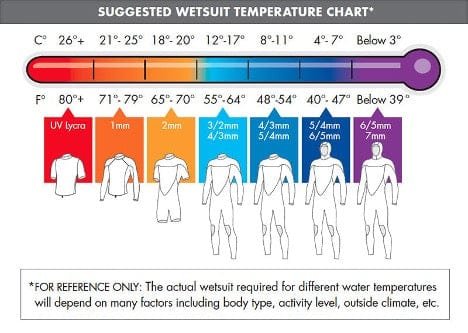

Thickness is the most visible neoprene parameter and is often the first thing consumers focus on. Thickness primarily determines thermal insulation at the surface. However, thickness alone does not define how warm or comfortable a wetsuit remains during use.

Two neoprene sheets with the same thickness can behave very differently if their hardness differs.

| Same Thickness | Different Outcome |

|---|---|

| Soft neoprene | High flexibility, lower resistance to compression |

| Firm neoprene | Better shape retention, reduced stretch |

Softer neoprene stretches easily and feels comfortable when first worn. Firmer neoprene resists deformation and maintains its structure more effectively over time. Thickness controls potential warmth, but hardness controls how much of that warmth is retained in real conditions, especially under pressure.

Shore Hardness as a Performance Dial for Wetsuit Designers

For wetsuit manufacturers, Shore hardness functions as a performance tuning parameter. Adjusting hardness allows designers to balance flexibility, insulation, and durability according to the intended use of the suit.

Hardness directly influences:

- Ease of movement in shoulders, hips, and knees

- Energy expenditure and muscle fatigue

- Compression behavior at depth

- Long-term resistance to permanent deformation

| Hardness Level | Wetsuit Behavior |

|---|---|

| Low | Very soft, highly flexible, comfortable |

| Medium | Balanced stretch and support |

| High | More durable, supportive, reduced stretch |

Choosing a hardness level is essentially choosing how the wetsuit behaves in motion, not just how it feels on a hanger.

Soft Neoprene: Comfort and Freedom of Movement

Low Shore hardness neoprene is prized for its immediate comfort. It stretches easily, conforms closely to the body, and reduces resistance during paddling or swimming. This makes it popular in high-mobility zones such as shoulders and underarms.

However, softer neoprene has trade-offs. The foam cells compress more easily under pressure, meaning that at depth, the gas inside the cells is reduced more significantly. As compression increases, insulation decreases. Softer foams also tend to experience faster material fatigue, especially when repeatedly stretched and relaxed.

From a manufacturing perspective, very soft neoprene often requires tighter quality control to avoid early breakdown and loss of shape.

Firmer Neoprene: Stability and Longevity

Higher Shore hardness neoprene offers greater resistance to compression and deformation. The cell walls are stronger, allowing the foam to maintain thickness and insulating properties better at depth.

This firmness improves:

- Long-term shape retention

- Resistance to permanent creasing

- Durability under repeated use

The trade-off is reduced stretch and a stiffer feel, particularly noticeable during paddling or arm rotation. For this reason, firmer neoprene is rarely used across an entire wetsuit but is often placed strategically in high-wear or high-pressure zones.

Why Softness Alone Is Not the Goal

Inexperienced manufacturers sometimes prioritize softness as a primary selling point. While this can create a strong first impression, it often leads to compromised performance over time.

Softer neoprene:

- Compresses more at depth

- Loses insulating air volume faster

- Recovers more slowly after repeated compression cycles

| Design Priority | Hardness Implication |

|---|---|

| Comfort | Lower hardness |

| Longevity | Higher hardness |

| Cold-water use | Balanced hardness |

This is why experienced wetsuit brands avoid extremes. They rarely choose the softest possible foam for the entire suit, especially for cold-water or technical applications.

Compression, Depth, and Thermal Retention

For divers and cold-water surfers, compression behavior is critical. As water pressure increases with depth, neoprene foam compresses, reducing thickness and insulation.

Harder neoprene resists this compression more effectively, retaining thermal properties deeper underwater. Softer neoprene may feel warmer at the surface but lose insulating capacity faster as depth increases.

Manufacturers targeting diving wetsuits often specify slightly higher Shore hardness values than those used in surfing wetsuits, even at the same nominal thickness, to preserve warmth under pressure.

Zoning Hardness for Advanced Wetsuit Design

Modern wetsuit design rarely relies on a single hardness value. Instead, manufacturers use hardness zoning, combining different foams within one suit.

Common zoning strategies include:

- Softer neoprene in shoulders and arms for mobility

- Medium hardness in torso areas for balance

- Firmer neoprene in knees, seat, and chest for durability

This approach allows designers to tailor performance to human movement patterns. Hardness zoning increases complexity in material sourcing and lamination but delivers a significantly improved user experience.

Shore Hardness and Long-Term Fit Retention

One of the most common consumer complaints about wetsuits is that they feel great initially but loosen or lose warmth after a season. Shore hardness plays a major role in this.

Foams with insufficient hardness may experience compression set, where the material fails to fully rebound after repeated compression. Over time, this leads to:

- Reduced thickness

- Looser fit

- Increased water flushing

Wetsuits designed with balanced hardness maintain their original shape longer, even if they feel slightly firmer at first wear.

Manufacturing Perspective: Hardness Control Is Process Control

From a factory standpoint, controlling Shore hardness is not trivial. It depends on:

- Foam formulation

- Cell size consistency

- Curing time and temperature

- Lamination pressure

Small variations in processing can cause measurable differences in hardness, even within the same batch. Reliable wetsuit manufacturers work closely with neoprene suppliers to ensure tight hardness tolerances, typically within ±2 Shore A for performance-grade foams.

Consistency matters because pattern design, seam tension, and stretch calculations all depend on predictable material behavior.

Human-Centered Perspective: What Users Actually Feel

Surfers, divers, and swimmers rarely talk about Shore hardness. Instead, they describe their experience in terms of:

- Shoulder freedom

- Ease of paddling

- Warmth after long sessions

- Whether the suit still fits after months of use

Shore hardness quietly influences all of these perceptions. It shapes how the wetsuit moves with the body, how it resists pressure, and how it ages over time.

A well-designed wetsuit feels natural in motion, stays warm when conditions demand it, and retains its performance beyond the first few outings. Achieving this balance is impossible without understanding and controlling hardness.

Why Shore Hardness Is a Strategic Choice for Wetsuit Brands

For wetsuit manufacturers, Shore hardness is not just a technical parameter. It is a strategic design choice that affects product positioning, target users, and brand reputation.

Entry-level suits may favor slightly softer foams for comfort, while premium or technical suits emphasize balanced or zoned hardness for performance and longevity. Cold-water, diving, and professional-use suits often prioritize compression resistance over initial softness.

Manufacturers who understand hardness deeply are better equipped to:

- Match materials to real use conditions

- Reduce warranty and fit complaints

- Deliver consistent performance across production runs

Neoprene may look simple, but its performance is defined by subtle engineering choices. Shore hardness is one of the most influential of those choices. It governs how neoprene stretches, compresses, insulates, and recovers over time.

Thickness tells you how warm a wetsuit could be. Shore hardness tells you how it will actually perform in motion, under pressure, and across seasons of use.

For wetsuit manufacturers, mastering Shore hardness is not about chasing softness or stiffness. It is about designing neoprene that works with the human body, the water environment, and the realities of repeated use. That understanding is what separates average wetsuits from truly reliable ones.

How is shore hardness measured in neoprene and what do the different scales mean?

In neoprene manufacturing and product design, terms like “soft,” “medium,” or “firm” are meaningless unless they can be translated into measurable, repeatable values. Shore hardness provides that translation. It converts subjective hand-feel into numerical data that engineers, material suppliers, and product designers can specify, test, and control across batches.

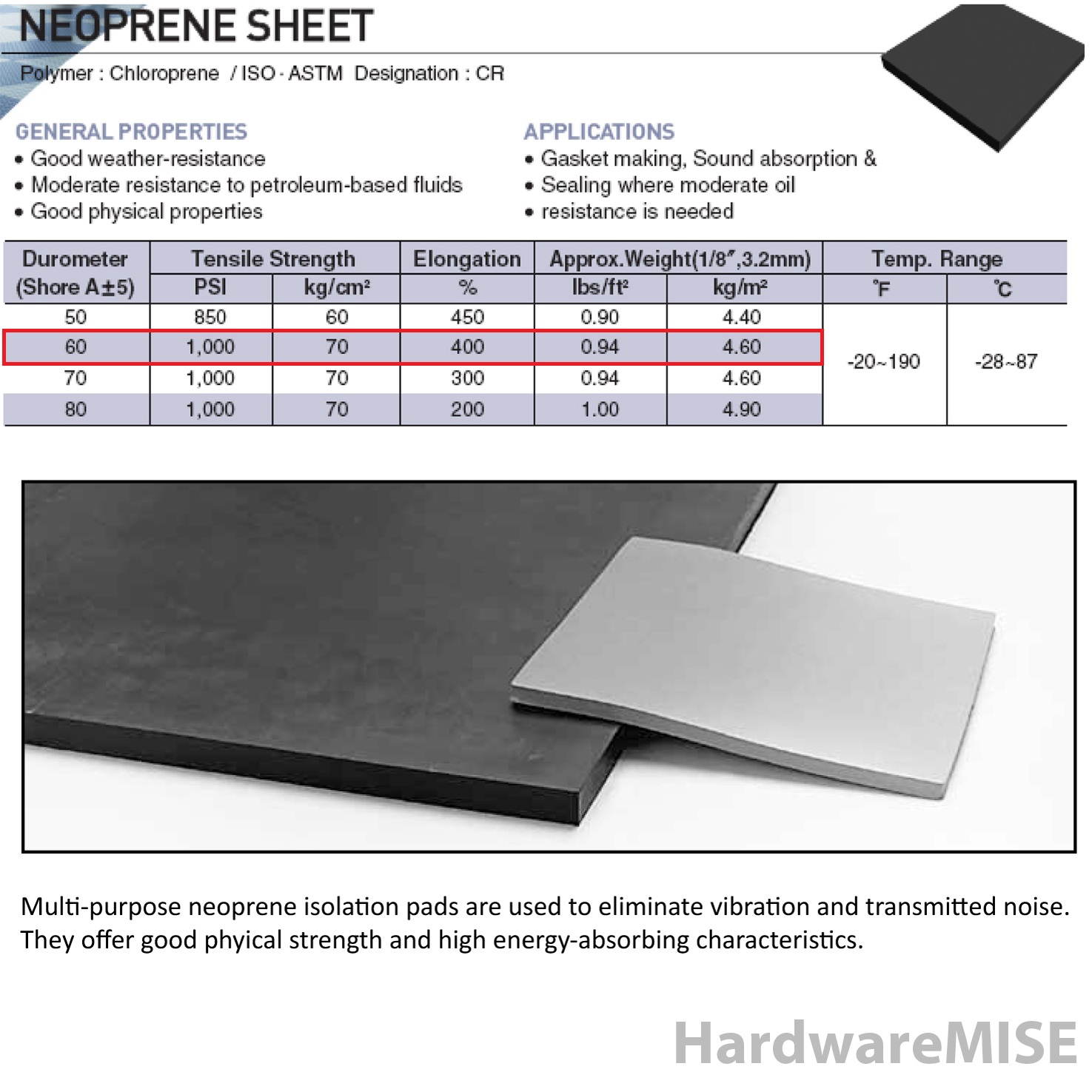

For neoprene foam, Shore hardness is measured using a durometer, with the Shore A scale being the most widely used and industry-accepted reference. The measurement reflects how resistant the neoprene surface is to indentation under a standardized load. Lower numbers indicate softer, more compressible foam; higher numbers indicate firmer, more supportive material.

This single metric influences stretch behavior, comfort, compression recovery, durability, and even manufacturing performance. In applications such as wetsuits, protective gear, orthopedic supports, and neoprene accessories, Shore hardness directly affects how the product feels on the body and how it performs over time.

The Shore Hardness System Explained Simply

Shore hardness testing is designed to be straightforward, but precision depends on proper method and interpretation. A durometer is a handheld or bench-mounted instrument equipped with a spring-loaded indenter. During testing:

- The indenter is pressed perpendicular into the neoprene surface

- The spring resistance reflects how much the material yields

- The device converts this resistance into a numerical reading

The higher the resistance to indentation, the higher the Shore hardness value.

| Scale | Typical Use |

|---|---|

| Shore 00 | Very soft gels, foams |

| Shore A | Rubber, neoprene |

| Shore D | Hard plastics |

Although neoprene is a foam, it behaves mechanically like a rubber material rather than a gel. For this reason, Shore A is the most relevant and practical scale for neoprene used in wetsuits, supports, bags, and industrial products.

Shore D is too coarse for flexible foams, while Shore 00 is generally reserved for ultra-soft gels or medical cushioning materials that deform under extremely light pressure.

Typical Shore A Ranges for Neoprene

Different neoprene applications require different hardness levels. Shore A values help designers balance comfort, flexibility, and support based on how the product will be used.

| Shore A Range | Material Feel |

|---|---|

| 5–15 | Extremely soft, high stretch |

| 15–25 | Soft, flexible |

| 25–35 | Medium firmness |

| 35+ | Firm, supportive |

Most wetsuit neoprene falls between 15 and 35 Shore A. Entry-level or recreational wetsuits often favor the lower end of this range for comfort and ease of movement, while performance or cold-water suits may use slightly firmer foams to improve structure, thermal retention, and durability.

Outside of wetsuits, neoprene used in braces, protective equipment, or load-bearing accessories may exceed 35 Shore A to provide better support and shape retention.

What Shore Hardness Actually Represents in Neoprene Foam

It is important to understand what Shore hardness does—and does not—measure. Shore A reflects surface resistance to indentation, not overall stiffness or tensile strength. Two neoprene foams with identical Shore A values may behave very differently when stretched, compressed repeatedly, or subjected to tearing forces.

Shore hardness is influenced by:

- Foam density

- Cell structure

- Gas content within the cells

- Surface lamination and coatings

As a result, Shore hardness should be interpreted as part of a broader material profile, not a standalone indicator of quality.

Why Neoprene Hardness Isn’t One Fixed Number

Unlike molded rubber parts, neoprene foam sheets are produced in blocks and then sliced into sheets of varying thicknesses. This introduces natural variation that must be managed through quality control.

Neoprene sheets can vary:

- Across thickness

- Across production batches

- Across foam formulations

| Variable | Effect on Reading |

|---|---|

| Cell size | Softer or firmer feel |

| Gas content | Compression behavior |

| Lamination | Surface resistance |

For example, larger cell structures often feel softer at the same Shore A reading because they compress more easily under dynamic load. Gas content affects how quickly the foam rebounds after compression, influencing perceived softness during movement. Fabric lamination adds surface resistance, sometimes increasing measured Shore hardness without significantly changing internal foam behavior.

Because of these factors, responsible manufacturers test multiple points across a sheet and across batches, rather than relying on a single measurement.

Testing Conditions Matter More Than Many Buyers Realize

Shore hardness testing is sensitive to environmental and procedural conditions. Without standardized testing protocols, readings can vary enough to mislead material selection decisions.

Shore hardness readings depend on:

- Temperature

- Compression time

- Sample thickness

| Test Condition | Result Impact |

|---|---|

| Cold test | Appears harder |

| Warm test | Appears softer |

| Thin sample | Lower reading |

Temperature affects foam elasticity. Neoprene tested in a cold environment resists indentation more strongly, producing higher Shore A values. In warmer conditions, the same material may appear noticeably softer. This is particularly relevant for wetsuits, which operate in cold water but are often tested at room temperature.

Sample thickness also plays a critical role. Very thin samples allow the indenter to “feel” the backing surface, resulting in artificially low readings. Industry practice typically requires minimum thickness thresholds or stacked samples to ensure reliable measurements.

Professional factories standardize:

- Ambient temperature

- Dwell time before reading

- Sample preparation and thickness

This standardization ensures that Shore hardness values are comparable across batches and suppliers, not just internally consistent.

Shore A Versus Shore 00: Why Shore A Is the Industry Standard

Given that neoprene is soft, it is reasonable to ask why Shore 00 is not used more frequently. The answer lies in measurement resolution and repeatability.

Shore A provides:

- Better differentiation within the typical neoprene firmness range

- More stable readings across varying thicknesses

- Greater alignment with rubber and elastomer industry norms

Some ultra-soft foams—particularly experimental or specialty cushioning materials—may reference Shore 00 values to capture very low resistance ranges. However, for most neoprene used in commercial products, Shore A offers a more practical balance between sensitivity and consistency.

Using Shore A also simplifies communication across supply chains. Designers, foam producers, and garment factories generally speak the same “Shore A language,” reducing misunderstanding during specification and sourcing.

How Shore Hardness Influences Real-World Performance

Shore hardness directly affects how neoprene performs in use. Softer neoprene offers greater stretch and comfort but may compress permanently over time. Firmer neoprene provides better support and durability but can restrict movement if overused.

In wetsuits:

- Lower Shore A improves flexibility and comfort

- Higher Shore A improves shape retention and insulation stability

In braces and supports:

- Higher Shore A provides structural support

- Lower Shore A may lead to insufficient stabilization

In bags and protective cases:

- Medium Shore A balances cushioning and durability

Manufacturers often blend foams of different hardness levels within a single product, using softer panels in high-mobility zones and firmer panels where support is required.

Shore Hardness and Quality Control

From a manufacturing perspective, Shore hardness is a key quality control metric. It allows suppliers to detect formulation drift, foaming inconsistencies, or curing issues before material reaches downstream production.

Consistent Shore hardness:

- Improves cutting predictability

- Stabilizes sewing and bonding behavior

- Reduces variability in finished products

However, Shore hardness alone does not guarantee performance. It must be evaluated alongside density, compression set, tear strength, and lamination integrity to form a complete picture of neoprene quality.

Practical Takeaway for Designers and Buyers

Shore hardness gives wetsuit designers and neoprene product developers a repeatable, objective language for discussing material behavior with foam suppliers. It replaces subjective descriptors with measurable targets that can be specified, tested, and enforced.

The key is not to treat Shore A as a single “magic number,” but to understand what it represents, what influences it, and how it interacts with other material properties. When used correctly, Shore hardness becomes a powerful tool for aligning design intent, manufacturing control, and end-user experience.

3. Which shore hardness ranges are commonly used in wetsuit production and why?

In wetsuit manufacturing, Shore hardness is one of the most quietly decisive parameters. While consumers often focus on thickness, lining, or brand-specific stretch claims, experienced wetsuit designers know that Shore A hardness largely determines how a suit feels, performs, and ages in real water conditions.

Most wetsuit manufacturers concentrate on neoprene within the 15–35 Shore A range. This window is not the result of marketing preference or arbitrary specification. It reflects decades of field testing across surfing, diving, freediving, triathlon, and commercial water sports. Within this range, neoprene can deliver an effective balance of flexibility, thermal retention, compression resistance, and durability.

Crucially, modern wetsuits almost never rely on a single hardness value. Instead, they use zoned hardness design, assigning different Shore A ranges to different body areas based on movement, load, and wear patterns.

Understanding Shore A hardness in wetsuit context

Shore A hardness measures a rubber material’s resistance to indentation. In simple terms, it describes how soft or firm neoprene feels when pressure is applied. In wetsuits, this translates directly into:

- How easily the material stretches during paddling or swimming

- How much the neoprene compresses at depth

- How well it retains insulating air cells over time

- How resistant it is to abrasion, tearing, and permanent deformation

A difference of just 3–5 Shore A points can significantly change how a wetsuit behaves in use, especially after repeated dives or extended exposure to cold water.

Why the 15–35 Shore A range dominates wetsuit design

The 15–35 Shore A range represents a functional envelope where neoprene remains elastic enough for athletic movement while retaining sufficient structural integrity for insulation and longevity.

Below this range, neoprene becomes too compressible and fatigues quickly. Above it, the material feels stiff, restricts movement, and reduces wearer comfort.

Within this band, manufacturers can tune performance by matching hardness to:

- Water temperature

- Activity intensity

- Expected depth or pressure

- Target product lifespan

Common hardness bands and where they’re used

| Shore A Range | Typical Use | Why It Works |

|---|---|---|

| 15–20 | High-flex panels | Maximum mobility |

| 20–25 | Premium full suits | Comfort + warmth |

| 25–30 | Cold-water suits | Shape retention |

| 30–35 | Reinforced zones | Durability |

Each band serves a distinct role, and understanding these roles explains why wetsuits are rarely uniform in hardness.

15–20 Shore A: maximum flexibility zones

Neoprene in the 15–20 Shore A range is extremely soft and elastic. It stretches easily with minimal resistance, making it ideal for areas requiring a full range of motion.

Typical applications include:

- Shoulder panels

- Underarm zones

- Upper arm and side torso sections

This softness reduces muscle fatigue during paddling or swimming and improves overall comfort, particularly in high-mobility sports like surfing or triathlon.

However, this softness comes with trade-offs. Ultra-soft neoprene:

- Compresses more under hydrostatic pressure

- Loses thickness faster at depth

- Experiences faster compression set over time

For these reasons, manufacturers limit its use to localized flex zones rather than full-suit construction.

20–25 Shore A: the premium full-suit core

The 20–25 Shore A range is widely considered the “sweet spot” for premium wetsuits. It balances softness with sufficient structural support to maintain insulation and shape.

This hardness range is commonly used for:

- High-end full wetsuits

- Performance-oriented cold-water suits

- Multi-sport wetsuits requiring both comfort and durability

At this level, neoprene still stretches comfortably but resists excessive compression. The closed-cell structure retains trapped air more effectively, which directly supports thermal performance.

Many flagship wetsuits marketed as “super stretch” actually rely heavily on 20–25 Shore A neoprene combined with advanced linings, rather than ultra-soft foam alone.

25–30 Shore A: cold-water and depth-focused applications

As water temperature drops or depth increases, compression resistance becomes more important than pure stretch. Neoprene in the 25–30 Shore A range offers higher density and improved shape retention.

This hardness range is typically used in:

- Cold-water wetsuits

- Diving and freediving suits

- Torso and core panels where insulation is critical

At depth, softer neoprene collapses more readily, reducing insulation. Slightly firmer neoprene maintains thickness longer, helping divers stay warmer during extended sessions.

The trade-off is reduced flexibility, which is why this range is rarely used in shoulders or arms.

30–35 Shore A: reinforcement and high-wear zones

Neoprene above 30 Shore A begins to feel noticeably firmer. While unsuitable for large movement areas, it excels in locations exposed to abrasion, compression, and repeated stress.

Typical applications include:

- Knee panels

- Seat and lower back areas

- Chest loading panels for spearfishing or freediving

This hardness improves:

- Tear resistance

- Abrasion durability

- Long-term dimensional stability

Used strategically, it extends wetsuit lifespan without compromising comfort.

Why ultra-soft neoprene isn’t used everywhere

Ultra-soft neoprene (≤15 Shore A) is often showcased in marketing because it feels impressive in hand. Dry, it appears incredibly stretchy and luxurious. In water, however, its limitations become clear.

Ultra-soft neoprene:

- Compresses rapidly under pressure

- Loses effective thickness at depth

- Fatigues faster after repeated compression cycles

| Benefit | Trade-off |

|---|---|

| Extreme stretch | Faster fatigue |

| Soft hand feel | Reduced lifespan |

| Easy donning | Lower compression resistance |

Because thermal insulation in neoprene depends on trapped gas cells, excessive compression directly reduces warmth. For this reason, manufacturers reserve ultra-soft neoprene for targeted movement zones, not structural areas.

Why very firm neoprene is limited in wetsuits

At the other extreme, neoprene above 35 Shore A offers excellent compression resistance and durability but introduces comfort issues.

High-hardness neoprene:

- Restricts movement

- Feels stiff during paddling or swimming

- Increases donning and doffing effort

As a result, its use is limited to:

- Reinforcement panels

- Impact or abrasion-prone zones

- Structural areas with minimal movement

Using it extensively would undermine the wetsuit’s primary purpose: enabling natural movement in cold water.

Zoned hardness design: the modern standard

Modern wetsuits rarely use a single hardness value throughout the garment. Instead, designers map hardness based on biomechanics and wear patterns.

| Body Zone | Preferred Hardness |

|---|---|

| Shoulders & arms | Lower Shore A |

| Torso core | Medium Shore A |

| Knees & seat | Higher Shore A |

This zoned approach allows manufacturers to:

- Maximize flexibility where movement is greatest

- Preserve insulation where heat loss is critical

- Reinforce areas exposed to abrasion and compression

The result is a wetsuit that feels softer, lasts longer, and performs better across varied conditions.

Shore hardness and thickness work together

It’s important to note that Shore hardness does not act in isolation. Thickness and hardness interact closely.

For example:

- A 3 mm neoprene at 22 Shore A may feel similar in stiffness to a 5 mm neoprene at 18 Shore A

- Thicker, softer neoprene may compress more at depth than thinner, firmer neoprene

Designers must therefore evaluate hardness in context, considering thickness, lining materials, and intended use.

Activity-specific hardness considerations

Different water sports place different demands on neoprene hardness.

Surfing and triathlon prioritize:

- Shoulder mobility

- Lightweight feel

- Rapid movement

These suits emphasize lower Shore A zones.

Diving and freediving prioritize:

- Compression resistance

- Thermal stability at depth

- Long-term shape retention

These suits favor medium to higher Shore A values in core areas.

Commercial and rental wetsuits often use:

- Higher overall Shore A

- Reduced stretch

- Greater durability

This sacrifices comfort slightly in exchange for longevity and lower maintenance costs.

Aging and fatigue behavior

Over time, neoprene experiences compression set, where it no longer fully rebounds after being compressed. Hardness influences how quickly this occurs.

- Softer neoprene fatigues faster but feels better initially

- Firmer neoprene retains thickness longer but feels stiffer

High-quality wetsuits balance initial comfort with long-term performance by combining multiple hardness zones rather than relying on a single foam grade.

Real-world insight from wetsuit design

High-end wetsuits frequently advertise “maximum stretch” or “super-flex” materials. Behind these claims is not a uniform ultra-soft neoprene, but careful hardness zoning combined with lining engineering.

The most successful wetsuit designs use:

- Softer neoprene only where it truly matters

- Medium hardness for thermal stability

- Firm panels for protection and durability

This approach explains why premium wetsuits feel flexible without collapsing after a season of use.

Practical takeaway for buyers and designers

The widespread use of 15–35 Shore A neoprene in wetsuits reflects practical engineering, not trend-driven choice. Each hardness band serves a clear function, and performance emerges from how these bands are combined—not from pushing softness to extremes.

For wetsuit designers, the key question is not “What is the softest neoprene available?” but rather:

“Where should softness be used, and where should it be controlled?”

Understanding Shore hardness as a zoning tool rather than a single specification allows wetsuits to deliver mobility, warmth, and durability at the same time—which is ultimately why this hardness range has endured across generations of wetsuit design.

How does neoprene shore hardness affect flexibility, insulation, and performance?

Neoprene shore hardness is one of the most decisive yet misunderstood parameters in wetsuit design. It directly influences how easily a wetsuit stretches during movement, how effectively it retains insulating air at depth, and how well it holds its performance over time. Designers often face a constant trade-off: softness delivers comfort and freedom of motion, while firmness delivers thermal stability, compression resistance, and durability.

Understanding shore hardness is not about chasing the softest or firmest foam. It is about matching material behavior to real use conditions—water temperature, session length, movement intensity, and expected service life. A wetsuit that feels exceptional in a fitting room may underperform after months of cold-water use if hardness is misjudged. Conversely, a suit that initially feels firm may outperform expectations in demanding environments.

What Shore Hardness Means in Neoprene Foam

Shore hardness, usually measured on the Shore A scale, describes the resistance of neoprene foam to indentation. In practical terms, it reflects how easily the foam deforms under load and how quickly it recovers once the load is removed.

In neoprene used for wetsuits, shore hardness is influenced by:

- Foam formulation and cell structure

- Gas content within closed cells

- Crosslink density of the rubber matrix

- Aging and post-processing conditions

Two neoprene sheets with the same thickness can feel dramatically different if their shore hardness differs. This difference becomes more pronounced once the wetsuit is submerged, compressed, stretched, and repeatedly cycled during real use.

Flexibility: Movement Efficiency and Muscle Fatigue

Flexibility is the most immediately noticeable effect of shore hardness. It determines how freely a wetsuit allows the body to move during paddling, swimming, duck diving, or repetitive arm motion.

| Hardness Level | Flexibility Effect |

|---|---|

| Low Shore A | Easy stretch, low resistance |

| Medium Shore A | Balanced movement |

| High Shore A | Noticeable resistance |

Low Shore A neoprene stretches with minimal force. This reduces resistance around high-mobility zones such as shoulders, hips, and knees. Surfers and swimmers often perceive this as superior comfort, especially during short or high-intensity sessions.

However, extreme softness can increase muscle stabilization demand. When neoprene offers little resistance, muscles must work harder to control movement under load, which may increase fatigue over long sessions.

Medium Shore A neoprene offers controlled stretch. It supports movement while providing enough resistance to maintain structure. This balance is often preferred in performance wetsuits designed for extended use.

High Shore A neoprene resists stretch more strongly. While it can feel restrictive during dynamic motion, it provides structural support that reduces uncontrolled deformation. This is why firmer neoprene is often placed strategically in core or lower-body panels.

From a fatigue perspective, softer neoprene reduces immediate resistance, but medium hardness often delivers better energy efficiency over time, particularly for endurance-focused users.

Insulation: Compression Behavior Under Pressure

Neoprene insulates by trapping gas within its closed-cell structure. The effectiveness of this insulation depends not only on thickness, but on how well those cells resist compression at depth.

| Hardness | Compression at Depth | Warmth Retention |

|---|---|---|

| Low | High compression | Lower |

| Medium | Moderate | Stable |

| High | Low compression | Higher |

As depth increases, hydrostatic pressure compresses neoprene. Softer foams compress more easily, reducing internal gas volume and therefore insulation. This is why a wetsuit that feels warm at the surface may feel noticeably colder after repeated dives or prolonged immersion.

Low Shore A neoprene compresses significantly. In cold or deep-water environments, this leads to rapid heat loss as insulating air is displaced. These foams are best suited to warm water or shallow activity.

Medium Shore A neoprene maintains a balance. It compresses enough to remain flexible but retains sufficient cell structure to preserve warmth over time.

High Shore A neoprene resists compression most effectively. This preserves internal air pockets and slows heat loss, making it the preferred choice for cold-water, diving, or prolonged exposure applications.

For cold-water wetsuits, insulation stability under compression is often more important than surface comfort. This is why serious cold-water designs prioritize compression resistance over initial softness.

Performance Over Time: Fatigue, Aging, and Shape Retention

Neoprene is subjected to thousands of stretch–relax cycles during its lifetime. Shore hardness plays a major role in how well the foam tolerates this repeated stress.

| Hardness | Long-Term Behavior |

|---|---|

| Low | Softens further, fatigues sooner |

| Medium | Stable over seasons |

| High | Retains structure longest |

Low Shore A neoprene tends to fatigue faster. Over time, the foam softens further, cell walls weaken, and rebound slows. This results in:

- Permanent thinning in high-stress zones

- Reduced insulation

- Loss of fit precision

Medium Shore A neoprene typically shows the best balance of longevity and comfort. It maintains elasticity without excessive permanent deformation, making it suitable for frequent users.

High Shore A neoprene retains its structure longest. It resists permanent compression and tearing, which is why it is often used in:

- Rental wetsuits

- Professional training suits

- High-wear reinforcement panels

The trade-off is that firmer neoprene may never feel “broken in” to the same degree as softer foams.

Dive Deeper: Comfort Versus Endurance

Comfort perception is often biased toward first-use experience, but wetsuit performance should be evaluated across its full service life.

Short-session users often prefer:

- Softer neoprene

- Immediate comfort

- Maximum stretch with minimal resistance

These users may surf occasionally or swim for limited durations, where long-term foam fatigue is less critical.

Long-session or frequent users benefit from:

- Medium hardness neoprene

- Controlled stretch

- Better fatigue resistance and thermal stability

Divers, cold-water surfers, instructors, and daily users often prioritize consistent performance over seasons, even if initial comfort feels slightly reduced.

Panel Mapping: Using Multiple Hardness Levels Strategically

Modern wetsuits rarely rely on a single hardness throughout. Designers increasingly use panel-specific hardness mapping to optimize performance.

Common strategies include:

- Lower hardness in shoulders and arms for mobility

- Medium hardness in torso for insulation balance

- Higher hardness in knees, hips, and seat for durability

This approach allows wetsuits to deliver both comfort and endurance without forcing a single compromise. Shore hardness selection, therefore, becomes a design tool rather than a fixed material choice.

The Relationship Between Hardness, Thickness, and Fit

Shore hardness cannot be evaluated in isolation. Thickness and fit interact closely with hardness to determine real-world performance.

For example:

- A thinner neoprene with slightly higher hardness may feel as flexible as a thicker, softer foam

- A softer neoprene in a loose-fitting suit may compress excessively, reducing warmth

- A firmer neoprene in a well-tailored fit may outperform a softer foam in insulation and comfort

Experienced designers adjust hardness alongside patterning, seam placement, and thickness distribution to achieve targeted outcomes.

Human-Centered Takeaway

Neoprene shore hardness defines the personality of a wetsuit. It governs how the suit feels during the first ten minutes and how it performs after hundreds of hours in the water.

A wetsuit that feels perfect during a brief fitting but loses warmth, shape, or resilience after a season is not truly superior. Conversely, a suit that feels slightly firm at first but delivers stable insulation, consistent stretch, and durability over time often proves to be the better long-term choice.

Hardness selection should always be guided by how long, how often, and how intensely the wetsuit will be used. When shore hardness is matched to real usage patterns rather than initial impressions, neoprene delivers the balance of flexibility, insulation, and performance that wetsuit users actually depend on.

What factors influence the optimal shore hardness choice for different types of wetsuits?

What Factors Influence the Optimal Shore Hardness Choice for Different Types of Wetsuits?

Selecting the optimal Shore hardness for wetsuit neoprene is never a single-variable decision. It is the result of interacting environmental, biomechanical, and user-driven factors that determine how the suit will perform in real water conditions. Water temperature, depth, movement intensity, neoprene thickness, and target user expectations all influence where a wetsuit should sit on the softness–firmness spectrum.

For manufacturers, Shore hardness is not chosen in isolation. It functions as part of a material system that must balance comfort, thermal retention, compression resistance, and durability. A hardness value that works perfectly for a warm-water surf suit can fail completely in a cold-water diving application, even at the same thickness.

Understanding these influences allows wetsuit designers to make deliberate, defensible hardness choices rather than relying on generalized assumptions.

Water Temperature and Depth

Water temperature is the first and most obvious driver of hardness selection, but depth is equally important. As water gets colder and pressure increases, neoprene must resist compression to retain insulating air pockets.

| Water Condition | Hardness Preference |

|---|---|

| Warm water | Lower Shore A |

| Temperate | Medium Shore A |

| Cold water | Medium–High Shore A |

| Deep diving | Higher Shore A |

In warm, shallow conditions, softer neoprene is acceptable because thermal demand is lower and compression is minimal. Comfort and flexibility take priority. In cold water, especially below 10 °C, thermal retention becomes critical. Firmer neoprene resists cell collapse under pressure, preserving insulation during longer sessions.

For diving, depth amplifies this effect. Even moderate depths significantly compress soft foam, reducing thickness and warmth. Diving wetsuits therefore favor higher Shore hardness values to maintain insulation at depth, even if this reduces stretch.

Activity Type and Movement Patterns

Different water sports place stress on wetsuits in different ways. The optimal hardness must reflect how the body moves, not just environmental conditions.

| Activity | Movement Profile | Hardness Bias |

|---|---|---|

| Surfing | Shoulder-intensive, dynamic | Softer |

| Swimming / triathlon | Continuous, rhythmic | Medium |

| Diving | Limited motion, high pressure | Firmer |

| Kayaking | Upper-body torque | Zoned (soft + firm) |

Surfing demands high shoulder mobility for paddling. Softer neoprene in the upper body reduces resistance and fatigue, even if it sacrifices some insulation. Triathlon and open-water swimming require a balance: enough softness for stroke efficiency, but enough firmness to maintain body position and buoyancy.

Diving involves comparatively little motion but significant pressure exposure. Divers value warmth, stability, and durability over extreme flexibility. Firmer neoprene maintains thickness and structural integrity under compression.

Kayaking and similar activities involve rotational forces and repeated upper-body torque. Zoned hardness—soft in high-mobility areas and firmer in load-bearing zones—delivers better comfort and longevity.

Thickness and Hardness Interaction

Thickness and hardness cannot be evaluated independently. They amplify each other’s effects on feel and performance.

| Thickness | Hardness Consideration |

|---|---|

| Thin (2–3 mm) | Can be softer without instability |

| Medium (4–5 mm) | Requires balanced hardness |

| Thick (6–7 mm) | Often firmer for stability |

Thin neoprene has less internal structure and compresses less overall, so it can tolerate lower hardness without becoming unstable. Medium-thickness neoprene must strike a balance: too soft and it compresses excessively; too firm and it restricts movement.

In thick wetsuits, softness becomes problematic. Very soft 6–7 mm neoprene can feel bulky, sag under its own weight, and lose shape quickly. Firmer foam helps thick suits maintain structure, reduces water flushing, and improves long-term fit.

User Level and Expectations

User experience level strongly influences perceived “ideal” hardness.

| User Type | Typical Preference |

|---|---|

| Beginners | Immediate comfort, easy donning |

| Enthusiasts | Balance of feel and durability |

| Professionals | Performance zoning and control |

Beginners often prioritize comfort and ease of use. Softer neoprene feels less restrictive and is easier to put on and take off. Enthusiast users, who spend more time in the water, begin to value durability and thermal consistency alongside comfort.

Professional athletes and serious divers focus on performance. They expect hardness zoning, stable compression behavior, and predictable long-term fit. For them, initial softness is less important than how the suit performs after dozens of sessions.

Rental and training wetsuits represent a special category. They are designed to withstand repeated use by many users. These suits typically use firmer neoprene to resist compression set, abrasion, and loss of shape, even if they feel stiffer initially.

Water Entry, Flushing, and Fit Stability

Hardness also influences how well a wetsuit maintains a seal against water movement. Softer neoprene conforms easily to the body, but it may also deform under motion, allowing more water flushing. Firmer neoprene maintains edge definition and panel shape, improving seal stability at cuffs, necks, and seams.

For cold-water applications, reducing water exchange can be as important as insulation thickness. Manufacturers often choose slightly higher hardness in sealing zones to improve fit stability without compromising overall comfort.

Long-Term Durability and Compression Set

Repeated compression and stretching cause neoprene foam to fatigue over time. Softer foams are more prone to compression set, where the material does not fully rebound after use. This leads to thinner sections, looser fit, and reduced warmth.

Harder neoprene generally shows better resistance to permanent deformation. For users who wear wetsuits frequently or for extended sessions, this durability factor becomes increasingly important.

Manufacturers targeting long service life often bias hardness slightly higher than what feels optimal at first wear, knowing that performance will stabilize after break-in.

Design Zoning as a Solution to Competing Demands

Modern wetsuit design rarely relies on a single hardness value. Instead, manufacturers use hardness zoning to reconcile conflicting requirements.

Common zoning strategies include:

- Softer neoprene in shoulders and arms for mobility

- Medium hardness in the torso for balance

- Firmer neoprene in knees, seat, and chest for durability and warmth

Zoning increases material complexity and sourcing requirements, but it allows designers to optimize performance for each body zone. This approach is especially common in premium wetsuits, where performance consistency matters more than uniform softness.

Market Positioning and Brand Strategy

Hardness selection also reflects brand positioning. A “premium” wetsuit does not necessarily mean softer neoprene everywhere. Premium often means:

- Intelligent material zoning

- Predictable performance across conditions

- Consistent fit over time

Entry-level suits may emphasize immediate comfort, while high-end suits emphasize controlled performance and longevity. Hardness choices must align with the brand’s promise and the expectations of its target users.

The Role of Testing and Field Feedback

Optimal hardness cannot be determined solely in the lab. Manufacturers rely on:

- Durometer measurements for consistency

- Compression testing to simulate depth

- Field testing with athletes and divers

- Long-term wear evaluations

Feedback from real users often reveals whether a hardness choice supports or undermines the intended design goals. Successful wetsuit programs iterate hardness choices over multiple seasons, refining the balance between comfort and performance.

Why Hardness Is a System Decision

Shore hardness interacts with every other aspect of wetsuit design: thickness, panel layout, seam construction, and even pattern shaping. Changing hardness without adjusting these elements often leads to unexpected outcomes.

This is why experienced wetsuit manufacturers treat hardness as a system-level decision. They evaluate it in the context of:

- Environmental conditions

- Movement demands

- Material thickness

- User profile

- Expected product lifespan

There is no universally “best” Shore hardness for wetsuits. The optimal choice depends on how and where the suit will be used, who will use it, and what performance promise the brand is making.

Hardness is not a standalone spec; it is a tuning tool. When chosen thoughtfully and in combination with thickness and zoning, it enables wetsuits to deliver comfort, warmth, mobility, and durability in the proportions users actually need.

Manufacturers who understand this complexity avoid chasing extremes. Instead, they design neoprene systems that perform consistently—not just in the showroom, but in real water, under real conditions, over real time.

How do manufacturers test and ensure consistent shore hardness in neoprene sheets?

In neoprene production, Shore hardness consistency is not achieved at the end of the line. It is the result of controlled chemistry, disciplined process management, and repeatable testing protocols applied throughout foam production. Manufacturers who rely on final inspection alone inevitably struggle with variation. Those who achieve stable hardness do so by controlling inputs, monitoring drift, and validating results at multiple stages.

For applications such as wetsuits, medical supports, protective gear, and neoprene-based accessories, Shore hardness directly influences comfort, compression behavior, durability, and assembly performance. A deviation of just a few Shore A points can alter stretch, bonding behavior, and long-term compression set. This is why professional manufacturers treat hardness control as a process system, not a single measurement.

Hardness control starts long before cutting or sewing begins, and well before the neoprene ever reaches a garment factory.

Standard Hardness Testing Process

Consistent Shore hardness measurement depends on standardized testing conditions and disciplined methodology. Reputable manufacturers follow a defined testing sequence to minimize variability introduced by environment, operator handling, or sample preparation.

| Step | Purpose |

|---|---|

| Sample conditioning | Normalize temperature |

| Multi-point testing | Capture variation |

| Averaging results | Reduce anomalies |

| Batch comparison | Track drift |

The process typically begins with sample conditioning. Neoprene foam is temperature-sensitive, and hardness readings vary significantly between cold and warm states. Manufacturers condition samples in a controlled environment—usually at a defined room temperature for a set period—before testing. This step ensures that readings reflect material properties rather than ambient fluctuations.

Next, multi-point testing is conducted using a calibrated Shore A durometer. Rather than testing a single spot, technicians measure multiple locations across the foam sheet. These readings are recorded individually rather than averaged on the spot, allowing variability to be observed rather than masked.

Once multiple readings are collected, manufacturers calculate an average hardness value and compare it against specification limits. Outliers are examined to determine whether they represent normal variation or process instability.

Finally, results are evaluated at the batch level. Hardness values are not viewed in isolation; they are compared against previous batches to identify trends. Gradual drift often signals formulation or process changes that need correction before out-of-spec material is produced.

Importantly, hardness testing is usually performed on raw foam sheets before lamination. This isolates foam behavior from fabric or adhesive effects, allowing more precise control.

Why Single-Point Testing Is Unreliable

One of the most common mistakes in neoprene sourcing is reliance on single-point hardness data. Neoprene foam is not perfectly uniform, especially across large sheets produced from foam blocks.

Neoprene foam can vary:

- Across sheet width

- Across sheet length

- Between center and edge zones

| Testing Method | Risk |

|---|---|

| Single point | Misleading |

| Multi-point | Reliable |

Foam blocks are sliced into sheets, and subtle differences in gas expansion, curing, or cooling can create gradients. Edges may cool faster than the center, and thickness variation can influence hardness readings. A single measurement taken from a “good” location can falsely suggest compliance, while other areas of the same sheet fall outside acceptable limits.

Professional factories typically test 5 to 10 points per sheet, depending on sheet size and application requirements. For critical applications, some manufacturers map hardness across defined zones, creating a profile rather than a single value.

This approach allows manufacturers to detect localized issues early, such as uneven foaming or curing imbalance, before material is released for lamination or shipment.

Controlling Hardness at the Formulation Level

Testing alone does not create consistency. Shore hardness is ultimately determined by foam formulation and process conditions. Manufacturers who achieve tight hardness control focus on repeatable chemistry and tightly regulated production parameters.

Hardness is influenced by:

- Rubber compound ratios

- Blowing agent quantity

- Curing time and temperature

| Variable | Effect |

|---|---|

| More gas | Softer foam |

| Denser matrix | Firmer foam |

| Over-curing | Increased hardness |

The rubber compound ratio defines the base elasticity of the foam. Small deviations in polymer composition or filler content can shift hardness noticeably. For this reason, experienced manufacturers use precise weighing systems and documented formulations rather than manual adjustments.

The blowing agent controls cell formation and expansion. Higher gas generation produces larger cells and lower density, resulting in softer foam. Insufficient or inconsistent gas release leads to denser, firmer material. Because blowing reactions are sensitive to temperature and timing, process stability is critical.

Curing conditions further refine hardness. Over-curing increases cross-link density, raising hardness and reducing elasticity. Under-curing may leave foam too soft and unstable. Manufacturers carefully control oven temperature profiles and dwell times to achieve repeatable results.

Consistency depends on precise repetition, not constant adjustment. Well-run factories avoid “tuning by feel” and instead rely on documented settings and statistical process control.

Process Monitoring During Foaming

Advanced neoprene producers do not wait until foam sheets are cut to assess hardness trends. They monitor indicators during foaming that correlate strongly with final Shore A values.

These indicators may include:

- Foam expansion ratio

- Block density measurements

- Curing temperature curves

By correlating these process metrics with hardness test results, manufacturers build predictive control models. When process indicators drift, corrective action can be taken before large volumes of material are affected.

This proactive approach distinguishes mature operations from reactive ones. It reduces waste, stabilizes output, and improves confidence in batch-to-batch consistency.

Lamination Changes Perceived Hardness

While hardness specifications are typically defined on raw foam, most neoprene products use laminated material. Lamination alters how hardness is perceived, even if the underlying foam remains unchanged.

Once fabric is laminated:

- Surface resistance increases

- Hand feel becomes slightly firmer

- Stretch behavior changes

Fabric layers introduce surface stiffness and distribute indentation force over a wider area. As a result, laminated neoprene often measures slightly higher Shore A values than raw foam, even when foam hardness is identical.

For this reason, manufacturers usually specify hardness on unlaminated foam, with lamination effects treated as a secondary consideration. Comparing laminated materials from different suppliers without referencing raw foam hardness often leads to confusion and incorrect conclusions.

Professional suppliers can explain how lamination affects perceived firmness and provide guidance on how raw foam specifications translate into finished material behavior.

Multi-Stage Inspection During Production

Hardness control does not stop after foam production. Leading manufacturers implement multi-stage inspections to ensure that hardness remains within tolerance through subsequent processing.

Typical checkpoints include:

- Post-slicing inspection of foam sheets

- Pre-lamination hardness verification

- Post-lamination feel and recovery checks

While Shore A testing after lamination is less precise, it can reveal anomalies caused by uneven adhesive application, excessive heat, or fabric tension. These checks act as safeguards rather than primary control points.

The goal is not to re-measure hardness endlessly, but to ensure that downstream processes do not introduce unintended changes.

Quality Documentation and Traceability

Consistent hardness across time requires documentation and traceability, not just good intentions. Advanced neoprene manufacturers maintain detailed records linking hardness data to specific batches and process conditions.

These records typically include:

- Batch-level hardness measurements

- Foam formulation identifiers

- Production dates and shifts

- Lamination run references

This level of traceability allows manufacturers to:

- Reproduce successful materials reliably

- Investigate performance complaints efficiently

- Identify gradual drift before it becomes critical

When a customer reports that a wetsuit panel feels firmer than expected, traceability allows the supplier to review historical hardness data and correlate it with production conditions. Without this documentation, troubleshooting becomes guesswork.

From a buyer’s perspective, traceability also provides reassurance that material behavior is controlled rather than accidental.

Statistical Control and Long-Term Stability

High-volume neoprene producers often apply statistical process control to hardness data. Rather than reacting to individual out-of-spec readings, they analyze trends over time.

Control charts help identify:

- Gradual hardness drift

- Increased variability

- Process instability tied to specific shifts or equipment

This approach allows manufacturers to intervene early, adjusting process parameters before material falls outside specification limits. It also reduces over-correction, which can introduce new variability.

Long-term stability is achieved when hardness variation stays within a narrow, predictable band rather than oscillating around the target value.

Communication Between Supplier and Customer

Consistent hardness is not only a manufacturing issue; it is also a communication issue. Clear specification and alignment between supplier and customer are essential.

Effective specifications define:

- Target Shore A value

- Acceptable tolerance range

- Test conditions and method

Without this clarity, disputes arise even when both parties believe they are compliant. A hardness value measured under different conditions or at different locations can legitimately differ, leading to confusion if expectations are not aligned.

Professional suppliers proactively discuss these details rather than assuming shared understanding.

Consistent Shore hardness in neoprene sheets is achieved through process control, disciplined testing, and traceable documentation, not through final inspection alone. Manufacturers who manage hardness successfully understand that the number on a datasheet is the output of many upstream decisions.

If a supplier cannot clearly explain how hardness is tested, where it is tested, how variation is controlled, and how results are tracked over time, the hardness value itself carries little meaning.

In neoprene manufacturing, hardness consistency is a sign of operational maturity. It reflects not just material quality, but the supplier’s ability to repeat success reliably—batch after batch, season after season.

What trade‑offs exist between low and high shore hardness neoprene in wetsuit design?

In wetsuit design, Shore hardness is one of the most influential yet least visible parameters shaping real-world performance. While thickness and lining technology receive most consumer attention, Shore A hardness determines how neoprene behaves under movement, pressure, and time. Designers constantly manage trade-offs between softness and firmness, knowing that each choice affects flexibility, thermal retention, durability, and long-term comfort.

Low shore hardness neoprene delivers exceptional stretch and immediate comfort, making it ideal for high-mobility activities. High shore hardness neoprene, by contrast, resists compression, holds its shape under pressure, and lasts longer—but at the cost of stiffness. No single hardness value solves all requirements. The challenge lies in balancing competing priorities across different body zones and use cases.

Understanding these trade-offs is essential for building wetsuits that perform well not just in the fitting room, but after months of paddling, diving, and repeated compression in cold water.

How Shore hardness influences neoprene behavior

Shore A hardness measures resistance to indentation, but in wetsuits it translates into several practical behaviors:

- Stretch resistance during arm and shoulder movement

- Compression rate under hydrostatic pressure

- Recovery after repeated compression cycles

- Resistance to abrasion, tearing, and fatigue

A difference of even 5 Shore A points can noticeably change how a wetsuit feels in motion and how it performs at depth. Designers therefore treat hardness not as a single spec, but as a tuning parameter that interacts with thickness, lining, and pattern construction.

Flexibility versus durability: the core trade-off

The most obvious trade-off between low and high shore hardness neoprene is flexibility versus durability.

| Hardness | Flexibility | Durability |

|---|---|---|

| Low (15–20 Shore A) | Excellent | Moderate |

| Medium (20–30 Shore A) | Balanced | Good |

| High (30–35 Shore A) | Limited | Excellent |

Low hardness neoprene stretches easily and conforms to body movement with minimal resistance. This is particularly valuable in sports requiring repetitive arm motion, such as surfing, swimming, and paddle sports. Wearers experience less shoulder fatigue and a more natural range of motion.

However, this flexibility comes at a cost. Softer neoprene:

- Fatigues faster under repeated stretch

- Develops compression set more quickly

- Is more vulnerable to abrasion and tearing

High hardness neoprene resists deformation. It holds its shape longer and tolerates repeated compression better, making it more durable in high-stress zones. The trade-off is reduced stretch, which can feel restrictive if used extensively in movement-intensive areas.

Movement efficiency and user comfort

From a human-centered perspective, flexibility strongly influences perceived comfort. A wetsuit that moves with the body feels lighter and less tiring, even if it is thicker or heavier on paper.

Low shore hardness neoprene excels here:

- Easier paddling and swimming motion

- Reduced muscle strain during long sessions

- Improved comfort for beginners and recreational users

High hardness neoprene, while durable, can increase resistance during movement. Overuse in shoulders or hips may lead to:

- Faster fatigue

- Restricted stroke length

- Reduced enjoyment, especially in warm-water or high-activity scenarios

This is why modern wetsuits rarely rely on a single hardness level. Designers prioritize movement efficiency where motion is continuous, and durability where motion is limited.

Thermal insulation implications

Thermal performance is often assumed to depend mainly on thickness, but hardness plays a critical role—especially under pressure.

Low hardness neoprene:

- Compresses easily at depth

- Loses internal gas volume more quickly

- Provides slightly reduced insulation over time

High hardness neoprene:

- Maintains cell structure under pressure

- Retains thickness and insulation longer

- Performs better in cold or deep water

In shallow water and surface sports, compression is minimal, so softness does not dramatically reduce warmth. In diving or cold-water applications, however, neoprene may experience repeated compression cycles that collapse softer foam, reducing effective insulation.

This explains why firmer neoprene is favored in cold-water diving suits, even when thickness is similar to softer surf suits.

Longevity and aging behavior

Neoprene does not fail suddenly; it degrades gradually through compression set and fatigue. Shore hardness strongly influences how a wetsuit ages.

Softer neoprene:

- Feels excellent when new

- Loses rebound elasticity faster

- May “bottom out” in high-pressure zones

Firmer neoprene:

- Feels stiffer initially

- Retains thickness and shape longer

- Maintains performance over extended use

A wetsuit designed entirely with low hardness neoprene may impress during initial fittings but show noticeable thinning at knees, hips, and torso after a season. Conversely, a suit built with higher hardness throughout may last longer but feel uncomfortable from day one.

Thermal consistency over time

Another subtle trade-off lies in thermal consistency, not just initial warmth.

Low hardness neoprene may be warm initially but lose insulation after repeated use as compression set accumulates. High hardness neoprene delivers more stable thermal performance across its lifespan, which is why it is preferred for:

- Cold-water diving

- Commercial and rental wetsuits

- Professional or extended-duration use

For recreational users, the immediate comfort of softer neoprene may outweigh long-term thermal stability. For professionals, consistent insulation often takes priority.

mixed zoning strategy

To resolve these trade-offs, modern wetsuits rely on zoned hardness design, assigning different Shore A values to different body regions based on movement and load.

| Body Area | Recommended Shore A | Purpose |

|---|---|---|

| Shoulders & arms | 15–20 | Maximum mobility |

| Torso | 22–28 | Core warmth retention |

| Knees & seat | 28–35 | Reinforcement, durability |

This approach allows designers to:

- Preserve flexibility where motion is constant

- Maintain insulation where heat loss matters most

- Reinforce areas exposed to abrasion and compression

Zoning reduces the need to compromise. Instead of choosing between comfort and durability, designers allocate each property where it delivers the most value.

Activity-specific trade-offs

Different water activities emphasize different sides of the hardness trade-off.

Surfing and paddle sports prioritize:

- Shoulder mobility

- Lightweight feel

- Rapid, repetitive motion

These suits favor lower shore hardness in upper body zones.

Diving and freediving prioritize:

- Compression resistance

- Stable insulation at depth

- Long-term durability

These suits use medium to high hardness neoprene in the torso and core, accepting reduced flexibility in exchange for thermal reliability.

Rental and training wetsuits often prioritize:

- Durability

- Abrasion resistance

- Lower replacement frequency

They typically use higher average hardness, sacrificing some comfort to reduce maintenance costs.

Psychological versus functional comfort

There is also a distinction between perceived comfort and functional comfort.

Ultra-soft neoprene feels luxurious when dry or during brief fittings. In extended use, however, excessive softness can lead to:

- Cold spots as foam compresses

- Loss of support in load-bearing zones

- Faster material breakdown

Slightly firmer neoprene may feel less impressive initially but provide better comfort over long sessions by maintaining structure and insulation.

Why “softest possible” is rarely the best design choice

Marketing often promotes “maximum stretch” or “ultra-soft” neoprene as the ultimate upgrade. In reality, pushing softness too far introduces imbalance.

A wetsuit that is soft everywhere:

- Compresses unevenly

- Loses insulation where pressure is highest

- Requires earlier replacement

A wetsuit that is too firm:

- Restricts movement

- Increases fatigue

- Feels uncomfortable during active use

Smart wetsuit design avoids extremes. It uses softness strategically, not universally.

Manufacturing and consistency considerations

From a production standpoint, Shore hardness also affects consistency and yield.

Softer neoprene:

- Requires tighter control during foaming

- Is more sensitive to density variation

- Shows performance variation between batches

Firmer neoprene:

- Is more forgiving in processing

- Maintains dimensional stability more easily

- Shows better consistency in bulk production

This influences cost and quality control decisions, particularly for large-scale manufacturing.

Human-centered insight

From the wearer’s perspective, the best wetsuit is not the one with the softest neoprene, but the one that feels balanced throughout the session.

A suit that is soft in the shoulders, supportive in the torso, and durable at the knees will:

- Feel natural during movement

- Stay warm over time

- Maintain performance across seasons

This balance explains why experienced surfers and divers often prefer suits that feel slightly firmer at first but perform more consistently over months of use.

Practical takeaway for wetsuit designers and buyers

The trade-offs between low and high shore hardness neoprene are unavoidable. Softness improves mobility and comfort, while firmness enhances insulation stability and durability. The key is not choosing one over the other, but deciding where each belongs.

Low shore hardness neoprene is best used where movement dominates. High shore hardness neoprene belongs where structure, compression resistance, and longevity matter most. Between these extremes lies a medium range that anchors the suit’s core performance.

Modern wetsuits succeed not by eliminating trade-offs, but by managing them intelligently through zoned design. This is why the most comfortable, warm, and durable wetsuits rarely rely on a single hardness value—and why understanding these trade-offs remains central to wetsuit engineering and wearer satisfaction.

How should brands select the appropriate neoprene shore hardness for specific water sports and market segments?

Selecting the right neoprene shore hardness is one of the most consequential material decisions a brand makes when developing wetsuits and water-sports apparel. Shore hardness directly influences flexibility, thermal performance, compression resistance, durability, and perceived quality, all of which shape how a product performs in real water conditions and how it is judged by end users.

Unlike thickness, which many consumers immediately understand, shore hardness works more subtly. Two wetsuits with the same thickness can feel radically different in the water depending on hardness choice. For brands, the challenge is not to identify a single “best” hardness, but to align hardness selection with sport-specific demands, environmental conditions, and the expectations of a defined market segment.

A recreational surfer paddling for short sessions, a triathlete racing at high cadence, and a cold-water diver spending extended time at depth all place very different stresses on neoprene foam. Effective hardness selection starts with understanding these stresses and translating them into material requirements rather than relying on generic softness claims.

Understanding Shore Hardness as a Design Variable

Neoprene shore hardness, typically measured on the Shore A scale, reflects resistance to indentation and deformation. In wetsuit applications, it governs how easily the foam stretches, how much it compresses under hydrostatic pressure, and how well it recovers after repeated use.

Key performance dimensions influenced by hardness include:

- Stretch resistance during movement

- Compression behavior at depth

- Long-term shape retention

- Fatigue resistance under repeated cycles

- Structural support in high-stress zones

Brands that treat hardness as a fixed specification often struggle to balance comfort and longevity. Brands that treat it as a tunable design variable, adjusted by sport and market, achieve more consistent performance outcomes.

Water Sports-Specific Hardness Guidelines

Different water sports impose distinct mechanical and thermal demands on neoprene. As a result, hardness targets vary meaningfully by activity.

| Sport | Typical Shore A | Rationale |

|---|---|---|

| Surfing | 15–22 | Maximum flexibility for paddling |

| Swimming / Triathlon | 20–25 | Balance mobility and compression |

| Scuba / Diving | 25–35 | Maintain insulation under depth pressure |

| Kayaking / Paddle sports | 20–28 | Shoulder flexibility and core durability |

These ranges should be viewed as starting points, not rigid rules. Final specifications depend on thickness, panel design, and intended water temperature.

Surfing: Prioritizing Flexibility and Immediate Comfort

Surfing wetsuits are defined by repetitive upper-body movement. Paddling efficiency, shoulder freedom, and comfort during dynamic transitions matter more than long-term compression resistance.

For this reason, surfing suits typically use lower Shore A neoprene, especially in:

- Shoulders and arms

- Upper chest and back

- Neck and entry panels

Softer neoprene reduces resistance during paddling and minimizes shoulder fatigue. However, excessive softness can lead to faster foam fatigue and insulation loss over time. Brands targeting high-performance surfing often combine low-hardness neoprene with strategic reinforcement in knees and seat areas to preserve durability without sacrificing mobility.

Entry-level surf suits frequently emphasize softness across larger panels because first-time users equate comfort with quality. Premium surf brands, by contrast, often accept slightly firmer foams in non-critical zones to extend product lifespan.

Swimming and Triathlon: Balancing Mobility With Compression Control

Triathlon and open-water swimming place unique demands on neoprene. Athletes require:

- Unrestricted shoulder rotation

- Minimal drag and surface resistance

- Controlled buoyancy and body positioning

Typical Shore A ranges for these suits fall in the 20–25 range, where stretch remains high but compression resistance improves compared to very soft foams. This balance helps maintain buoyancy and thermal consistency during extended swims.

Triathlon suits often use hardness zoning, such as: